Multifunction integrated valve

An integrated valve, multi-functional technology, applied in the components of the pumping device for elastic fluids, rotary piston type/swing piston type pump components, machines/engines, etc., can solve the insufficient temperature control function of the multi-functional integrated valve and other problems, to achieve the effect of solving the lack of temperature control function and improving the sensitivity of temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

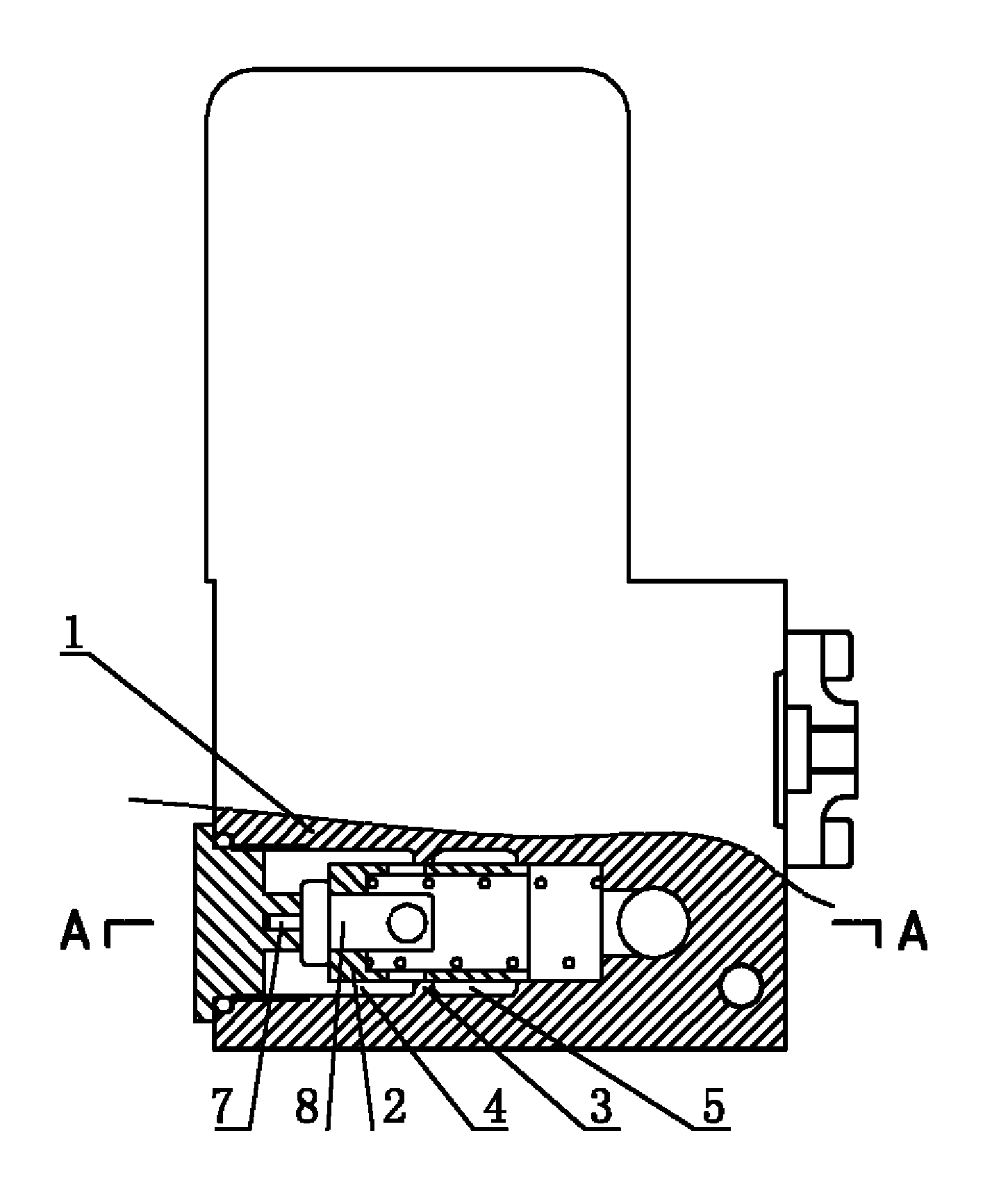

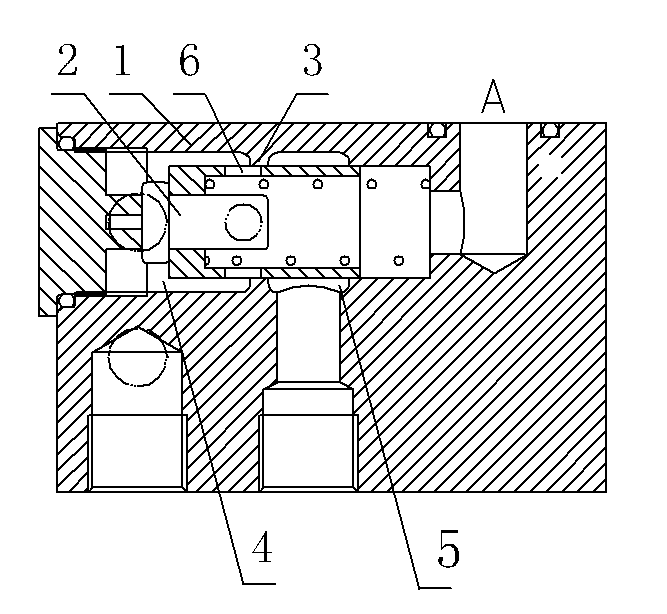

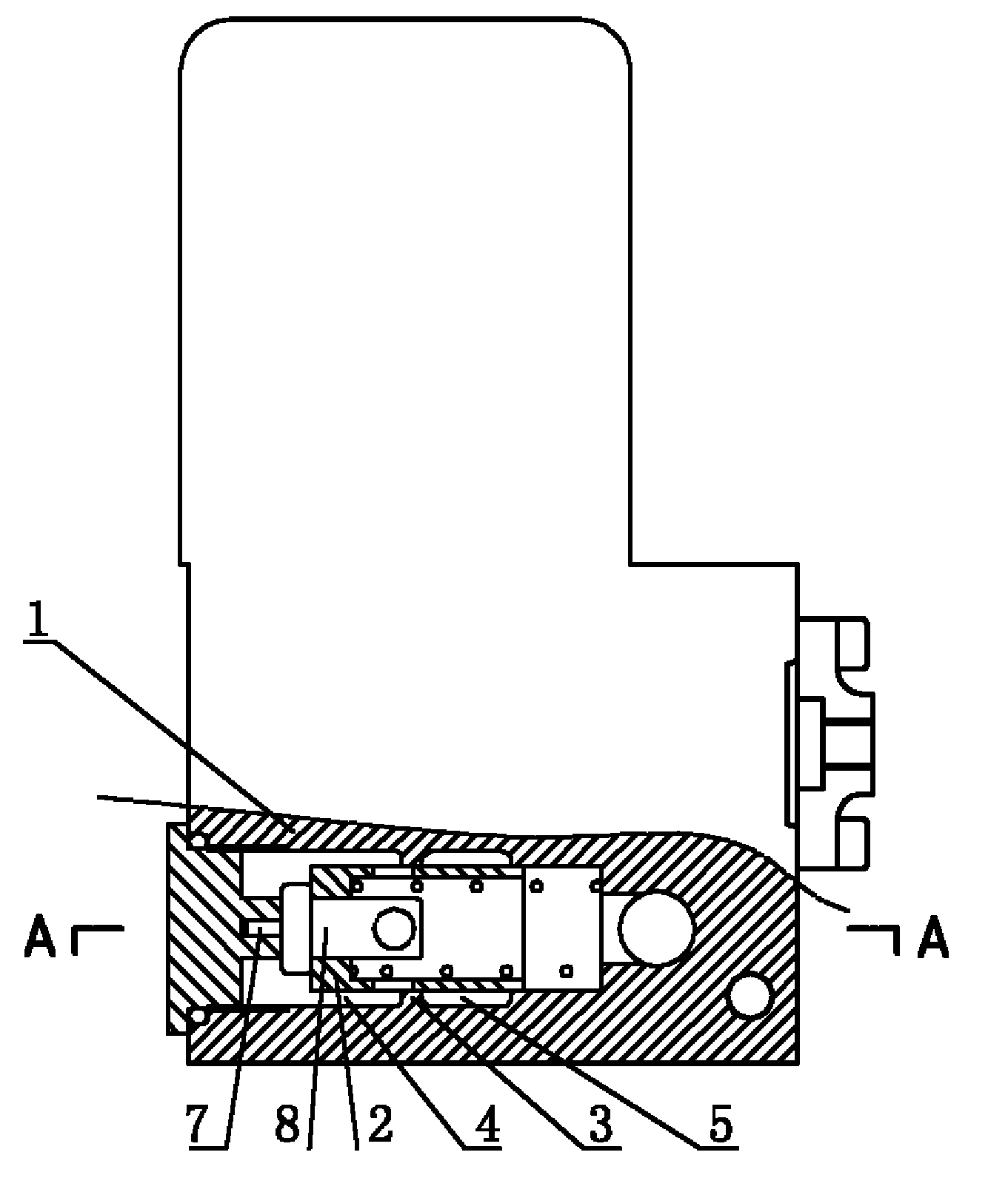

[0009] See figure 1 with figure 2 , the present invention includes a valve body 1, the valve body 1 is connected to an oil filter, the valve body 1 is embedded with an oil cut-off valve assembly and a temperature control valve assembly, the temperature control valve assembly includes a temperature control valve core 2, and the temperature control valve core 2 is installed In the temperature control valve cavity of the valve body 1, the valve body 1 is processed with an annular step 3 on the peripheral surface of the temperature control valve cavity, and the annular step 3 cooperates with the temperature control valve core 2 to divide the temperature control valve cavity into a left cavity 4 and a right cavity 5. There is a circular hole 6 on the surface of the temperature control valve core 2 . The left cavity 4 communicates with the oil filter, and the right cavity 5 communicates with the external oil cooler; the temperature control valve assembly also includes a telescopic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com