Apparatus for converting rotary motion into linear motion

A technology of rotary motion and linear motion, applied in transmission devices, friction transmission devices, feeding devices, etc., can solve the problems of high material consumption, extending the diameter of driving shaft rollers and steering shaft rollers, and large steering roller diameters, etc., to achieve Save material and avoid the effect of back reversal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

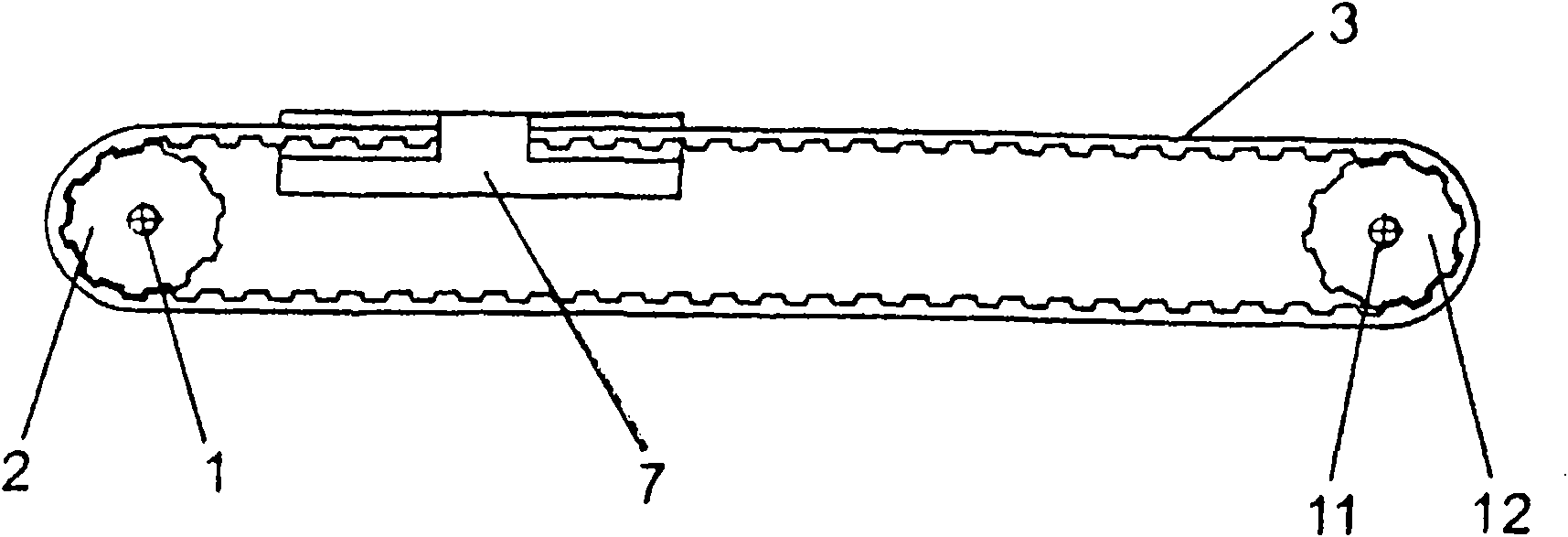

[0028] figure 1 2 shows an arrangement corresponding to the prior art O, wherein the linear shaft 7 moves between the roller 2 of the driving shaft 1 and the roller 12 of the steering shaft 11 by means of the traction member 4 .

