Curtain wall unit lifting device and construction method thereof

A curtain wall unit and hoisting device technology, applied in hoisting devices, transportation and packaging, load hoisting components, etc., can solve the problems of delayed construction progress, poor flexibility, building height restrictions, etc., to reduce the accident rate, improve the Construction efficiency, the effect of reducing manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The orientation terms "up", "down", "top", "bottom", "horizontal" and "longitudinal" mentioned below are all determined with reference to the working state of the hoisting device when hoisting the curtain wall unit.

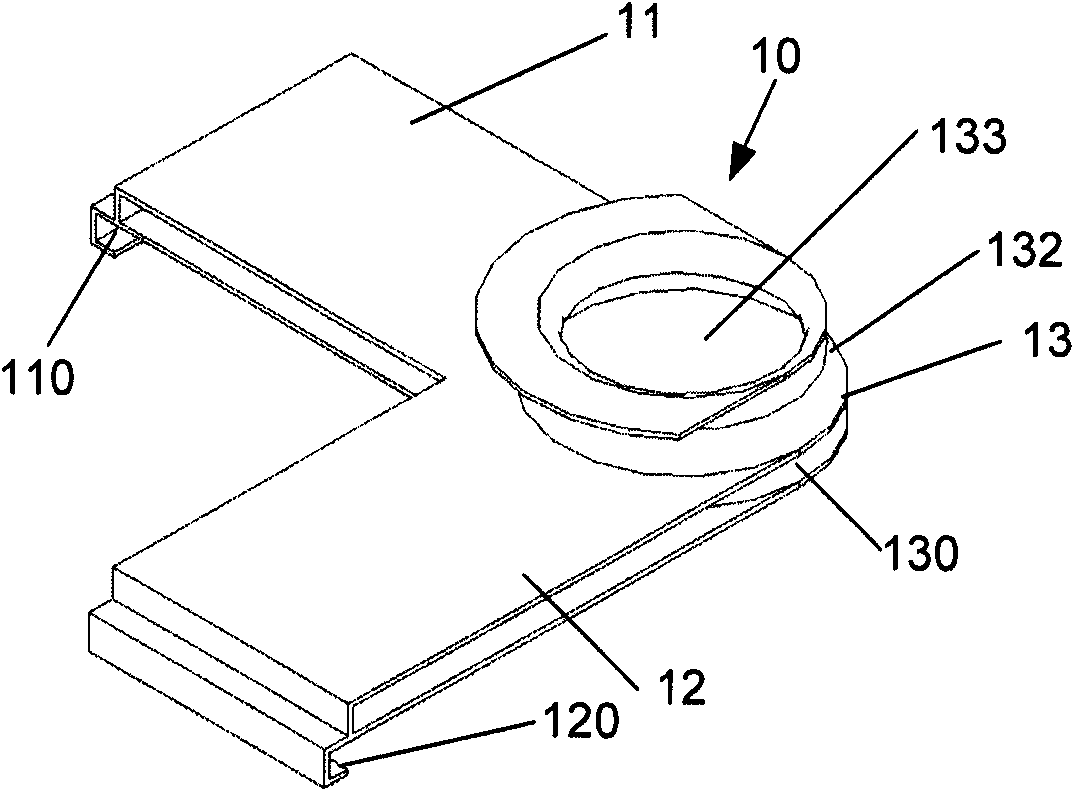

[0038] Such as figure 1 As shown, the gripper 10 is a right-angled piece, which has two straight ends 11, 12 and a bent portion 13, on which two straight ends 11, 12 are formed with draw-in slots 110, 120, and the two draw-in slots 110, 120 are mutually Vertically, two layers of circular grooves 132 , 130 are formed on the bending portion 13 , and the two layers of circular grooves 132 , 130 are penetrated by the same central hole 133 .

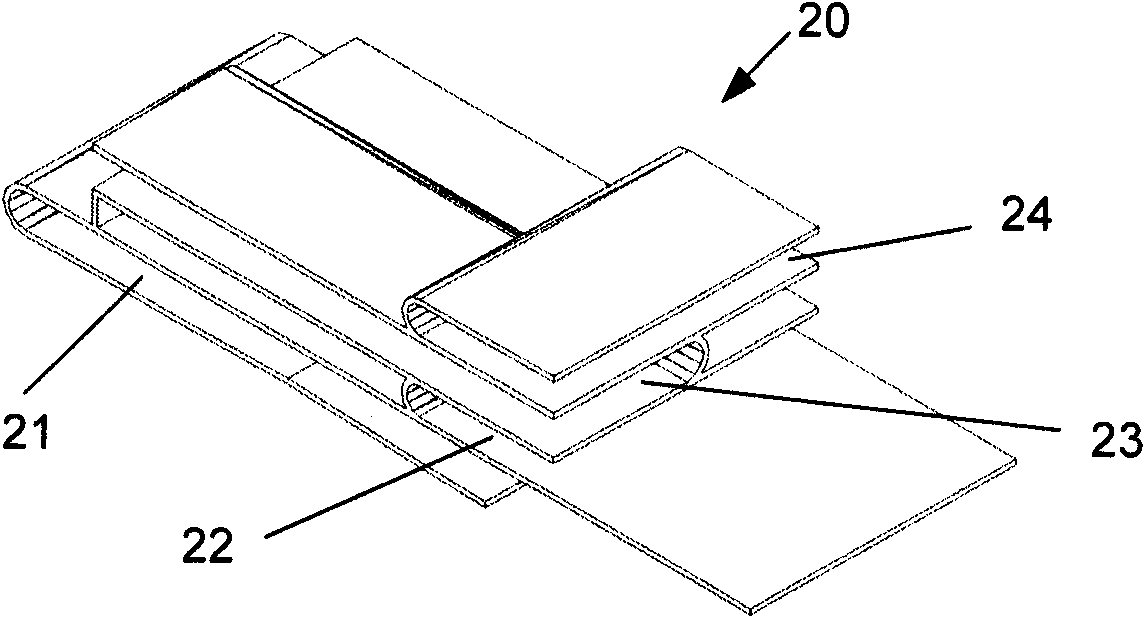

[0039] Such as figure 2 As shown, the sling stabilizing card 20 has a four-layer structure, the first layer structure 21 is a card slot, the second layer structure 22 is an isolation slot, the third layer structure 23 is a guide perforation, and the fourth layer structure 24 is an isolation slot.

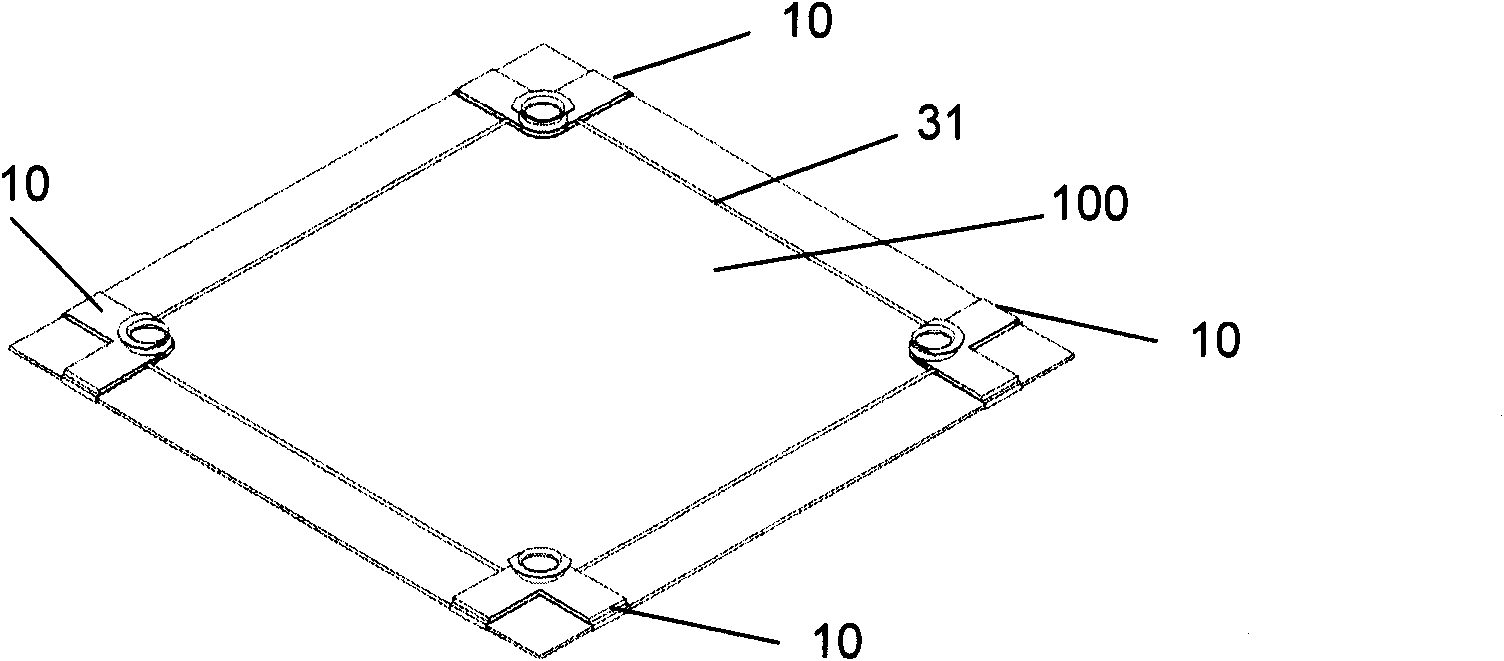

[0040] Such as ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com