Antioxidation method for finishing fuse

An anti-oxidation and fuse technology, applied in the measurement of resistance/reactance/impedance, measuring devices, instruments, etc., can solve the problem of reducing the success rate of fusing fuses, reducing the success rate of fusing fuses, and instability of fusing fuses, etc. problem, to achieve the effect of stable success rate and improving success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

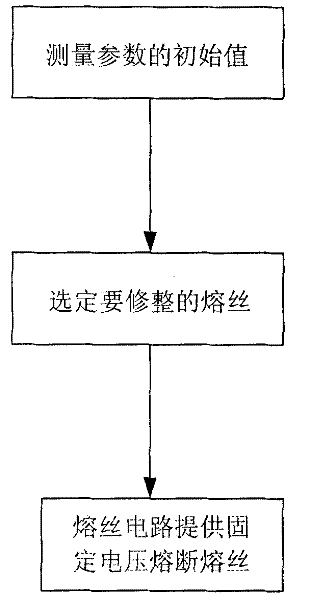

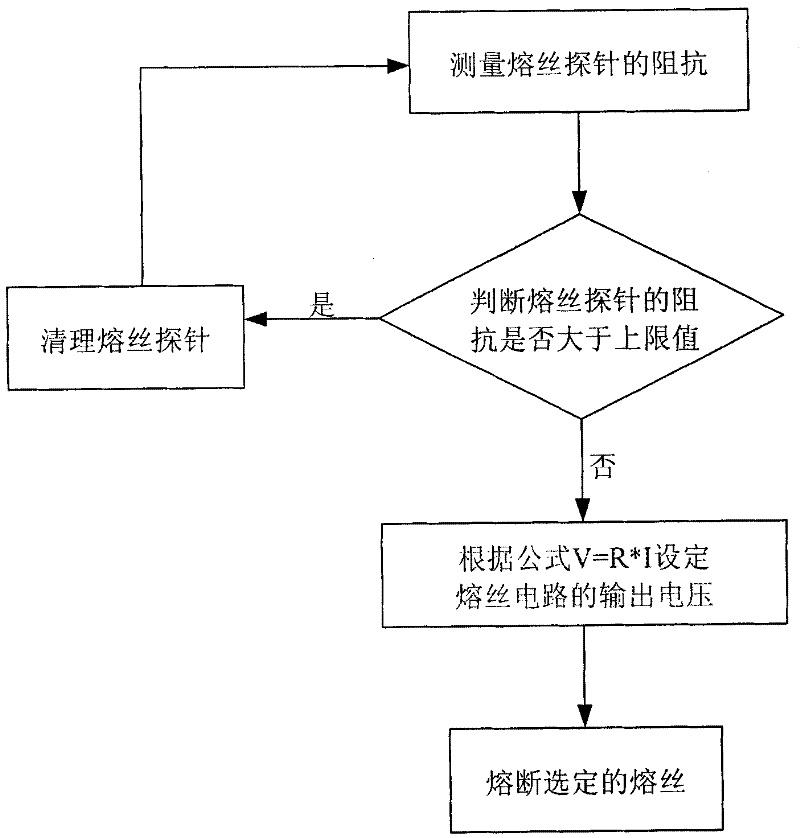

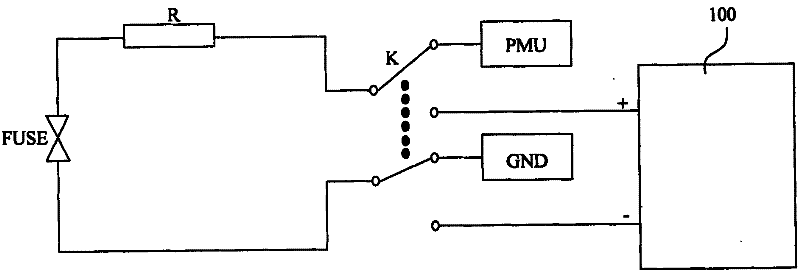

[0025] The following will combine Figure 2 ~ Figure 3 The method for repairing the anti-oxidation fuse of the present invention is further described in detail.

[0026] see figure 2 , the method for anti-oxidation trimming fuse of the present invention comprises the following steps:

[0027] Measure the impedance of the fuse probe;

[0028] Determine whether the impedance of the fuse probe is greater than the upper limit, if yes, clean the fuse probe, and then return to the above steps, if not, perform the following steps;

[0029] Set the output voltage of the fuse circuit according to the formula V=R×I, wherein, V represents the output voltage of the fuse circuit, R represents the impedance of the fuse probe, and I represents the fuse current;

[0030] Blows the selected fuse.

[0031] The method for repairing the anti-oxidation fuse of the present invention can improve the success rate of fusing the fuse, so that the success rate of fusing the fuse tends to be stable;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com