Vehicle-mounted lamp with structure for preventing chassis deformation

A deformation structure and chassis technology, which is applied to vehicle components, optical signals, signal devices, etc., can solve problems such as the lamp head and the pan/tilt being stuck, the tip of the gear 60 under force, the teeth of the gear 60, and the gap between the gear 60 and the expansion. performance, enhanced reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

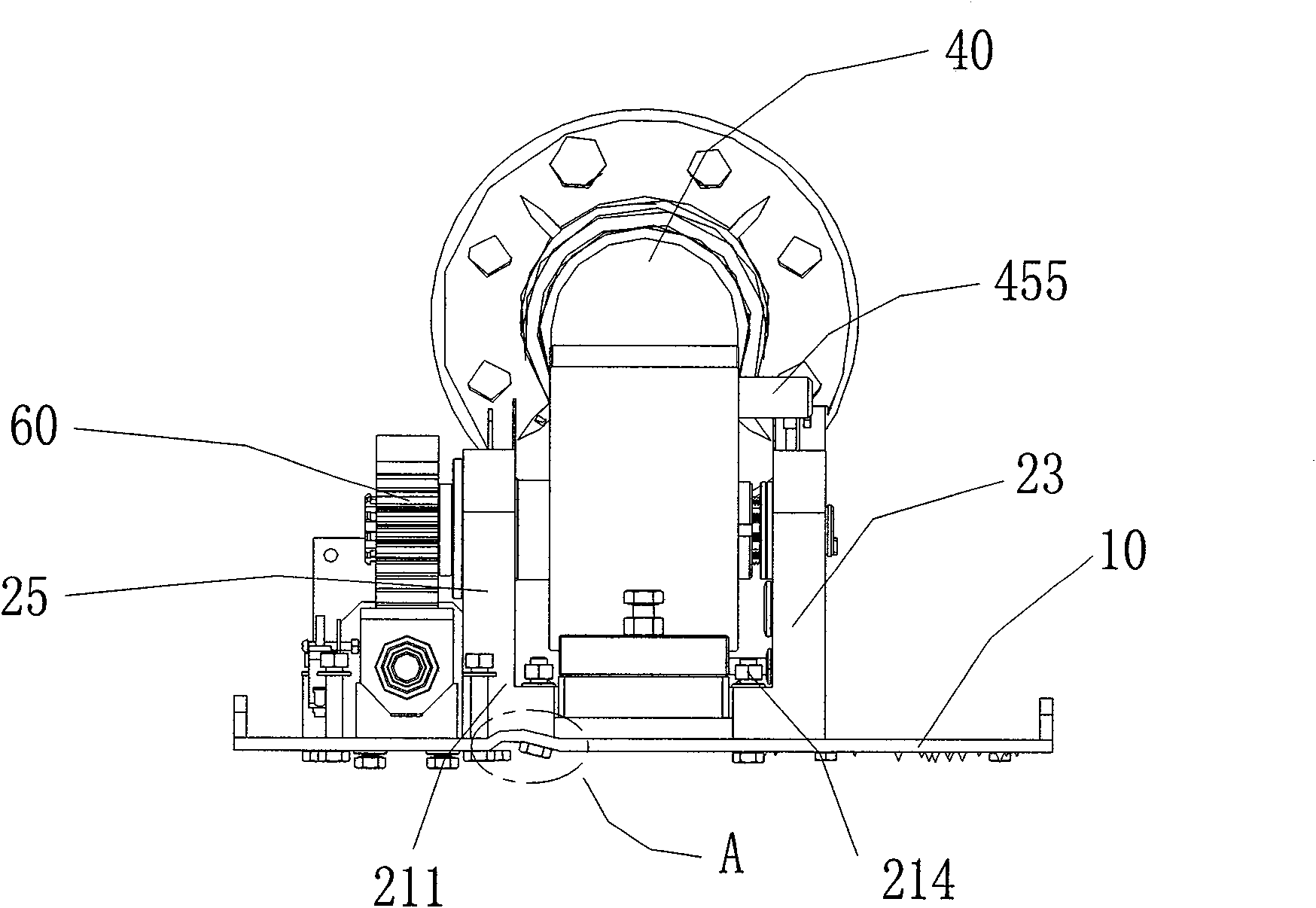

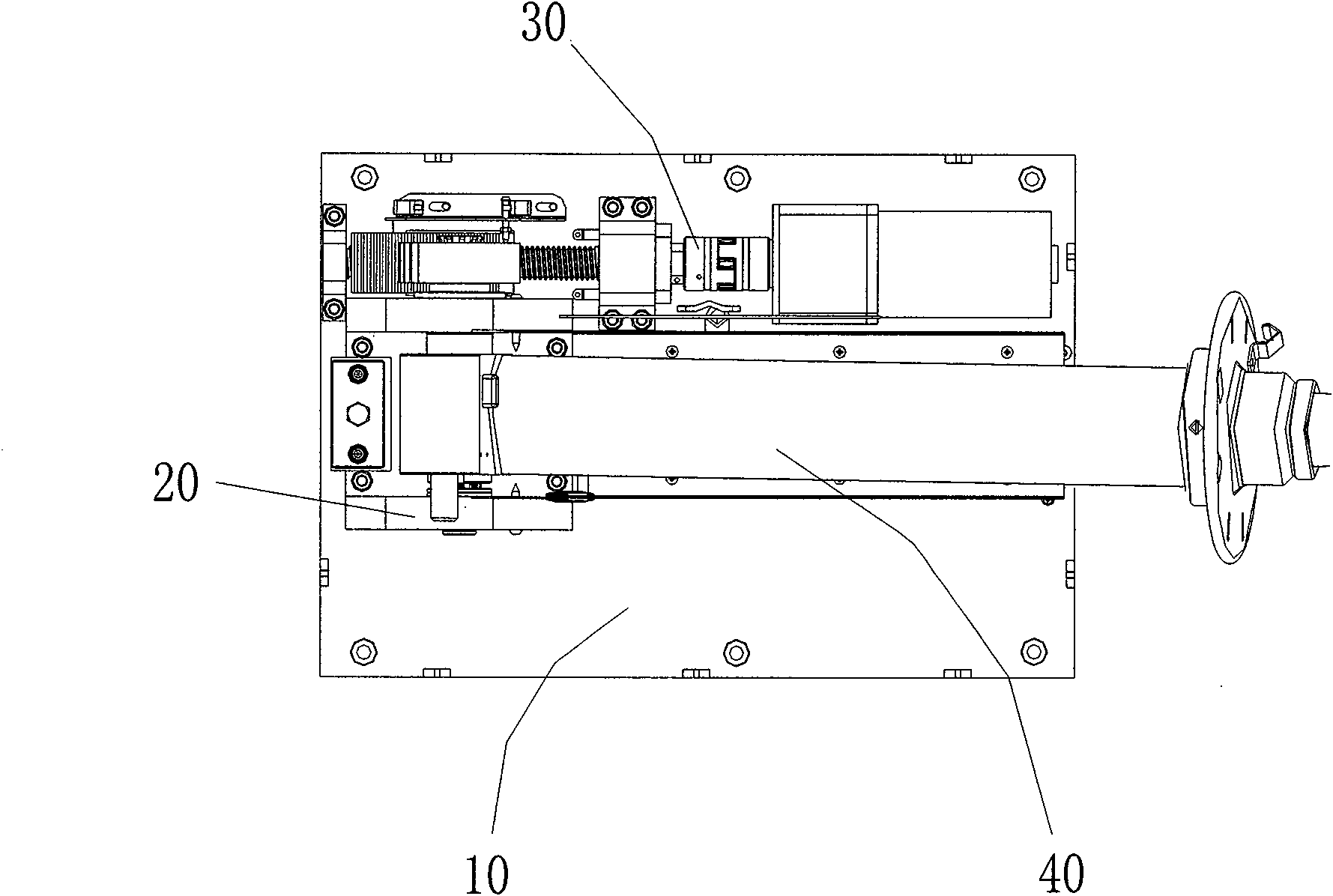

