Crank arm type flying cotton removing device

A clearing device, articulating arm technology, applied in textiles and papermaking, etc., to achieve the effect of improving yarn quality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

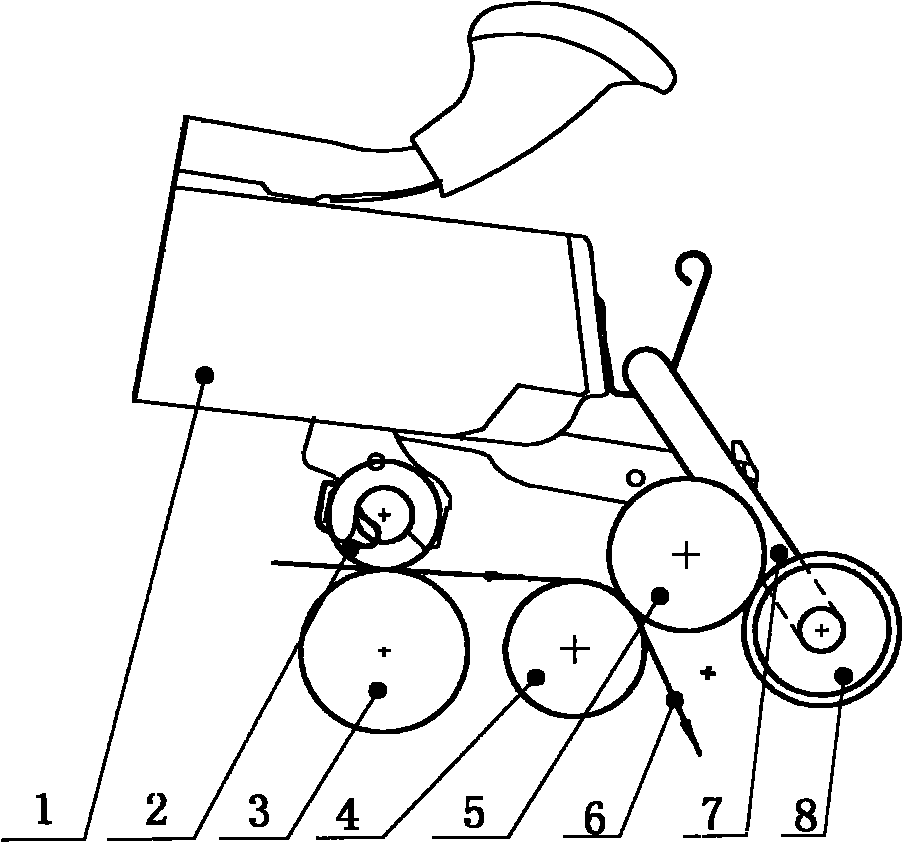

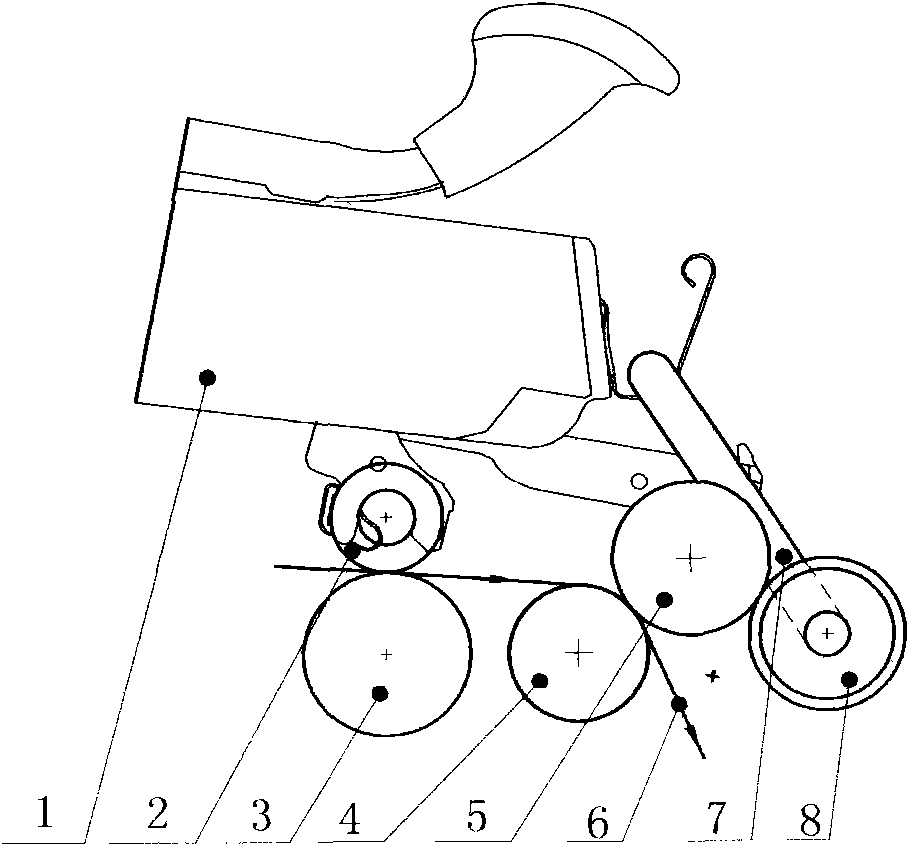

[0022] Embodiment one: see figure 1 , a crank-arm type cleaning device, using the cleaning roller 8 installed on the crank arm 7, the cleaning roller 8 is pressed on the front top roller 5, the middle top roller 2, and the front top roller 5 are installed on the cradle 1, the middle roller 3, and the front roller 4 are installed on the frame, the yarn 6 is twisted after being