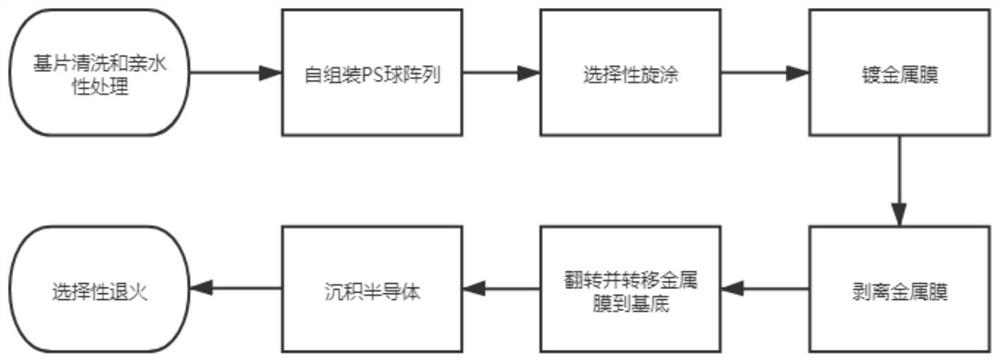

Preparation method of condensation type periodic nano bowl structure electrode capable of supporting high-temperature annealing

A high-temperature annealing and concentrating technology, applied in the direction of climate sustainability, sustainable manufacturing/processing, circuits, etc., can solve the problems of film damage, low success rate, uncontrollable nanobowl shape, etc., to improve electrode performance, The effect of improving semiconductor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

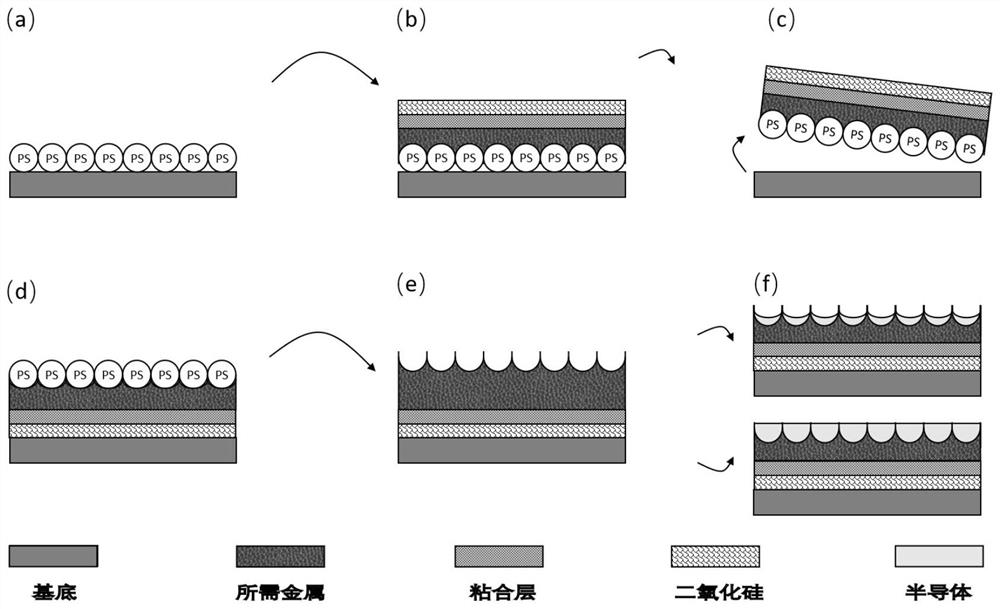

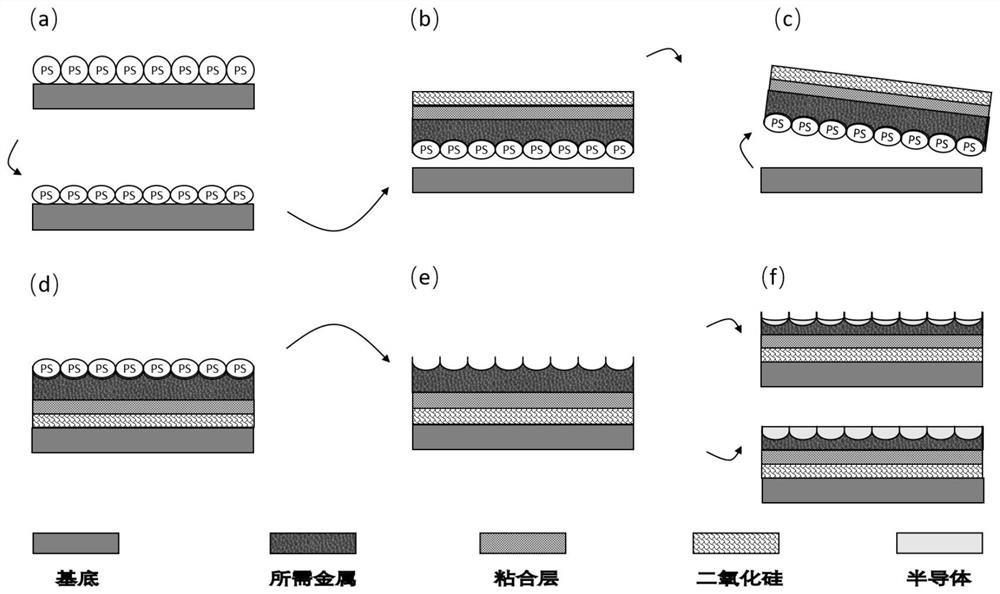

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing a light-concentrating periodic nanobowl structure electrode that can support high-temperature annealing, comprising the following steps:

[0040] 1) Silicon wafer cleaning and hydrophilization treatment: first cut the silicon wafer into a size of 2cm*2cm, then use acetone, isopropanol, absolute ethanol, and deionized water to ultrasonically clean it for 10 minutes, and put the silicon wafer into the plasma after drying In the cleaning machine, the adjustment parameters are power 30w, air environment, and flow rate 10sccm. After completion, start vacuuming. When the pressure is less than or equal to 38Pa, turn on the cleaning switch, turn it off after 10 minutes, open the air inlet, and open the chamber door to take out the sample.

[0041]2) Preparation of PS sphere array: Clean the Petri dish with a diameter of 30 cm and fill it with deionized water, let it stand for 10 minutes, and prepare a 500 nm PS sphere solution (PS: 1% H 2 SO 4 : 1% styre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com