Control box device of range hood

A range hood and control box technology, applied in the field of kitchen appliances, can solve problems such as inconvenience, inconvenience, damage to contact points, etc., and achieve the effects of avoiding circuit failures and facilitating overhaul and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

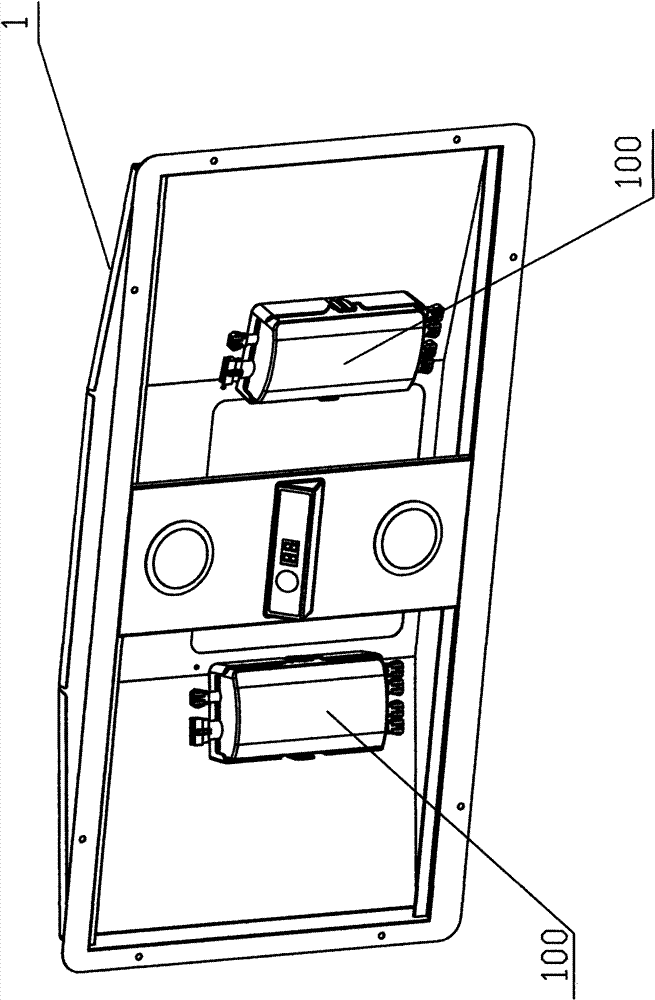

[0022] Such as figure 1 As shown, in the casing of the range hood 1, two control boxes 100 and fixing seats 200 respectively combined with the two control boxes 100 are installed, the two control boxes 100 are respectively the motor control box and the lighting control box, and the range hood The motor control circuit board of the range hood is arranged in the motor control box, and the lighting control circuit board of the range hood is arranged in the lighting control box. The structure and installation method of the motor control box and the lighting control box are the same.

