Synchronous hydraulic system of diffluence motor

A shunt motor and hydraulic system technology, applied to servo motors, fluid pressure actuators, mechanical equipment, etc., can solve the problem of increased cumulative synchronization errors of four hydraulic cylinders, affecting the life of hydraulic cylinders and shunt motors, and difficulty in continuous production, etc. problem, to achieve the effect of increasing the difficulty of installation, avoiding the phenomenon of suction, and preventing the phenomenon of suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

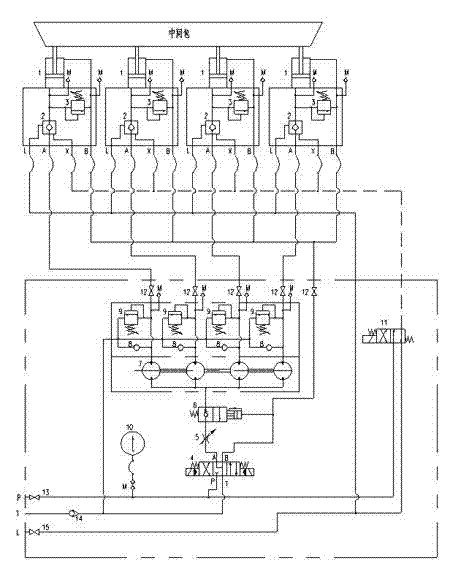

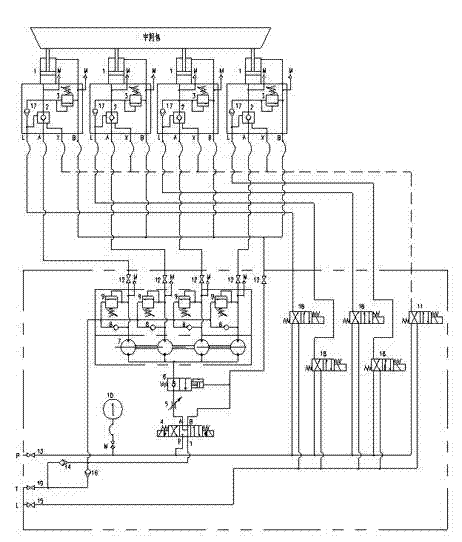

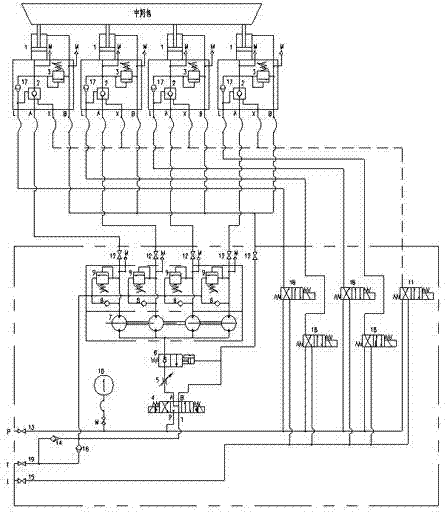

[0014] Such as figure 2 As shown, a shunt motor synchronous hydraulic system includes at least four hydraulic cylinders 1 connected to the tundish, a shunt motor 7, a first one-way valve 8, an overflow valve 9 and a first stop valve 12. The four hydraulic cylinders 1 Drive the tundish up and down, use the splitter motor 7 and the connected first one-way valve 8, overflow valve 9 and first stop valve 12 to synchronously control the positions of the four hydraulic cylinders 1, each hydraulic cylinder 1 is connected to a hydraulic control One-way valve 2 and safety relief valve 3, the hydraulic control one-way valve 2 is controlled by electromagnetic reversing valve 11 for locking the position of the hydraulic cylinder, that is, the position of the tundish, and a fourth one-way valve 17 is installed in the piston chamber of the hydraulic cylinder One end of the fourth one-way valve 17 is connected to the piston chamber of the hydraulic cylinder 1, and the other ends of the four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com