Dispersed cable saddle structure for bridge

A technology for cable saddles and bridges, applied in bridges, bridge parts, bridge construction and other directions, can solve the problems of large concrete stress, difficult to guarantee, large rotation and sliding resistance, etc., to achieve reasonable stress diffusion, convenient maintenance, and flexible rotation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

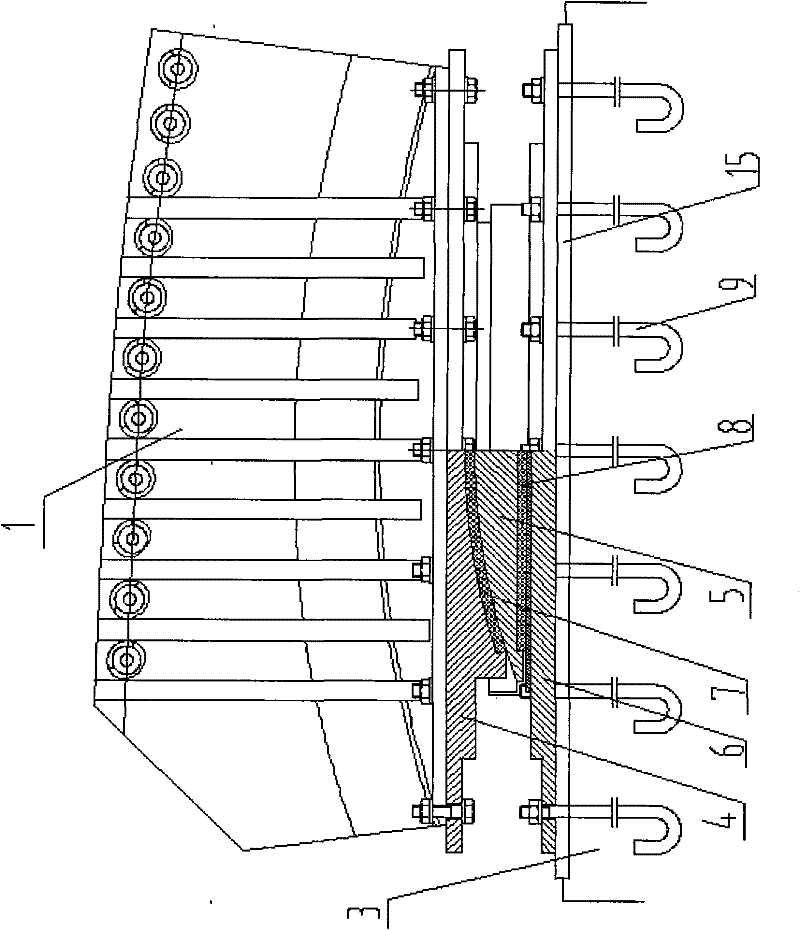

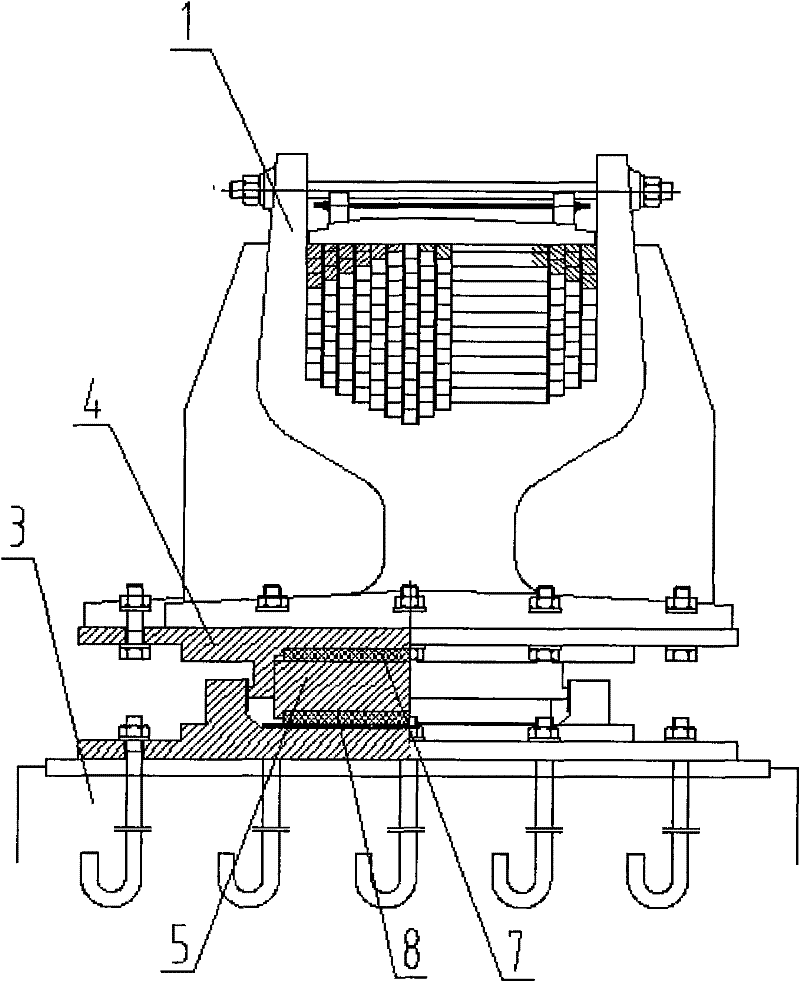

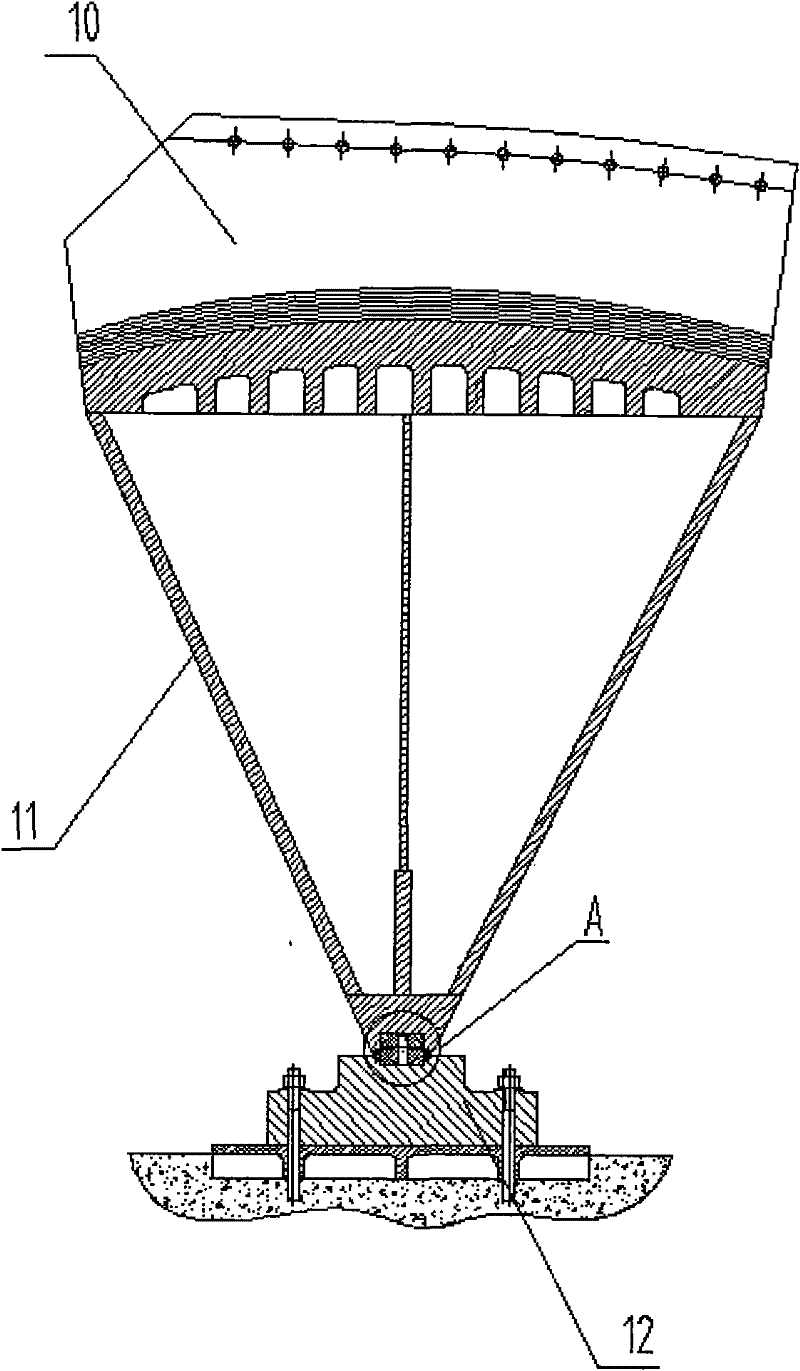

[0017] like figure 1 , 2 Shown: a loose cable saddle structure for bridges, a saddle head 1, a saddle assembly and a pad stone 3, the saddle head 1 is supported on the pad stone 3 through the saddle assembly, it is characterized in that : the saddle assembly includes an upper support plate 4, an intermediate liner 5 and a lower support plate 6, a cylindrical fit is formed between the upper support plate 4 and the intermediate liner 5 and a column is arranged between the two surface slide plate 7, a plane slide plate 8 is arranged between the middle lining plate 5 and the lower bearing plate 6, the saddle head 1 is fixed on the upper bearing plate 4, and the lower bearing plate 6 is fixed on the On the stepping stone 3.

[0018] A lower anchor bolt 9 is embedded in the pad stone 3 , and a steel plate 15 is connected to the upper end of the anchor bolt 9 , and the lower support plate 6 is fixed on the steel plate 15 .

[0019] The cylindrical slide 7 and the flat slide 8 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com