Patents

Literature

32results about How to "Area adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

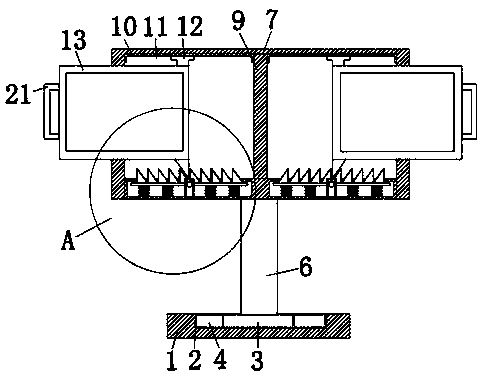

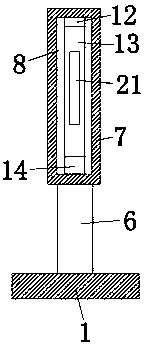

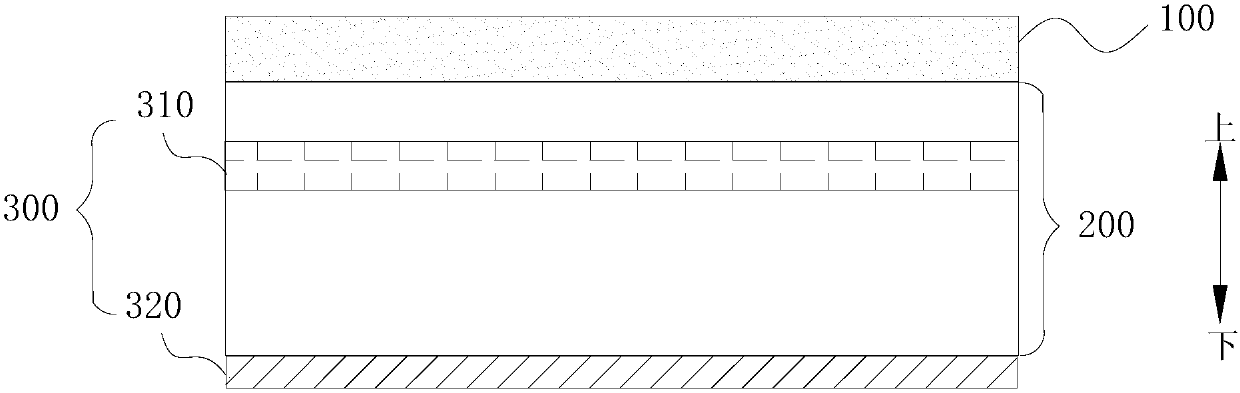

