Fixed type medium-frequency inversion direct-current rail welding machine

An inverting DC, fixed technology, applied in the characteristics of electrodes, welding equipment, arc welding equipment, etc., can solve the problem of inability to realize the distribution of the current density of the workpiece, and achieve the uniformity of distribution and the consistency of current transfer speed improvement. , the effect of stable success probability and stable fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

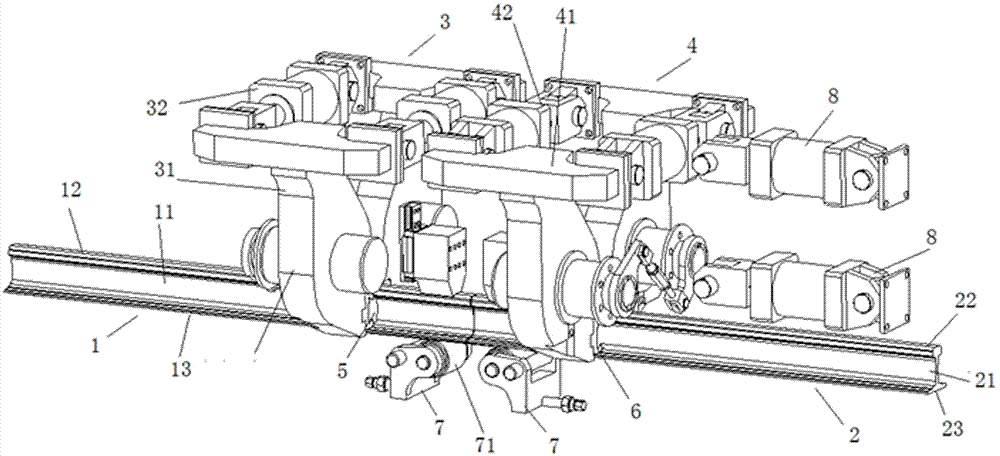

[0026] Such as figure 1 As shown, a fixed intermediate frequency inverter DC rail welding machine is used to weld the first rail 1 and the second rail 2, the first rail 1 includes the first rail waist 11, the first rail top 12 and the first Rail bottom 13, the second rail 2 includes a second rail waist 21, a second rail top 22 and a second rail bottom 23, the DC rail welding machine includes: a welding frame, which includes a static clamp 3, which holds The end is clamped at the first rail waist of the first rail 1; the clamping end of the movable clamp 4 is clamped at the second rail waist 21 of the second rail 2 for clamping the second rail 2 and The first rail 1 is butted against each other; a pair of first conductive electrodes 5 are arranged on the clamping end of the static fixture 3, and are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com