Device for emergently plugging risk source pipe orifice and rapid plugging method thereof

A plugging device and risk source technology, which is applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of unreasonable structure of the plugging device, the sealing is not tight, the sealing is not fast, etc., to achieve sufficient Rescue time, good sealing, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

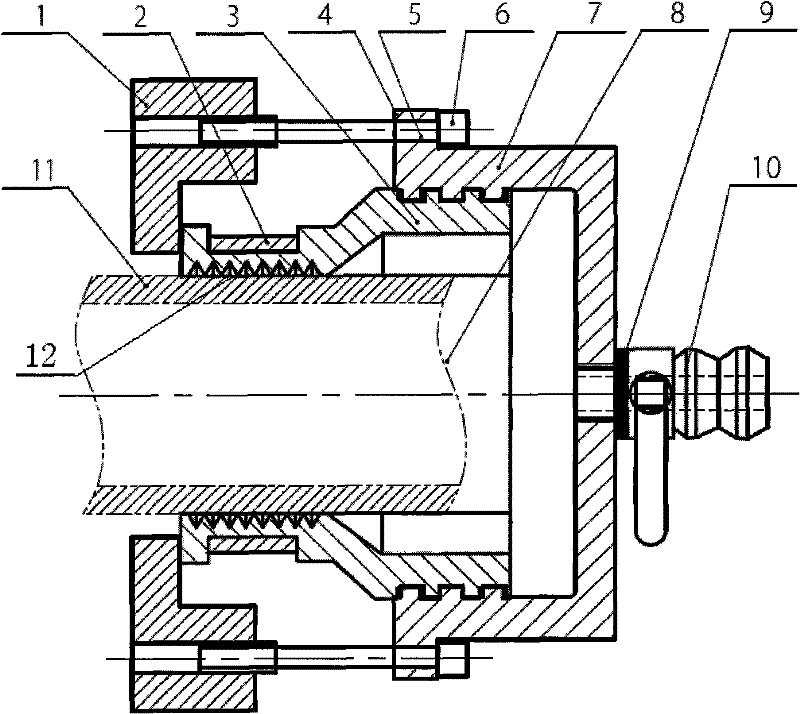

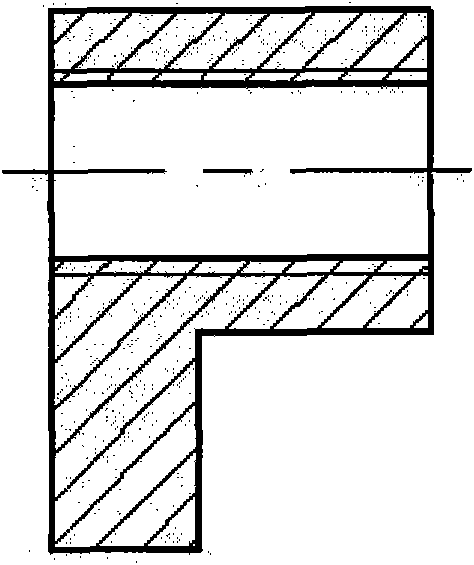

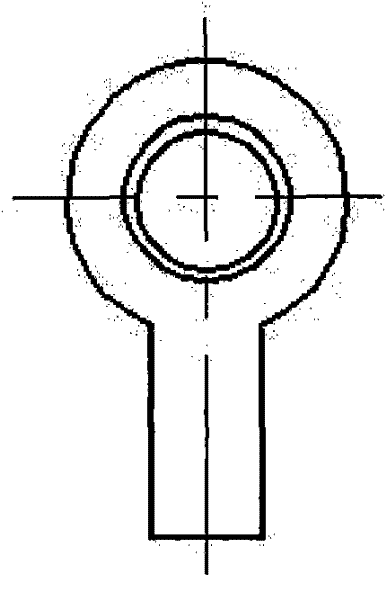

[0019] Such as figure 1 Described in: the pipe plugging device has a pipe plugging through cover 7 with a rectangular thread, and a valve 10 with the function of guiding water is connected to the outer end of the pipe plugging through cover 7. Open it for pressure relief; when blocking, screw the plug-through cover 7 with the diversion valve and the rubber sealing connection sleeve 3 together through a rectangular thread, and then cover the end of the leaking pipeline as a whole. The outlet pipe hoop is locked on the rubber sealing connecting sleeve 3, and the pipe hoop is locked with a special tool. The contact surface between the rubber sealing connecting sleeve 3 and the leaking pipe is a zigzag ring seal, and it can generate greater friction with the pipe wall If the leakage pressure of the pipeline is high, the internal fastening screw 6 can be used to connect the pull plate 1 and the pipe plugging cover 7 after the pipe clamp is locked; finally, the diversion valve 10 is...

Embodiment 2

[0021] The quick pipe plugging device can be directly applied to the leakage of the pipe port. When the leak occurs at the broken port of the pipe, it can be quickly blocked by putting it on the port of the pipe according to the above steps; After the pipe is cut, the device is set on the fracture and locked with a pipe clamp to quickly block and divert the flow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com