Air-free tire of replacing TPR (Thermo Plastic Rubber) material with air

A technology of airless tires and air, which is applied to non-pneumatic tires, tire parts, tires, etc., can solve the problems of poor shock absorption effect, high manufacturing cost, and personal safety hazards, so as to prolong the service life and save energy. The effect of simple energy and manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

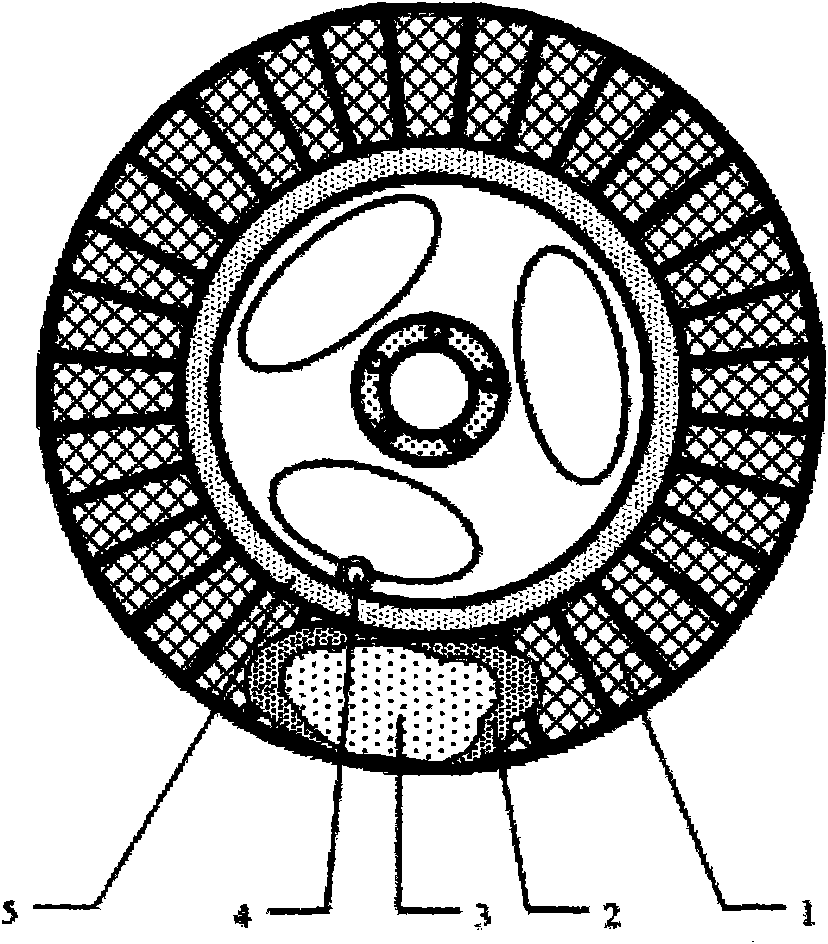

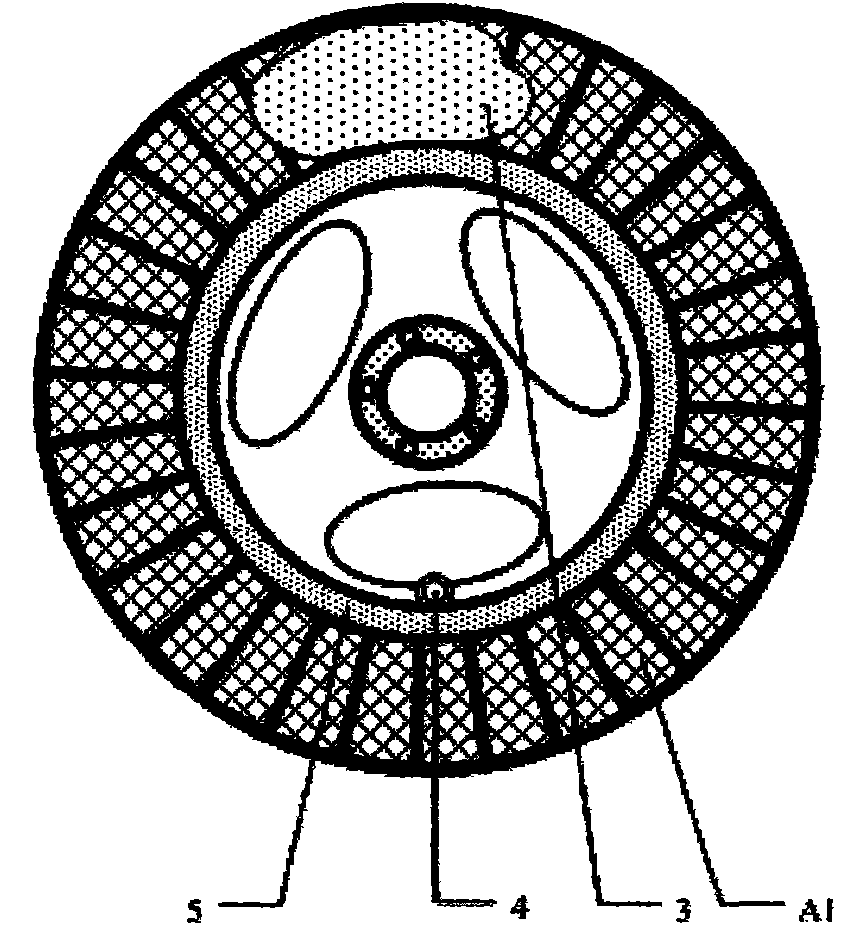

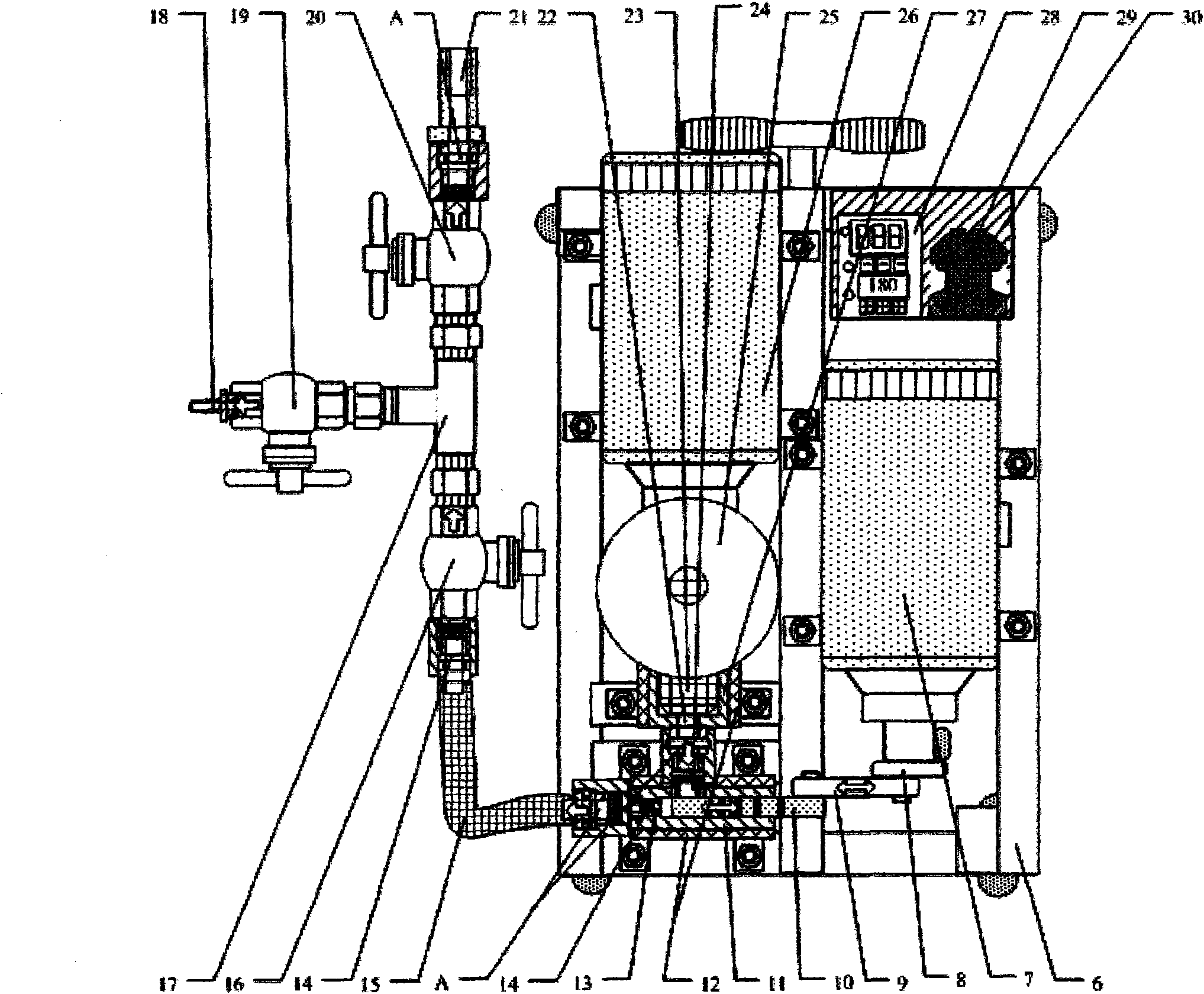

[0022] TPR material instead of air airless tire auxiliary component tire tire pressure positioning power-off device operation process: insert (43) the lower fixed rectangular single beam into the (5) wheel rim hollow of the wheel, and then (43) lower the fixed rectangular single beam Insert the (59) threaded pull rods welded together with (41) rectangular pull sleeves at both ends of the beam, and then install (50) the slide bar groove of the holder and the integrated (48) square head threaded ejector rod, (49) small bolts and (50) clamper upper and lower sliding block, (51) bearing sleeve, (52) bearing, (53) dovetail groove block, (54) rubber block, tighten (39) fixed clamper bolts, nuts and washers; Tighten two (48) square head threaded ejector rods to clamp (54) rubber block in (53) dovetail groove block, tightly clamp (5) wheel rim edge. It plays the role of stabilizing the tire pressure cut-off device. On (42), two ends of moving the rectangular double beams are inserted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com