Rail clamping device structure

A technology of rail clamps and splints, which is applied in the field of rail-type X-ray safety inspection systems, and can solve problems such as heavy workload, narrow working space for equipment operators, volume and weight restrictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. In the specification, the same or similar reference numerals designate the same or similar components. The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, but should not be construed as a limitation of the present invention.

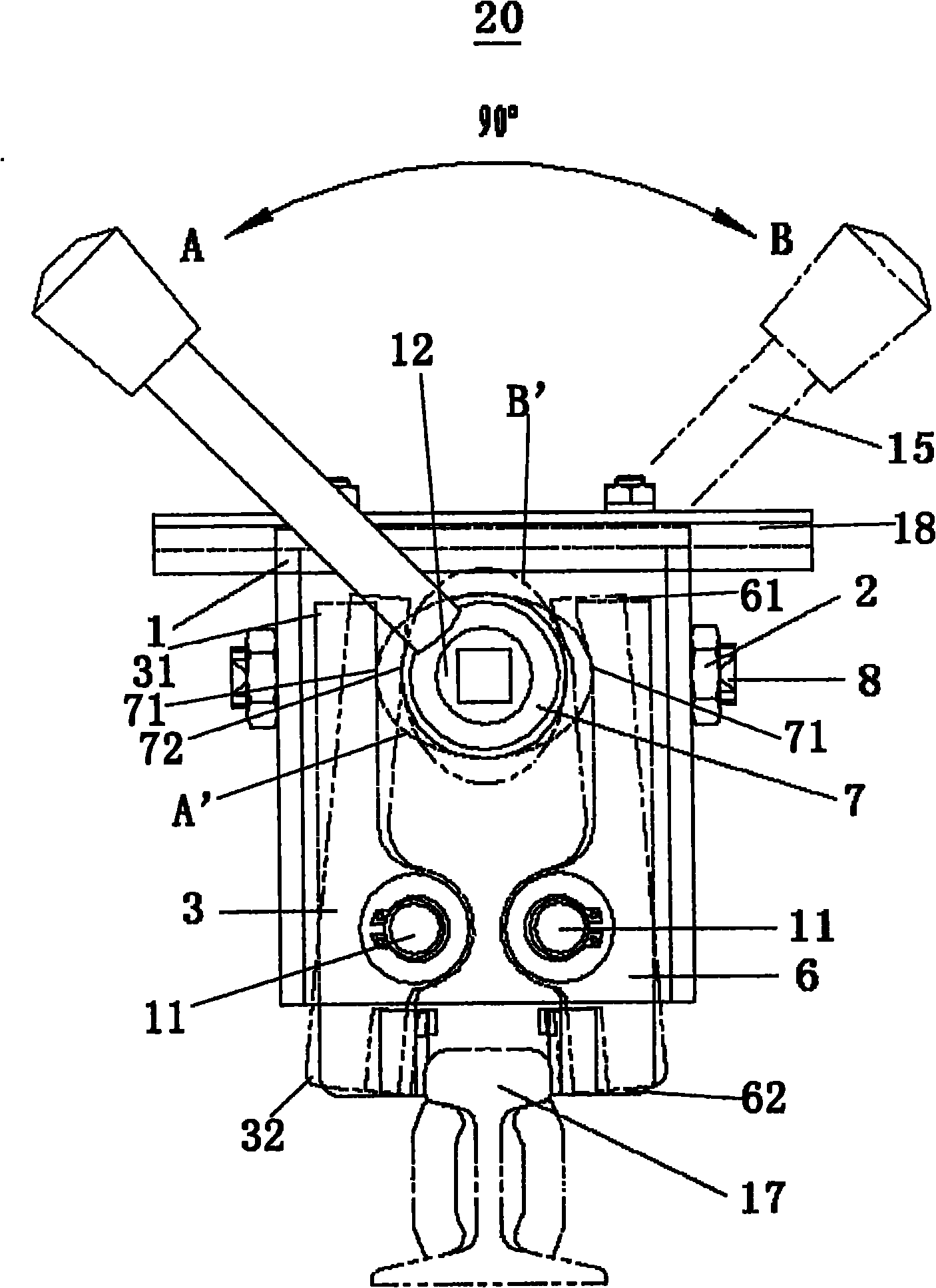

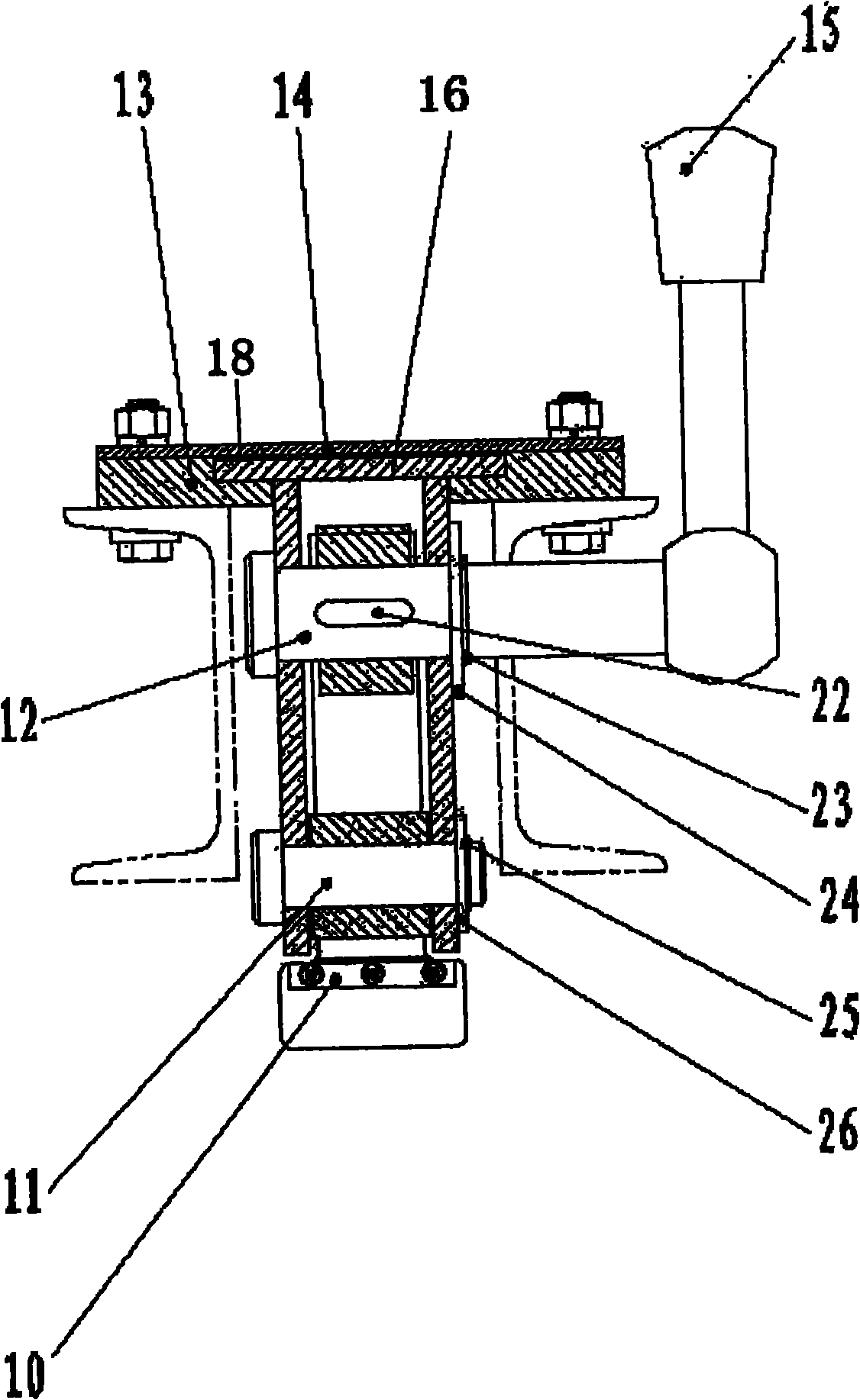

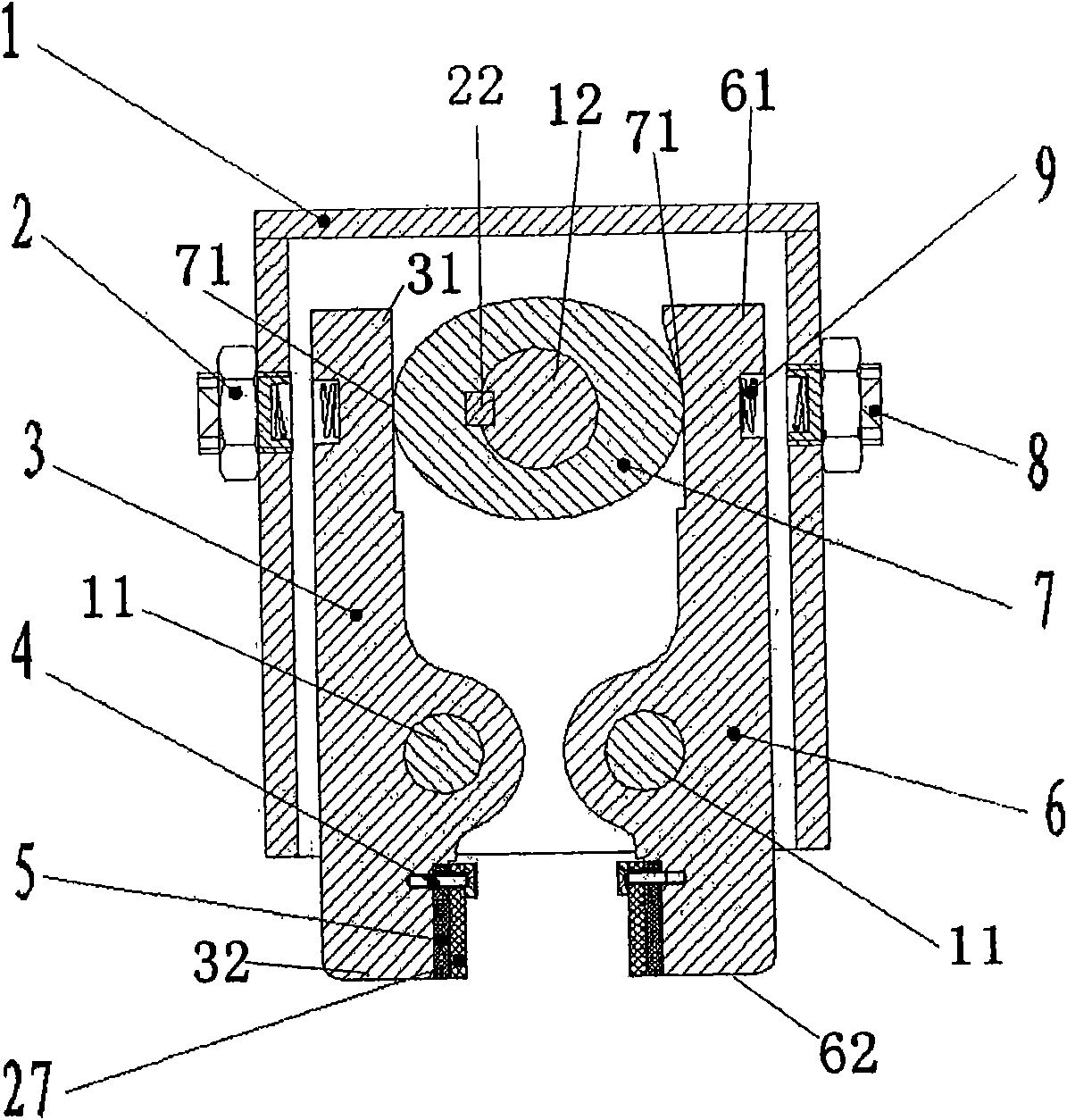

[0026] Such as figure 1 with figure 2 As shown, the present invention provides a rail clamp structure 20, which includes a frame 1, a cam mechanism 7 and at least one clamping plate, such as the two clamping plates 3 and 6 in the figure. The cam mechanism 7 is mounted on the frame 1 and can rotate around its center of rotation. At least one clamping plate 3, 6 is pivotally connected to the frame 1 through a pin shaft 11, wherein one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com