Automatic roller winding machine

A roll-rolling and automatic technology, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems that the cloth is not easy to be rolled, and the friction force of the driving roll is not enough, so as to achieve convenient rolling, convenient recording, The effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

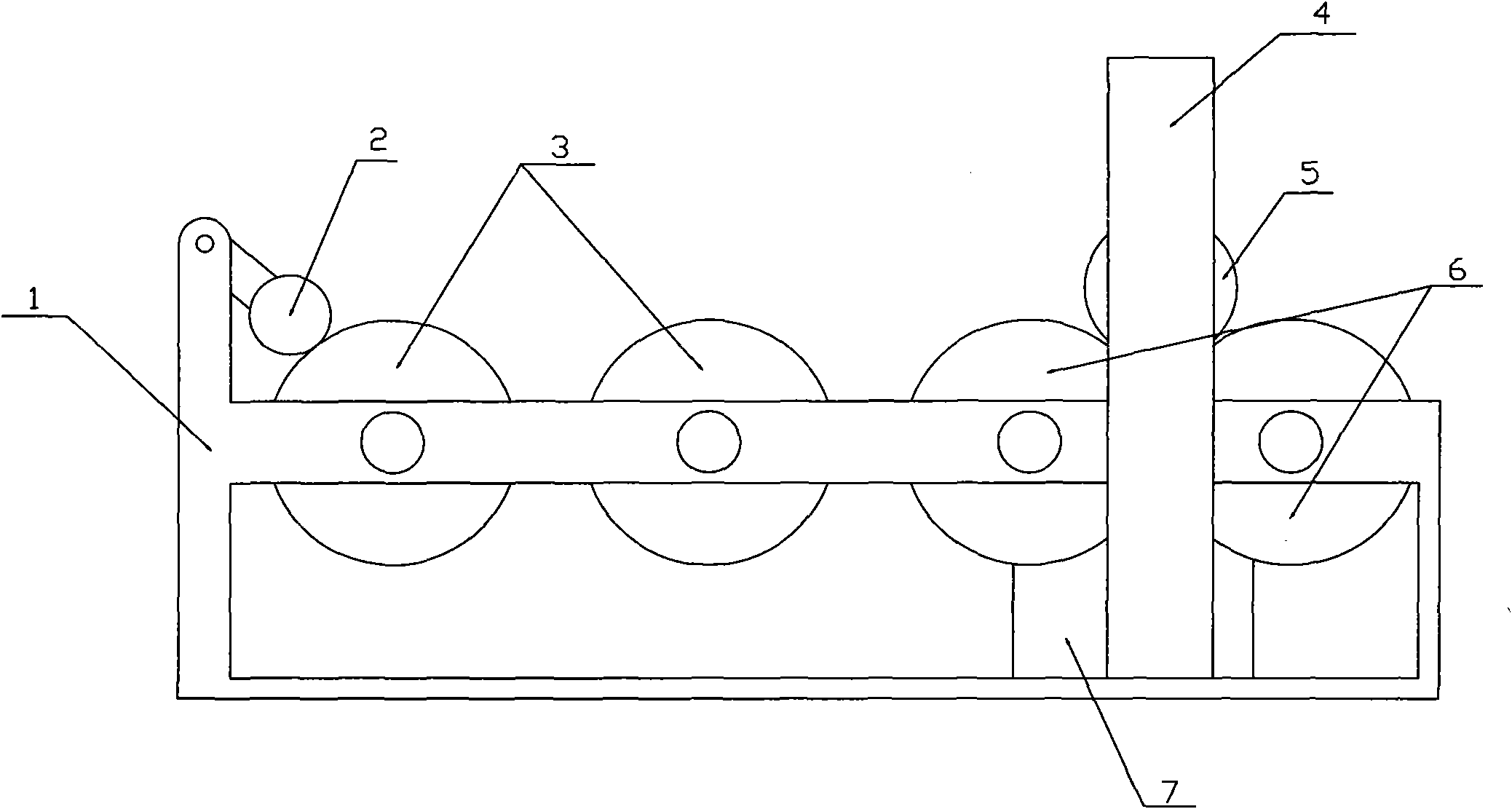

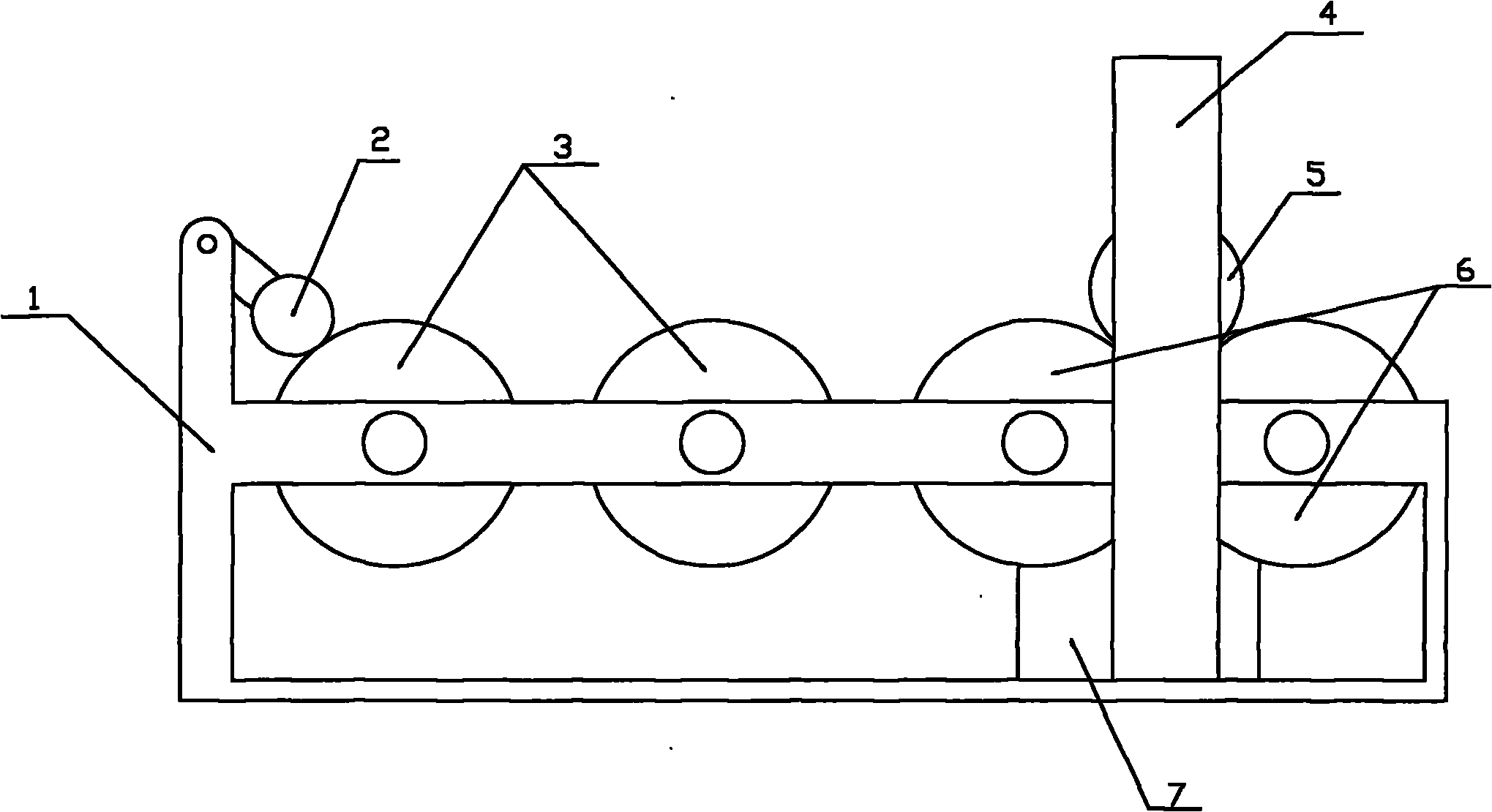

[0011] Such as figure 1 The schematic diagram of a kind of automatic rolling machine shown, comprises support 1, and support 1 is provided with conveying roller 3 and driving roller 6, and the top of driving roller 6 is provided with winding material roller 5, and the surface of described driving roller 6 is provided with There are wooden slats. The coiling roll 5 is movable and is located in the guide rail 4 in the vertical direction. The coiling roll 5 is pressed on the driving roll 6 by gravity, and the driving roll 6 rotates to drive the coiling roll 5 . In order to conveniently record the length of the rolled cloth, the conveying roller 3 is also provided with a code counter 2 .

[0012] The cloth passes through the counter 2 and the conveying roller 3, enters the middle of the two driving rollers 6, and is wound on the winding roller 5. The motor 7 moves to drive the driving roller 6 to rotate, and the driving roller 6 drives the winding roller 5 to rotate, and the clot...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap