Power capacitor

A technology for power capacitors and capacitors, which is applied to the terminal of fixed capacitors, the casing/package of fixed capacitors, and the components of fixed capacitors, etc., can solve the problems of high cost, many processing steps, and complicated operations, and achieves fewer steps and lower costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

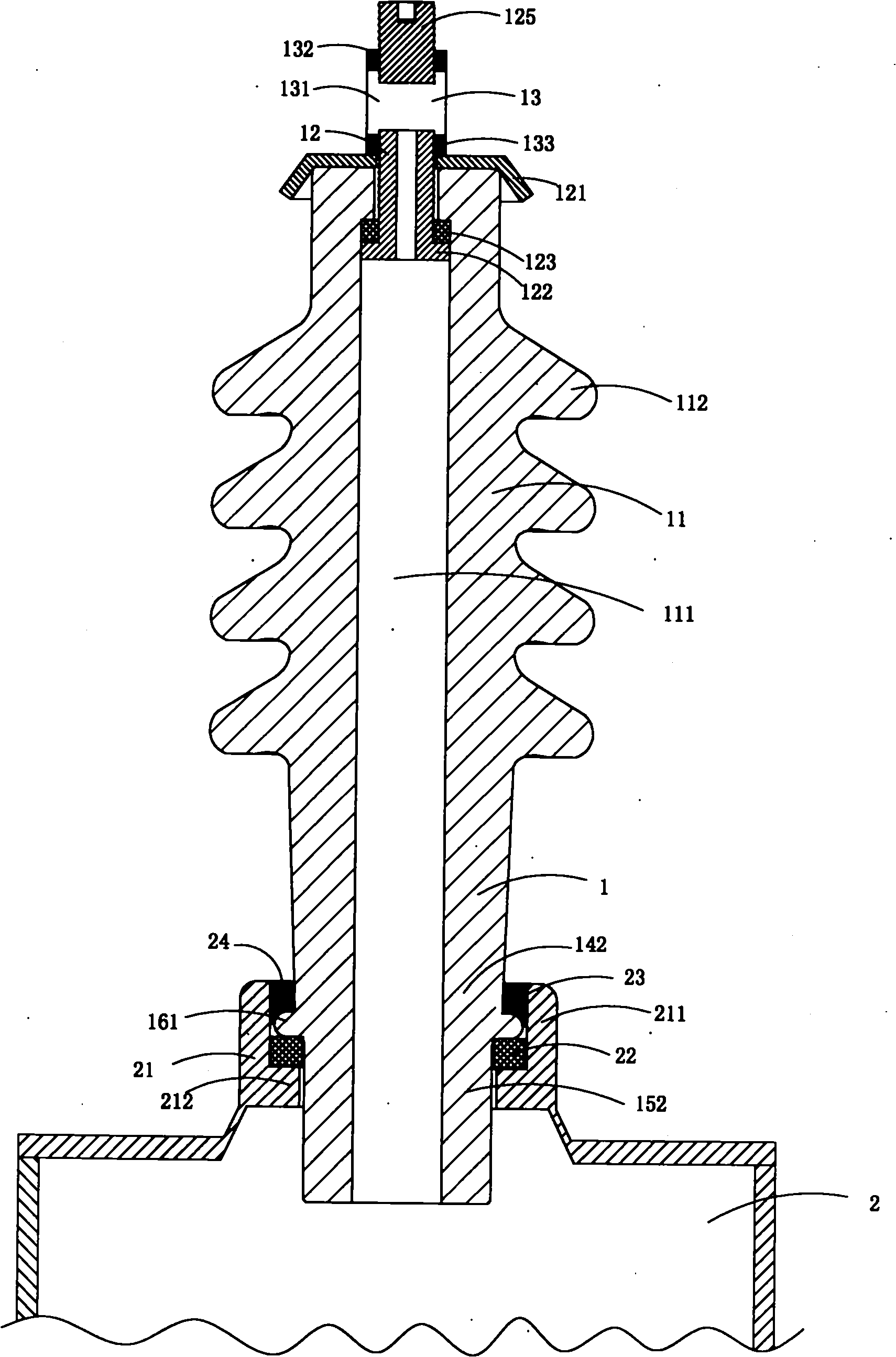

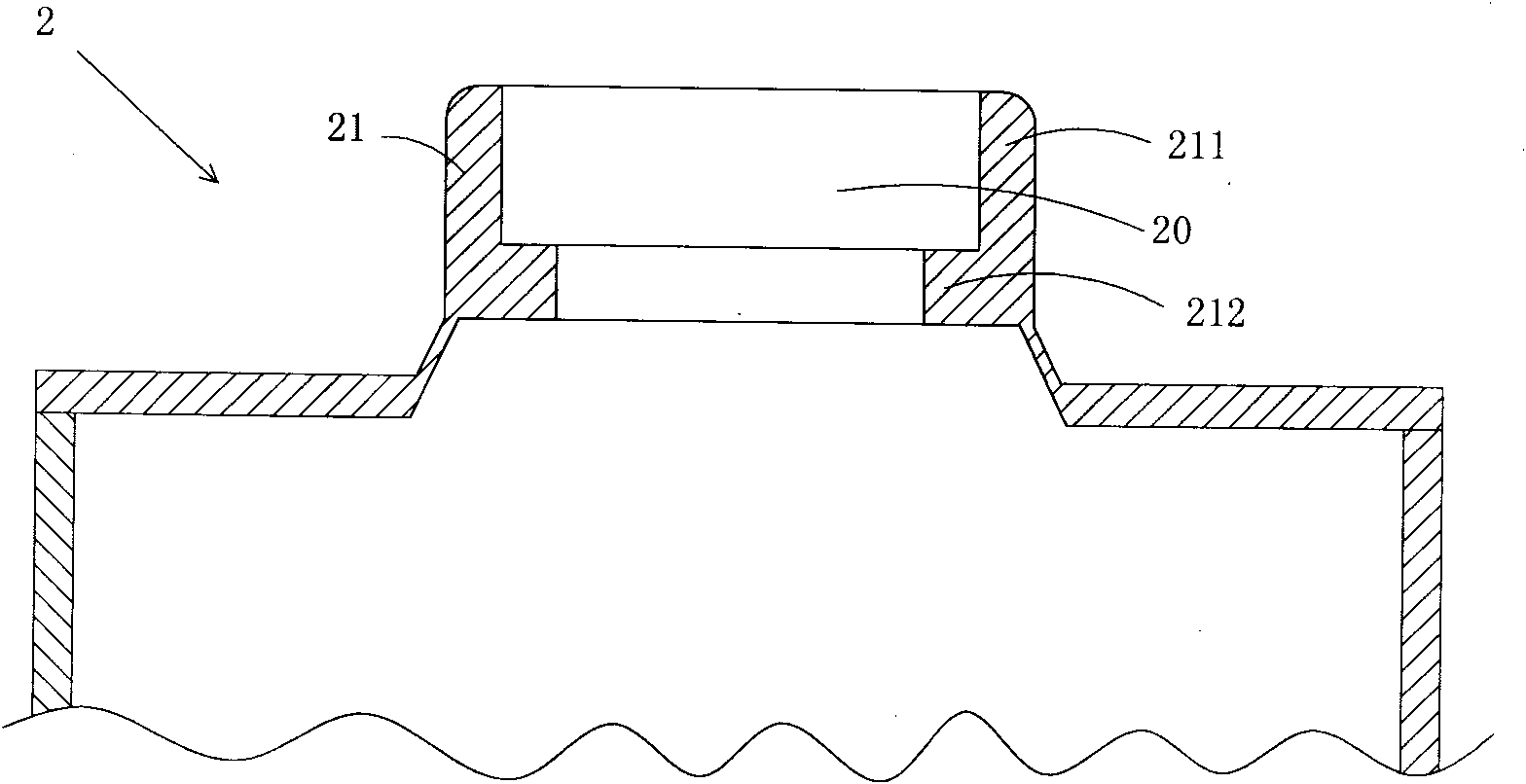

[0023] figure 1 and figure 2 A first embodiment of the invention is shown in which, figure 1 It is a structural schematic diagram of the first structure of the present invention; figure 2 for figure 1 A schematic diagram of the structure of the capacitor case in the power capacitor shown.

[0024] This embodiment is a power capacitor, see figure 1 and figure 2 , this kind of power capacitor includes a capacitor housing 2 and a terminal 1 fixed on the capacitor housing, and the terminal 1 includes a ceramic insulator body 11 and a wiring assembly 12 arranged on the top of the ceramic insulator body 11; the ceramic The insulator body 11 is provided with a through hole 111 along its central axis, a plurality of sheds 112 are provided on the middle outer wall of the insulator body, and a welding part 113 is provided at the lower part of the insulator body; The fixed installation base 20 of the ceramic insulator body 11 is fixedly installed; the welding part 113 of the ins...

Embodiment 2

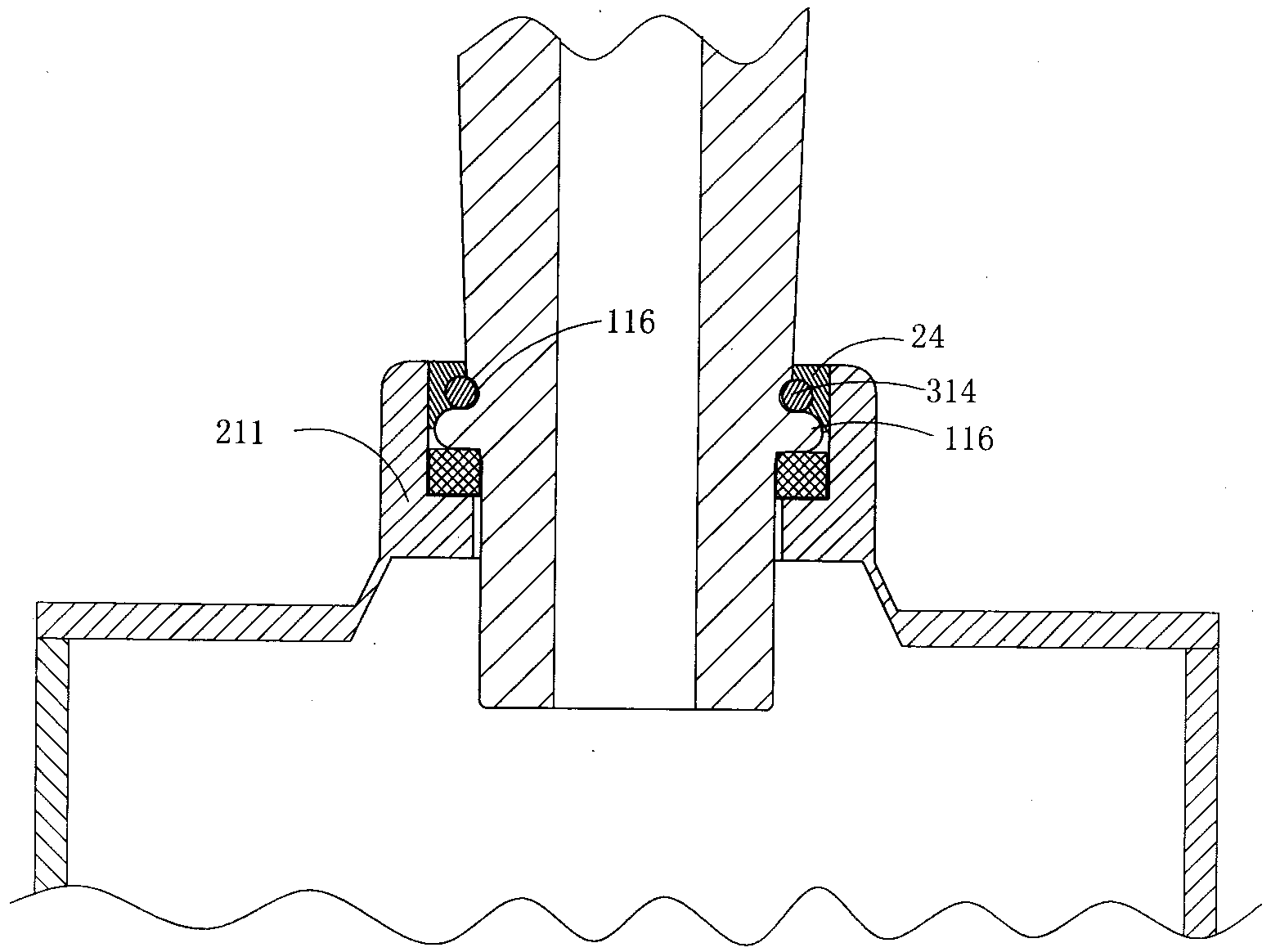

[0030] image 3 It is a structural schematic diagram of the second structure of the present invention, showing the second specific implementation manner of the present invention.

[0031] This embodiment is basically the same as Embodiment 1, the difference is: see image 3 , there is also an annular groove 116 between the annular positioning boss 161 and the umbrella skirt 112, the top of the sleeve area 211 of the fixed installation seat 20 is higher than the annular groove 116, the annular A metal retaining ring 314 is disposed in the groove 116 ; the metal retaining ring 314 is fixedly connected to the inner wall of the casing area 211 of the fixed installation seat 20 by soldering 24 .

Embodiment 3

[0033] Figure 4 and Figure 5 A third embodiment of the invention is shown, in which Figure 4 It is a structural schematic diagram of the third structure of the present invention; Figure 5 for Figure 4 A schematic diagram of the structure of the capacitor case in the power capacitor shown.

[0034] This embodiment is basically the same as Embodiment 1, the difference is: see Figure 4 and Figure 5 The welding portion 113 of the insulator body includes a blocking surface 141 with a larger outer diameter and a welding pipe 142 with a smaller outer diameter located below the blocking surface 141, the basic shape of the welding portion 113 is T-shaped; The fixed mounting base 20 includes a mounting tube 21 with a linear cavity, the mounting tube 21 is sheathed on the outer wall of the welding tube 142 in the welding part 113 of the insulator body, and the top end of the mounting tube 21 is located in the welding part 113 Below the blocking surface 141 ; the fixed mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com