Dead-zone compensation method for voltage source inverter

A voltage source inverter and dead-time compensation technology, applied in the direction of controlling electromechanical brakes, electrical components, controlling generators, etc., can solve the current vector angle estimation lag, high isolation requirements for voltage sampling circuits, and difficulty in ensuring current vector angle estimation. Accuracy and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

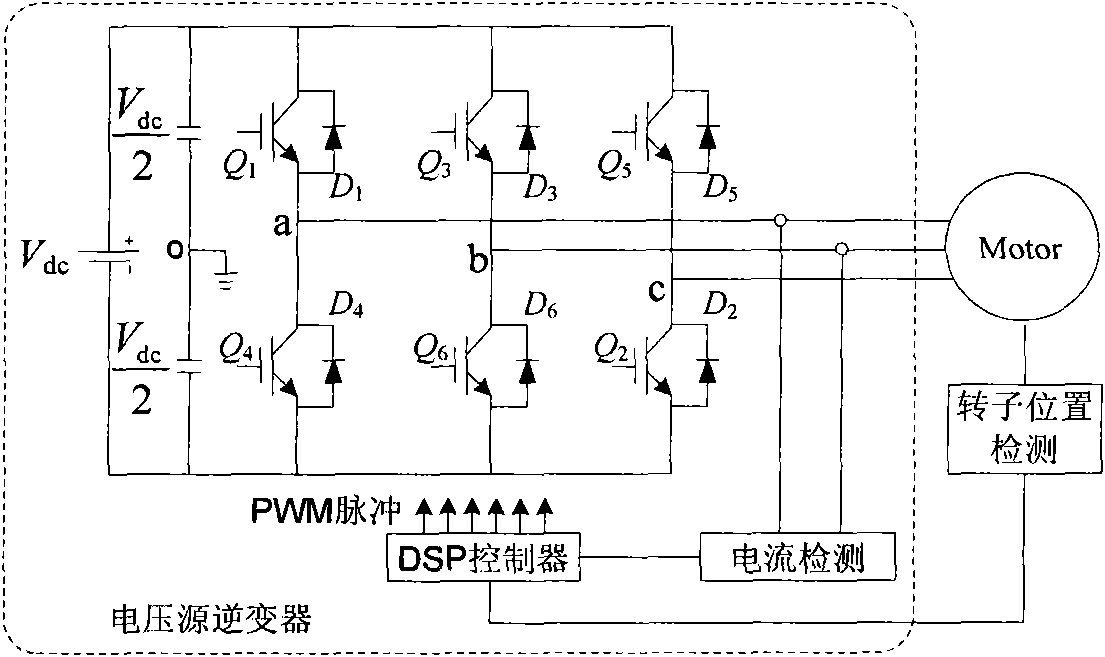

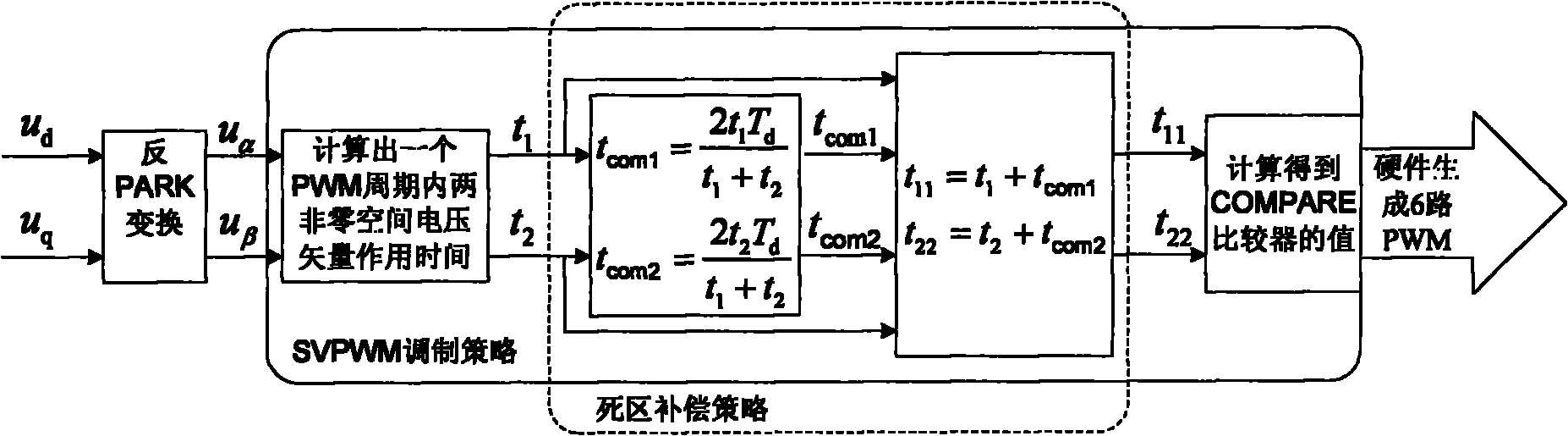

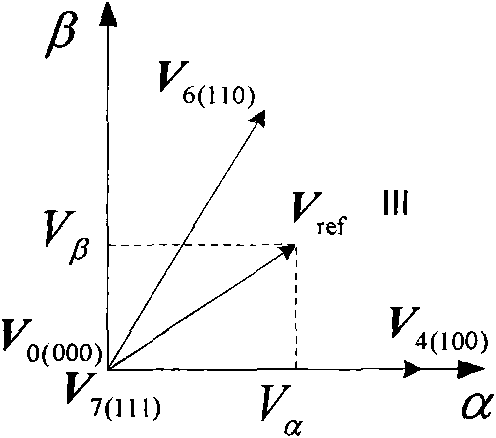

[0027] Taking the permanent magnet synchronous motor vector control system powered by a voltage source inverter as an example, the dead zone compensation method of the present invention is described, figure 1 Is the schematic diagram of the system structure. Such as figure 1 As shown, the voltage source inverter is composed of power modules, current sensors, and DSP controllers. figure 1 The power module of the medium voltage source inverter is Infineon FF600R06ME3; the parameters of the permanent magnet synchronous motor: the rated power is 20kW, the rated speed is 2500rpm, the number of pole pairs is 3, the stator phase resistance is 26mΩ, and the d-axis inductance is 0.52mH. The q-axis inductance is 1.02mH, and the permanent magnet flux linkage is 0.129Wb. The rotor position detection device installed on the motor detects the position of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com