Cylinder type electronic needle selecting device

An electronic needle selection and cylinder type technology, which is applied in knitting, weft knitting, textiles and papermaking, etc., to achieve the effect of improving adaptability, increasing production capacity and quick replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

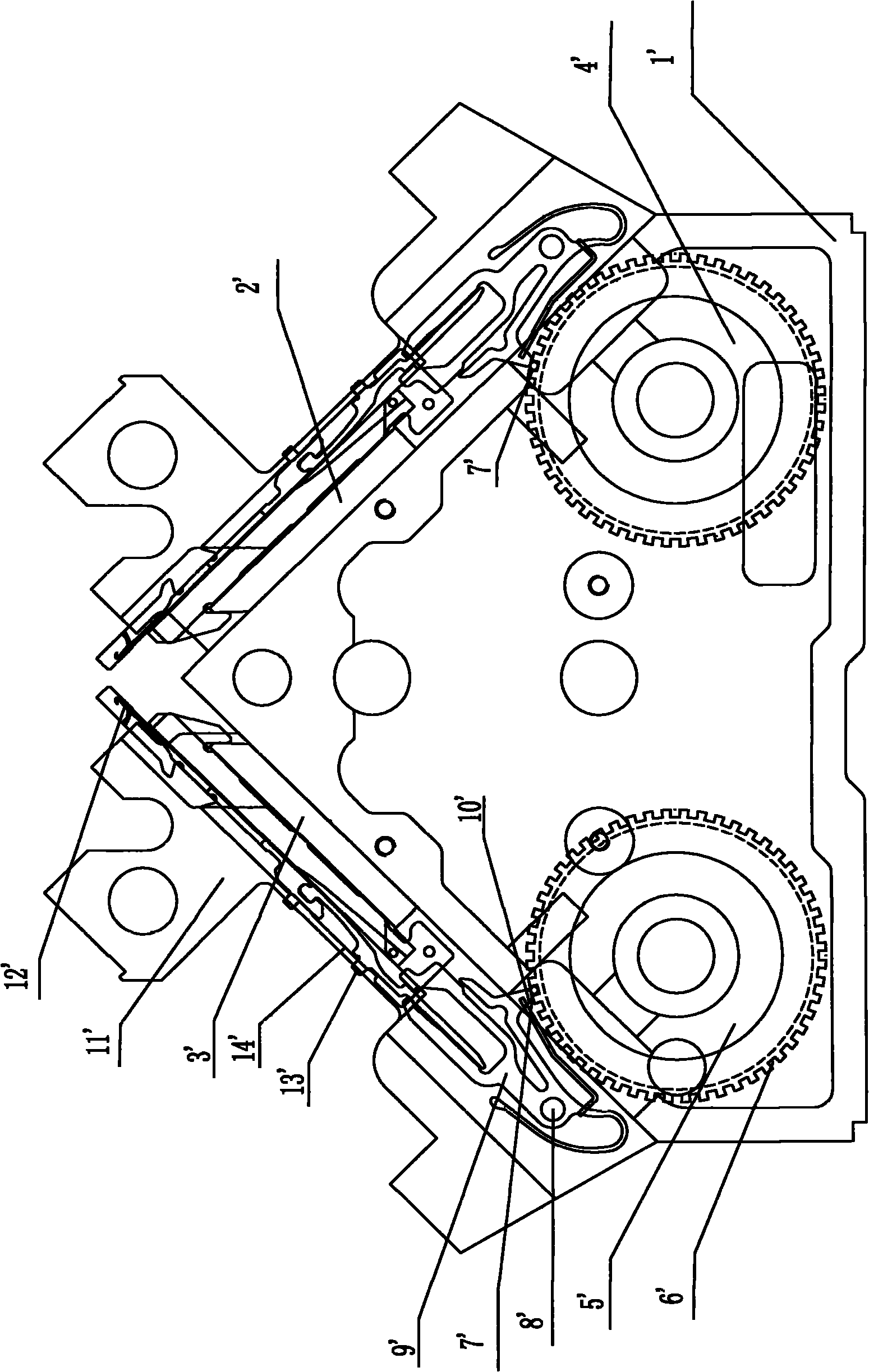

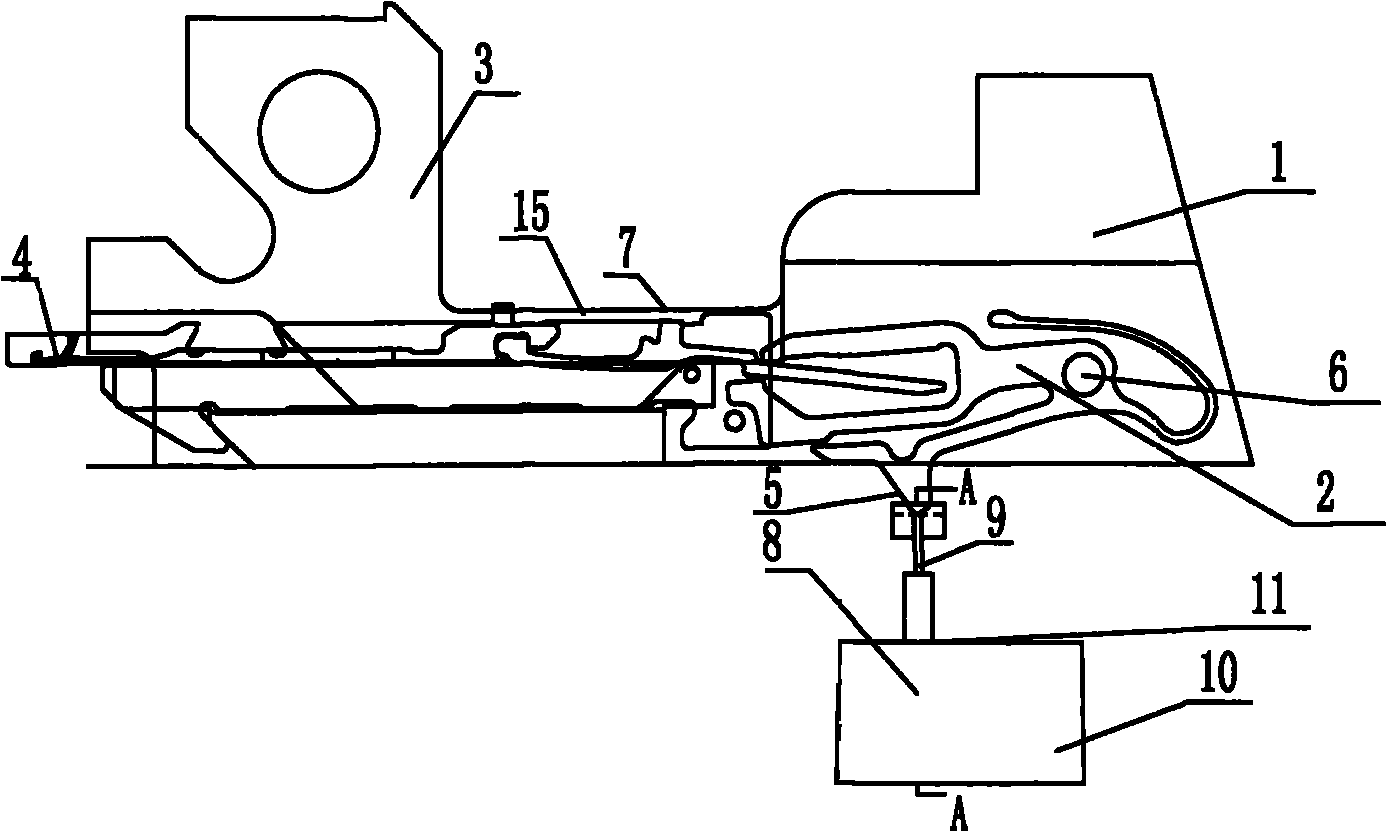

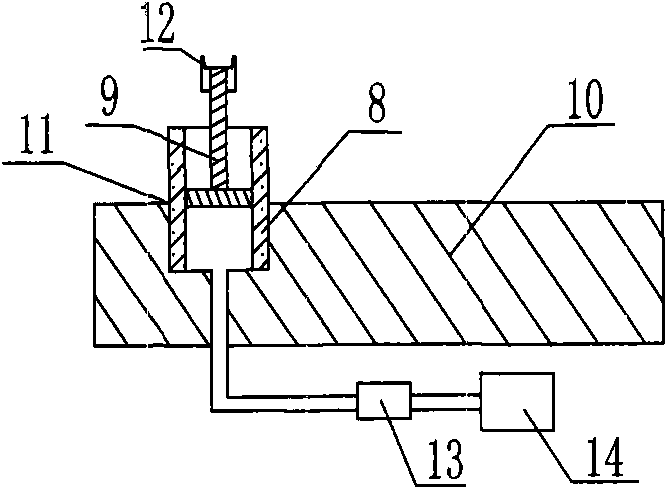

[0019] The electronic needle selection device of a cylinder type glove machine referred to in the present invention includes a needle plate 1 installed on a frame, on which a bird piece 2, a machine head 3, and knitting needles 4 are installed. The bird piece 2 includes the bird piece protrusion 5, the bird piece shaft 6, and the needle butt 7, wherein the bird piece 2 is fixedly connected with the needle plate 1 through the bird piece shaft 6, and the cylinder type needle selection device is installed on the frame below the needle plate 1, The cylinder type needle selection device includes a cylinder 8, a piston 9, and a cylinder frame 10, wherein the cylinder frame 10 is installed on the frame below the needle plate 1, and the cylinder frame 10 is provided with a hole 11, and the hole 11 is fitted with a Cylinder 8, piston 9 is installed in the cavity of cylinder 8, and the head of piston 9 is provided with groove 12, and the depth of groove 12 matches with the thickness of b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com