Roll winding device and method for winding a sheet of material

A technology of winding device and material roll, which is applied in the field of winding material, especially in the field of paper width, which can solve the problems of unsatisfactory material roll structure, unsatisfactory winding speed and unreliable transfer degree, so as to reduce the risk of resonance , good cushioning effect, and the effect of reducing the amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

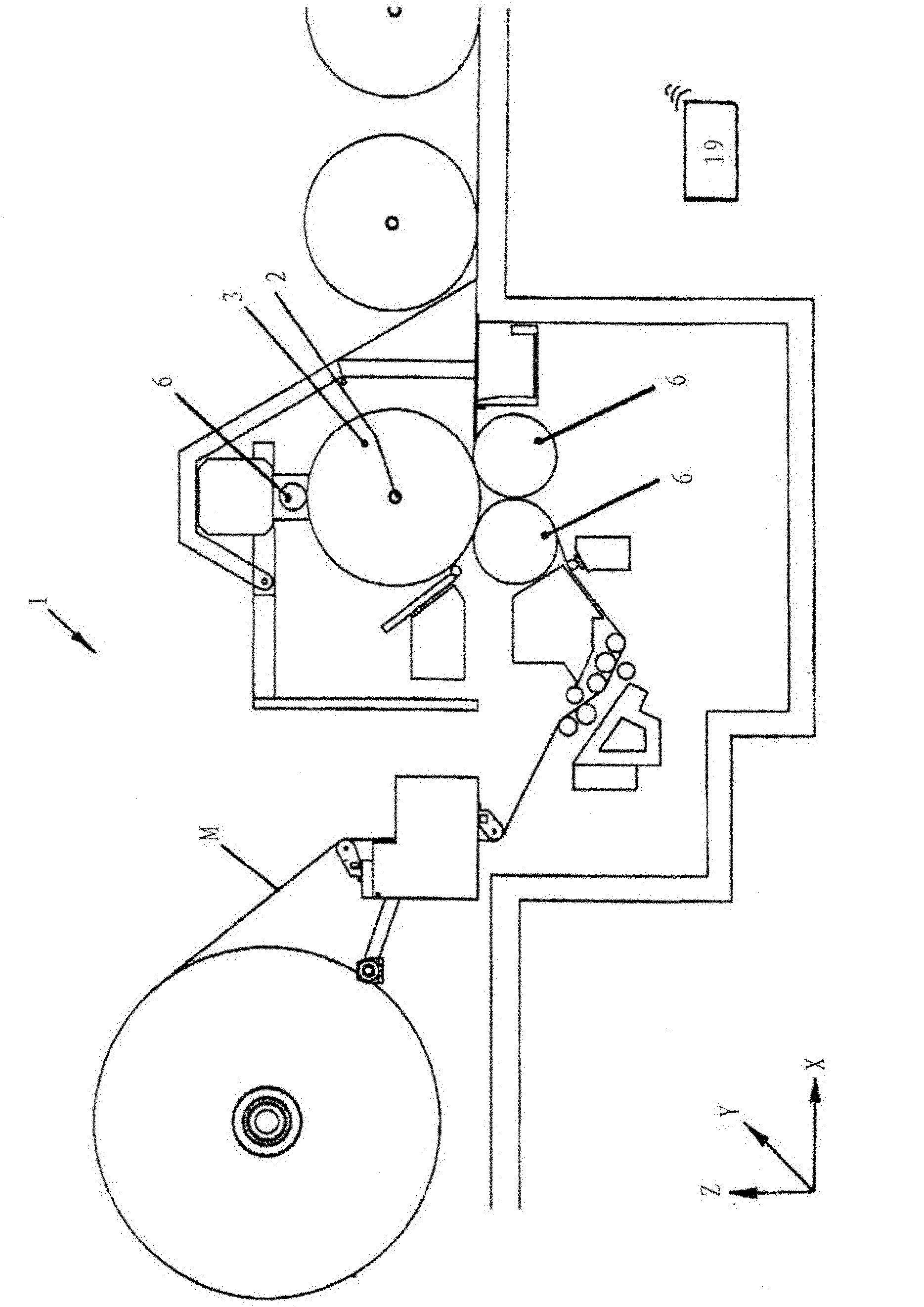

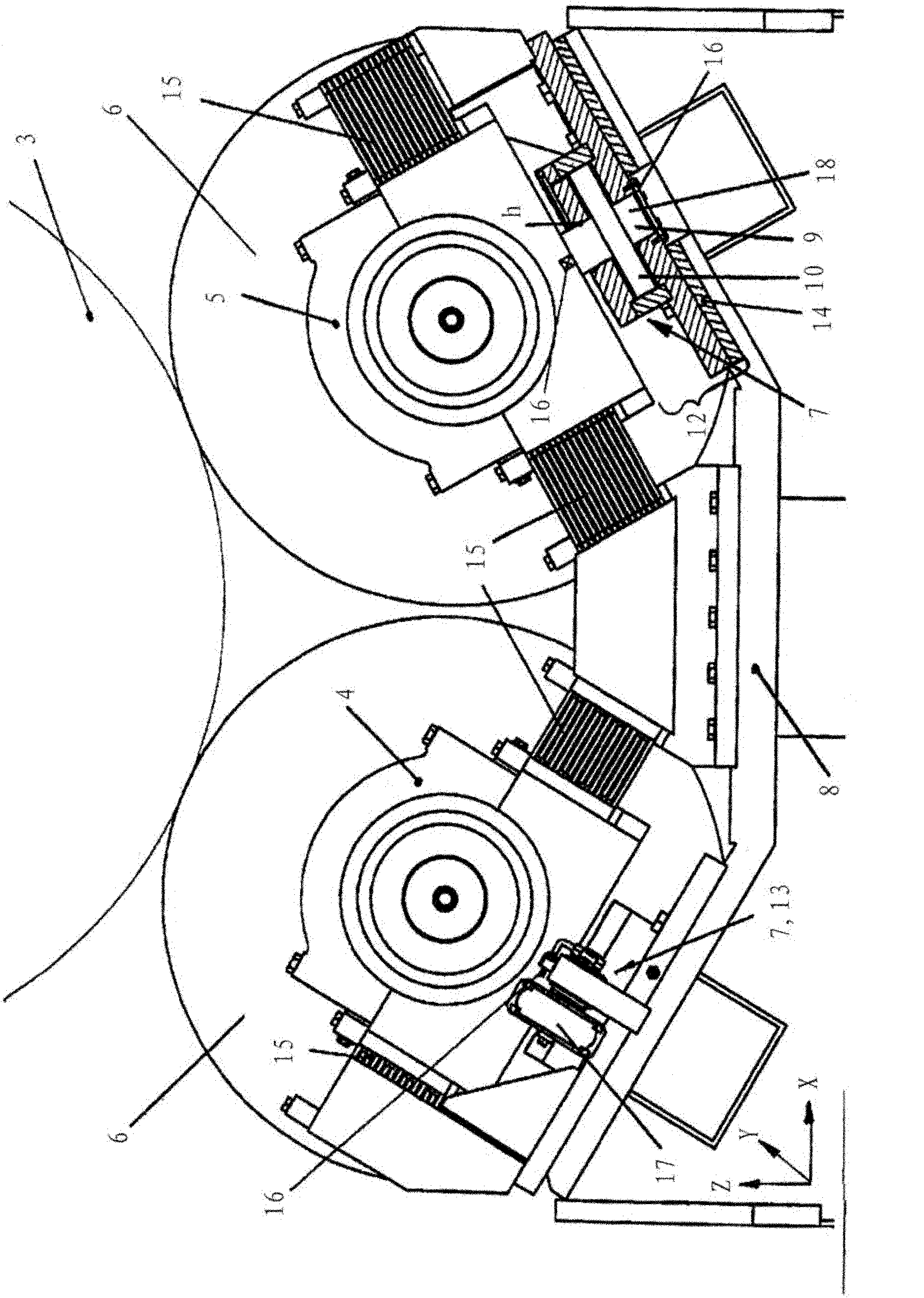

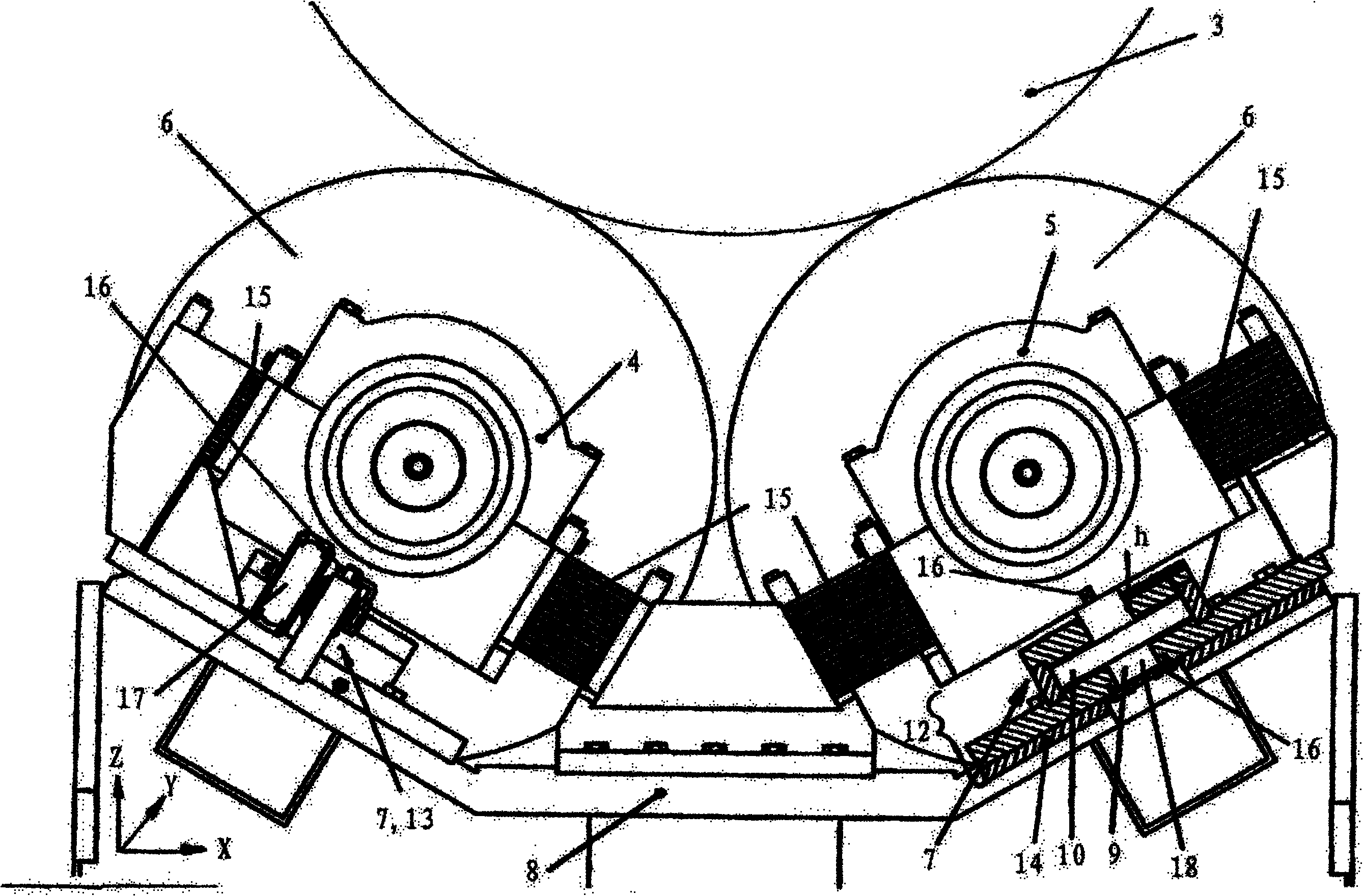

[0095] According to the material roll winding device 1 of the present invention in figure 1 and figure 2 The preferred embodiment shown in is realized in conjunction with an idler roll winding device which has a roller arrangement in its winding area. The roller arrangement has two rollers 6 designed as carrier rollers, at least one of which is drivable. Both rollers 6 are preferably drivable and connected to a common control / regulation unit 19 . In this case, it has proven to be suitable to adjust the rotational speed of the first roller 6 and to adjust the torque of the second roller 6 when the material web M, in particular the paper web, is in the running direction, ie the x-direction. The shafts of the rollers 6 are supported on roller bearings 4 , 5 which can be located at different height levels in the z-direction. Furthermore, the rollers 6 can have diameters of different thicknesses. Of course, at least one of the two rollers 6 can also have a coating or armor whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com