Electrically heatable laminated glazing

A technology of electric heating and heating wires, which is applied in the direction of ohmic resistance heating, electric heating devices, transparent/reflective heating devices, etc., and can solve problems such as injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

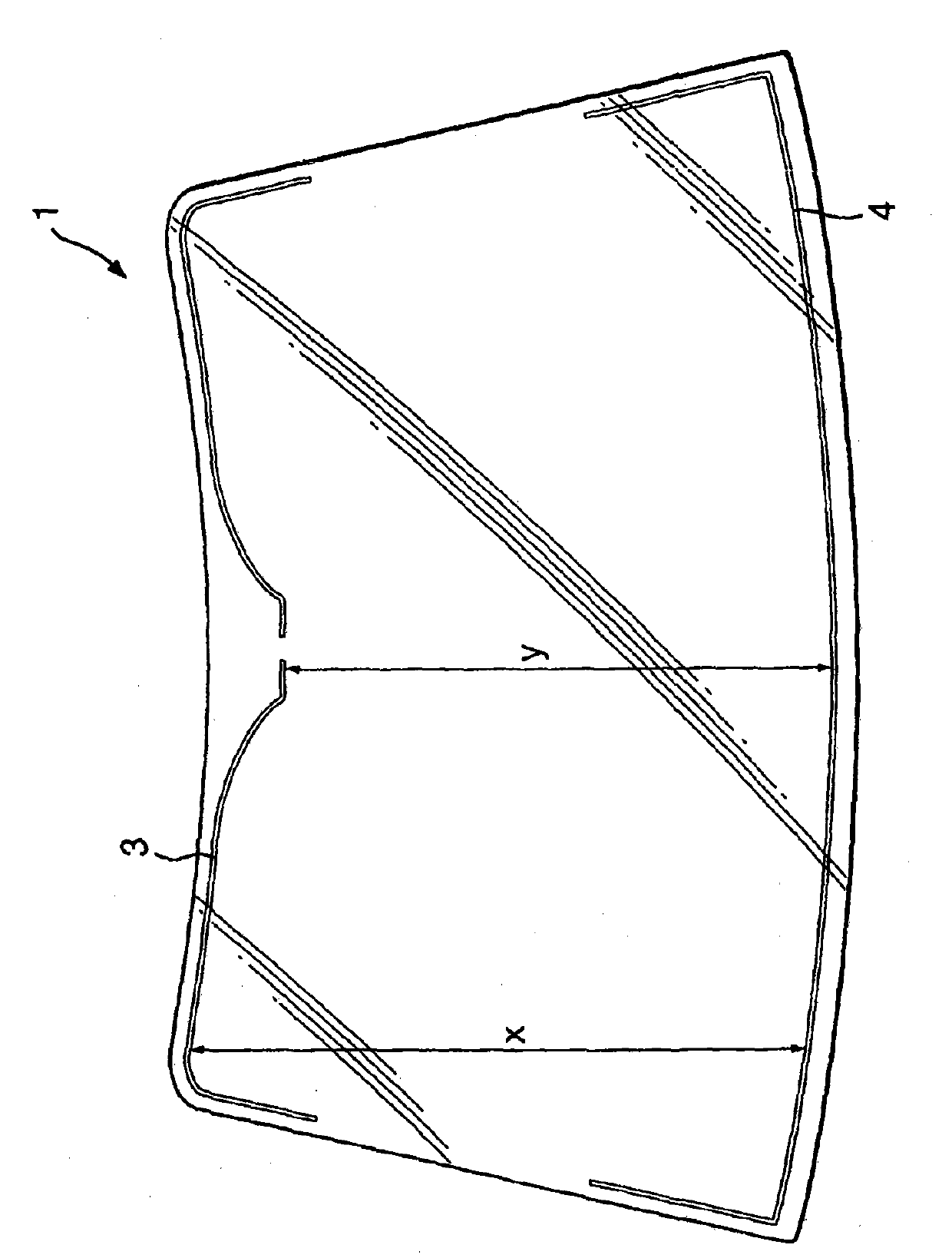

[0019] In order to minimize variations in power density along the wire heating window, the invention provides electrical connections (bus bars) that are shaped so that the length of the wires in the array extending between the electrical connections remains substantially constant.

