Fixed-focus lens

A fixed-focus lens and lens technology, applied in the field of fixed-focus lenses, can solve the problems of increased difficulty in lens assembly, increased overall length of the lens, and increased volume of the projection device, thereby reducing the difficulty in manufacturing, improving spherical aberration, and achieving good imaging quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

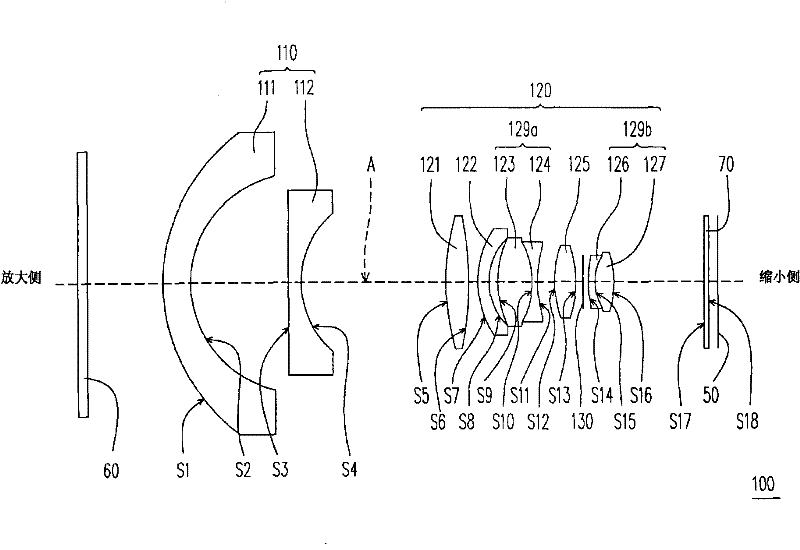

[0048] figure 1 It is a structural schematic diagram of the fixed-focus lens of the first embodiment of the present invention. Please refer to figure 1 , the fixed-focus lens 100 of this embodiment includes a first lens group 110 and a second lens group 120 . The first lens group 110 is disposed between an enlargement side and a reduction side, and includes a first lens 111 and a second lens 112 arranged in sequence from the enlargement side to the reduction side. Both the diopter of the first lens 111 and the second lens 112 are negative, the first lens 111 is an aspherical lens, and the second lens 112 is a spherical lens. In this embodiment, the first lens 111 is, for example, a convex-concave lens with a convex surface facing the magnification side, and the second lens 112 is, for example, a plano-concave lens with a plane facing the magnification side.

[0049] The second lens group 120 is disposed between the first lens group 110 and the reduction side, and includes a...

no. 2 example

[0073] image 3 It is a structural schematic diagram of the fixed-focus lens of the second embodiment of the present invention. Please refer to image 3 , the fixed-focus lens 100' of the present embodiment is the same as the above-mentioned fixed-focus lens 100 (such as figure 1 shown) are similar, and the differences between the two are described below. In this embodiment, the first lens group 110' of the fixed-focus lens 100' may further include a tenth lens 113 disposed between the second lens 112' and the third lens 121. The second lens group 120' may further include an eleventh lens 128 disposed between the third lens 121 and the fourth lens 122. The diopters of the tenth lens 113 and the eleventh lens 128 are, for example, negative and positive, respectively, and both are spherical lenses. In addition, in this embodiment, the relative positions of the third lens 121 and the eleventh lens 128 remain fixed, and the third lens 121 and the eleventh lens 128 are used to ...

no. 3 example

[0087] Figure 4 It is a structural schematic diagram of the fixed-focus lens according to the third embodiment of the present invention. Please refer to Figure 4 , the fixed-focus lens 100 " of the present embodiment is the same as the above-mentioned fixed-focus lens 100 (such as figure 1 shown) are similar, and the differences between the two are described below. In this embodiment, the first lens group 110" of the fixed-focus lens 100" may further include a tenth lens 113', which is disposed between the second lens 112" and the third lens 121. The second lens group 120" An eleventh lens 128 ′ may be further included, which is disposed between the third lens 121 and the fourth lens 122 . The diopters of the tenth lens 113' and the eleventh lens 128' are, for example, negative and positive, respectively, and both are spherical lenses. In addition, in this embodiment, the positions of the first lens group 110″, the fifth lens 123, the sixth lens 124, the seventh lens 125...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com