A switch

A switch and coil spring technology, applied in the switch field of coil spring contact shoes, can solve the problems of reducing the current carrying properties, etc., to achieve the effect of maintaining stability and high current carrying, high mechanical reliability, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0030] Hereinafter, a first embodiment of the present invention will be described specifically with reference to the drawings.

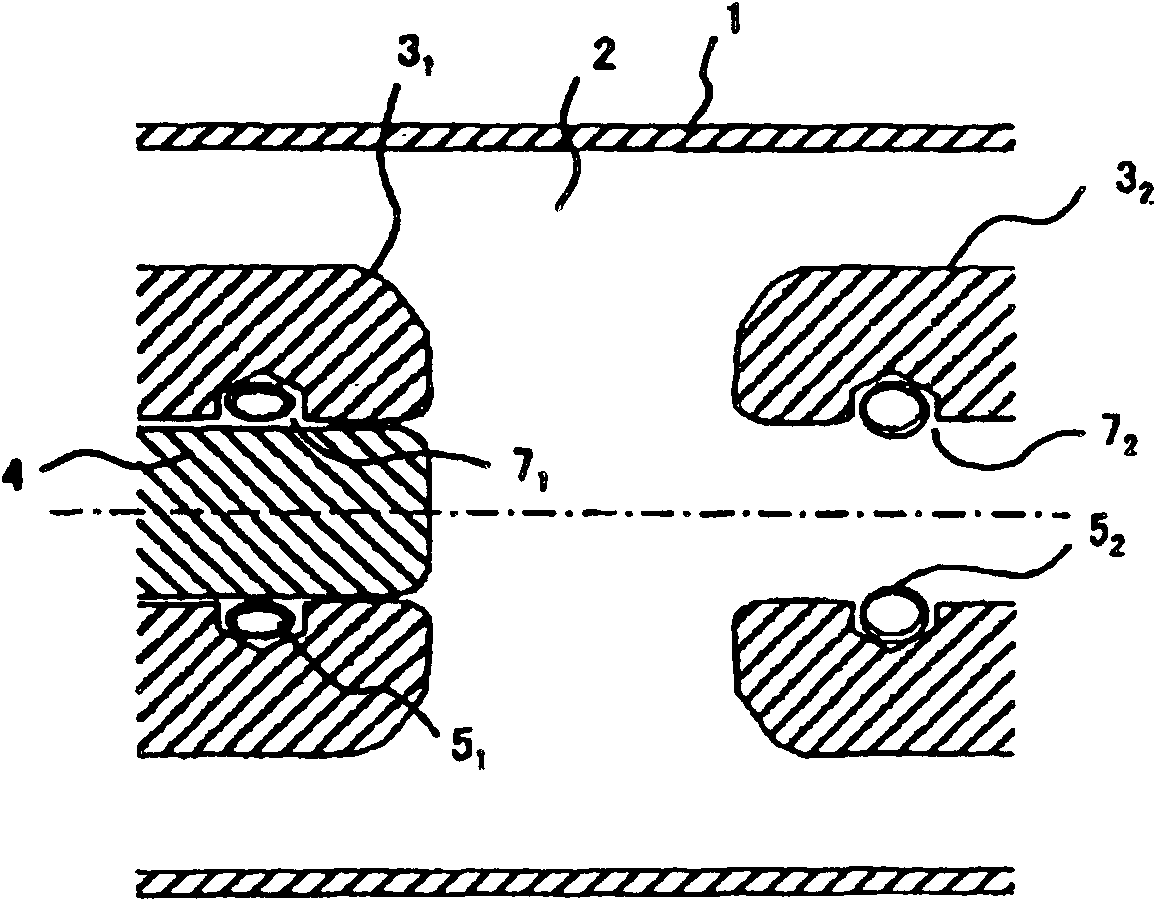

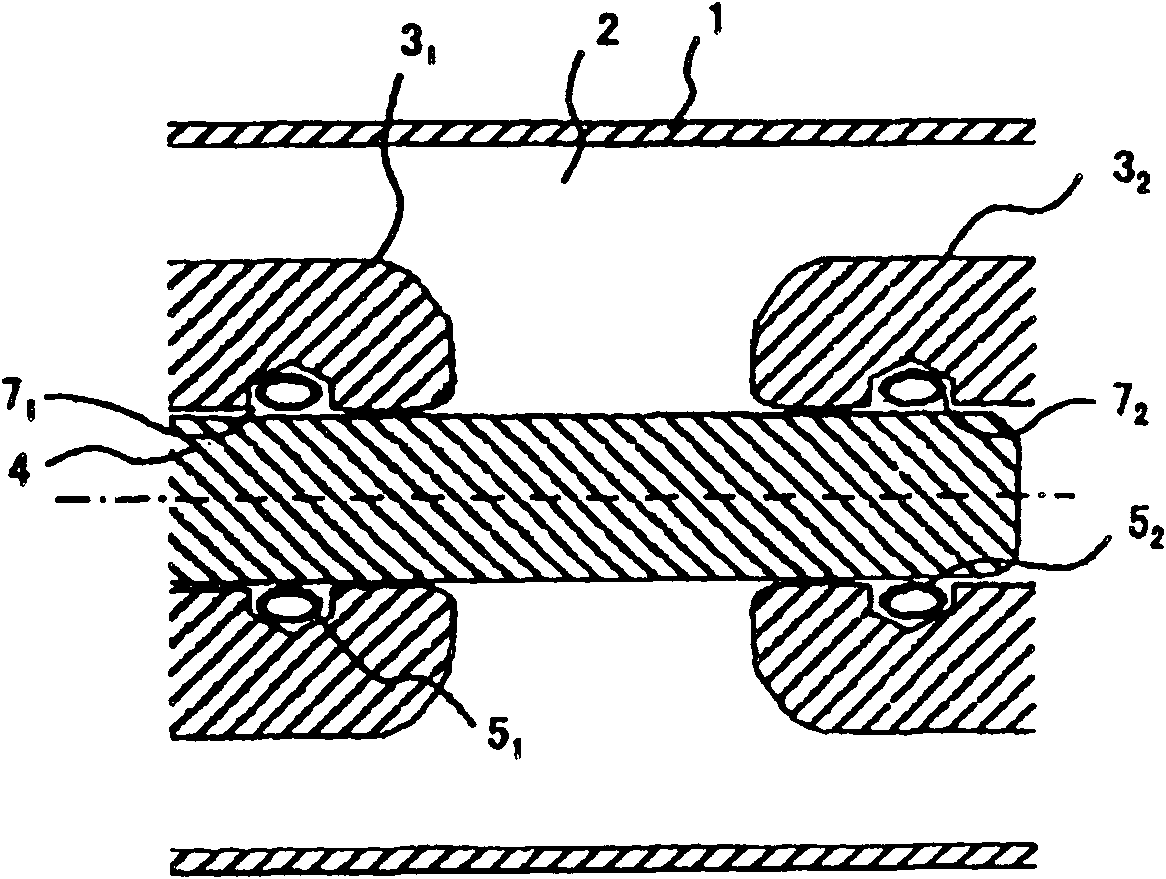

[0031] figure 1 is a cross-sectional view showing a switch using the coil-spring-shaped contact shoe in an off state according to the first embodiment.

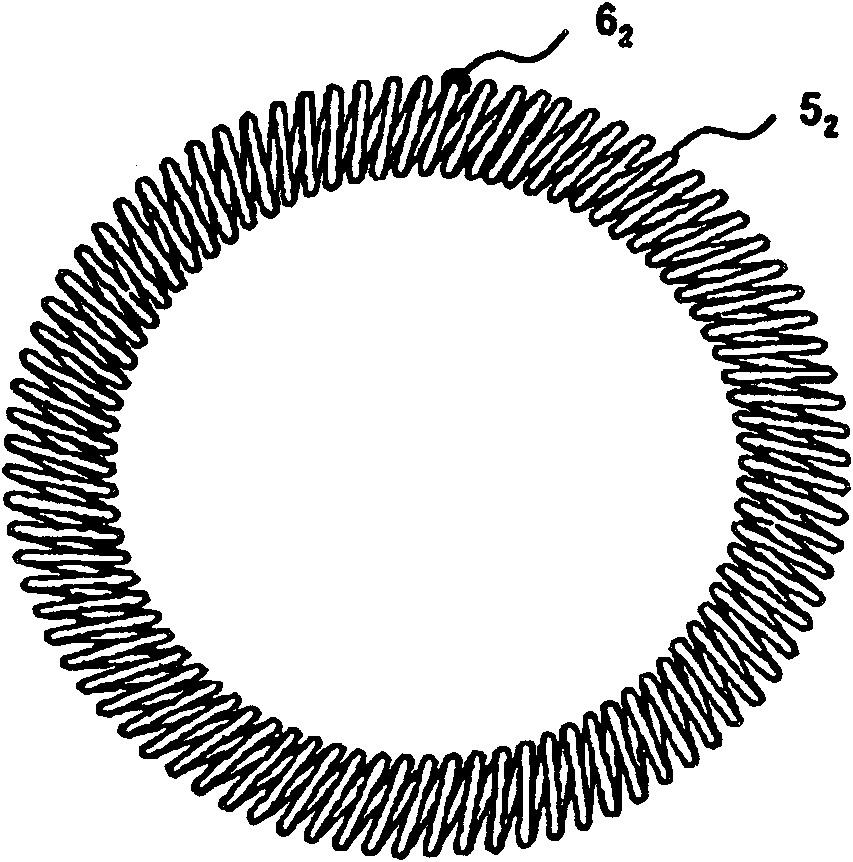

[0032] 0.4~0.6MPa SF 6 Gas is filled into the metal container 1 of the switch in order to ensure electrical insulation. Inside the metal container 1, the movable side contact part 3 1 and fixed side contact part 3 2 are arranged to face each other at predetermined intervals to form electrode portions (switch contact portions). And at the movable side electrode part 3 of one electrode constituting the electrode part 1 At , the cylindrical movable conductor 4 is slidably fixed. On the fixed side electrode part 3 of the other electrode constituting the electrode part 2 At , a cylindrical hollow body is provided for inserting the movable conductor 4 . First coil spring contact shoe 5 1 and a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com