Sealed material discharging pusher

A technology of propeller and discharge cylinder, which is applied in the field of discharge propulsion device and sealed discharge propeller, which can solve the problems of not considering sealing and unreasonable design, so as to ensure sealing, ingenious and reasonable structural design, continuous and uninterrupted The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific drawings and embodiments.

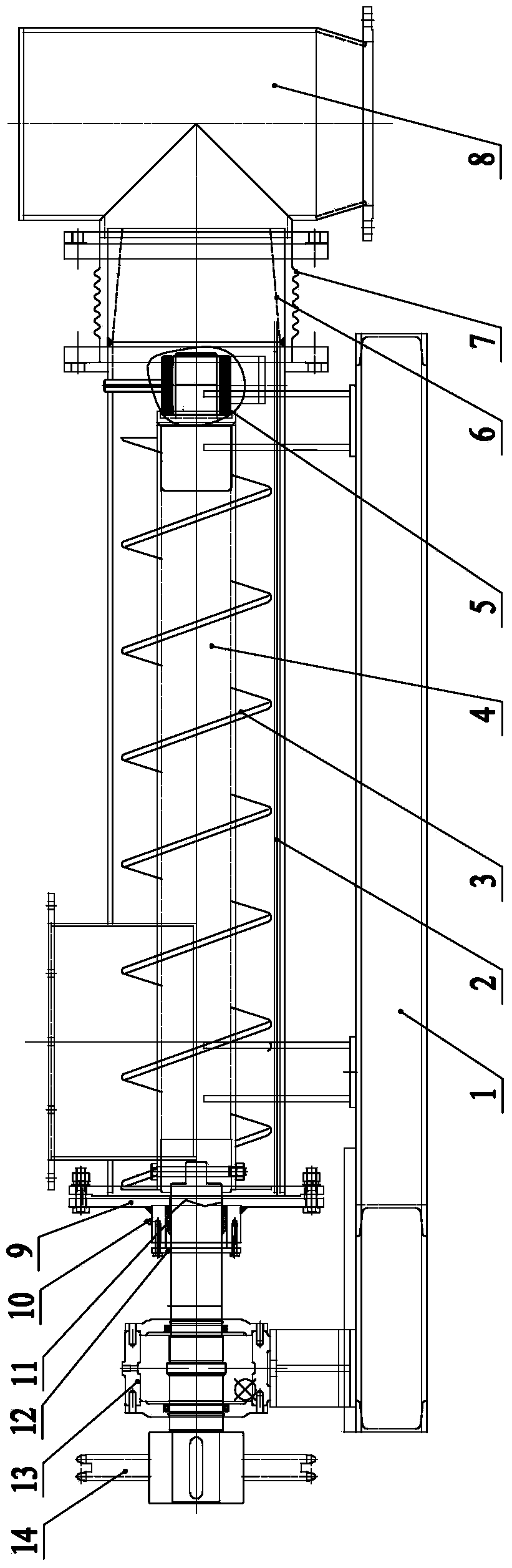

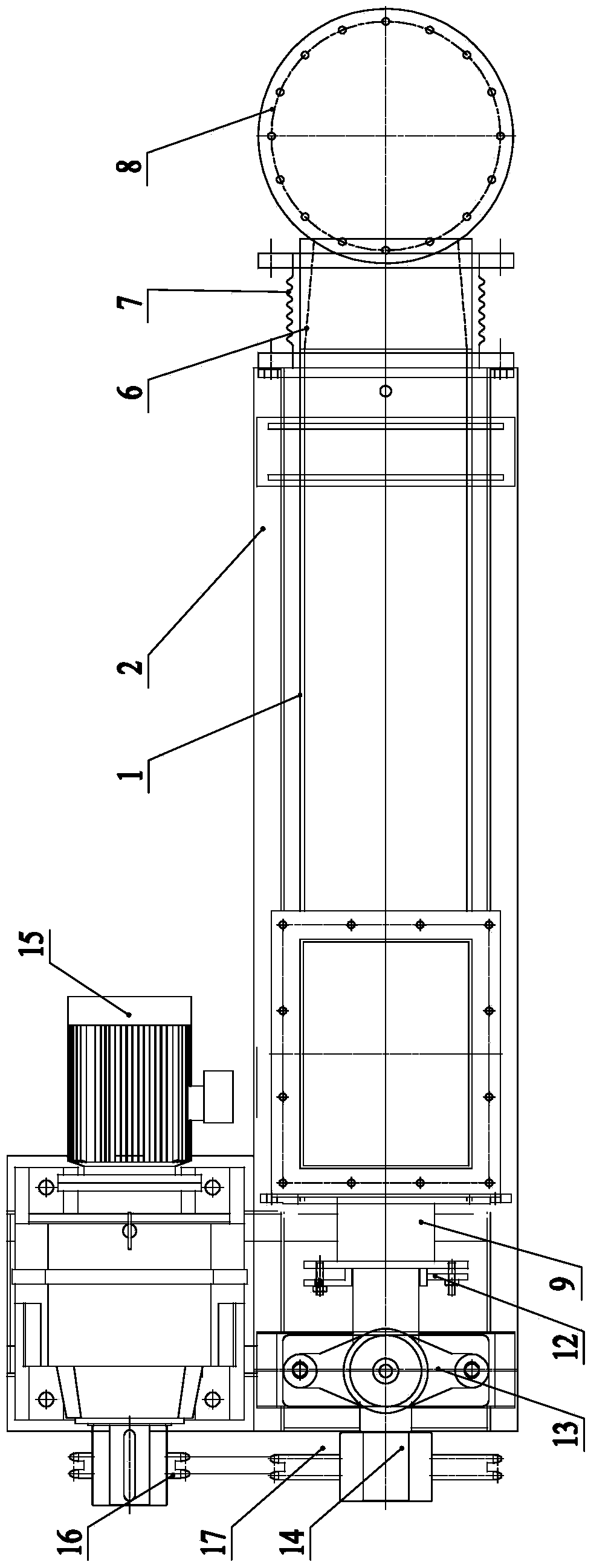

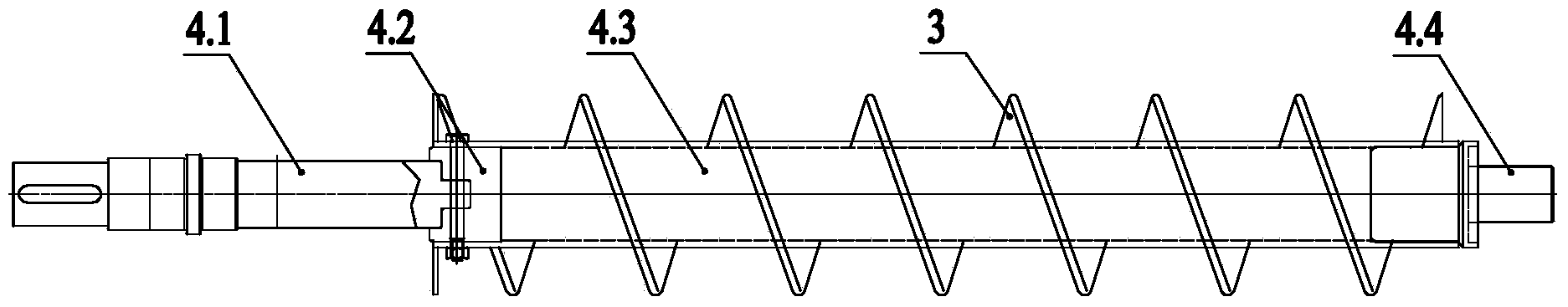

[0018] As shown in the figure: the sealed discharge propeller in the embodiment is mainly composed of a cylinder body 1, a frame 2, a spiral blade 3, a blade central shaft 4, a shaft sleeve 5, a tapered cylinder body 6, an expansion joint 7, and a discharge cylinder 8 , Packing disc 9, grease nozzle 10, packing 11, pressure cover 12, bearing seat 13, driven sprocket 14, motor reducer 15, driving sprocket 16 and chain 17 and so on.

[0019] Such as figure 1 , figure 2 As shown, the cylinder 1 is fixedly installed on the frame 2, the top of the first end of the cylinder 1 is provided with a feed inlet, the blade central axis 4 is arranged in the cylinder 1 along the length direction of the cylinder 1, and the helical blade 3 is fixed on the central axis 4 of the blade. In the embodiment of the present invention, the blade central shaft 4 is mainly composed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com