Method of manufacturing optical receiver module and apparatus for manufacturing the same

An optical receiver and optical connector technology, which is applied in the coupling of optics, optical components, optical waveguides, etc., can solve problems such as difficult core adjustment, and achieve the effect of achieving desired characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

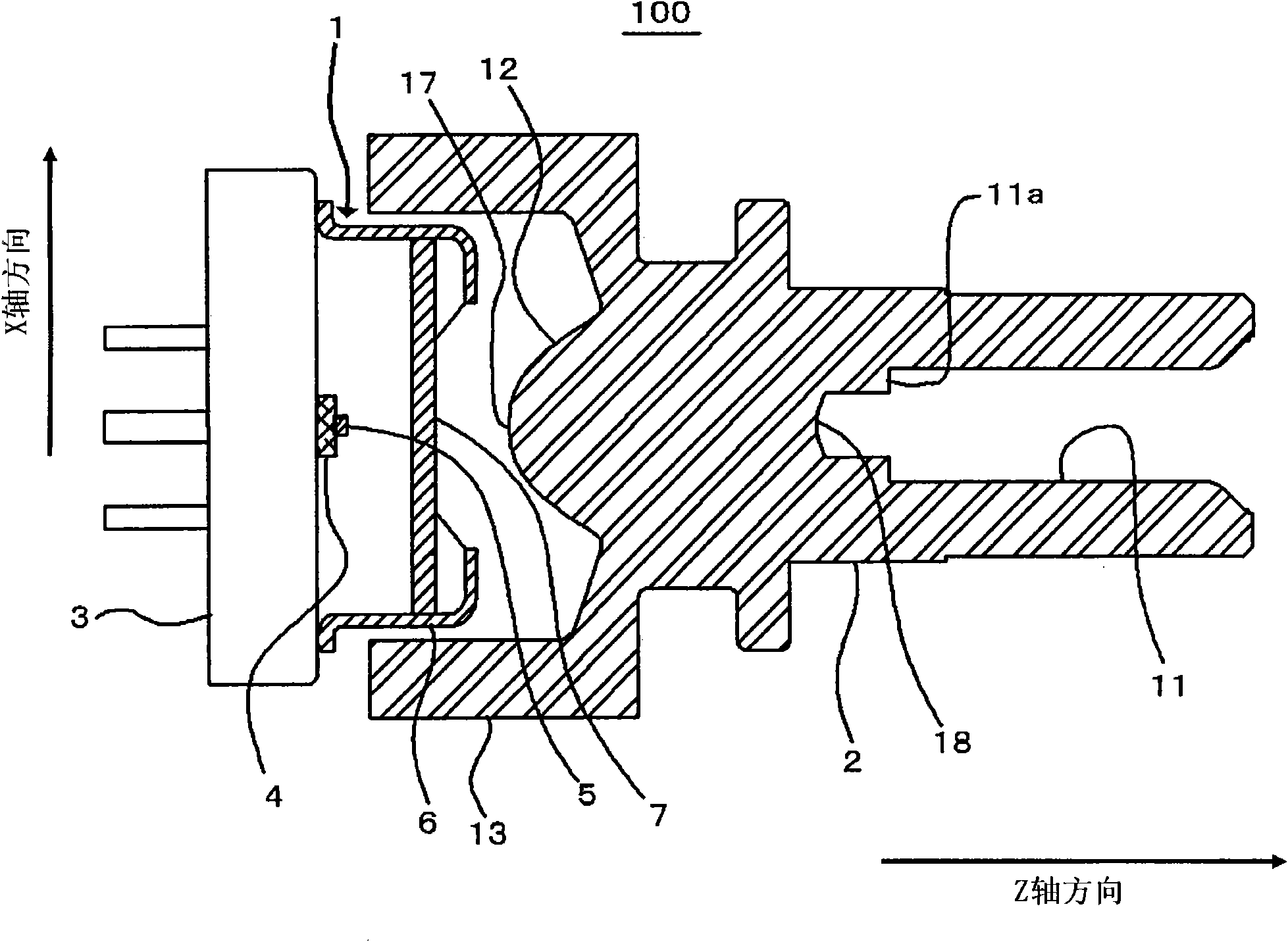

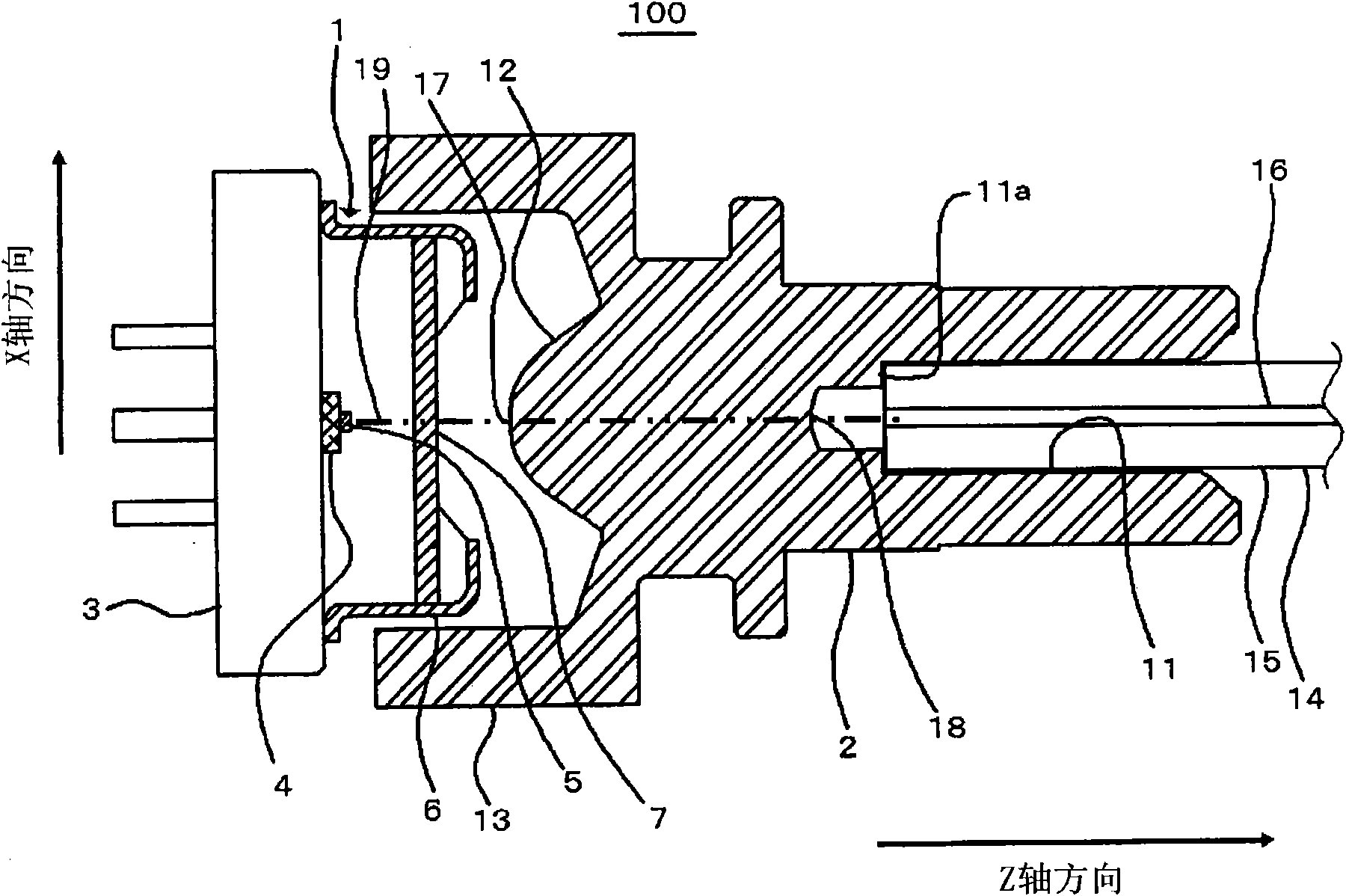

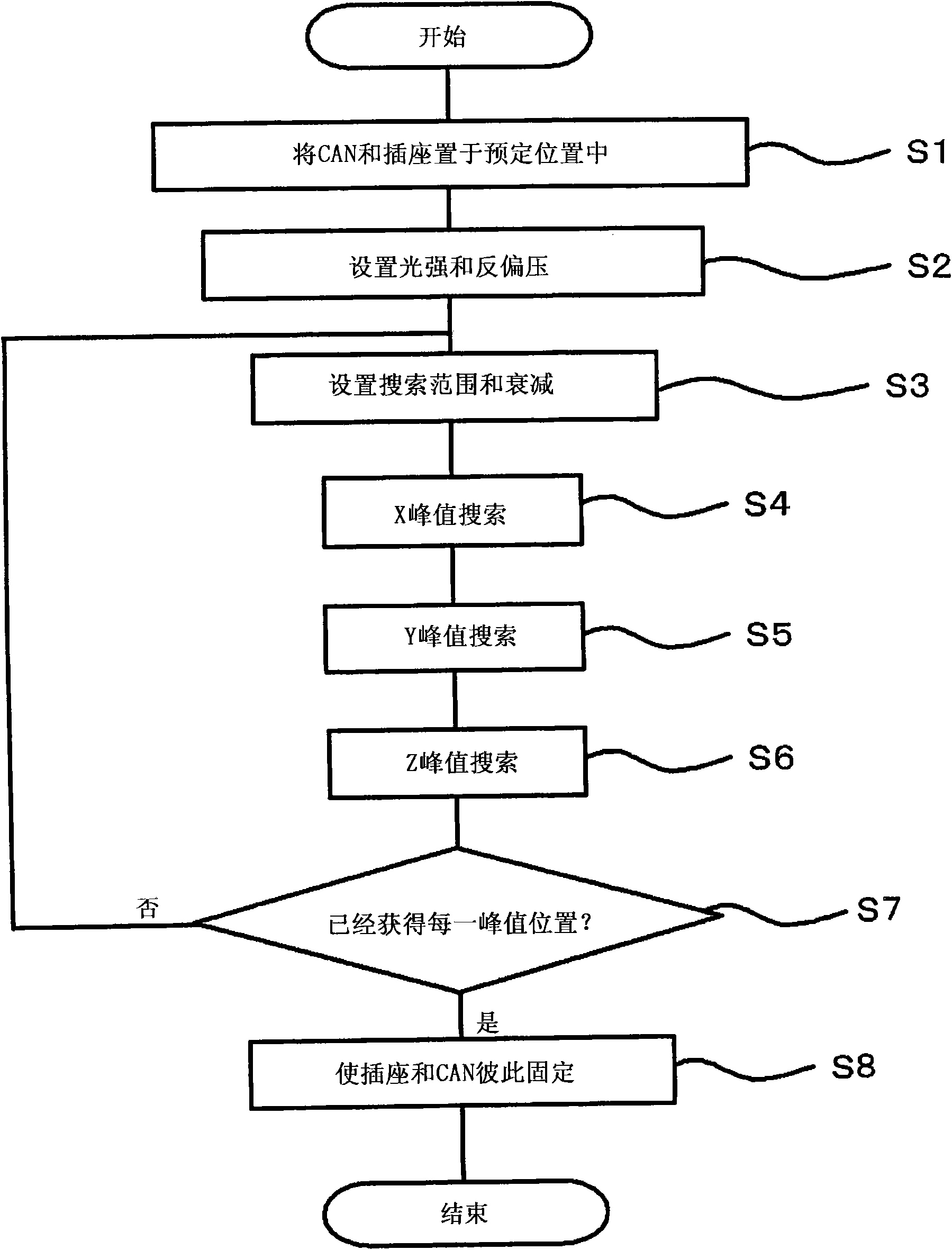

[0067] figure 1 is a cross-sectional view showing the structure of the optical receiver module 100 manufactured by the method for manufacturing the optical receiver module according to the first embodiment. figure 2 is to indicate that the optical connector 14 is inserted into the figure 1 A cross-sectional view of the situation of the optical receiver module 100. image 3 is a flowchart representing a method for manufacturing an optical receiver module according to the first embodiment. Figure 4 Indicates the light intensity distribution on the end face of the optical fiber connected to receptacle 2. Figure 5 Indicates the photocurrent varying with the position of the socket 2 in the X-axis direction. Figure 6 Indicates the photocurrent depending on the position of the socket 2 in the Z-axis direction. Figure 7 is a block diagram showing the structure of the optical receiver module manufacturing apparatus 150 according to the first embodiment.

[0068] The optical ...

no. 2 example

[0180] In the first embodiment described above, the method for manufacturing an optical receiver module is applied to the optical receiver module 100 having the lens 12 embedded in the socket 2 . On the other hand, in the second embodiment, the method for manufacturing an optical receiver module is applied to a Figure 12 The structure of the optical receiver module 200 is shown.

[0181] Such as Figure 12 As shown, an optical receiver module 200 to which the method for manufacturing an optical receiver module according to the present embodiment is applied includes a CAN 1 and a socket 2 (without a built-in lens).

[0182] The CAN 1 includes the same stem 3, the same carrier 4, and the same light-receiving element 5 as those of the first embodiment. In this embodiment, a transimpedance amplifier, a capacitor, etc., as well as a carrier 4 and a light receiving element 5 can be mounted on the stem 3 .

[0183] In this embodiment, the CAN 1 has a cap 21 instead of the cap 6 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com