Simulation testing device for transmission rate of battery assembly light-transmitting layer

A technology for simulating testing and battery components is applied in the field of transmittance testing of light-transmitting layers after molding of solar battery components, which can solve the problems of inaccurate test results, failure to consider, and inability to obtain the influence of the optical performance of battery components, so as to avoid test results. Inaccuracies, reducing test errors, monitoring and improving the effectiveness of component fabrication processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

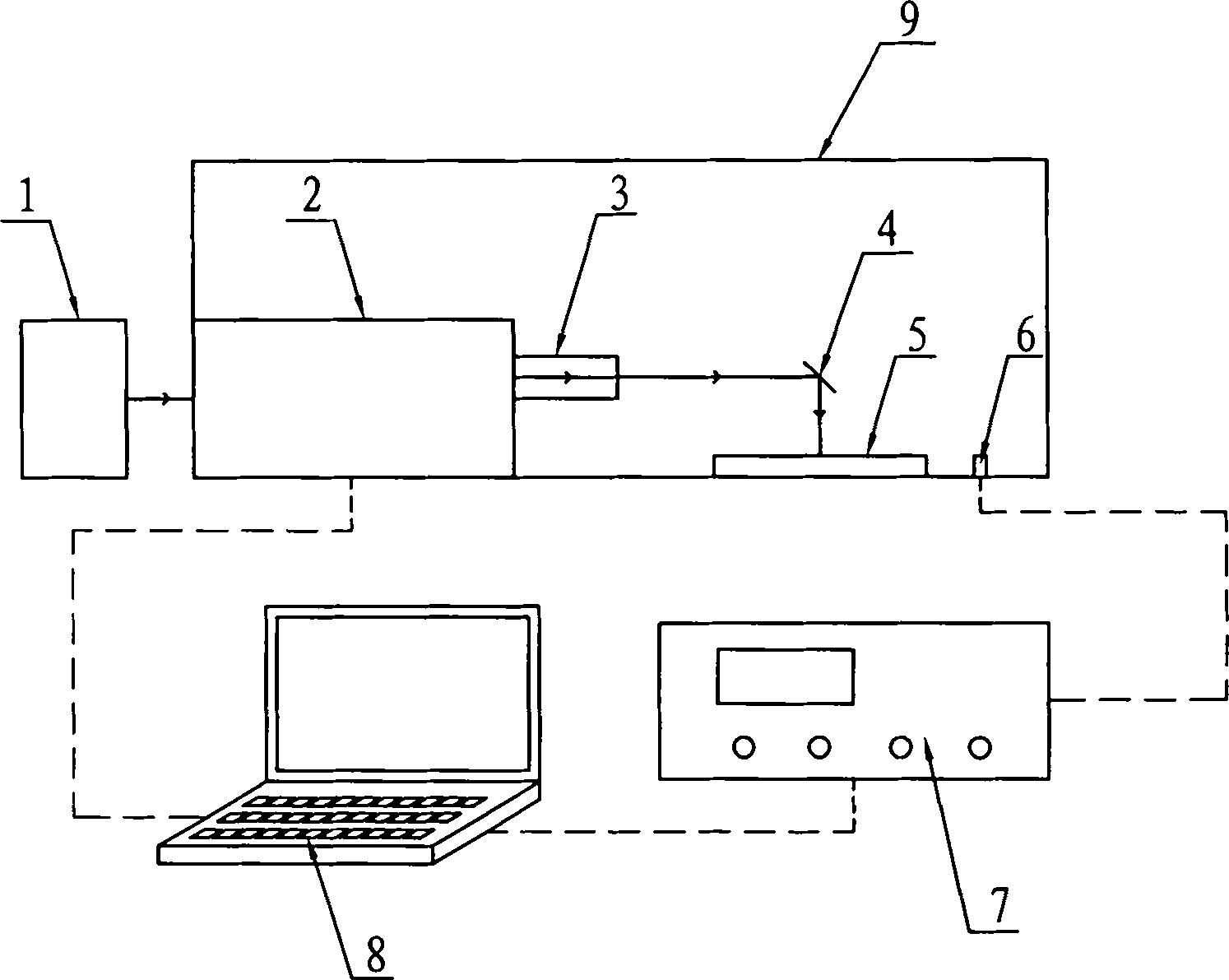

[0018] The simulated test device of the transmittance of the light-transmitting layer of the battery assembly, such as figure 1 As shown, it consists of a white light source 1, a monochromatic light splitting system 2, a collimator 3, a mirror 4, a sample stage 5, a terminal post 6, a micro-signal processing system 7 and a terminal information processing system 8, and the monochromatic light splitting System 2, collimator 3, reflector 4, sample stage 5 and binding post 6 are all placed in dark box 9, and collimator 3 is aligned with the exit slit of monochromatic light splitting system 2, and reflector 4 is arranged in the collimator. Between the straightener 3 and the sample stage 5, the terminal post 6 is located next to the sample stage 5, the terminal post 6 is electrically connected to the micro-signal processing system 7, the monochromatic light splitting system 2 is electrically connected to the terminal information processing system 8, and the micro-signal processing sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com