Hydraulic fluid pump for a motor vehicle brake system, comprising an eccentric drive

A technology of automobile braking system and hydraulic fluid, which is applied in the direction of brakes, liquid variable capacity machinery, pumps, etc., to achieve the effect of easy assembly and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

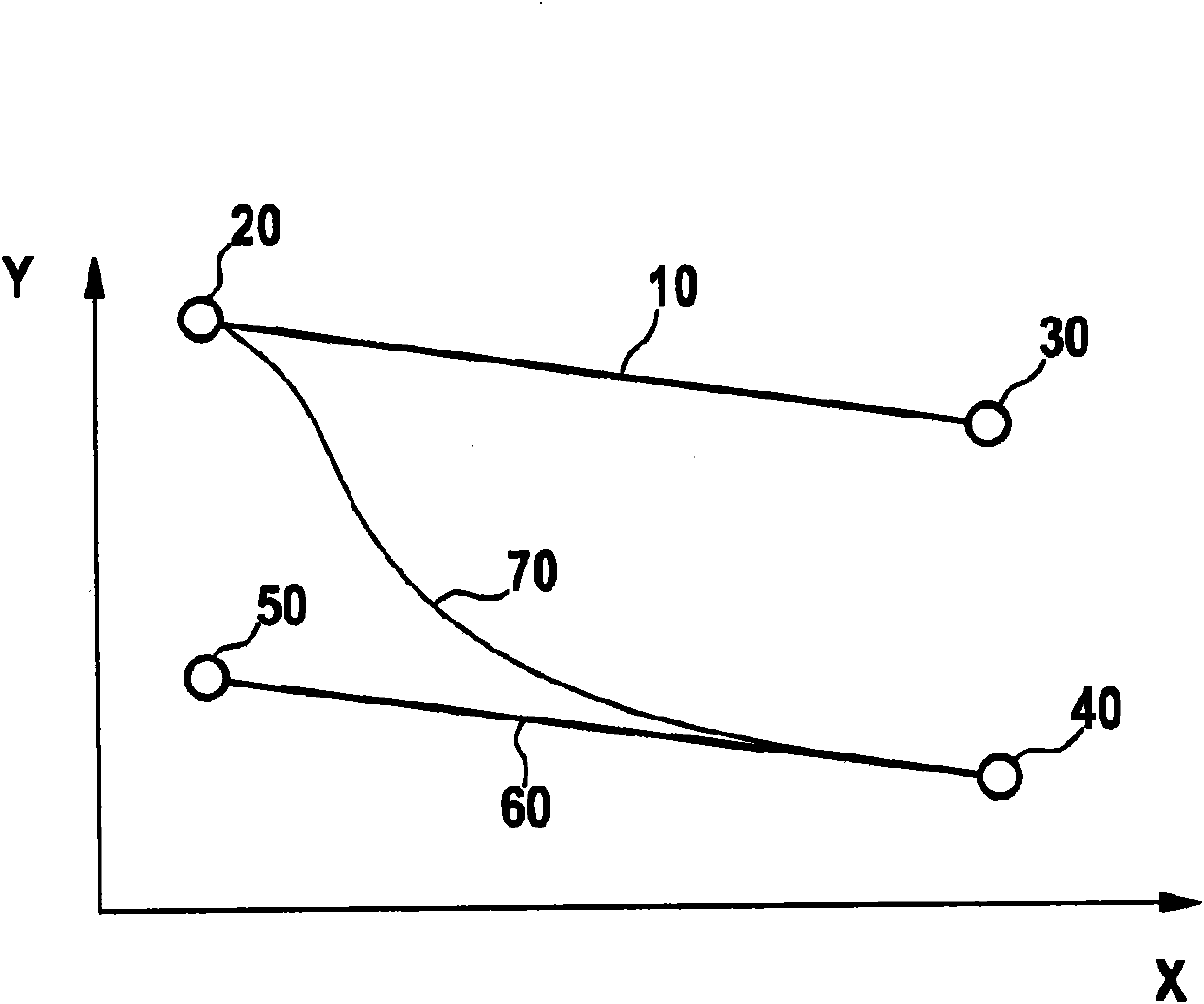

[0032] exist figure 1 In, as already explained above, it is shown how the solution according to the invention can suitably provide a delivery rate of the delivery device of the hydraulic fluid pump on the vehicle brake system which varies depending on the magnitude of the hydraulic back pressure. At this point, regarding the figure 1 The description can be found in the description above.

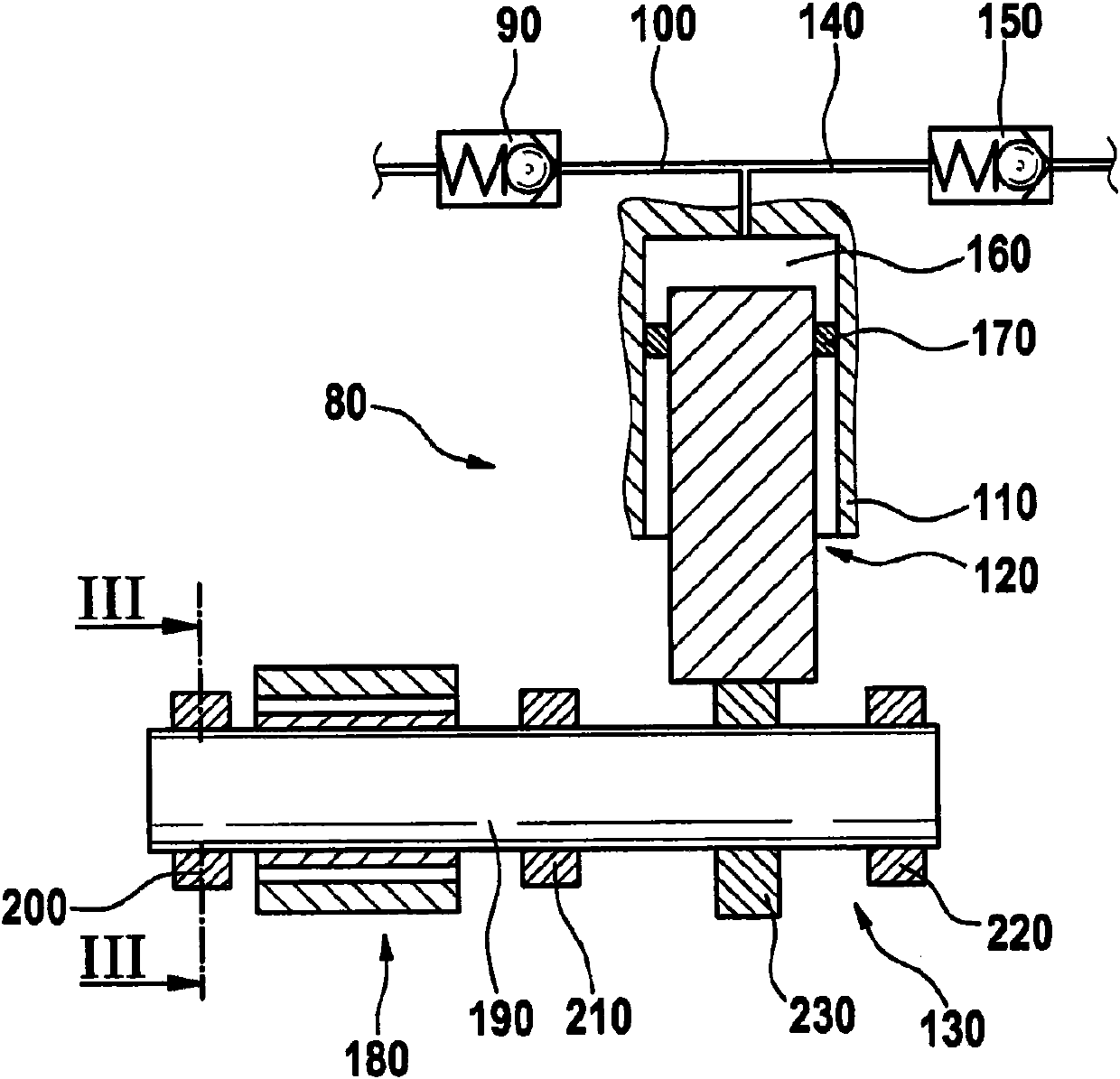

[0033] exist figure 2 A hydraulic fluid pump 80 is shown in , its main components include an inlet valve 150, an inlet pipe 140, a cylinder 110 with a piston 120 located therein, a corresponding eccentric gear 130, an outlet pipe 100 and an outlet valve 90 . Here, the inlet valve 150, the inlet line 140 and the outlet line 100 together with the outlet valve 90 are fluidically connected to the compression chamber 160 formed by the cylinder 110 and the piston 120, so that hydraulic fluid (not shown) passes through the piston The movement of 120 in cylinder 110 is sucked into and outputted f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com