Flow type bulk cargo stacking feeder

A feeder, flow technology, applied in conveyors, loading/unloading, conveyor objects, etc., can solve the problems of safety and low efficiency of conveying operations, and achieve improved equipment operation safety, convenient and decentralized material delivery. The effect of shock loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

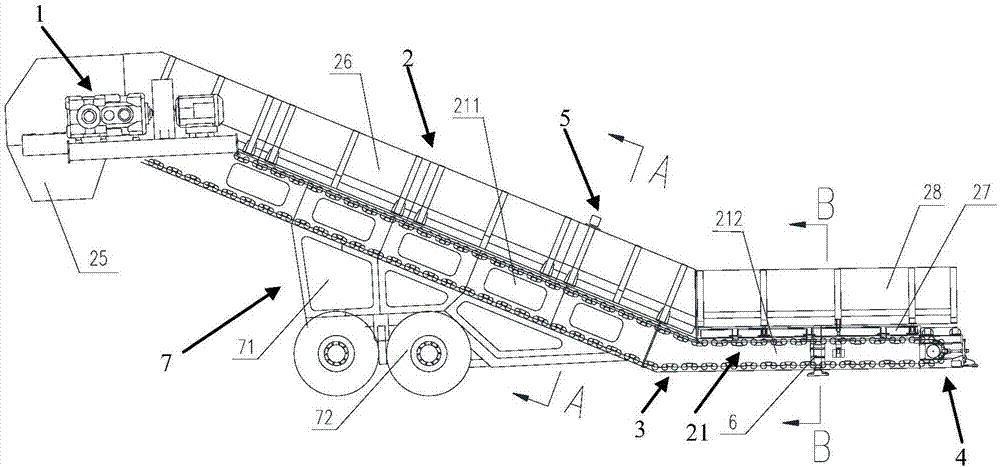

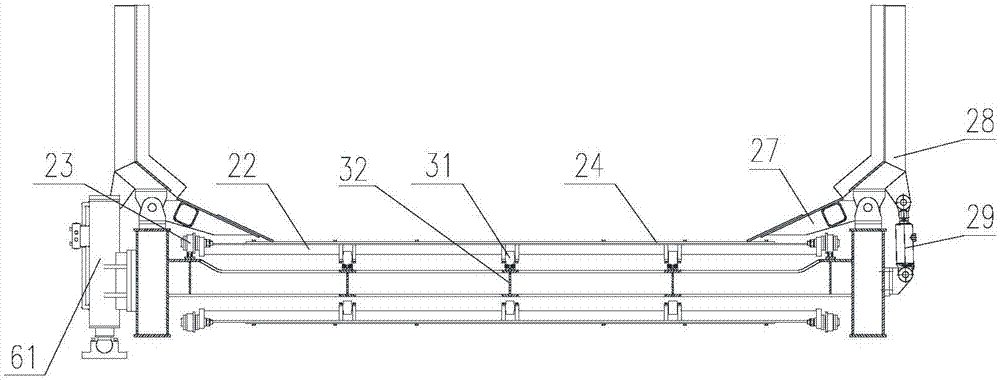

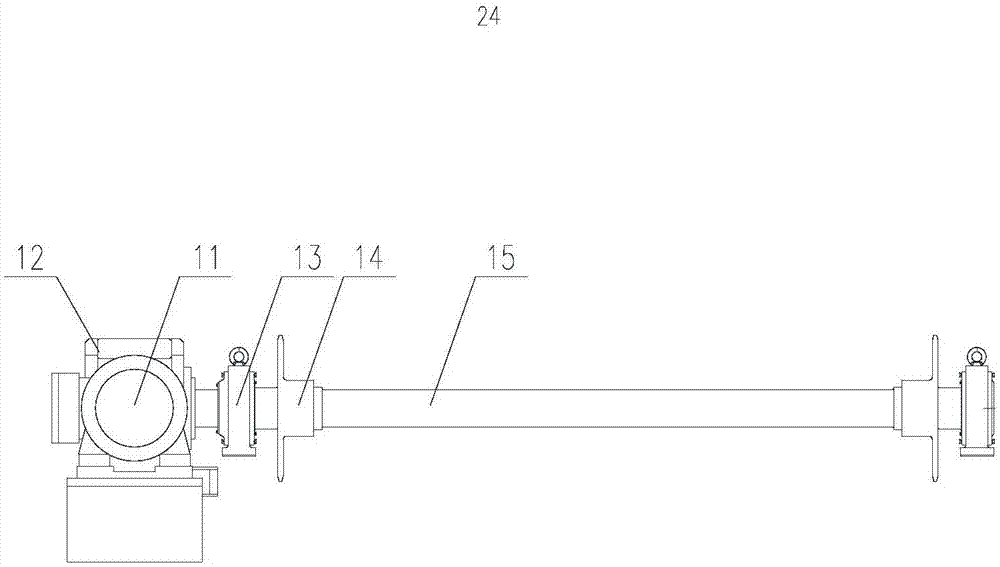

[0029] see figure 1 As shown, a mobile bulk storage feeder includes: a feeding mechanism 2 and a load-bearing mechanism 3 . The conveying mechanism 2 is driven by the driving device 1 for conveying materials; the load-bearing mechanism 3 is used to disperse the impact load generated when the materials fall, so as to reduce its adverse effect on the conveying mechanism 2 .

[0030] The conveying mechanism 2 includes a supporting body 21 and a chain plate 22 . The supporting body 21 is a frame structure for installing and fixing various components. The chain plate 22 is wound inside the supporting body 21 and rotates circularly for conveying materials.

[0031] When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com