Tenon-free floor strip

A floor and tenon-groove technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of noise, waste of floor materials, waste, etc., and achieve the effect of reducing costs, considerable waste, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

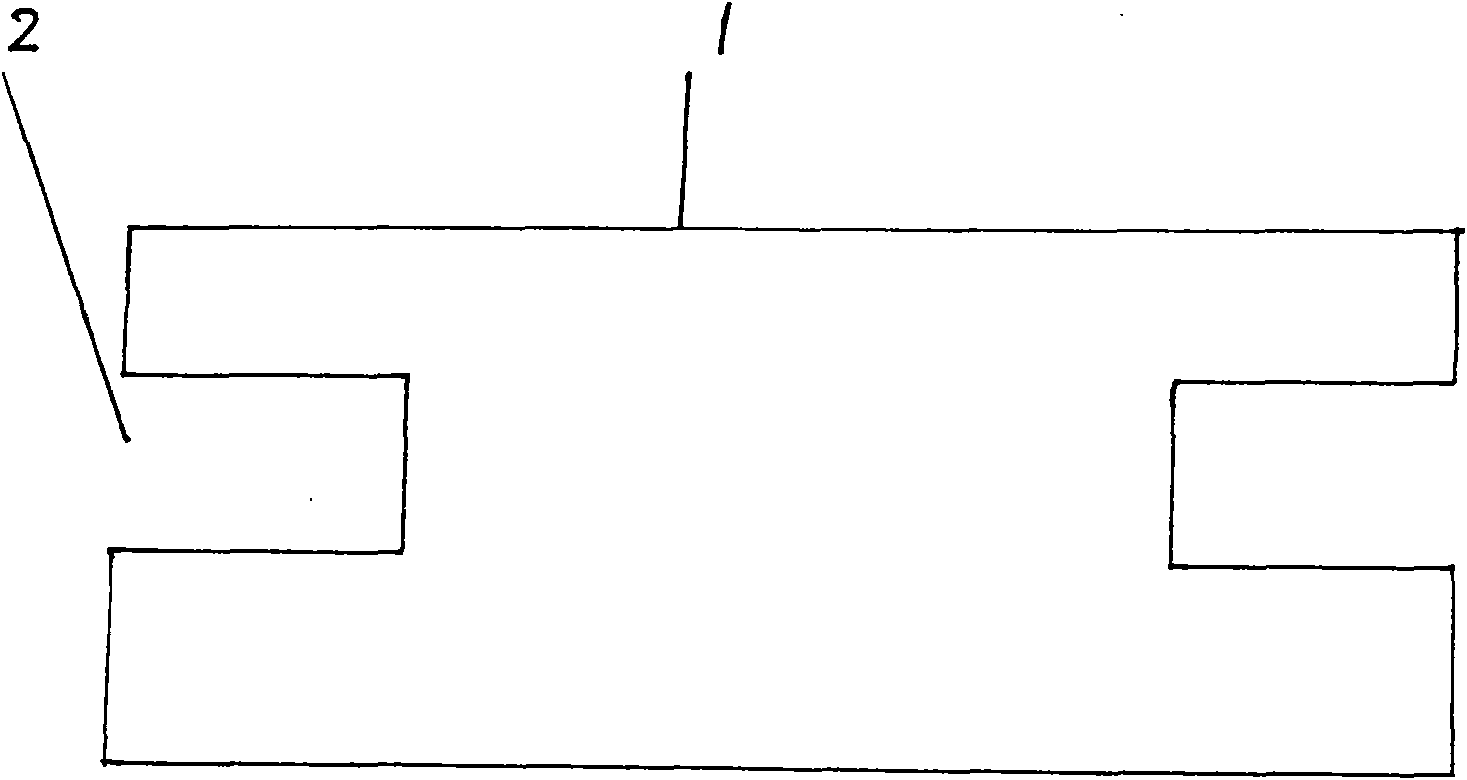

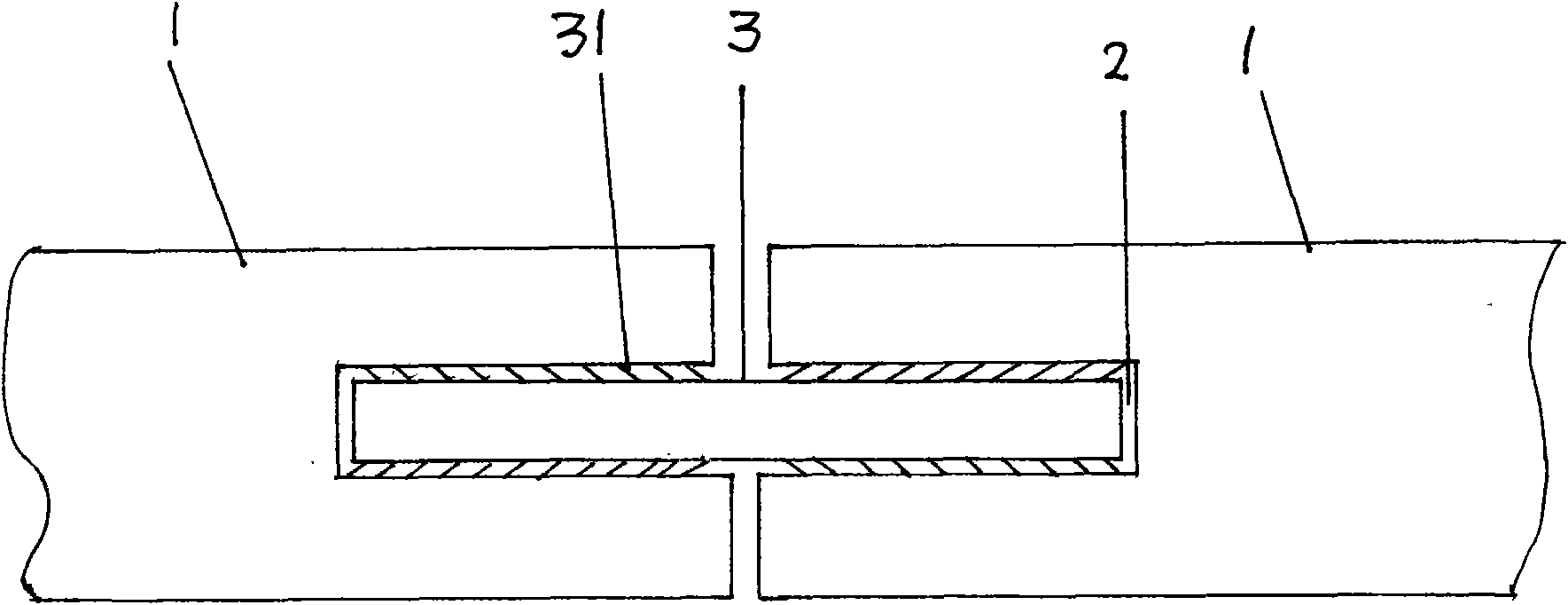

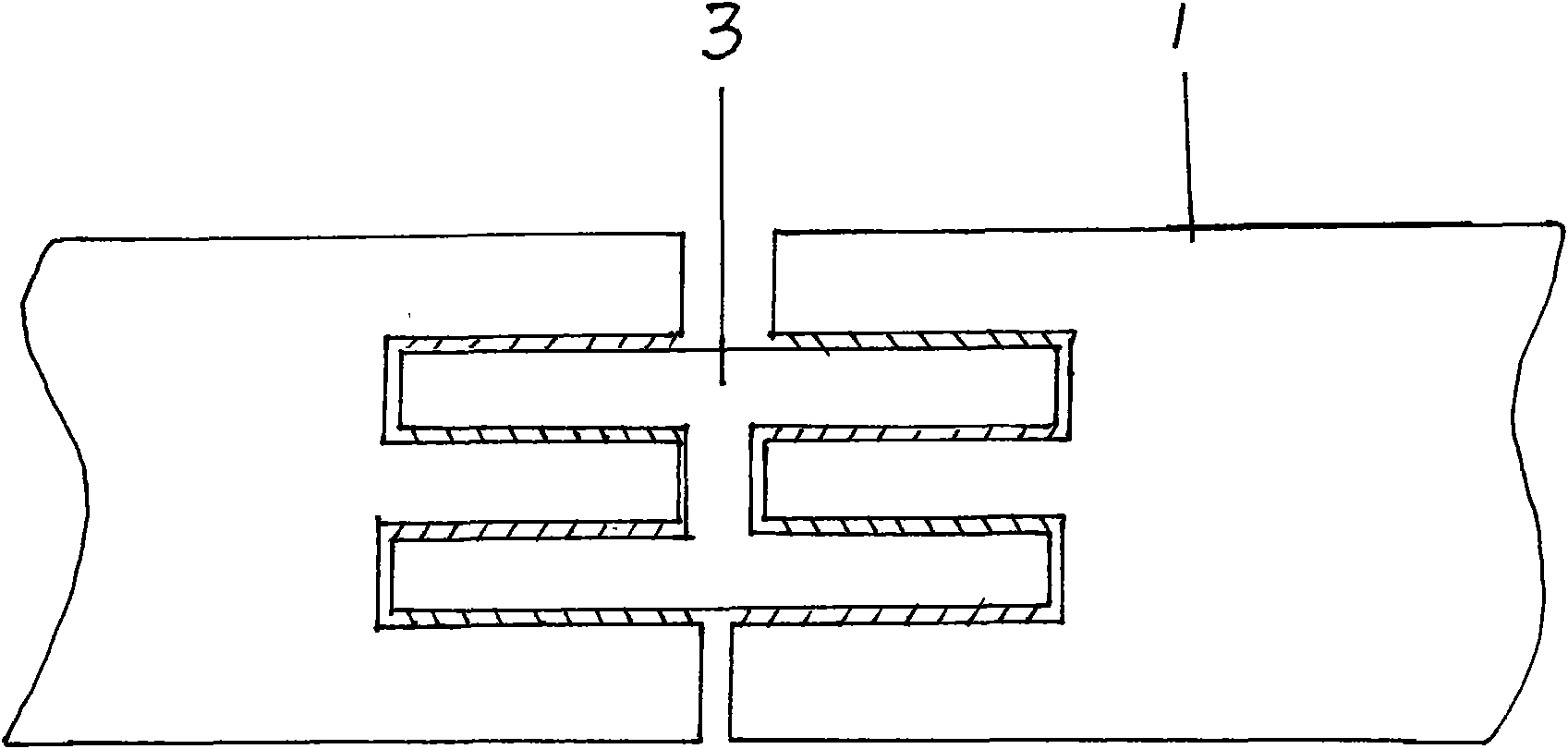

[0011] see figure 1 , a single-layer flat rectangular tongue and groove 2 is set on the two connecting sides of each floor strip 1, see figure 2 The method for connecting several floor strips is: choose a flat rectangular plastic profile as the connecting bar 3, the cross-sectional shape of this connecting bar is consistent with the shape after two flat rectangular tenons and grooves are combined, half of the plastic profile ( Half of the section) is embedded in a tongue and groove, and the other half of the plastic profile is embedded in the tongue and groove on the adjacent floor strips, that is, the adjacent floor strips are connected and assembled by connecting strips. Here you can think of the connecting strip as a separate tenon from the floor. In order to improve the firmness of the independent tenon (connecting strip) and the tenon groove, spines 31 are provided on the surface of the independent tenon (connecting strip). Exit the tongue and groove.

[0012] see i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com