clamped by the front top roller 5 and the front roller 4, and the cleaning roller 8 is pressed on the front top roller 5 The position where the flying flowers are produced is close to the output end of the yarn. Like this, the cleaning roller 8 is driven to rotate by the front top roller 5, thereby completing the removal of the flying flower fibers attached to the front top roller 5.

[0023] The cleaning roller 8 is connected with the curved arm 7, and the curved arm 7 can place the cleaning roller 8 on the above-mentioned position with magnetic force, gravity or general mechanical force.

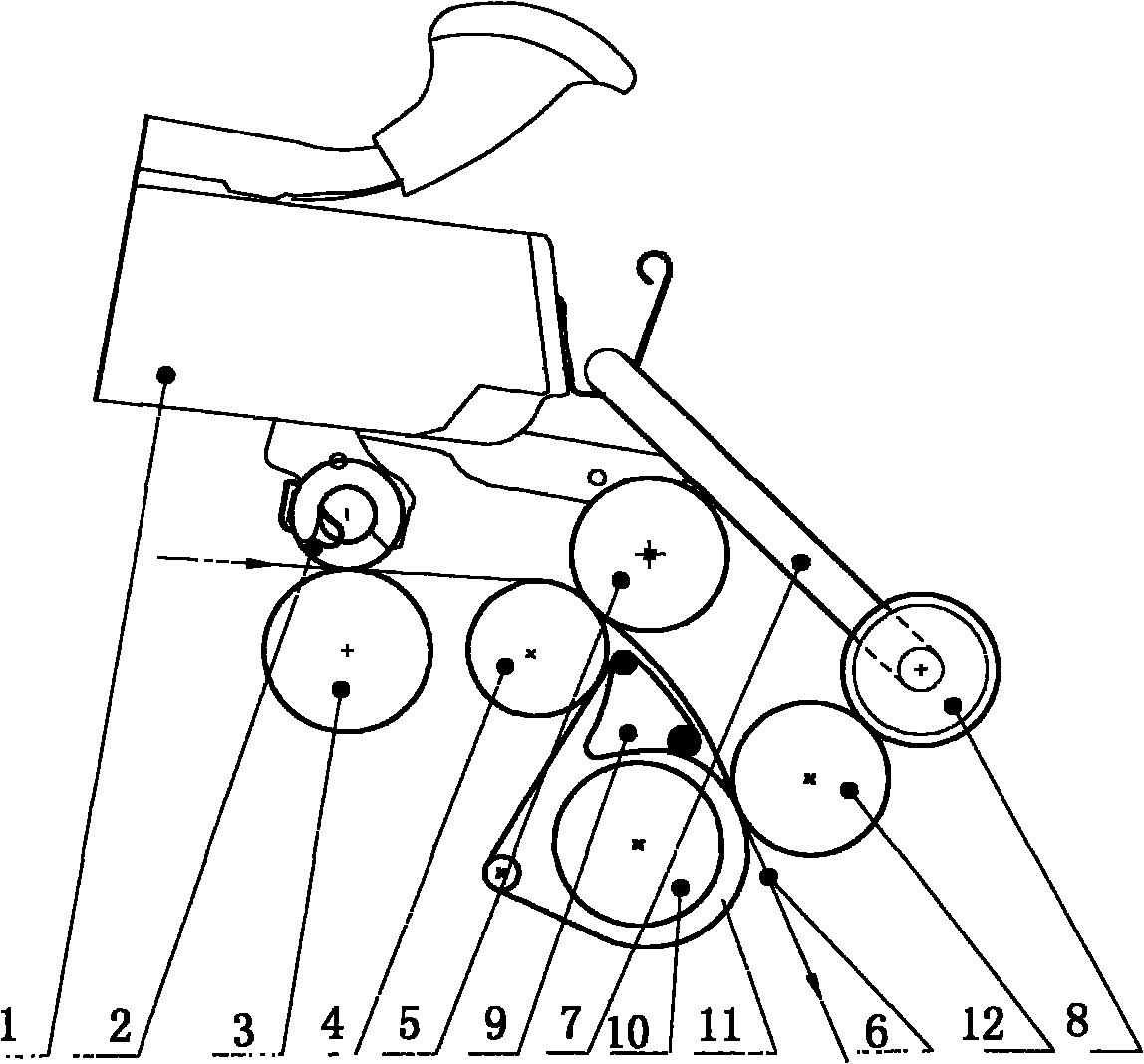

[0024] For c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap