Cold-bending processing equipment and method of steel pipe

A kind of processing equipment and cold bending technology, applied in the field of steel structure processing, can solve the problems of affecting the mechanical strength of steel pipes, the limitation of the application range of steel pipes, and the inability to control the quality of bending arcs, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

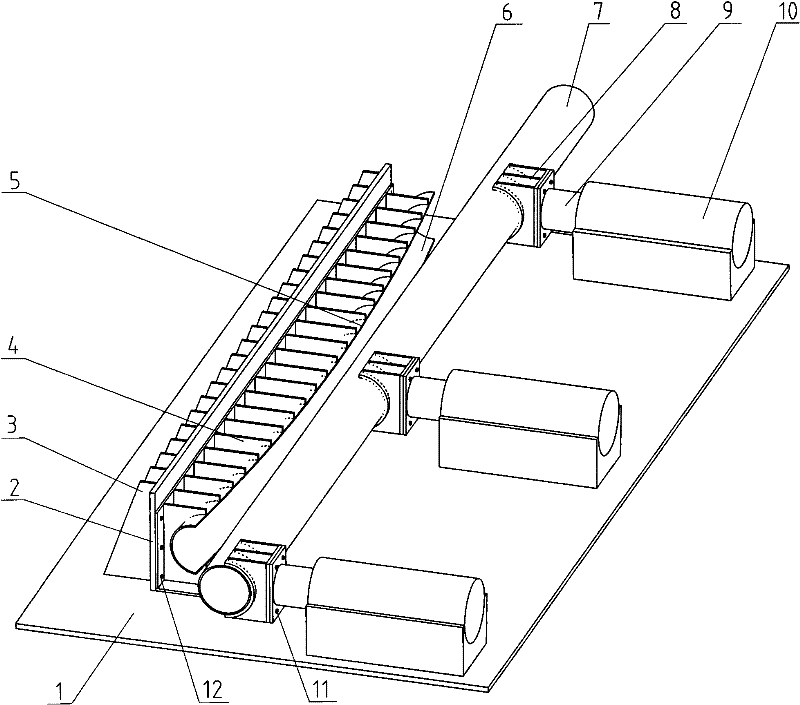

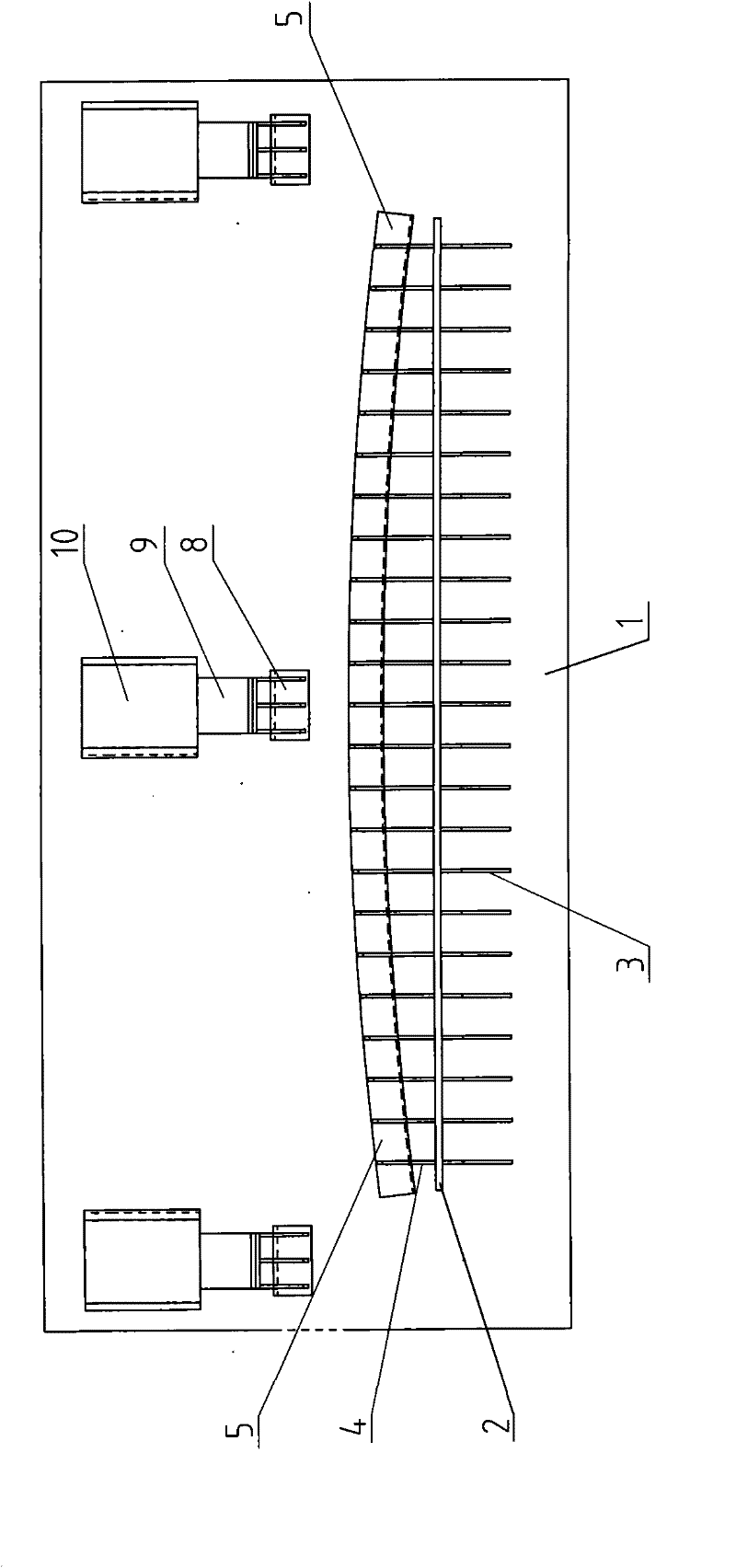

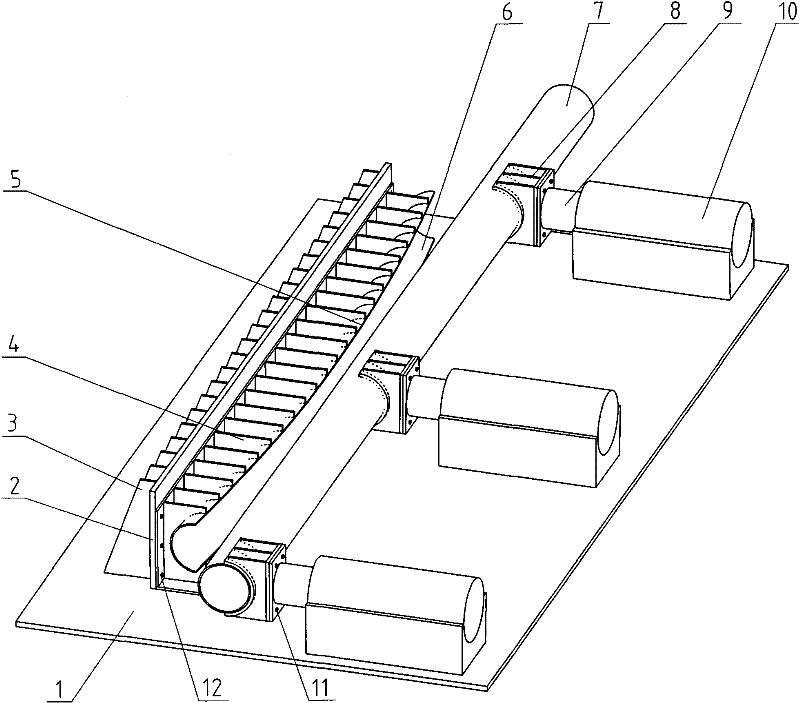

[0021] by Figure 1-2 As shown, 1 in the figure is the operating platform. On the operating platform 1, there is a mold backing plate 2 vertically arranged, and reinforcing plates 3 are evenly distributed at the rear of the mold backing plate 2, and evenly distributed through the front of the mold backing plate 2. The reinforced brace 4 is fixed with an arc-shaped mold 5, and the semi-circular concave surface 6 on the arc-shaped mold 5 is arranged outward along the parallel direction of the operating platform. The semi-circular concave surface 6 is the horizontal of the arc-shaped mold 5. Cross-section, the said mold backing plate 2 and the evenly distributed reinforcing ribs 4 are fixedly connected by bolts 12, which is convenient for disassembly; on the operating platform 1 and at the position (same height) corresponding to the semicircular concave surface 6 There are three sets of hydraulic cylinders 10 uniformly distributed, and a push rod arc mold 8 is fixed at the front e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com