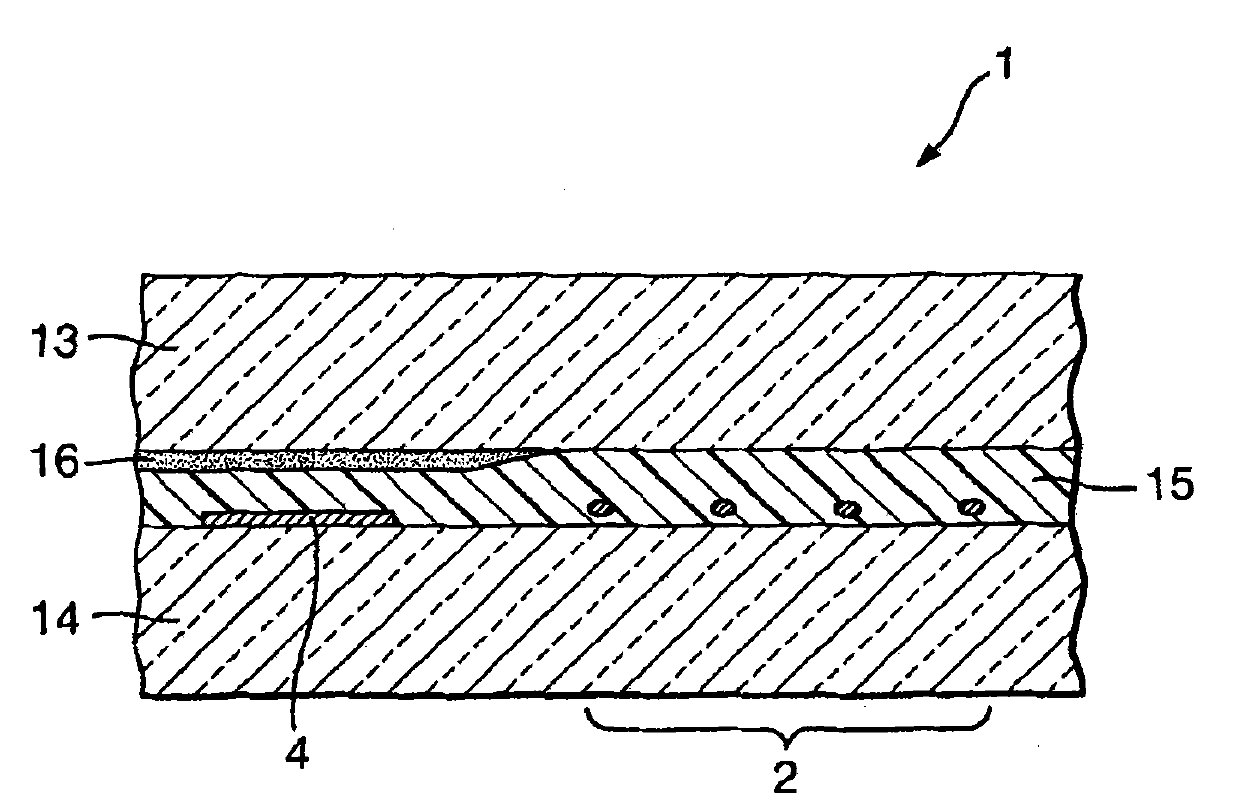

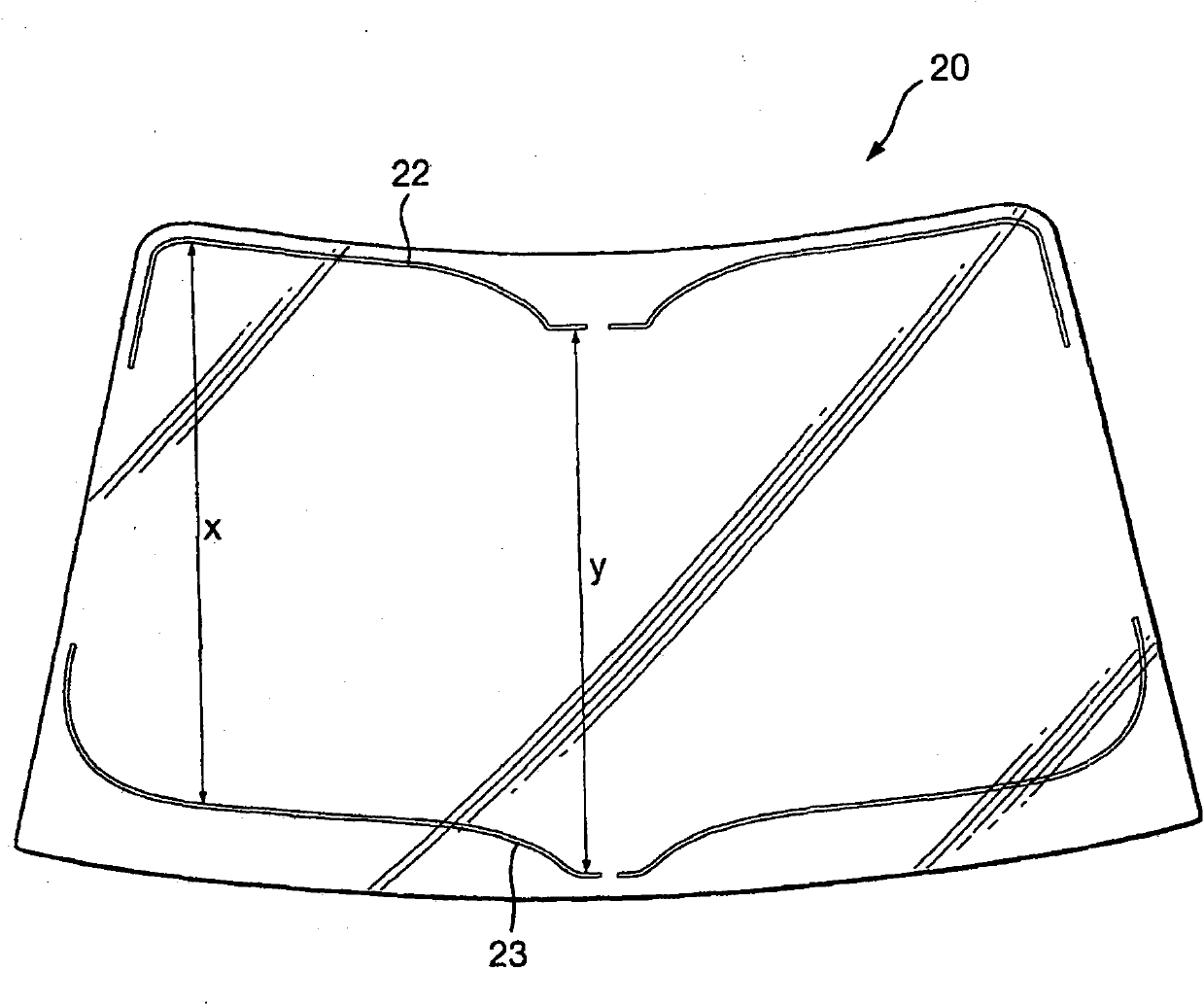

[0020] This concept is best exemplified by first considering a wire heated windshield commonly used in the prior art. figure 1 is a schematic plan view of a wire heated window with wire-free regions according to the prior art. The wire heating window 1 is generally trapezoidal in shape and comprises an array of fine, closely spaced wires 2, only a small portion of which are shown for clarity. The array of wires 2 is bounded by a first electrical connection means or bus bar 3 and a second electrical connection means or bus bar 4 . The wires in the array 2 extend between the first and second electrical connection means 3 , 4 . These electrical connection means 3, 4 connect the array to a power sour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com