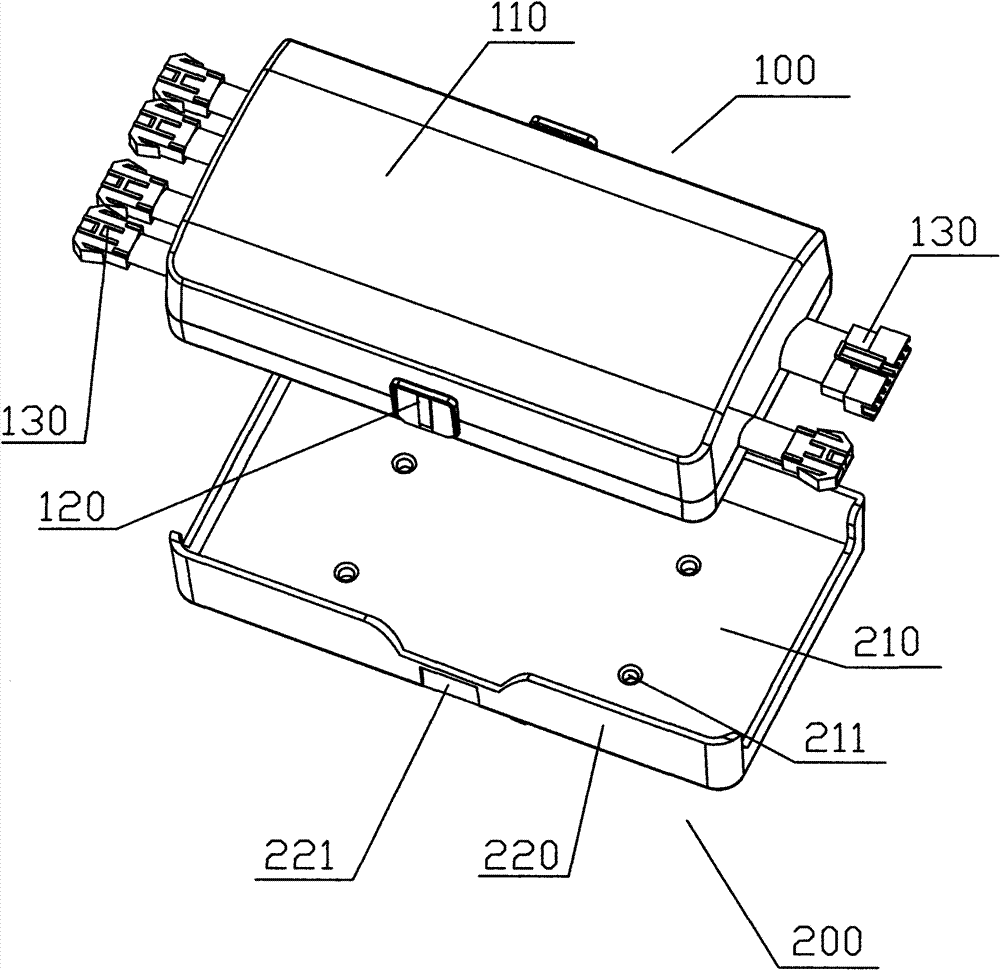

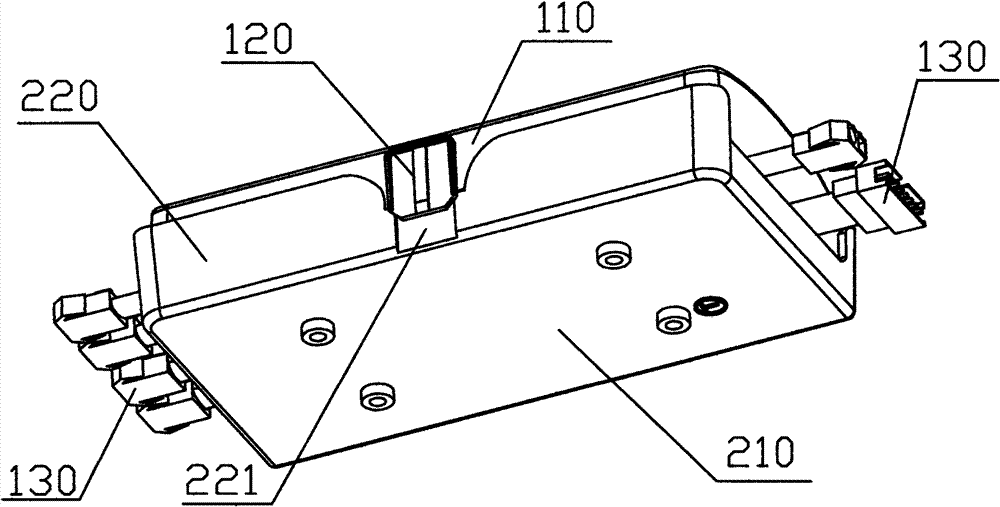

[0023] Such as figure 2 and image 3 As shown, the fixing base 200 includes a rectangular bottom surface 210 and four side panels 220 connected to the bottom surface 210, the bottom surface 210 and the four side panels 220 form a storage space, wherein the two short sides connected to the rectangular bottom surface 210 The heights of the two side panels 220 are smaller than the heights of the two...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap