Method for predicting service life of product by accelerated degradation testing based on degenerate distribution non-stationary time series analysis

An accelerated degradation test and timing analysis technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of accelerated degradation test product life prediction and reliability evaluation, insufficient comprehensive and reasonable description, and accelerated macroscopic statistical characteristic prediction And other issues

Active Publication Date: 2010-11-24

BEIHANG UNIV

View PDF2 Cites 60 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

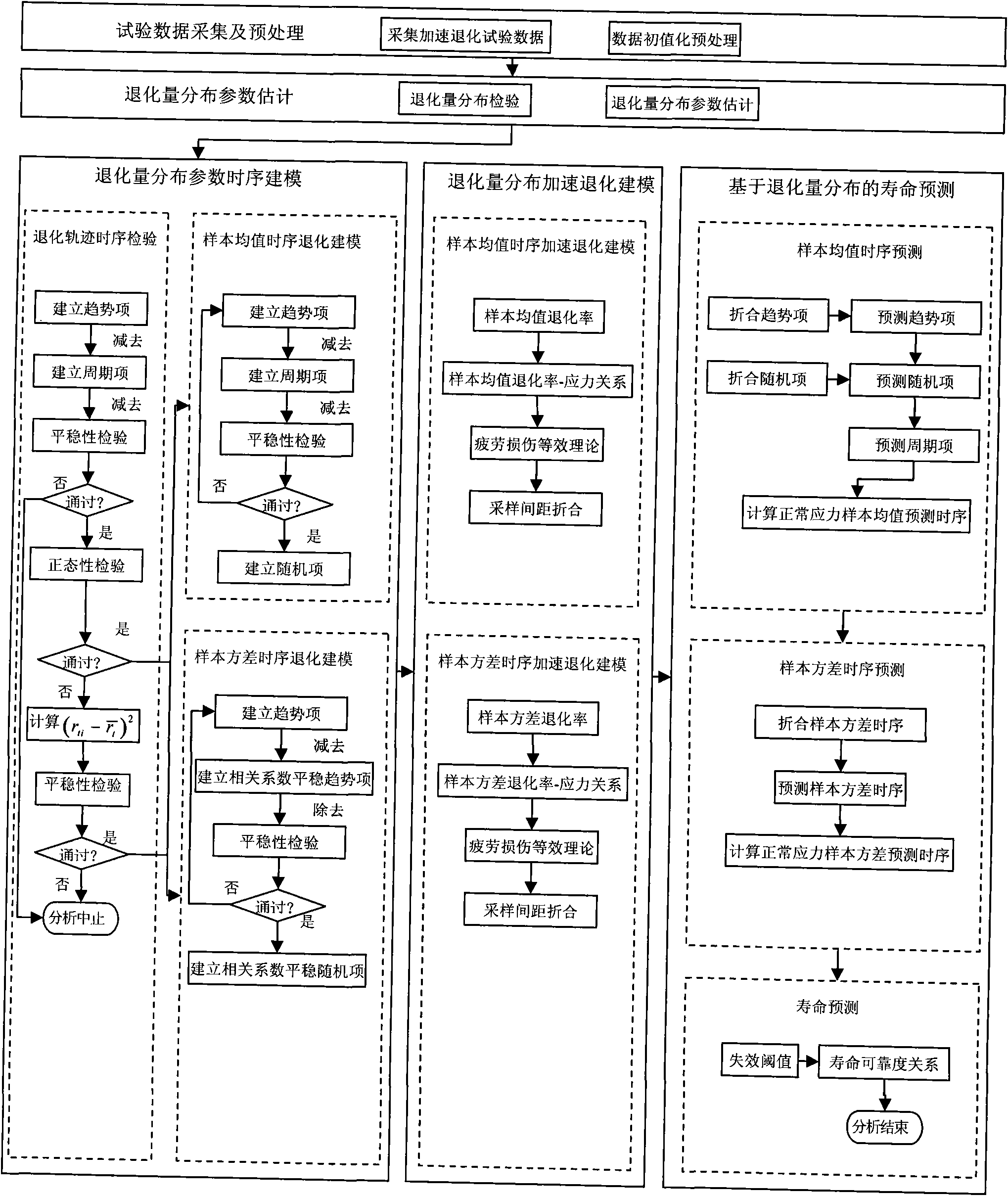

[0023] The purpose of the present invention is to solve the problem that the existing performance degradation prediction method based on the degradation quantity distribution is not comprehensive enough to describe the random process of the statistical data of the degradation test, and the existing performance degradation prediction method based on the time series analysis of the degradation quantity distribution is difficult to be directly applied For the problems of life prediction and reliability evaluation of accelerated degradation test products, the technical means based on non-stationary time series analysis of degradation distribution is adopted to achieve the prediction of product life and reliability that is more consistent with the actual situation of the project through the prediction of macroscopic statistical characteristics of accelerated degradation test data. Technical Effects of Reliability Evaluation

That is, the overall trend of performance degradation is irreversible

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0319] Step 1, test data collection and preprocessing;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for predicting service life of a product by an accelerated degradation testing based on degradation distribution non-stationary time series analysis. The method comprises the following steps of: 1, acquisition and preprocessing of test data; 2, parameter estimation of degradation distribution; 3, time series modeling of degradation distribution parameters; 4, accelerated degradation modeling based on the degradation distribution; and 5, service life prediction based on degradation distribution. The method can macroscopically describe degradation statistical regulation of all samples under accelerated stress, overall analyze the time series of the degradation distribution in an accelerated degradation process, can extrapolate the degradation distribution under the accelerated stress to normal stress to obtain product reliability reflecting the product accelerated degradation random process volatility regulation and service life relationship prediction, improve the credibility on estimation result of service life prediction and reliability, and save more time and is more efficient compared with performance degradation prediction under normal stress level.

Description

technical field [0001] The invention relates to an accelerated degradation test life prediction and reliability evaluation method, belonging to the technical field of accelerated test evaluation. Background technique [0002] The emergence of more and more long-life and high-reliability products makes product life and reliability evaluation more difficult. Predicting product life and reliability based on product performance degradation information has become an effective way. In order to evaluate the reliability of these products for which failure data is difficult to obtain but performance degradation data can be obtained, a degradation test method has emerged. [0003] At present, there are two main ideas for performance degradation prediction: [0004] 1. Each sample function of the stochastic process in which the amount of performance degradation changes with time is called the degradation trajectory, and the prediction is made based on the degradation trajectory. Thi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G06F19/00

Inventor 王立李晓阳姜同敏

Owner BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com