Methods relating to turbine engine control and operation

A technology of engines and gas turbines, which is applied in the direction of engine components, fuel control of turbines/propulsion devices, machines/engines, etc., and can solve problems such as not being able to determine the temperature in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

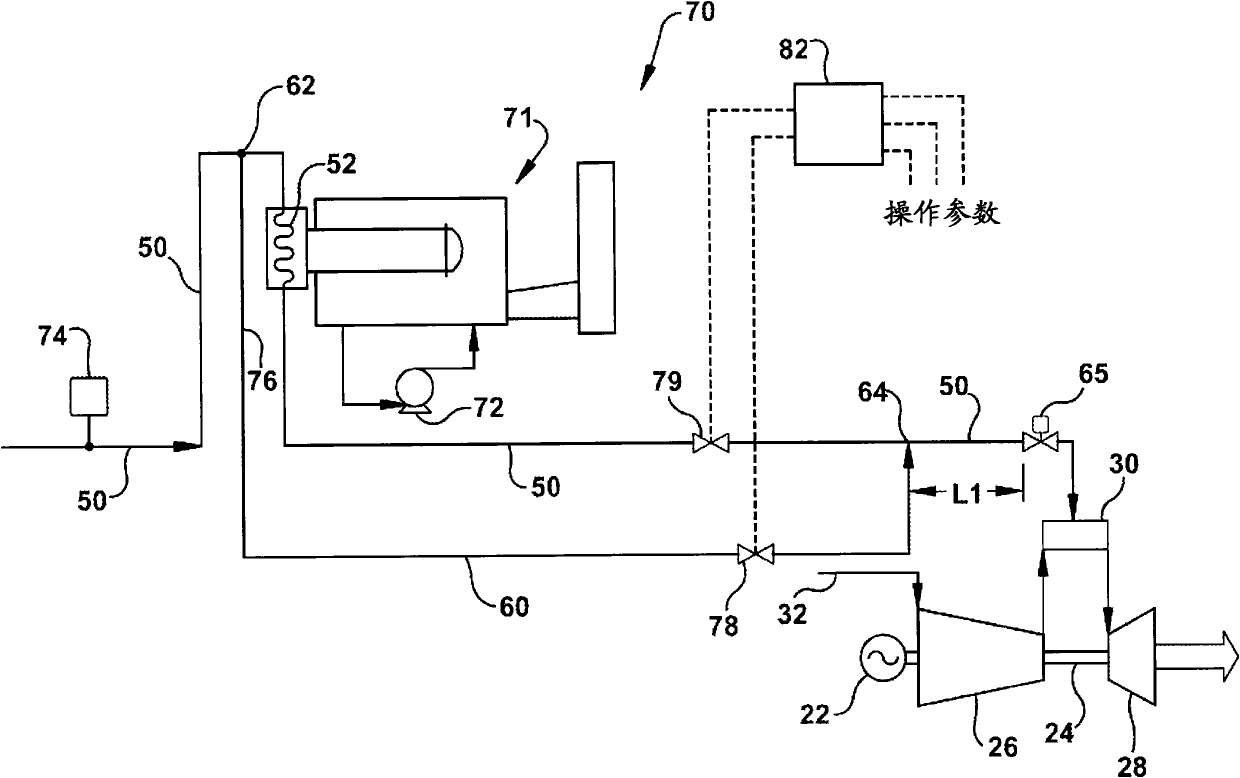

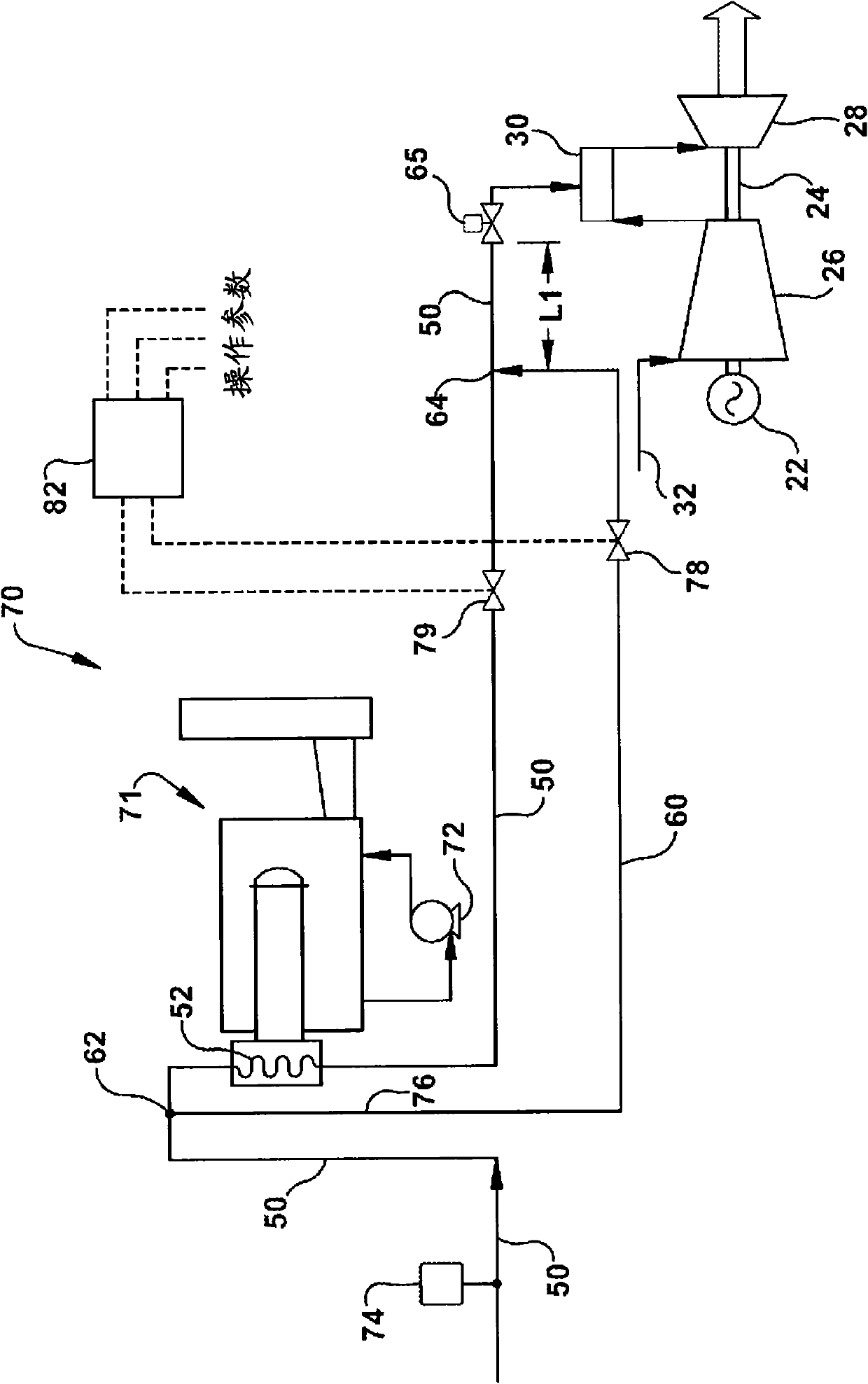

[0031] Referring now to the accompanying drawings, figure 1 A schematic diagram of a gas turbine engine 10 is shown and will be used to describe an exemplary environment in which the present invention may be employed. Those skilled in the art will appreciate that the invention is not limited to this type of use. As stated, the invention may be used in other types of gas turbine engines. In general, gas turbine engines operate by extracting energy from a pressurized hot gas stream produced by burning fuel in a compressed air stream. Such as figure 1 As shown, a gas turbine engine 10 may be configured with an axial compressor 11 mechanically coupled by a common shaft or rotor to a downstream turbine section or turbine 12 with a combustor 13 located between the compressor 11 and the turbine. Between 12.

