Trolley used for maintenance of electricity overhead power transmission line

A transmission line and power overhead technology, applied in the direction of overhead line/cable equipment, etc., can solve the problems of high safety, no reliable backup protection for outgoing operators, hidden dangers, etc., to reduce labor intensity, reduce tower and tower operation links , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

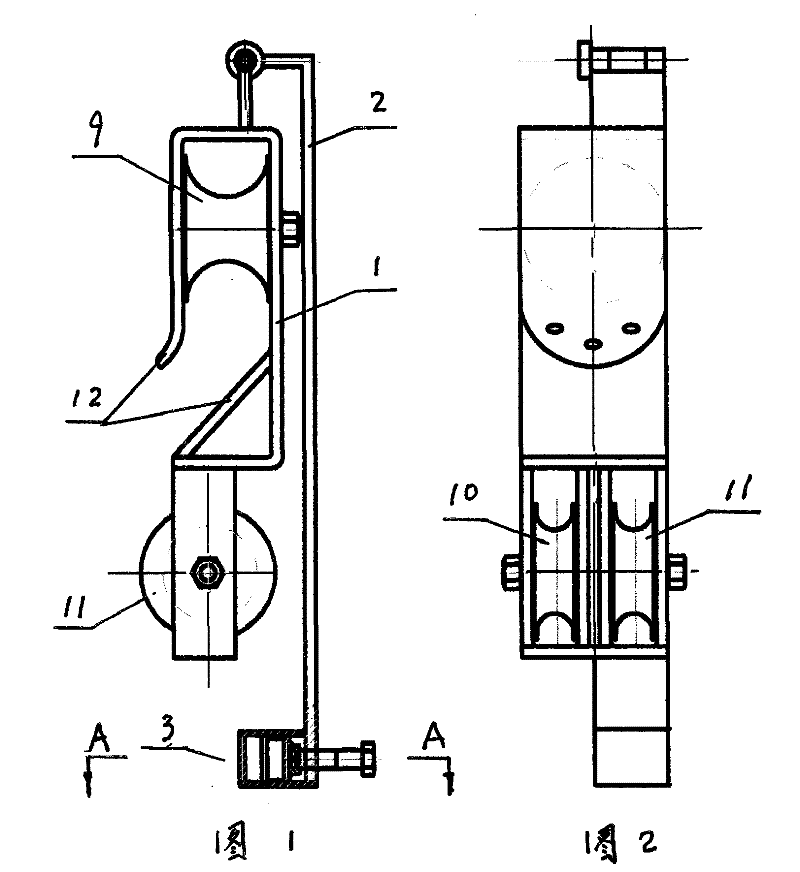

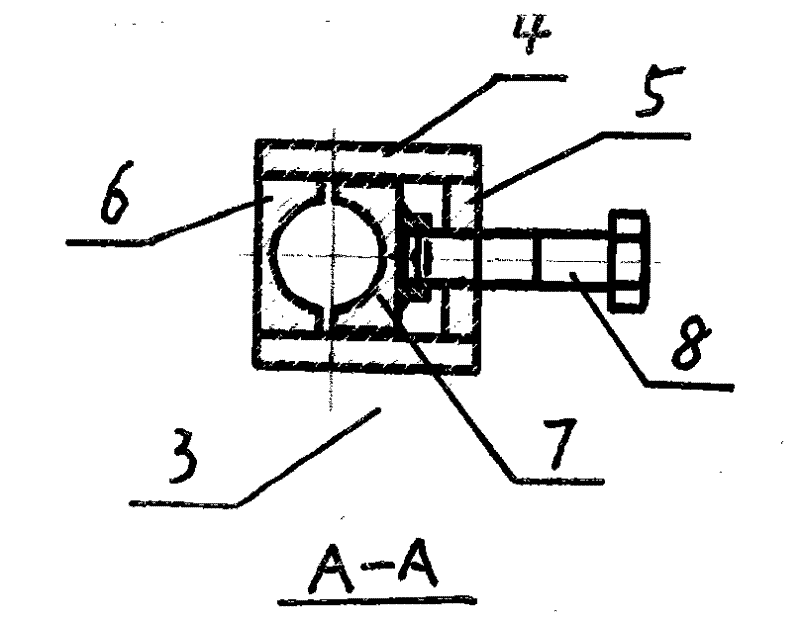

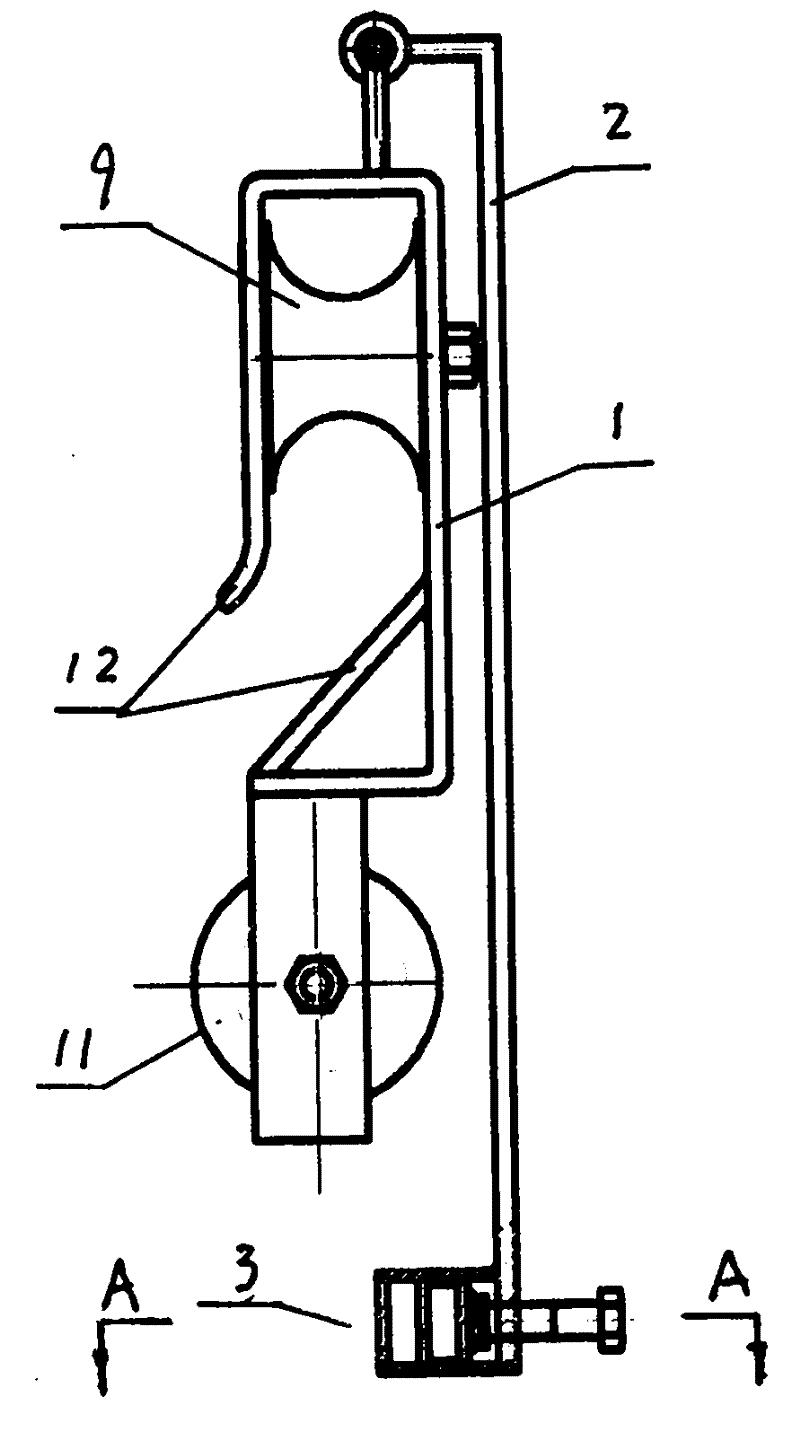

[0014] The present invention will be further described below using the accompanying drawings and examples.

[0015] The trolley for maintenance of overhead power transmission lines of the present invention comprises a frame 1, on which a hanging wire pulley 9 rotating with a fixed axis is arranged on the upper part of the frame 1, and an inlet 12 is arranged below the side of the hanging wire pulley 9 on the frame 1, and an inlet 12 is arranged on the lower part of the frame 1. A ladder head traction pulley 10 and a backup protection rope pulley 11 rotating coaxially with a fixed axis are arranged, and a control rod 2 is hinged on the top of the frame 1 . A damping rope slowing device 3 is provided at the lower end of the control rod 2, and the structure of the damping rope slowing device 3 includes a support 4 fixedly connected to the lower end of the control rod 2, and a fixed clip 6 is arranged in the support 4 With the opposite movable clamp block 7, the screw rod 8 fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com