Double-row charging head of microplate strip washer

A technology of plate washer and microplate, which is applied to cleaning methods, chemical instruments and methods, cleaning methods and utensils using liquids, etc. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

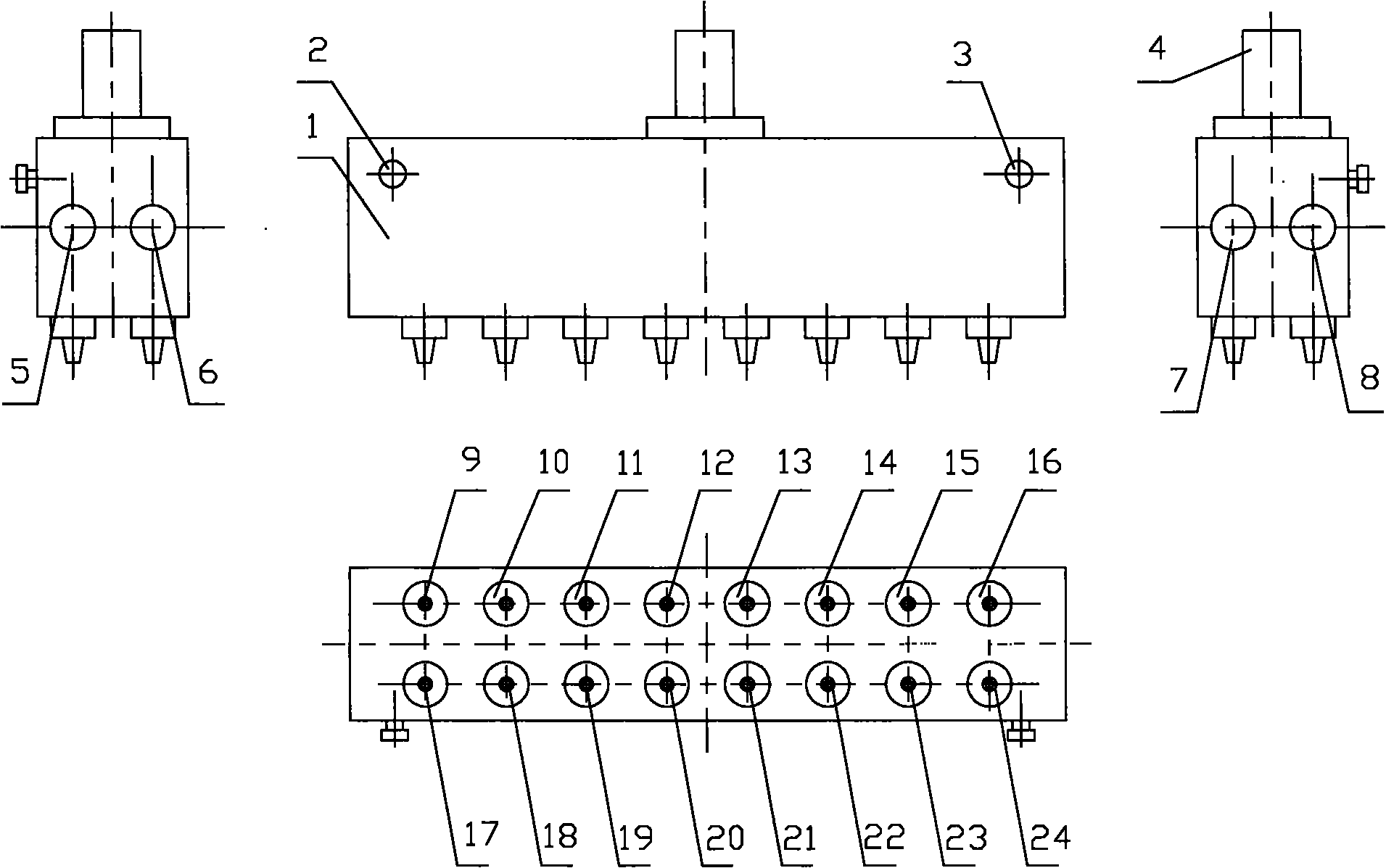

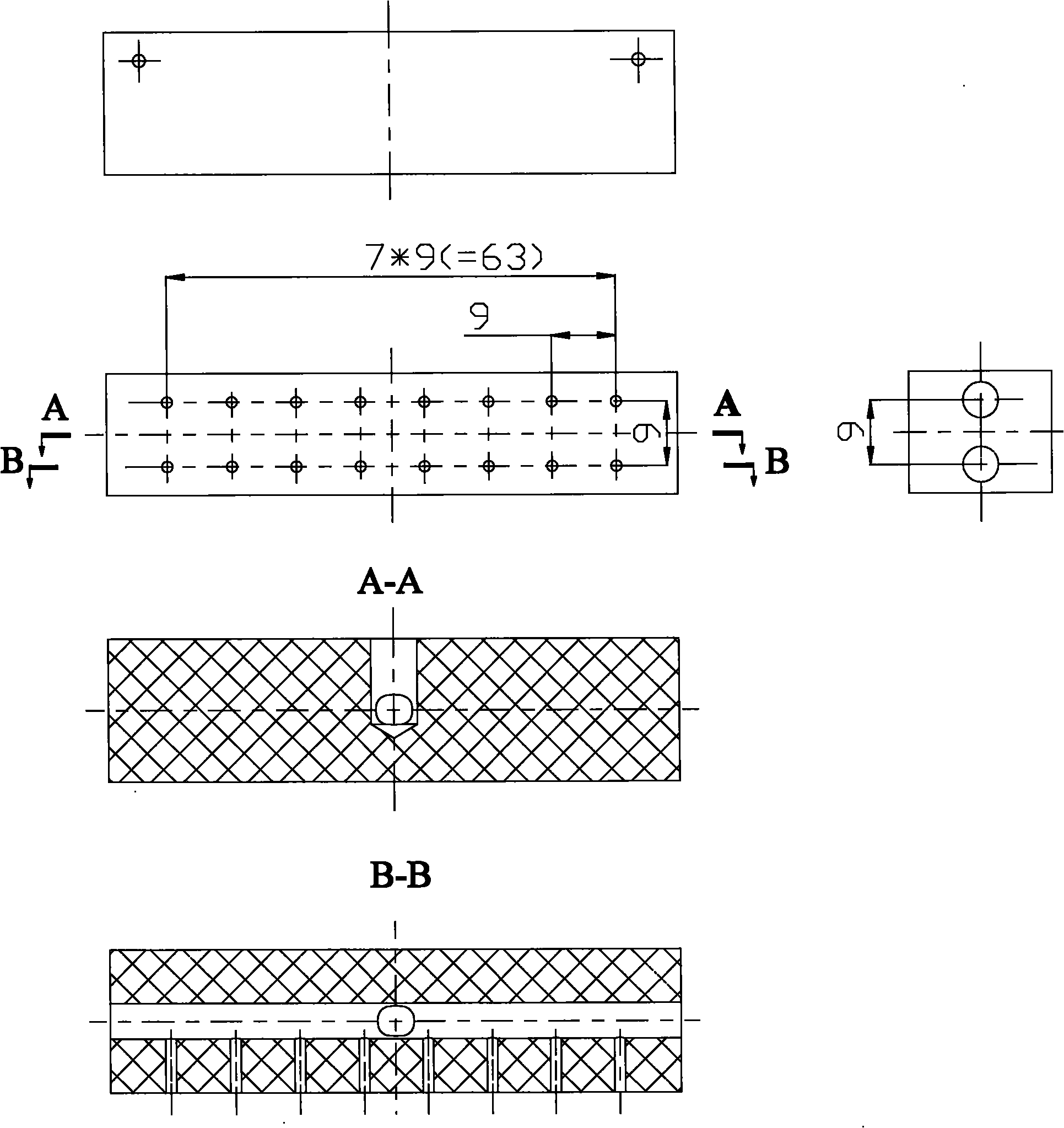

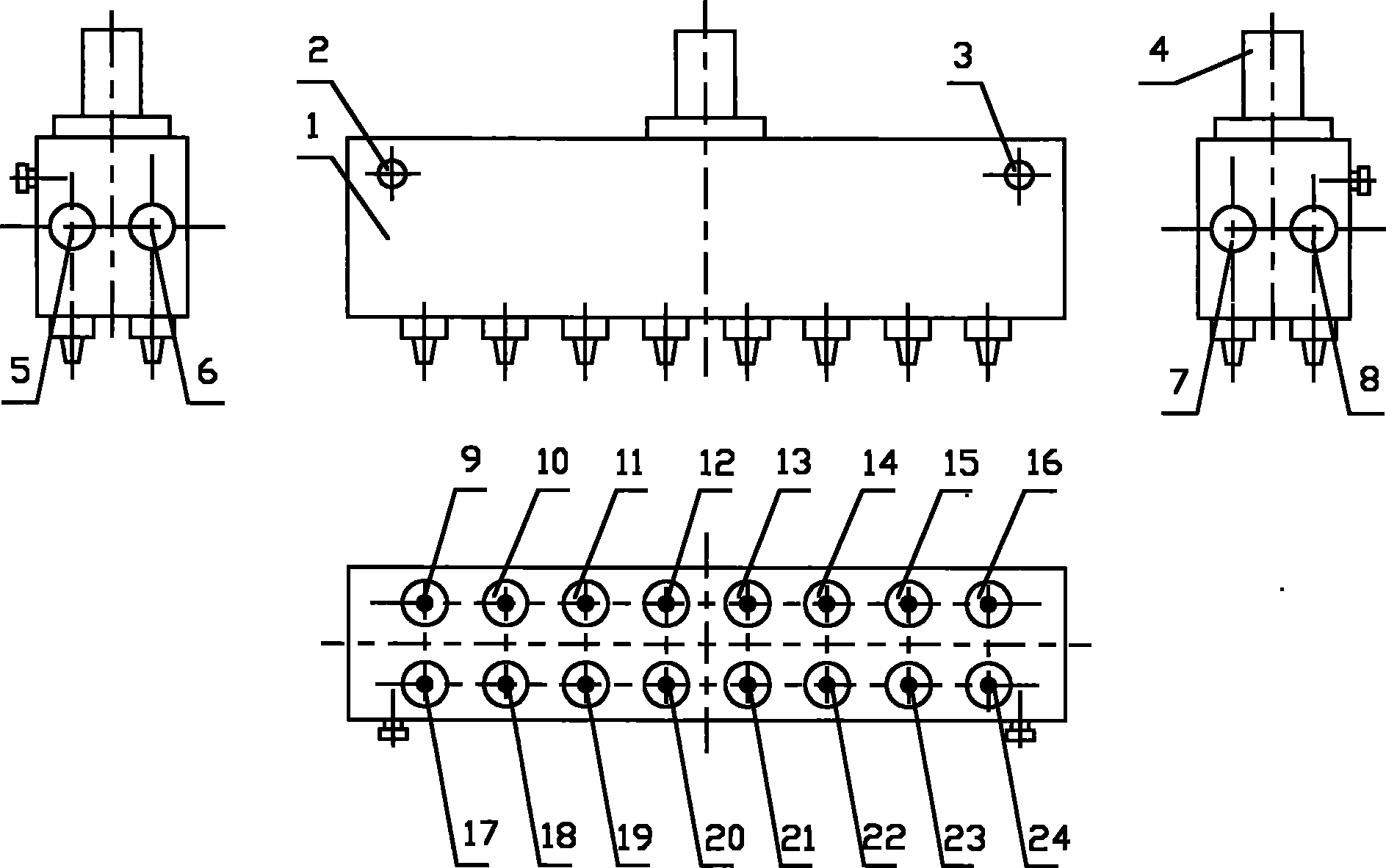

[0013] The filling head comprises a main body 1 of the filling head, suspension screws 2 and 3, pipe joints 4, silica gel plugs 5, 6, 7 and 8, and filling needles 9 to 24. Among them, the suspension screws 2 and 3 are respectively glued to the two blind holes in front of the main body 1 of the liquid filling head; the pipe joint 4 is glued to the hole on the top surface of the main body of the liquid filling head 1; 5, 6, 7, and 8 are respectively glued to the four holes on the left and right sides of the main body of the liquid filling head 1, and the outlets of the holes are blocked; the liquid filling needle tubes 9 to 24 are respectively glued to the main body of the liquid filling head 1 in two rows of 16 holes on both sides below. The whole liquid adding head is connected with the liquid adding movement mechanical device of the microplate washer (not shown) through suspension screws 2 and 3, and moves with it.

[0014] Two blind holes are symmetrically processed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com