Steam heater circular heating method

A technology of steam heater and circulation heating, which is applied in the direction of metal processing equipment, engine lubrication, workpiece surface treatment equipment, etc. It can solve the problems of unable to take protective measures, violent vibration of pipeline support, leakage of pneumatic shut-off valve, etc., to prevent local If the temperature of the process medium is too high or cause system safety hazards, improve the heating efficiency and prevent the effect of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

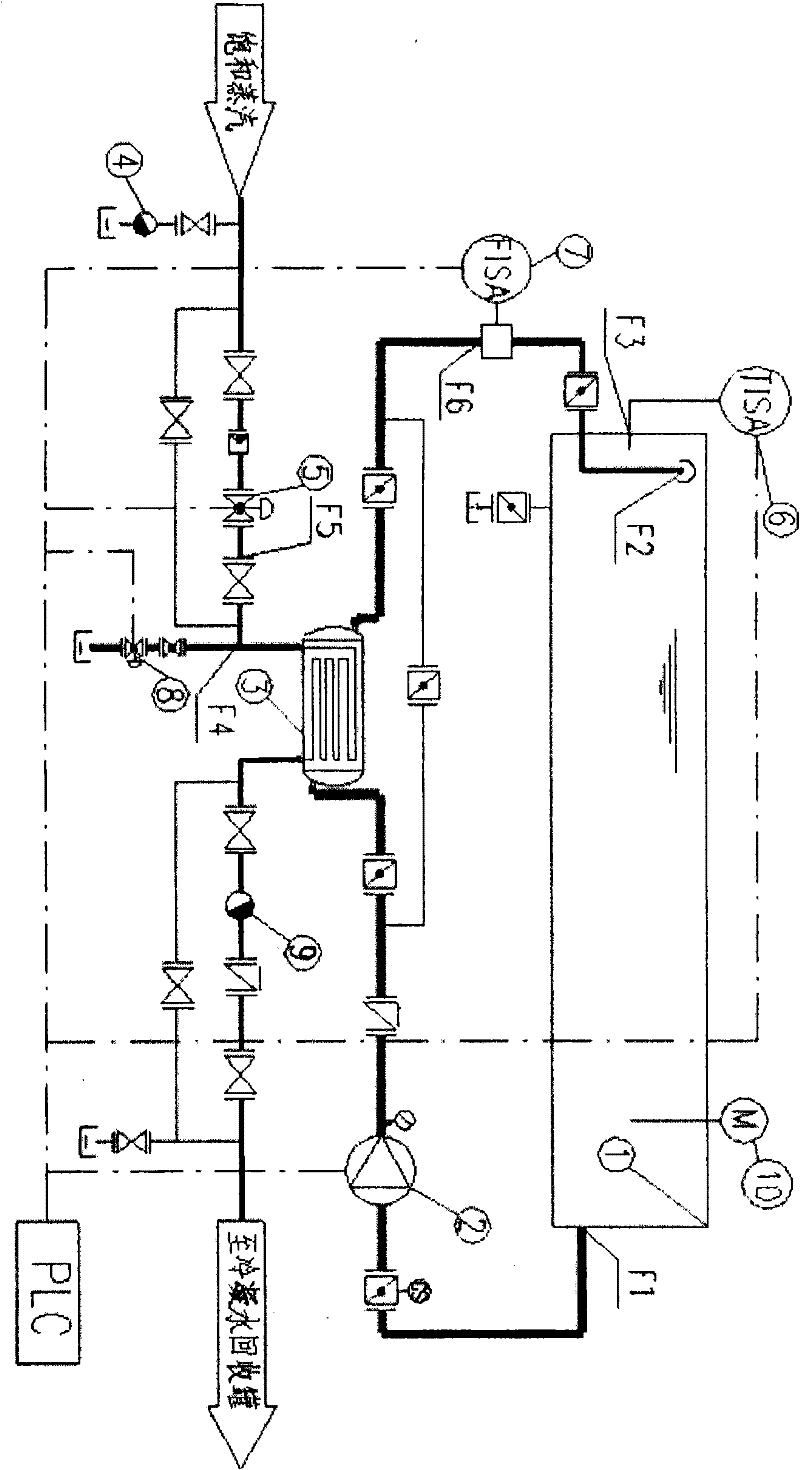

[0033] see first figure 2 , is a steam heater circulating heating system, mainly composed of a liquid supply main tank 1, a circulating heating pump 2, a steam heater 3, a steam trap 4, a first pneumatic shut-off valve 5, a temperature sensor 6, a flow sensor 7, a second Pneumatic cut-off valve 8, steam trap 9, stirring device 10 and other components.

[0034] A stirring device 10 is housed in the liquid supply main tank 1 . The two ends of the liquid supply main tank 1 are respectively connected to the steam heater 3 through pipelines, and a circulating heat pump 2 is arranged between the steam heater 3 and the liquid supply main tank 1 . One end of the steam heater 3 is connected to the saturated steam pipe, and the other end of the steam heater 3 is connected to the condensed water recovery tank. A flow sensor 7 is installed on the pipeline bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com