Metal alloy castings with cast-in-place tubes for fluid flow

A technology of casting alloys and casting magnesium alloys, which is applied to engine components, cylinder heads, cylinders, etc., and can solve problems such as corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

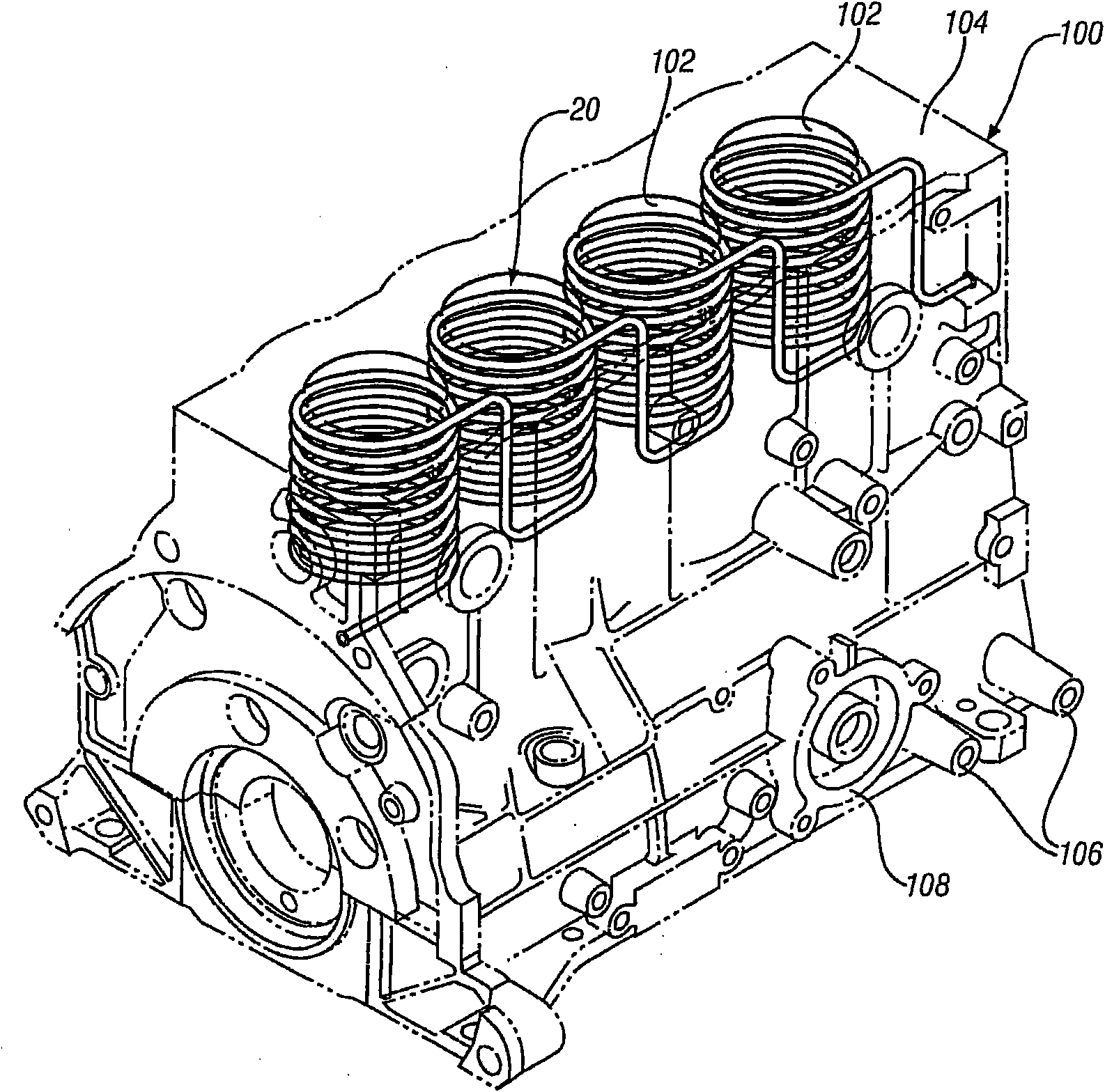

[0046] figure 1 is a diagrammatic view of the invention applied to a representative four-cylinder engine block generally incorporating the features and attributes of such components. A cylinder block or engine block 100 shown in outline is a machined casting comprising cylinders 102 for the pistons of a multi-cylinder reciprocating internal combustion engine. Typically, the deck 104 of the engine is machined as a flat surface capable of mating with a cylinder head (not shown) with a minimum of gaskets. The body is also adapted to allow the cylinder head and crankcase to be attached, while providing attachment points (e.g., perforated boss 106) and mounting flanges (e.g., shown at 108) for auxiliary mechanisms (e.g., AC generators, fuel pumps, etc.), including passages for coolants and lubricants.

[0047] The interconnected tubular structures 20 intended for circulation of engine coolant by means of separate coils surrounding the cylinders 102 are shown fully embedded in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com