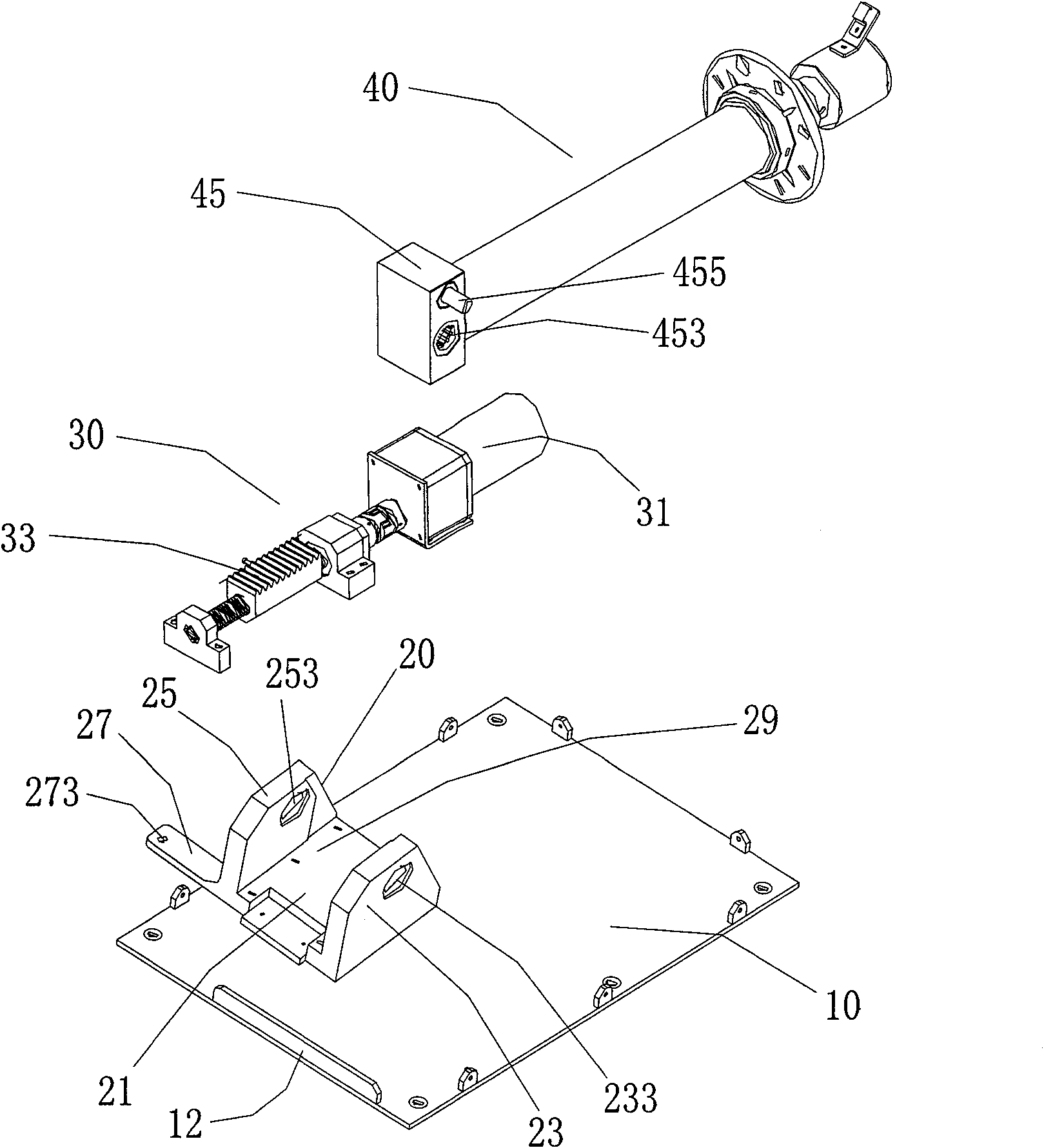

[0018] Please combine image 3 and Figure 4 As shown, they are respectively an exploded view and a top view of the parts on the vehicle-mounted lamp with a chassis deformation-preventing structure according to the present invention. The vehicle-mounted lamp 3 with a chassis-deformation-preventing structure includes: a square chassis 10, a mast fixing seat 20, and an upright propulsion mechanism 30 , lifting cylinder 40; mast holder 20 and vertical propulsion mechanism 30 are adjacently fixed on the chassis 10, mast holder 20 includes a base 21 and a corresponding first support arm 25 protruding from the base 21 With the second support arm 23, the base 21 and the two support arms (25, 23) form a concave-shaped accommodation groove 29, and one end of the lift cylinder 40 is connected to the vehicle-mounted lamp platform 41 and the lamp holder 42, and the other end is The connecting portion 45 is hinged to the support arms ( 25 , 23 ) and placed in the receiving groove 29 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com