Mixing and mincing auger

A technology of screw propellers and mixer trucks, applied in mixers with rotating stirring devices, transportation and packaging, chemical instruments and methods, etc., can solve the problems of increasing cutting and fully chopping time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

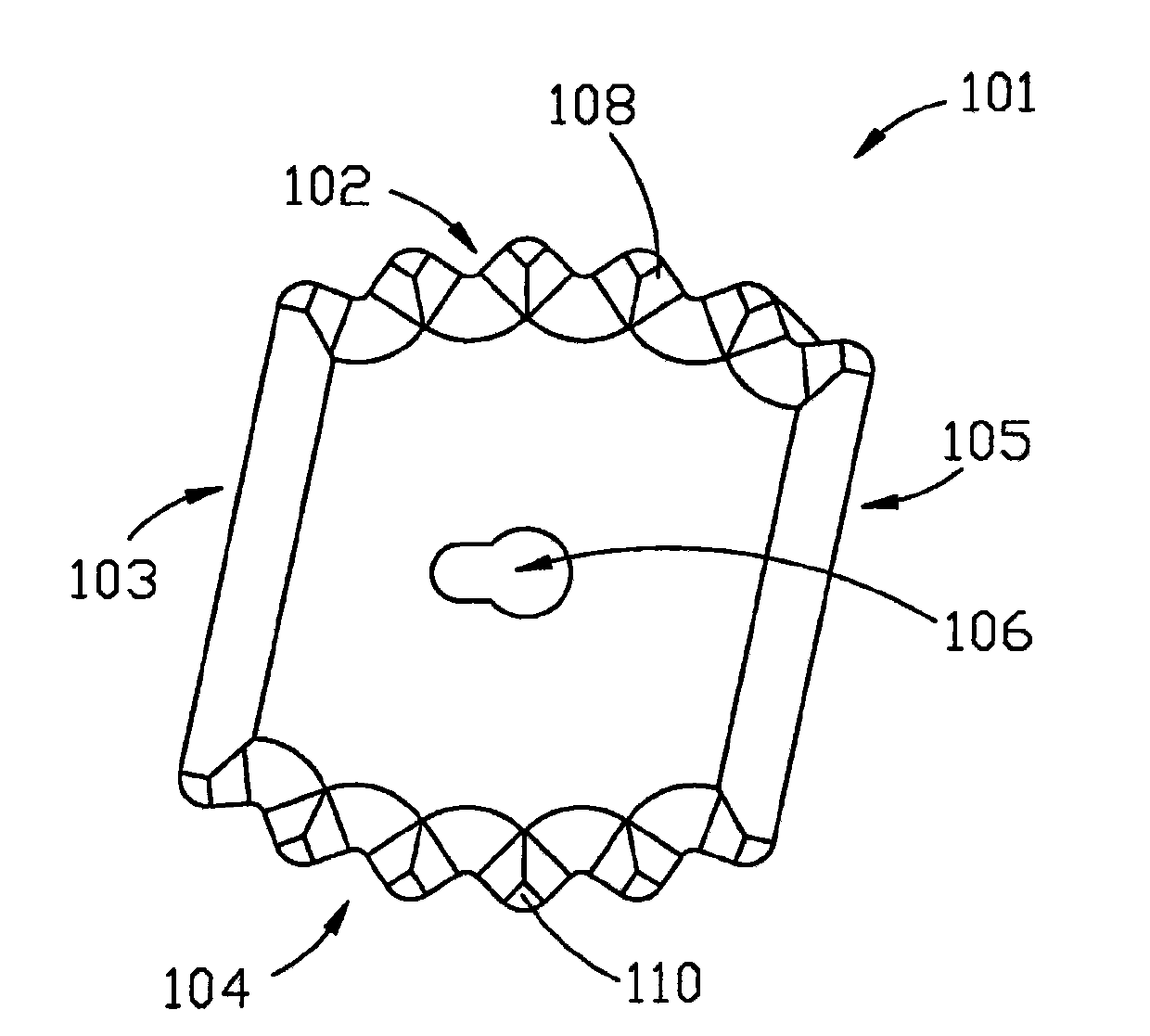

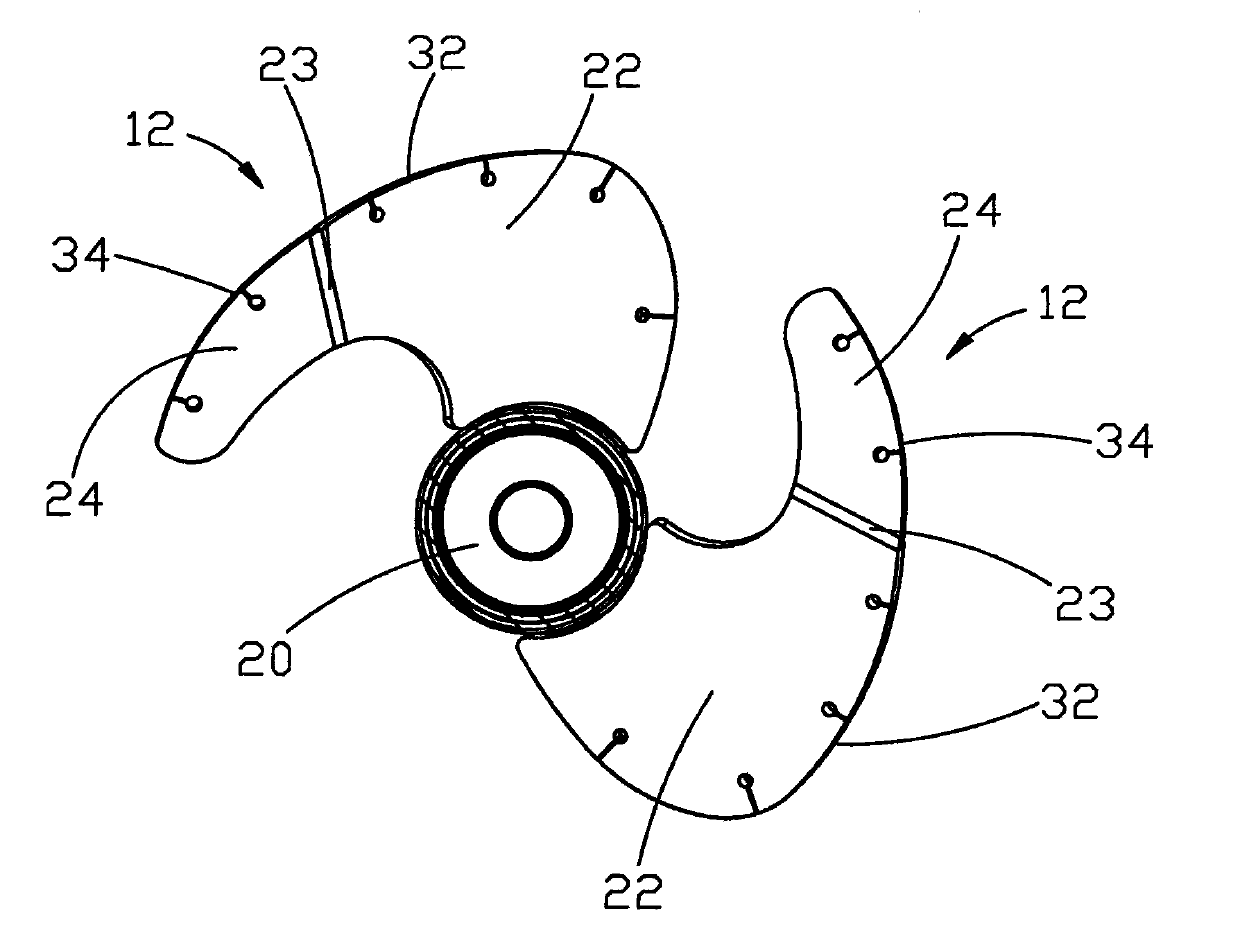

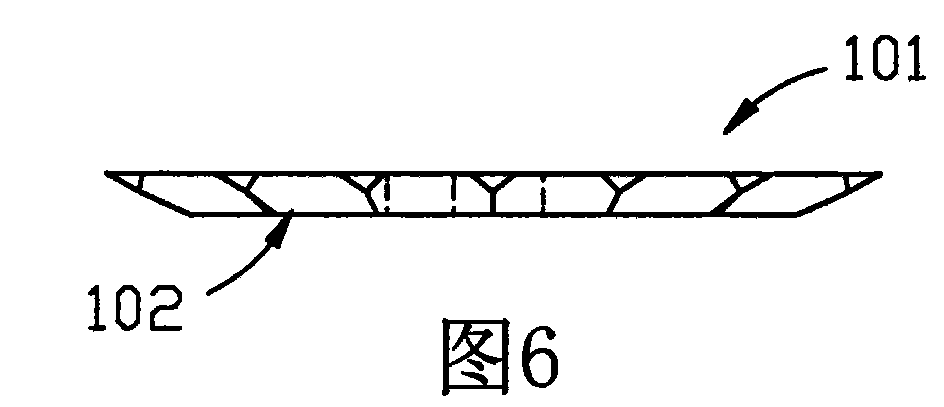

[0026] Looking at the drawings, we use the number 10 to indicate the screw propeller, which includes a rotating shaft 20 that can be mounted eg on the bottom of a mixing and chopping cart. Four different types of blades 12 , 14 , 16 and 18 are wedged on shaft 20 in terms of size and / or shape.

[0027] A helical blade 18 according to a first type of blade is fastened to one end of a shaft 20, and precisely to figure 1 The right end of the axis shown.

[0028] Seven blades 16 shaped according to blades of the second type are fastened to the shaft 20 after the helical blades 18 . The shaft connection portions of these blades 16 lie in a plane inclined with respect to a plane at right angles to the H-axis of the shaft 20 . The blades 16 have a flat shape; more precisely, each lies entirely in a single plane equivalent to the plane of connection to the shaft.

[0029] The successive blades 16 are spaced longitudinally at a constant distance D, and angularly at an angle between 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com