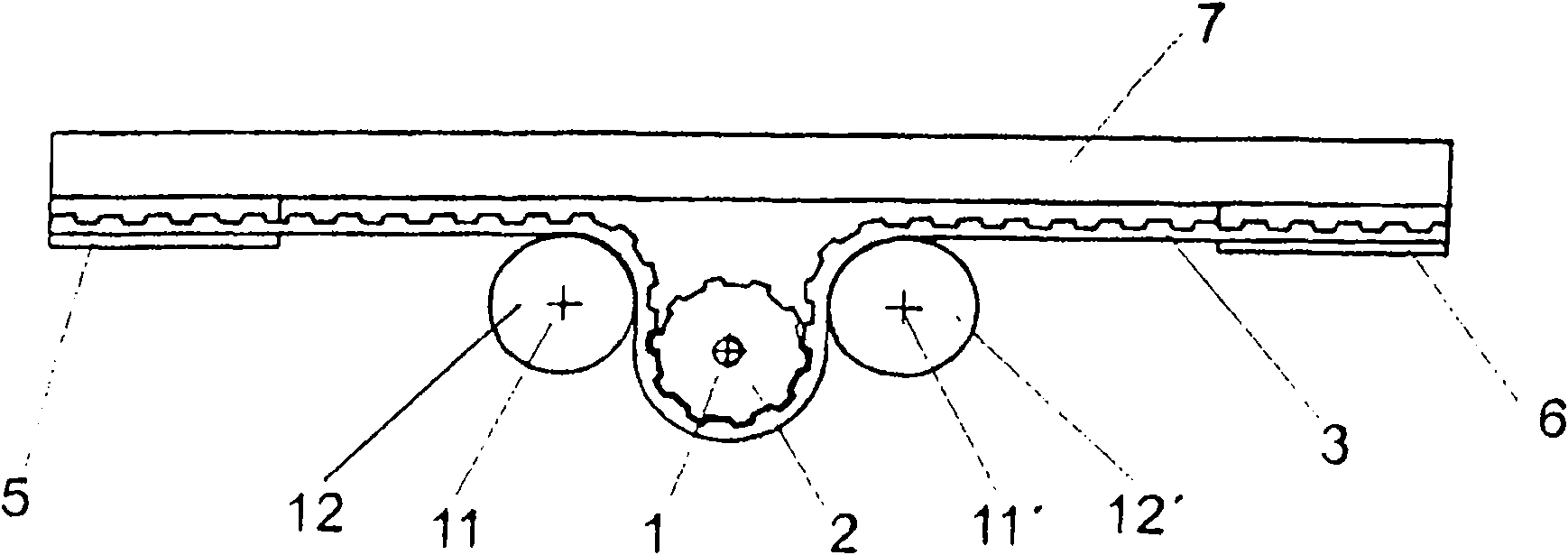

[0029] Figure 2a shows an arrangement of Ω corresponding to the prior art, wherein the linear axis 7 is moved by means of the traction element 4 . Here, the traction element 4 is driven by the roller 2 of the drive shaft 1 and guides the linear shaft 7 by means of reverse rotation through the rollers 12 , 12 ′ of the steering shaft 11 , 11 ′.

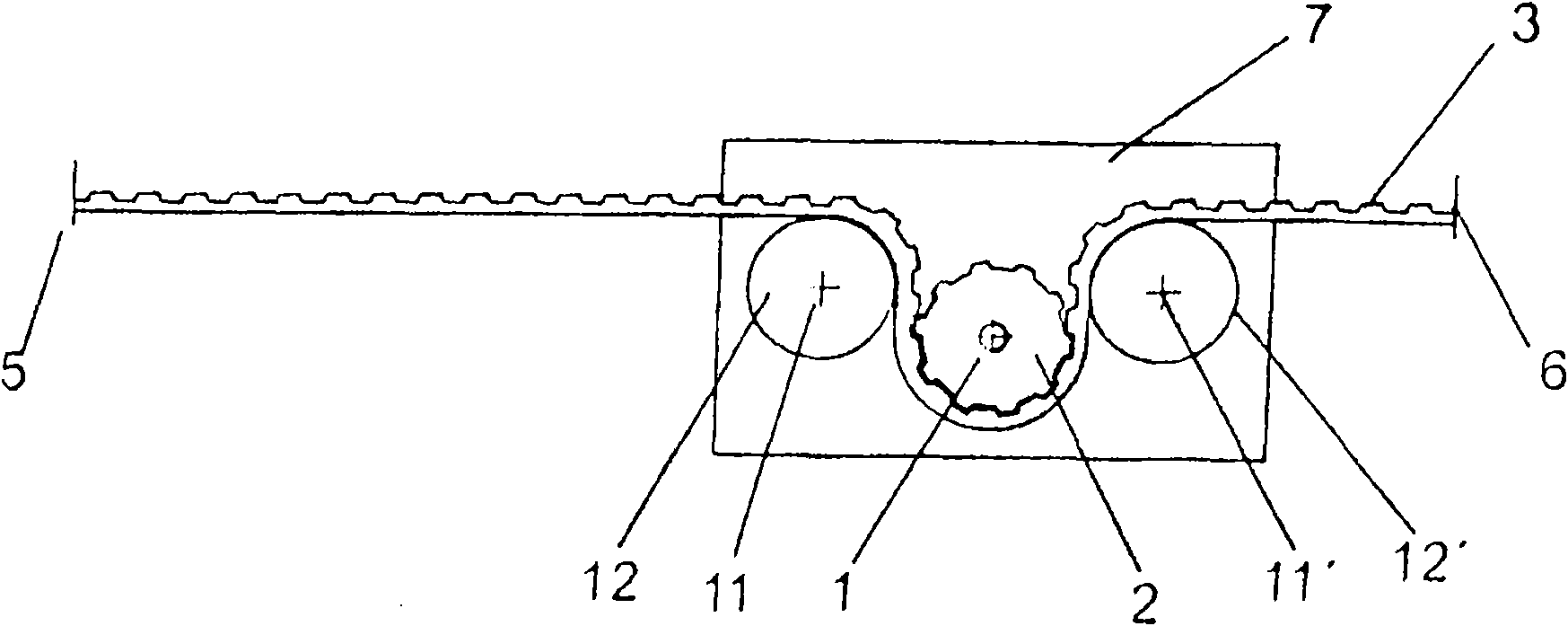

[0030] Figure 2b shows the Ω arrangement corresponding to the prior art, wherein the linear axis 7 ("trolley") moves by means of the traction element 4, the roller 2 of the drive shaft 1 and the two rollers 12, 12, 12' lies on said linear axis.

[0031] image 3 shows a device according to the invention for converting a rotary motion into a linear motion, wherein an end-limited traction element 4 (tooth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com