Washing/drying device comprising a moisture determining device and method for operating a washing/drying device

A technology for drying equipment and determining devices, which can be applied to washing devices, applications, household appliances, etc., and can solve the problems of high cost, troublesome processing of moisture sensors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

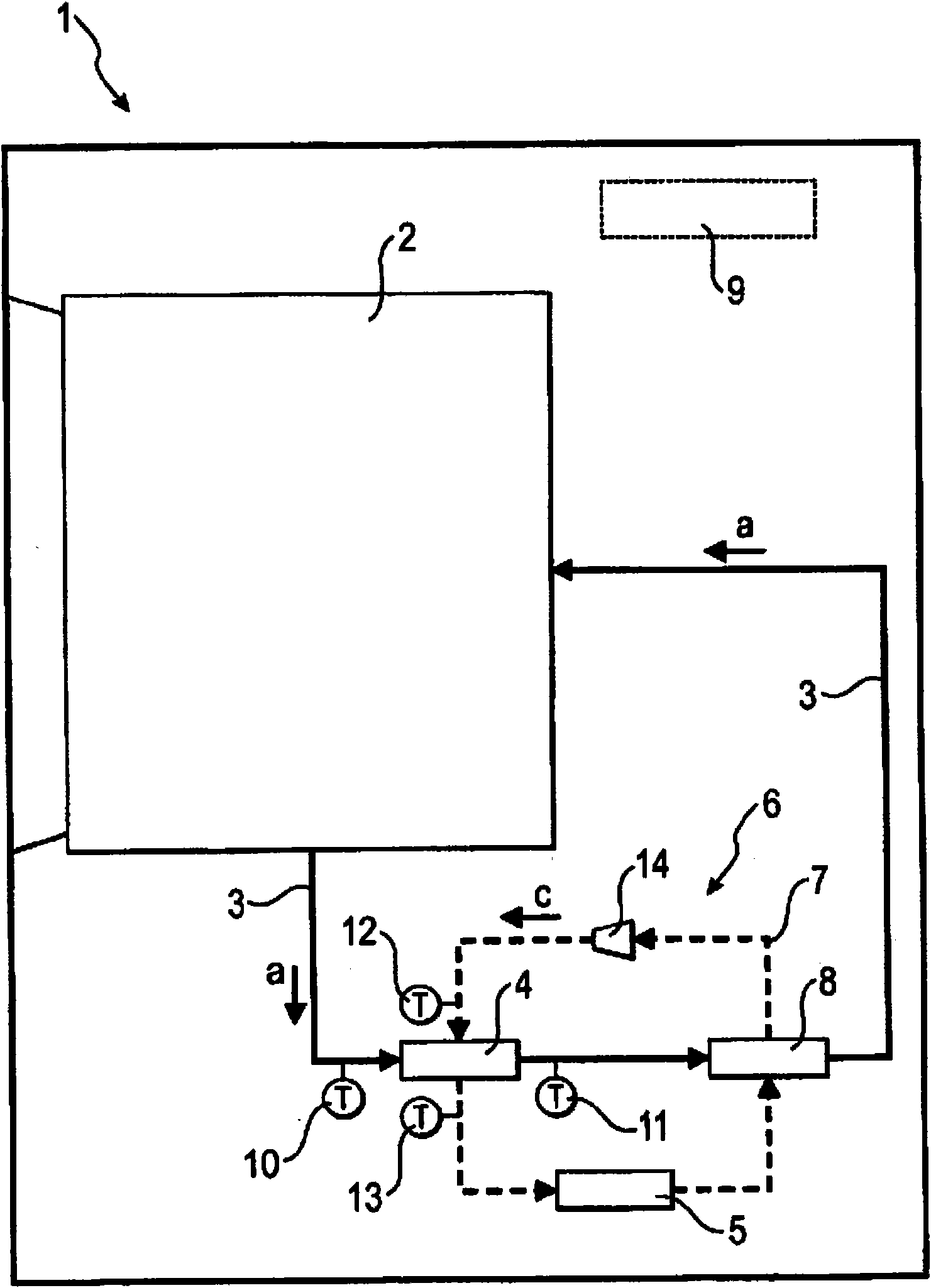

[0029] figure 1 A laundry drying appliance 1 is shown schematically with a laundry drum 2 which is fluidically connected to a circulation air channel or process air channel 3 . During the drying process, heated process air a is generally blown from the circulating air channel 3 into the laundry drum 2 by means of a circulating air fan (not shown here). There, the process air absorbs the hot moisture with the release of heat and is drawn again from the laundry drum 2 into the circulating air channel 3 and is first refrigerated there for at least partial condensation. In order to cool and condense the process air a cooling body 4 is connected into the circulating air duct 3 , through which cooling body 4 flows the hot and humid exhaust air from the laundry drum 2 . For subsequent heating of the refrigerated process air, a heater 8 is connected into the circulation air channel 3 . After heating, the hot, dry process air is blown onto the laundry drum 2 again.

[0030] In the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com