Upper-air obstacle-traversing in position method of large-sized prestress steel cable

A prestressed steel and prestressed technology, which is applied in the field of large-scale prestressed steel cables that have obstacles in place at high altitudes, can solve the problems of delayed construction period, difficult vertical lifting and construction, and many mechanical equipment and human resources, reducing the Traction, saving mechanical work, simple assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

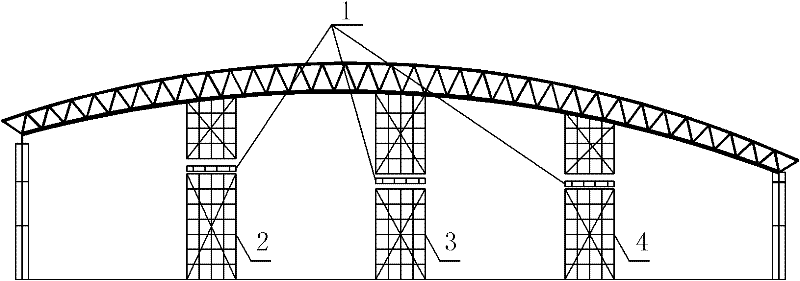

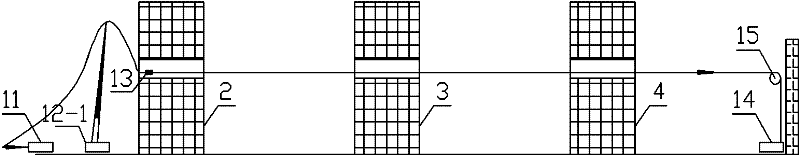

[0025] (a) Three load-bearing scaffolds are erected under the prestressed string structure, and when each load-bearing scaffold is erected to the installation position height of the prestressed steel cable in the final tension state, a prestressed steel cable crossing channel is reserved;

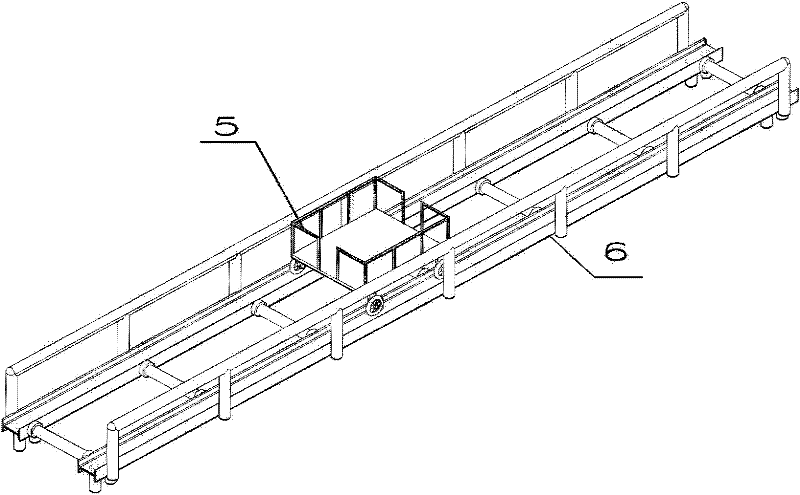

[0026] (b) Install a track guide limiting device fixedly connected with the corresponding load-bearing scaffold in each of the prestressed steel cable crossing channels; the track guide limiting device includes two parallel to each other and its There are grooves on the track, and a plurality of rollers are connected to rotate between the two tracks. A trolley rolls and translates with the grooves of the track through the rollers arranged at the bottom. The outer sides of the above-mentioned rails are respectively provided with limited-position guiding anti-deviation railings, and the bottoms of both ends of the rails are welded with retaining pipes fixedly connected to the corresponding loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com