Hose pump

A hose pump and hose technology, applied in the field of peristaltic pumps, can solve the problems of small pump housing see-through lens, abnormal noise, hose damage, etc., to ensure pumping efficiency and stability, increase service life, and reduce wear and tear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

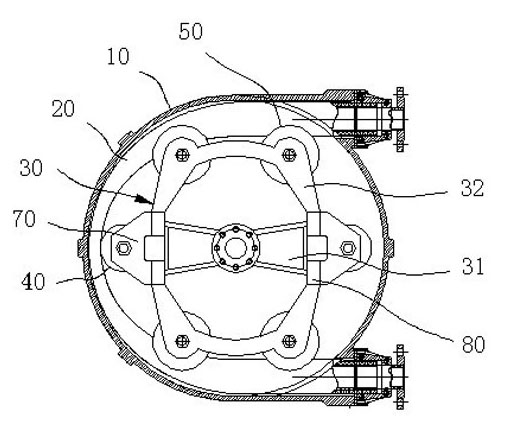

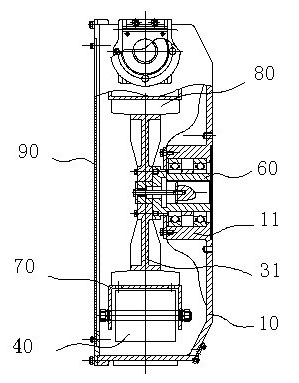

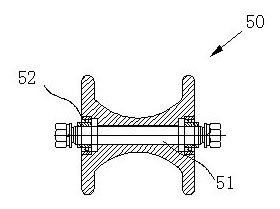

[0011] A hose pump such as figure 1 , including a pump casing 10, an end cover 90 provided on one side of the pump casing 10, and a hose 20 arranged along the circumferential inner wall of the pump casing 10. Both ends of the hose 20 extend to the outside of the pump casing 10 and are fixed. There is a rotor 30 and a main shaft 60 concentric with the rotor 30 for driving the rotor 30 , and the outer periphery of the rotor 30 is provided with a pressure roller 40 , which together with the circumferential inner wall of the pump casing 10 constitutes intermittent extrusion of the hose 20 Cooperate, the outer periphery of rotor 30 is also provided with sheave 50, and sheave 50 is supported and fixed by rotating shaft 51, as image 3 The two ends of the rotating shaft 51 are fixed on the rotor 30. The rotating shaft 51 and the rotor 30 are parallel to the center of rotation of the pressing roller 40. The arc of the bottom coincides with the arc surface of the outer wall of the hos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com