Extruding equipment

A technology of extrusion equipment and vacuum device, applied in the field of extrusion equipment, can solve the problems of product quality impact, termination, uneven feeding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

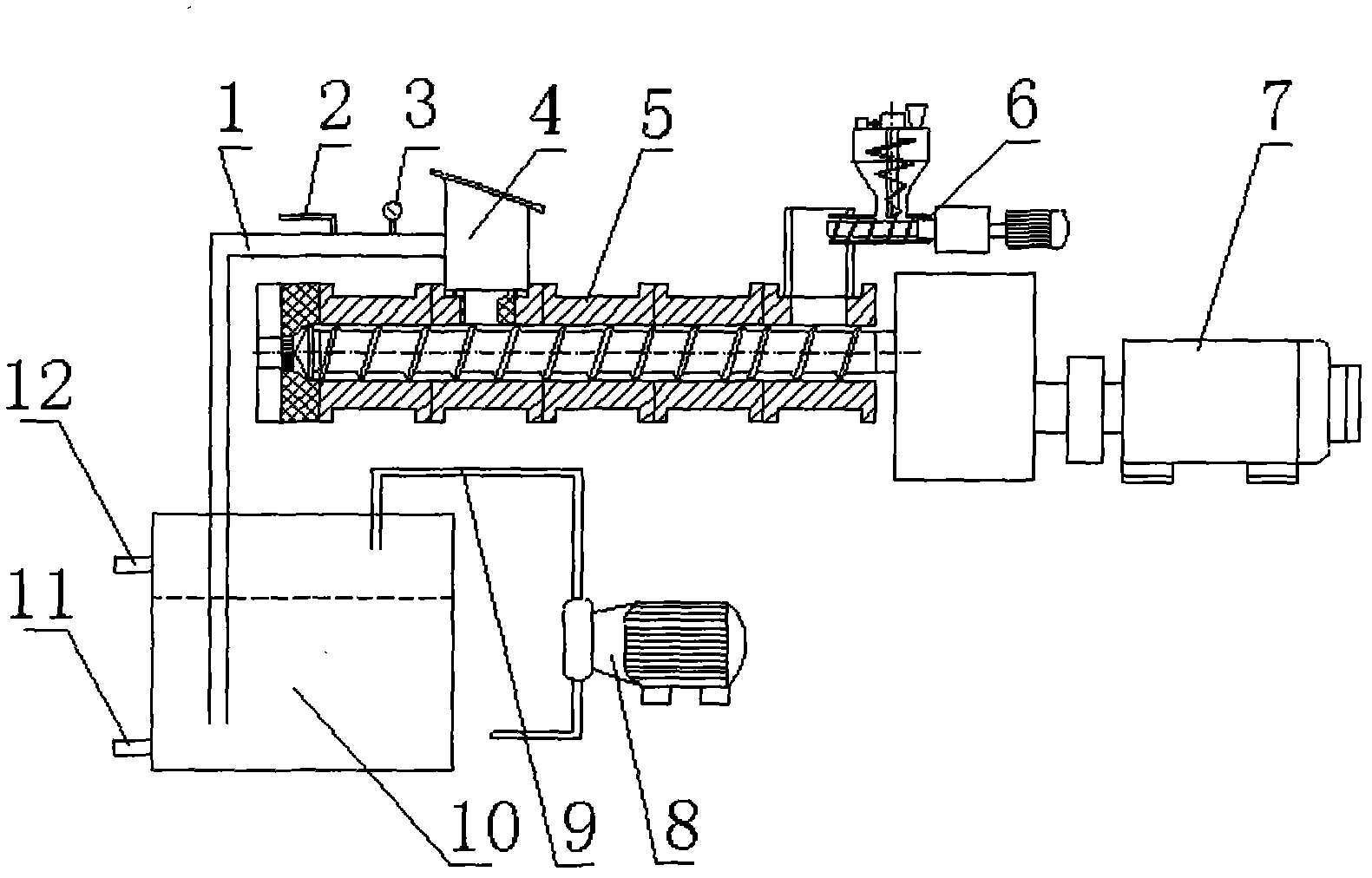

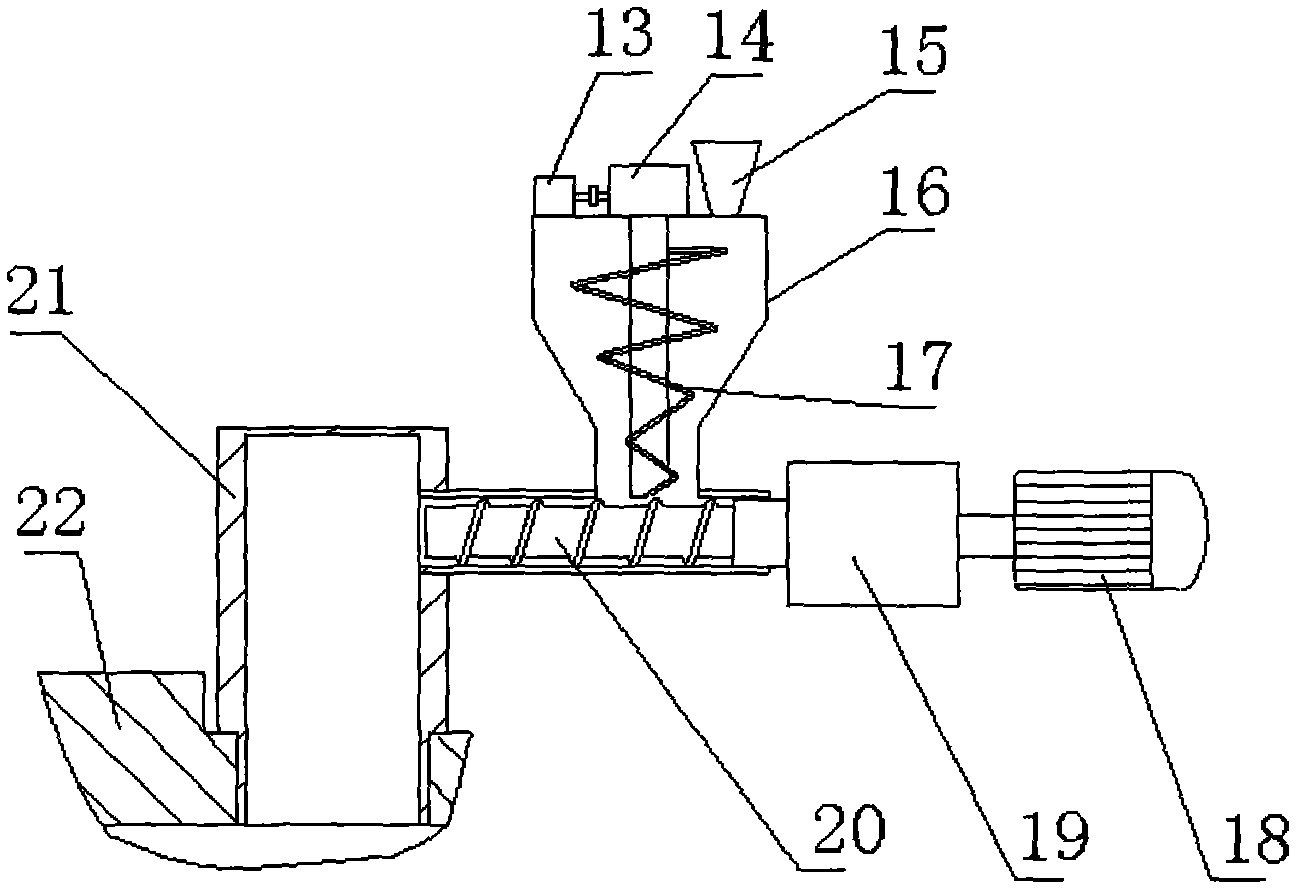

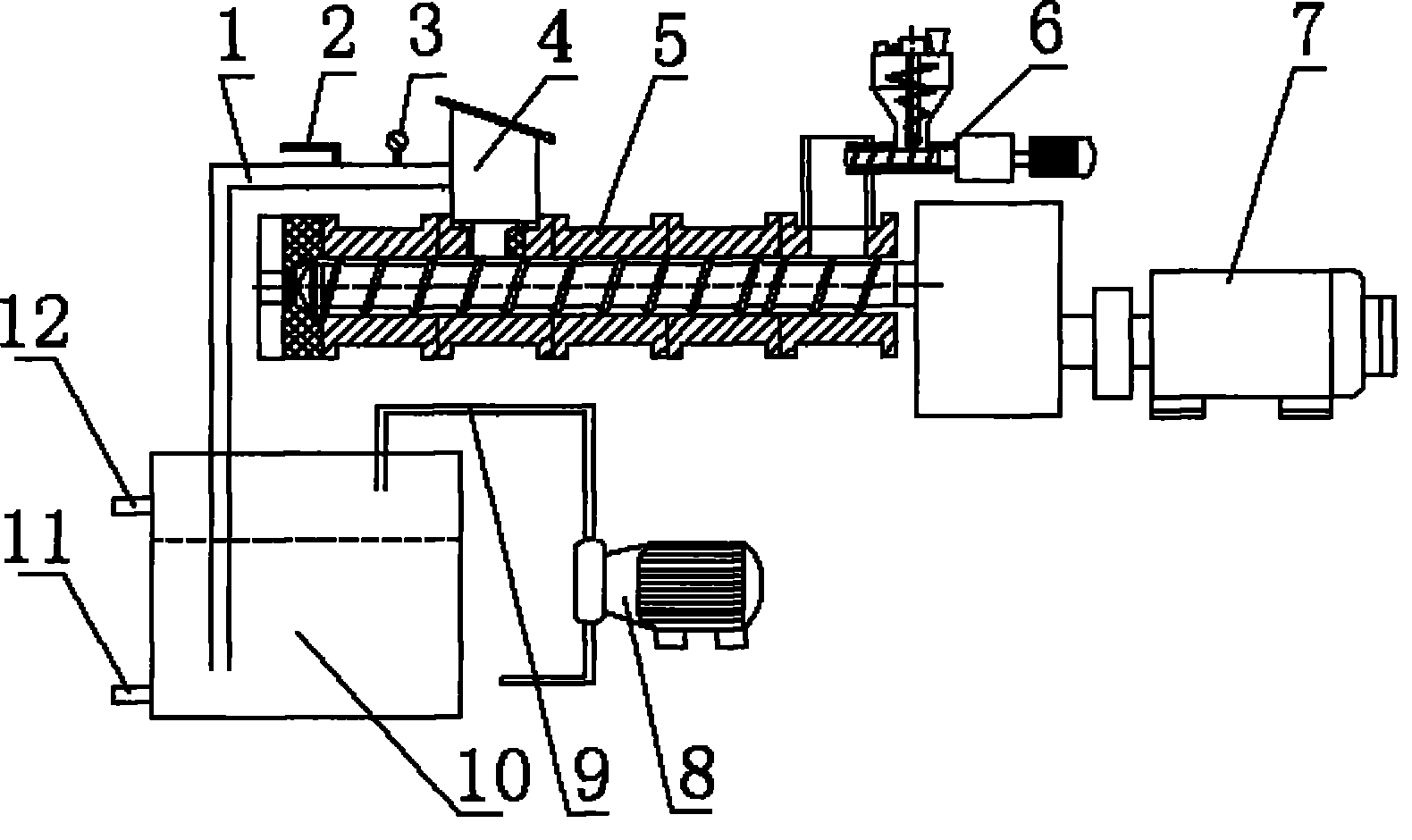

[0013] Such as figure 1 , figure 2 As shown, a kind of extruding equipment comprises feeding device 6, driving mechanism 7, barrel 5 and vacuumizing device, and vacuumizing device comprises exhaust port 4 on the barrel 5, pressure gauge 3, airflow control valve 2, vacuum pump 8. Volume separator 10, first exhaust pipe 1 and second exhaust pipe 9, there is volume separator 10 filled with water between exhaust port 4 and vacuum pump 8, the side wall of volume separator 10 has water inlet 11 and The water outlet 12, the first exhaust pipe 1 connected between the volume separator 10 and the exhaust port 4, the second exhaust pipe 9 connected between the volume separator 10 and the vacuum pump 8, the pressure gauge 3 and the air flow adjustment The valve 2 is arranged on the first exhaust pipe 1 . The first exhaust pipe 1 is detachably connected to the exhaust port 4 , and the second exhaust pipe 9 is detachably connected to the vacuum pump 8 . The feeding device comprises a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com