Separator with filtering function

A separator and functional technology, applied in the field of adhesive glue stirring device, can solve problems such as blocking glue return pipe, uneven surface of thin felt, affecting product quality, etc., and achieve the effect of ensuring normal production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

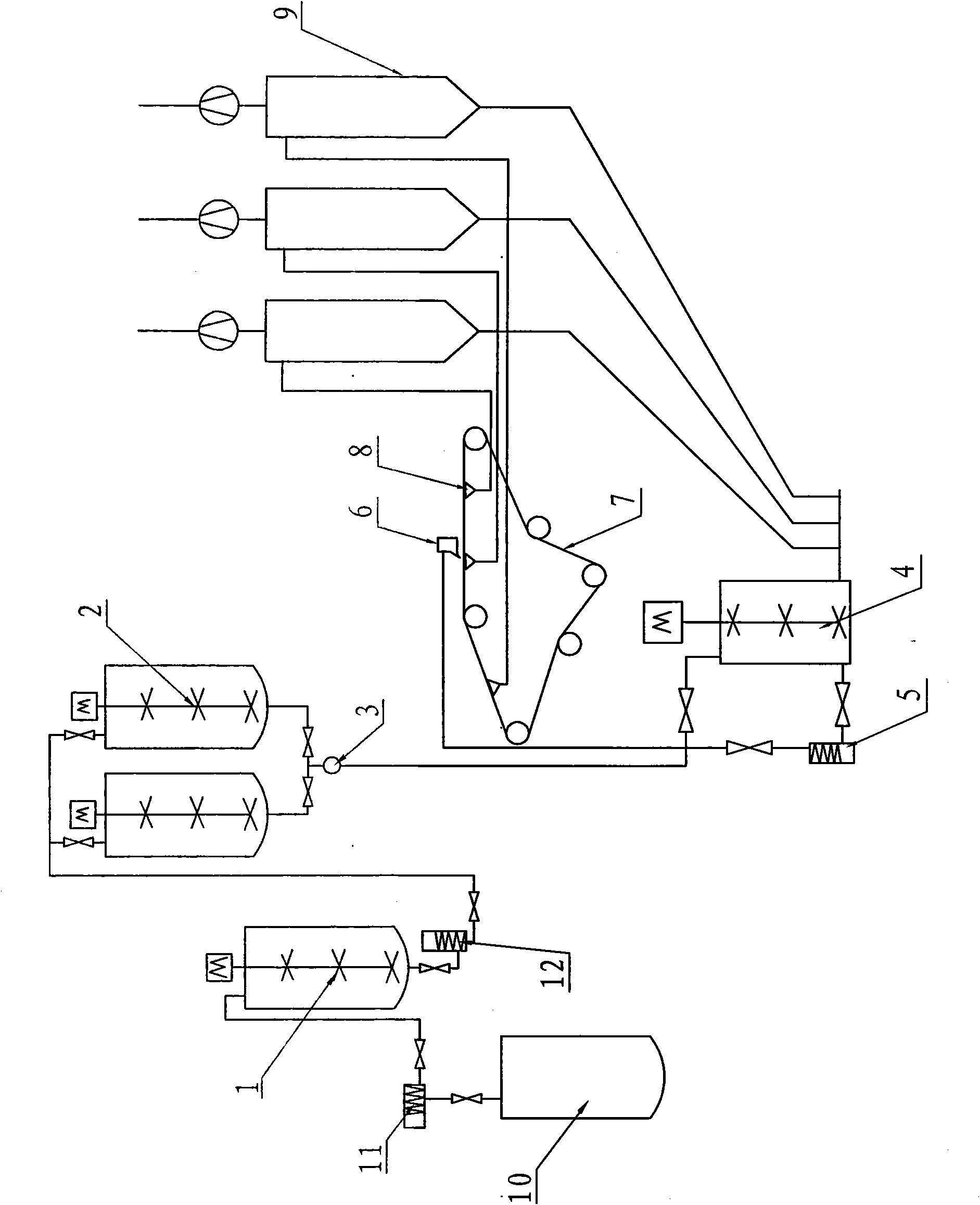

Method used

Image

Examples

specific Embodiment approach

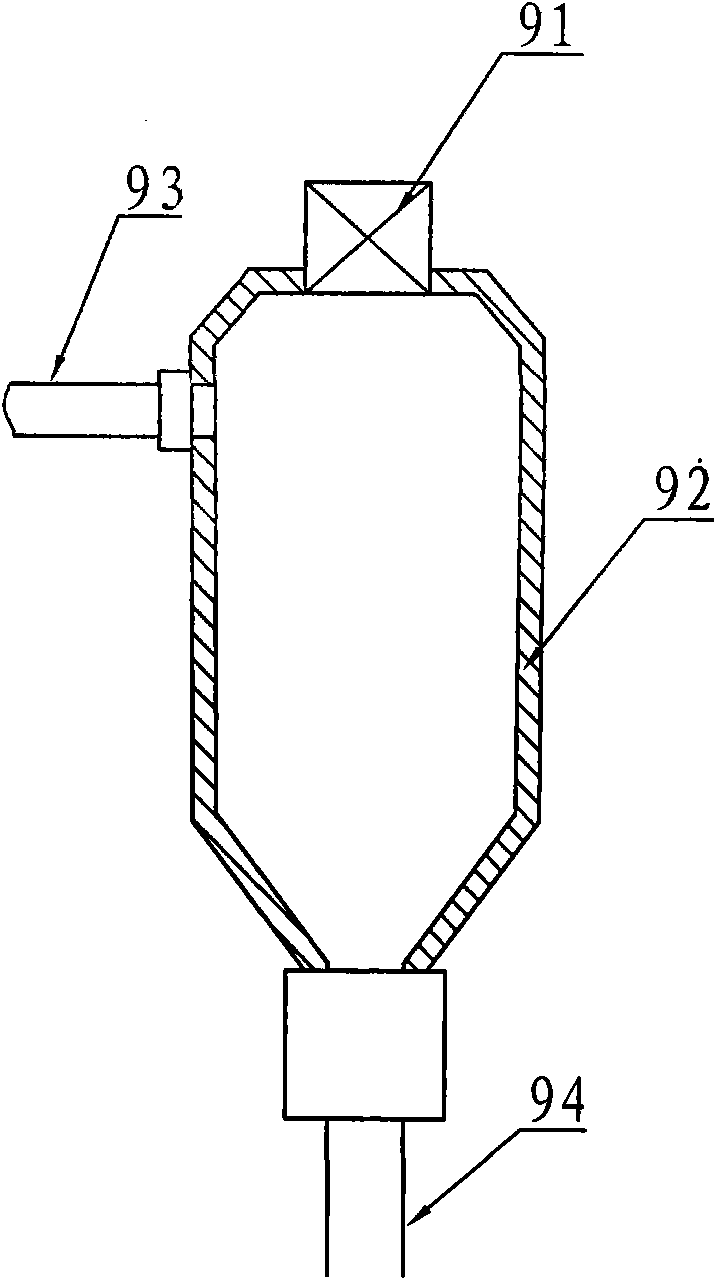

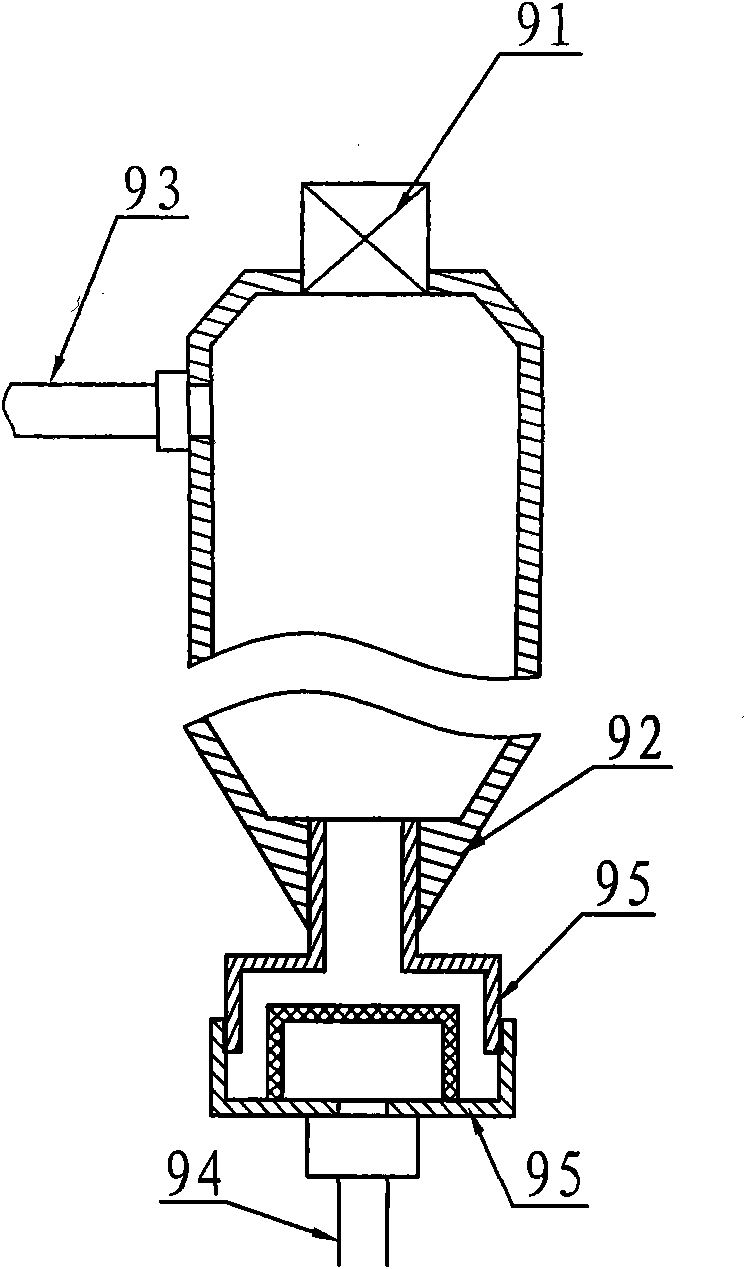

[0019] The separator with filtering function, such as image 3 As shown, it includes a fan 91, a bucket-shaped housing 92, a glue suction pipe 93 and a rubber discharge pipe 94. The fan 91 is installed above the bucket-shaped housing 92 and communicates with the inner cavity of the bucket-shaped housing 92. The glue The liquid suction pipe 93 is located on the upper side of the bucket-shaped casing 92, and is also connected with the inner cavity of the bucket-shaped casing 92. The rubber discharge pipe 94 is arranged at the lower end of the bucket-shaped casing 92, and is connected to There is a filter 95, and the filter 95 is connected to the rubber discharge pipe 94.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com