Powerful inflating-free explosion-proof and anti-puncture tire of large motor bus or large truck

A non-inflatable, bus technology, used in non-pneumatic tires, road tires, tire parts, etc., can solve problems such as hidden safety hazards, inconvenience, and easy tire blowouts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

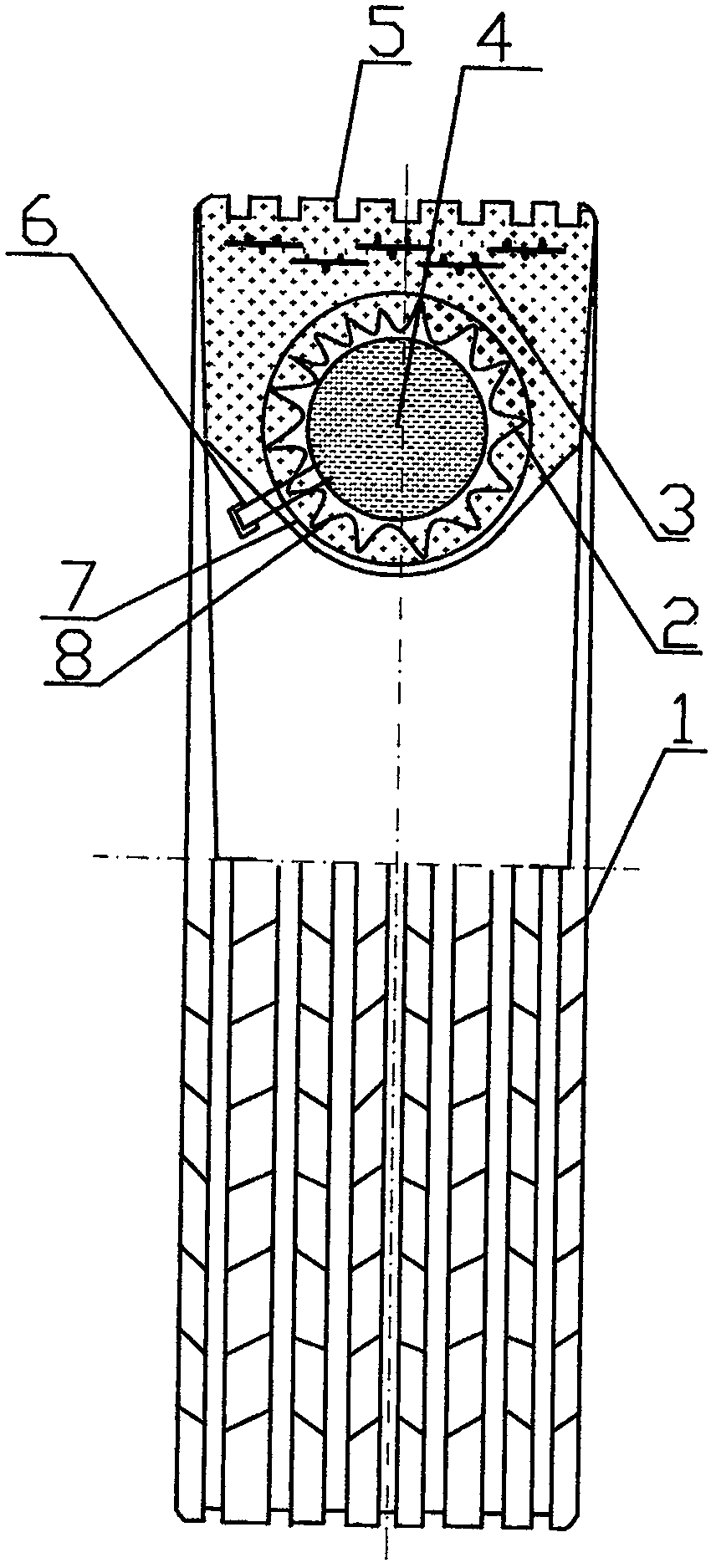

[0012] In the accompanying drawings, the structure of the tire 1 is made of the same process and materials as the ordinary tire, the difference is that the tire 1 is made into a sealed ring with an empty cavity inside, filled with silica gel 4, and the whole tire 1 is rotated along the direction of rotation of the tire. Add two layers of thin flat steel belt layers with staggered gaps, that is, the reinforced steel belt layer 3. The reinforced steel belt layer 3 can be made of high-elasticity and high-toughness elastic steel such as manganese steel. The gap is filled with a certain thickness of rubber, and the flat steel belt is punched with a number of spherical protrusions and pits on both sides, and the surface is frosted to increase the adhesion of rubber on the surface of the thin flat steel belt, and a layer of wire glue is wound outside the flat steel belt layer. Layer, and then in the direction along the tire ring (that is, at an angle of 90 degrees or close to 90 degre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com