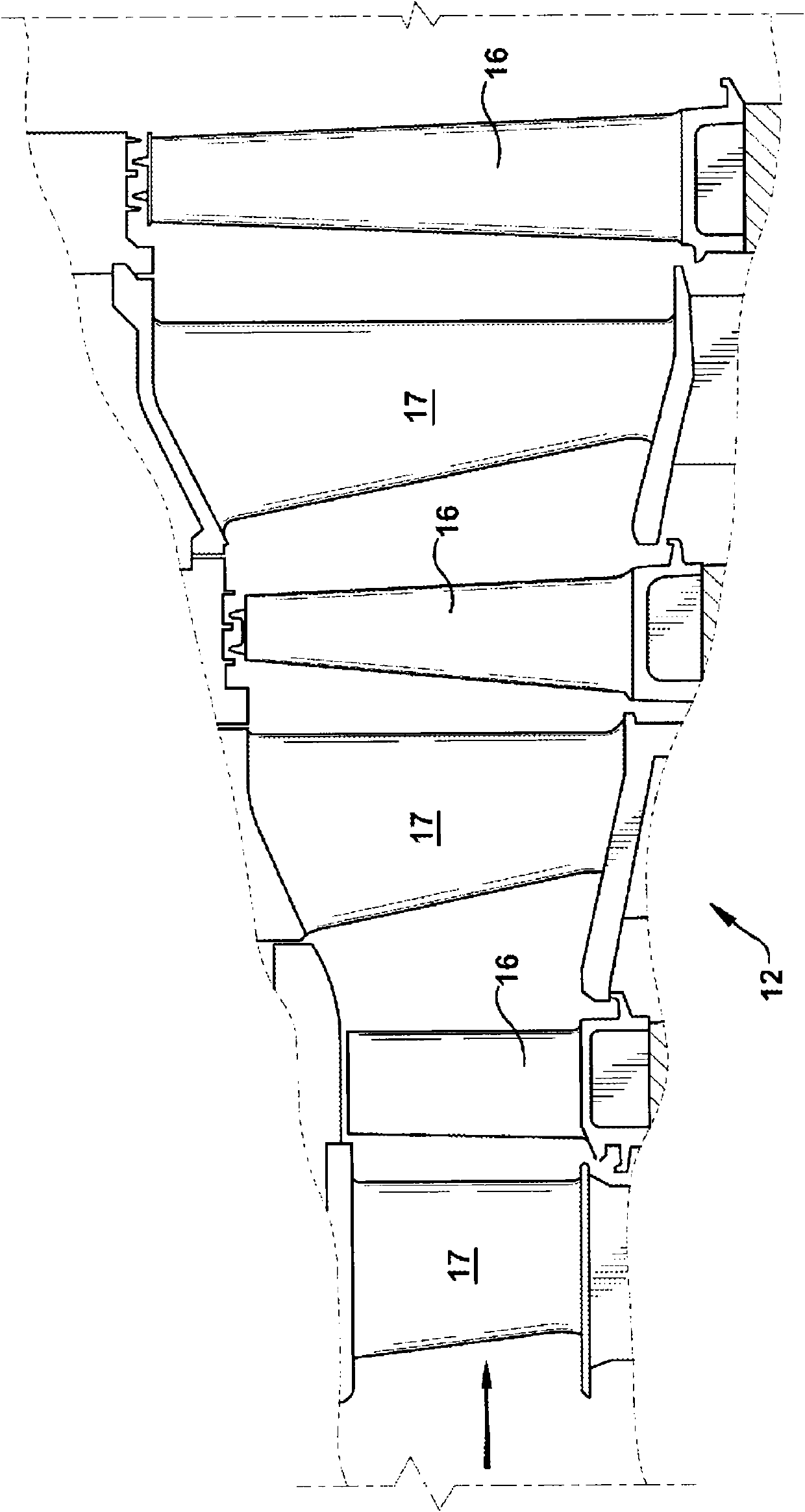

[0032] figure 2 shows the available figure 1 A view of an exemplary multi-stage axial compressor 11 used in a gas turbine engine. As shown, compressor 11 may include mul...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap