Film-coating device

A technology of a coating device and a coating chamber, which is applied in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve the problem of uneven thickness of the film layer, and achieve the effect of uniform consumption and improvement of uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings.

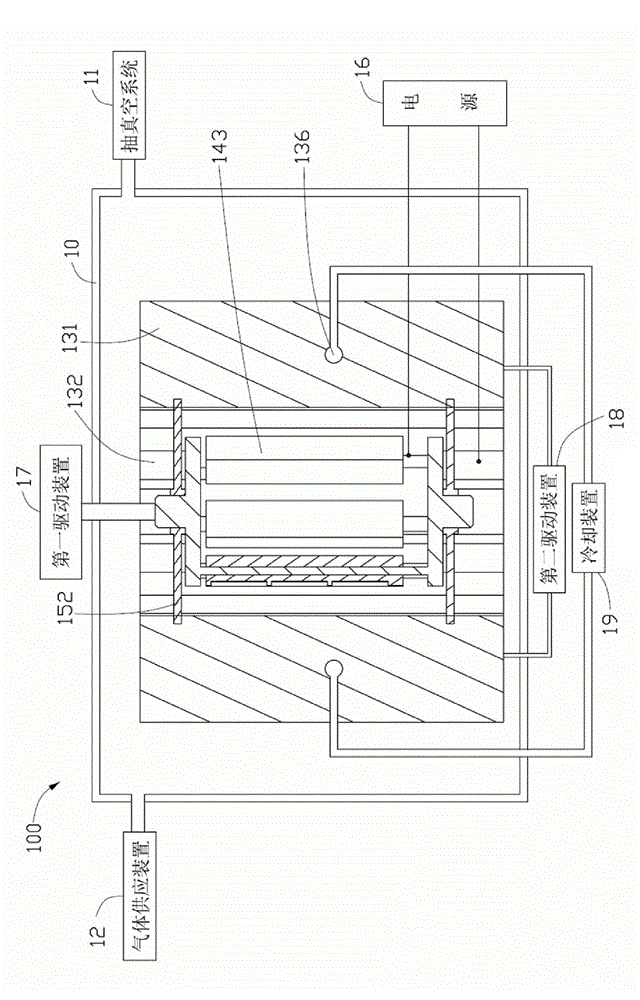

[0010] figure 1 Shown is a coating device 100 provided by an embodiment of the present invention, which includes a coating chamber 10, a vacuum system 11, a gas supply device 12, a target carrier device 13, a substrate carrier device 14, two Connecting device 15 , a power source 16 , a first driving device 17 , a second driving device 18 and a cooling device 19 .

[0011] The coating chamber 10 is used for accommodating the target carrying device 13 , the substrate carrying device 14 and the connecting device 15 .

[0012] The vacuum system 11 communicates with the coating chamber 10 and is used for extracting the gas in the coating chamber 10 .

[0013] The gas supply device 12 communicates with the coating chamber 10 and is used for supplying reaction gas, such as argon, to the coating chamber 10 .

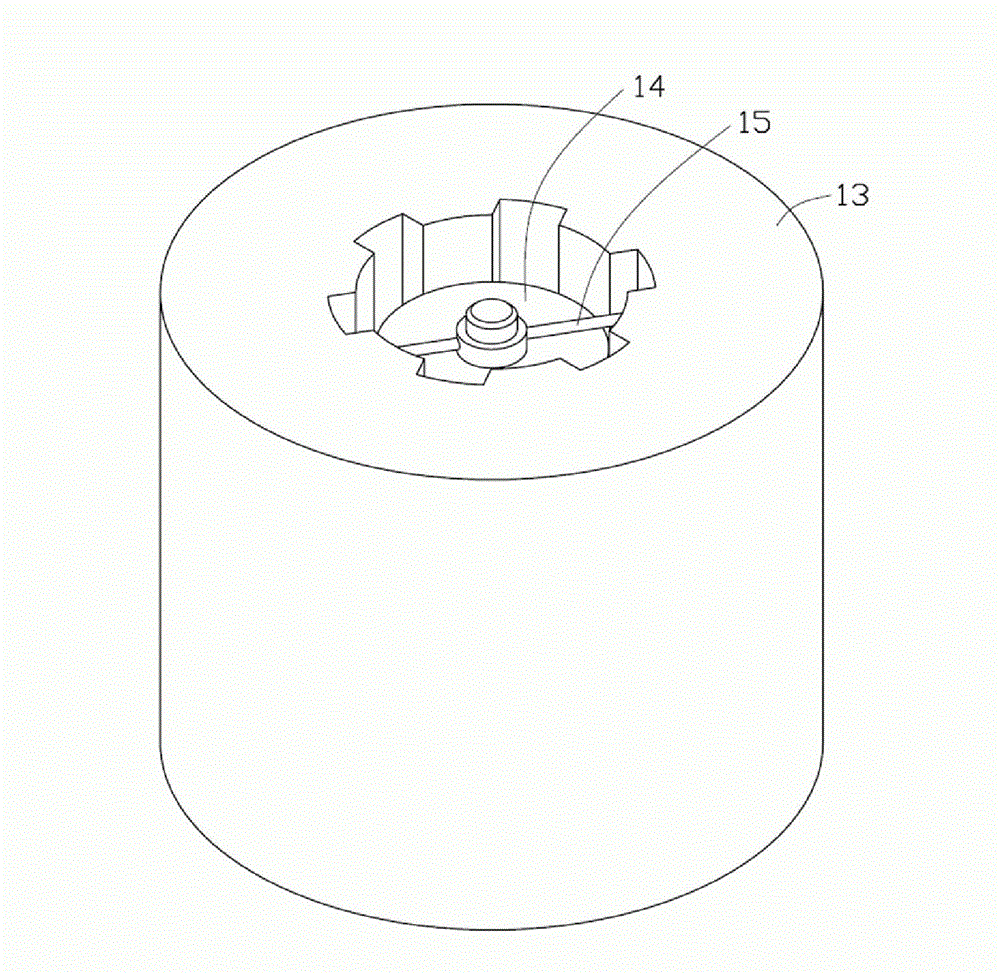

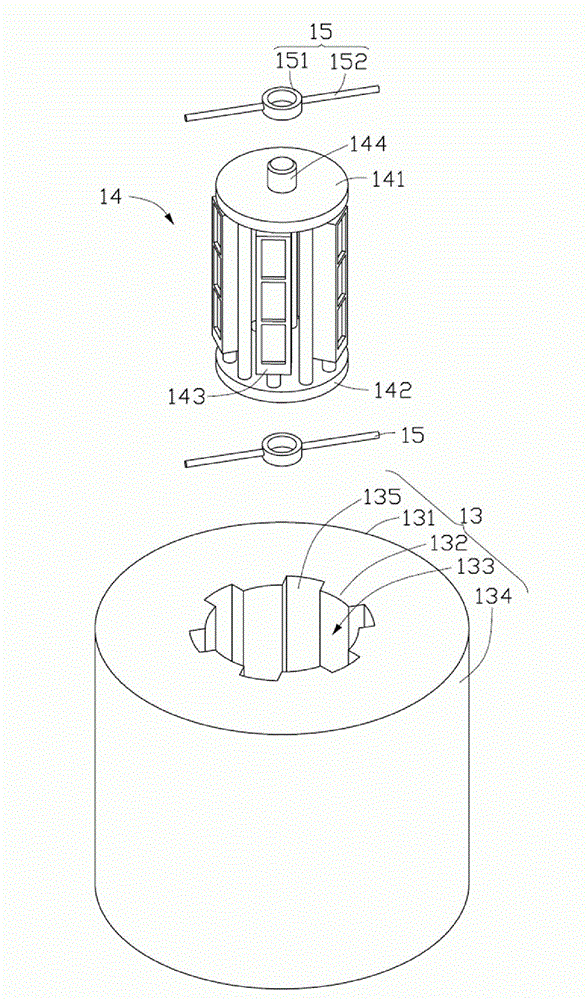

[0014] see figure 2 and image 3 , the target carry...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap