Assembled buckle structure

A buckle structure, combined assembly technology, applied in the direction of transportation, packaging, vehicle parts, etc., can solve the problems of poor deformation ability of elastic clips, falling off of decorative strips, insufficient deformation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

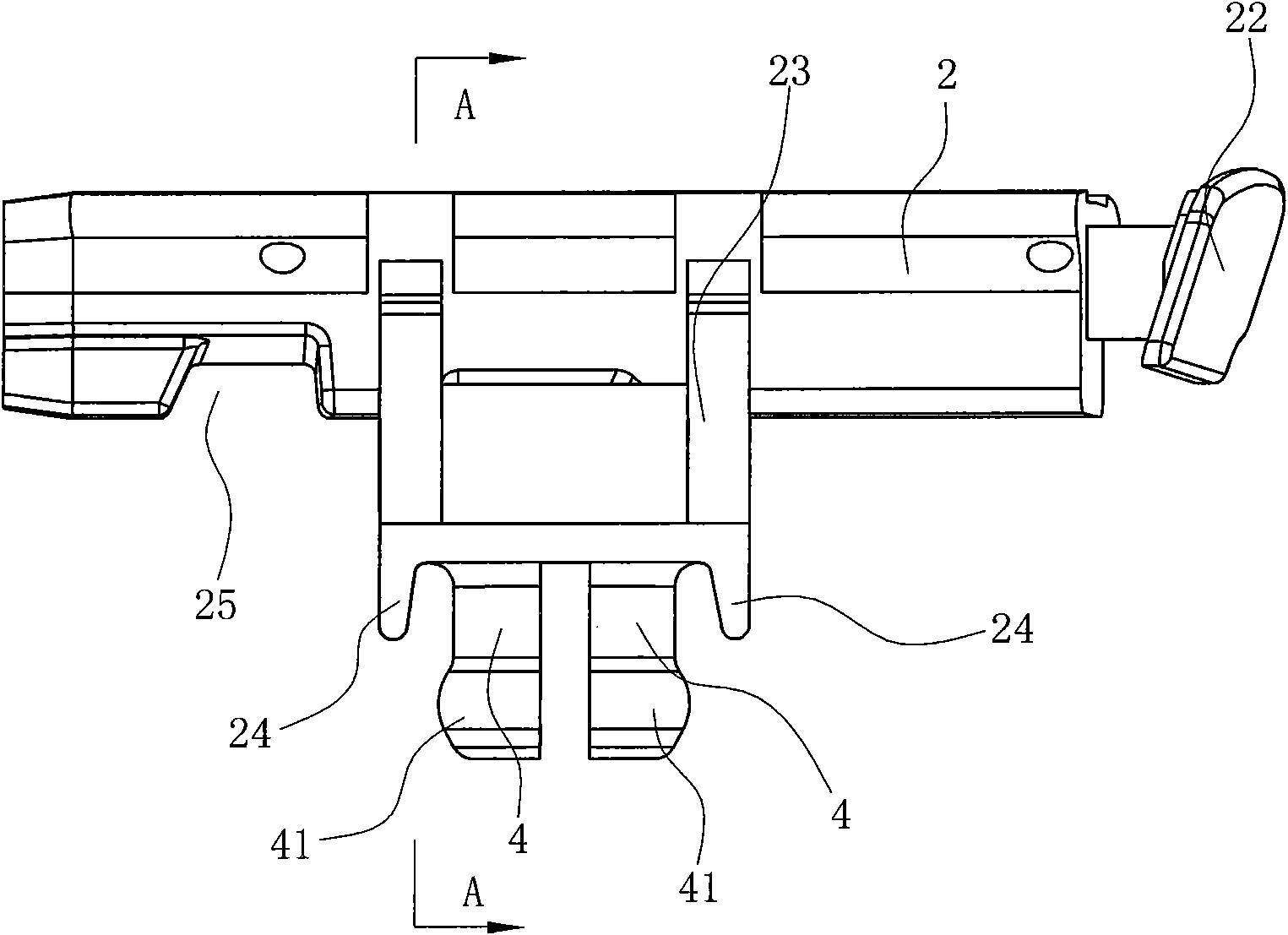

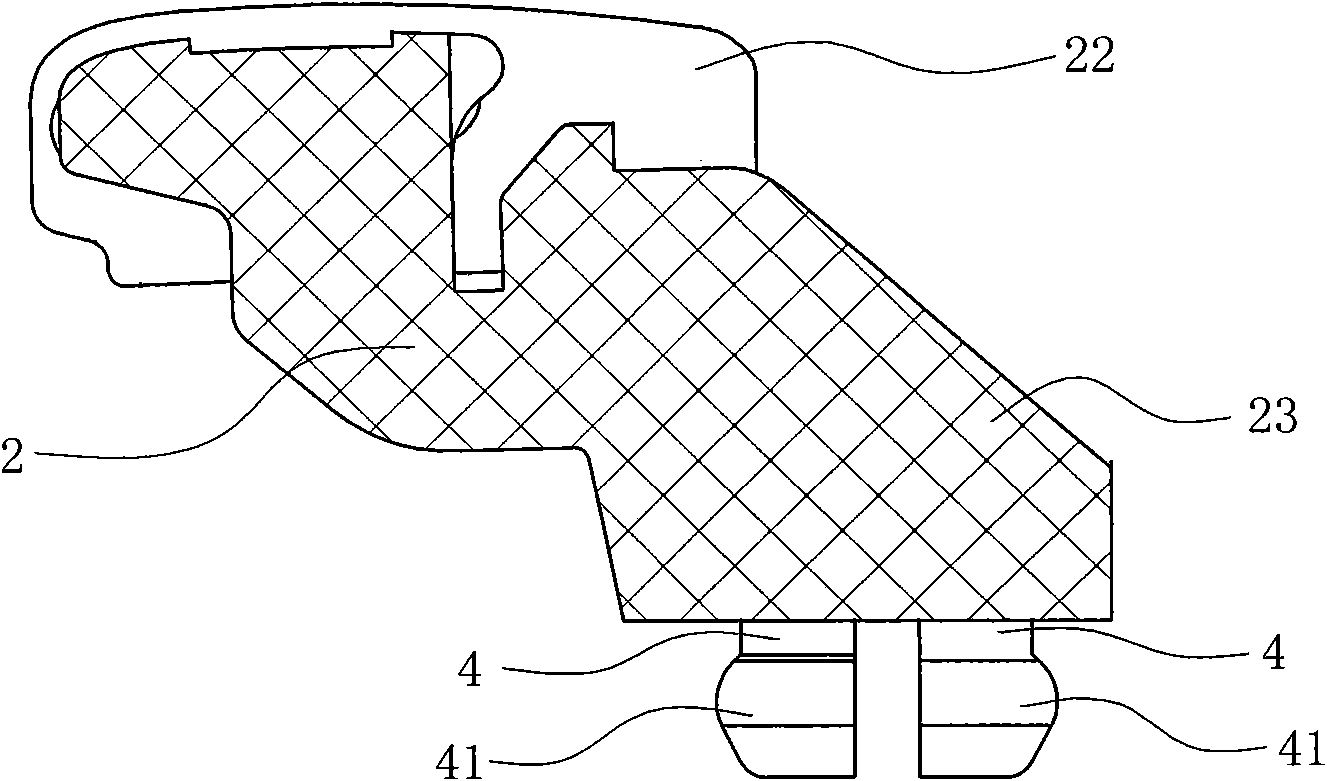

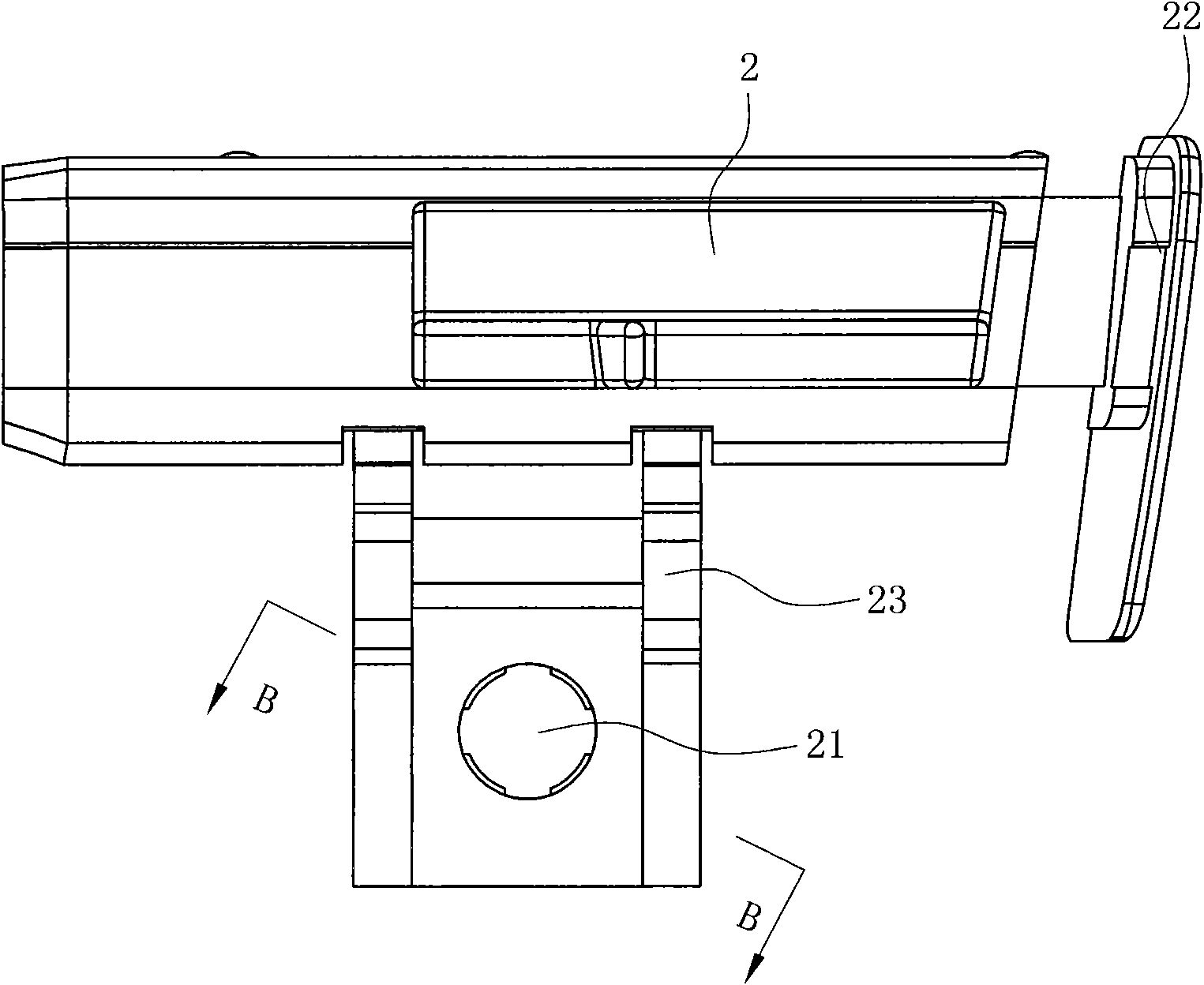

[0033] like Figure 1-13 Shown is an embodiment of the present invention.

[0034] A buckle structure adopting combined assembly, the buckle structure is a buckle for installing a door frame trim strip on a door frame.

[0035] like Figure 1~5 As shown, it includes a base 2 for inserting into the decorative strip 1 (door frame trim) for the positioning of the decorative strip 1. The base 2 has a decorative surface 22 that can cover the outer end surface of the decorative strip 1. The surface of the decorative surface 22 is Chrome plating is performed to match the color of the decorative strip, and the front of the base body 2 has a bayonet 25 for auxiliary fixing of the decorative strip 1 . The side portion of the base body 2 has a connecting portion 23 extending forward, and the lower end surface of the connecting portion 23 has a protrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com