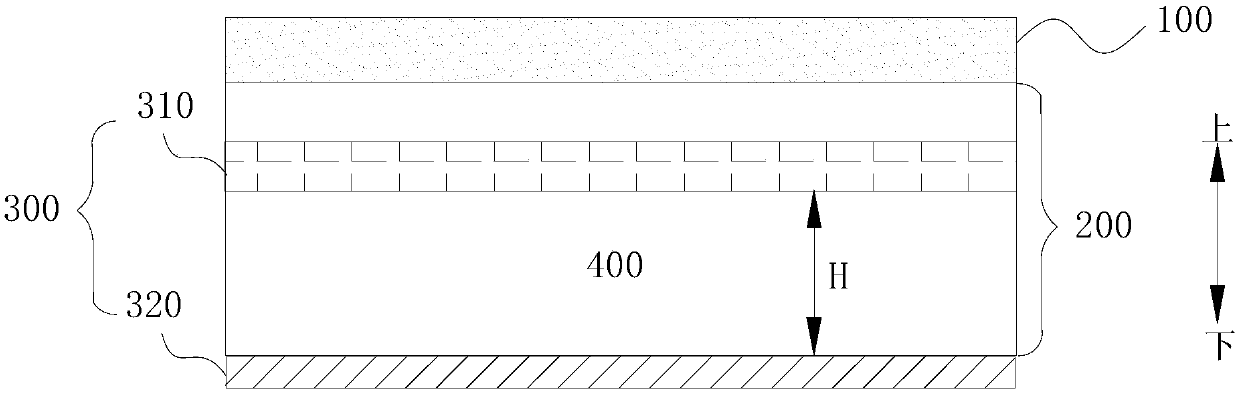

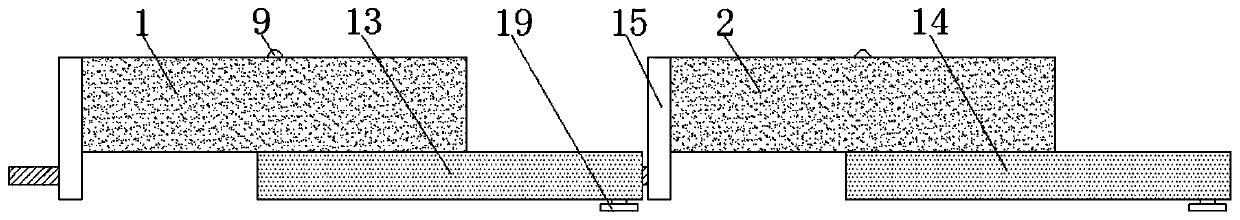

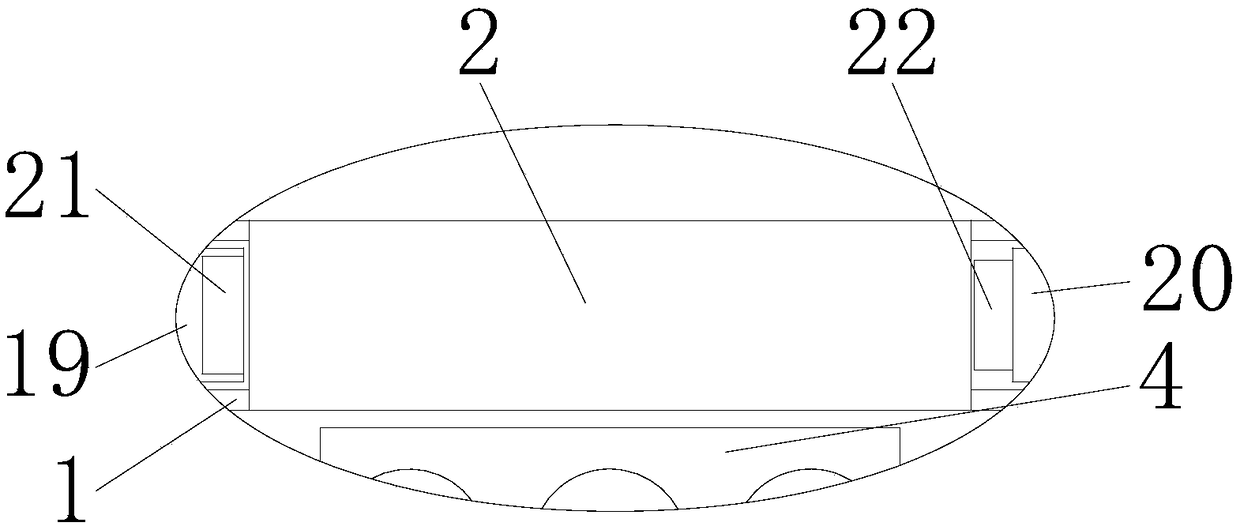

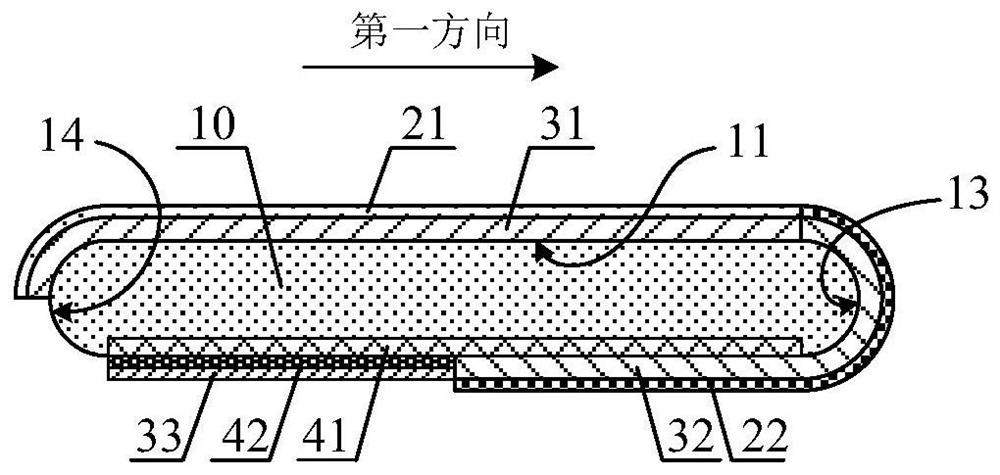

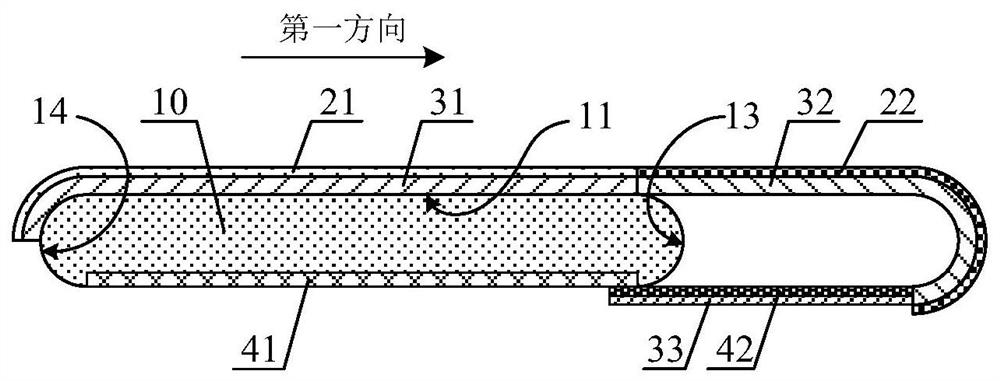

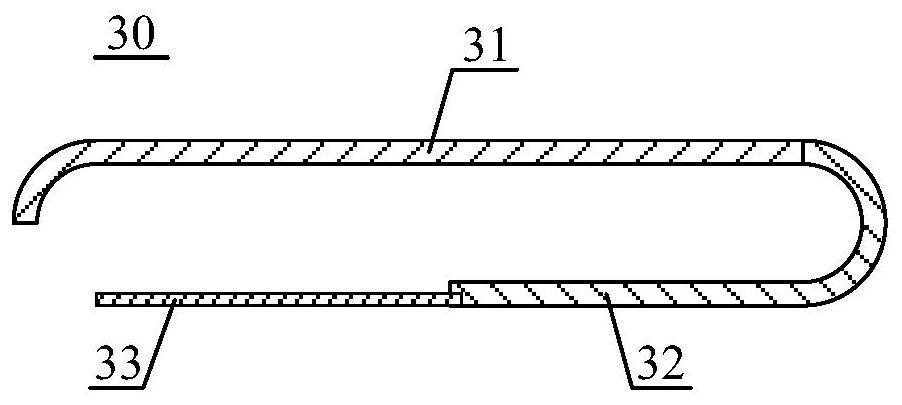

Display device and using method thereof

ActiveCN110868486AIncrease the display area towards the frontDisplay area adjustment towards the frontDevices with multiple display unitsTelephone set constructionsComputer hardwareComputer graphics (images)

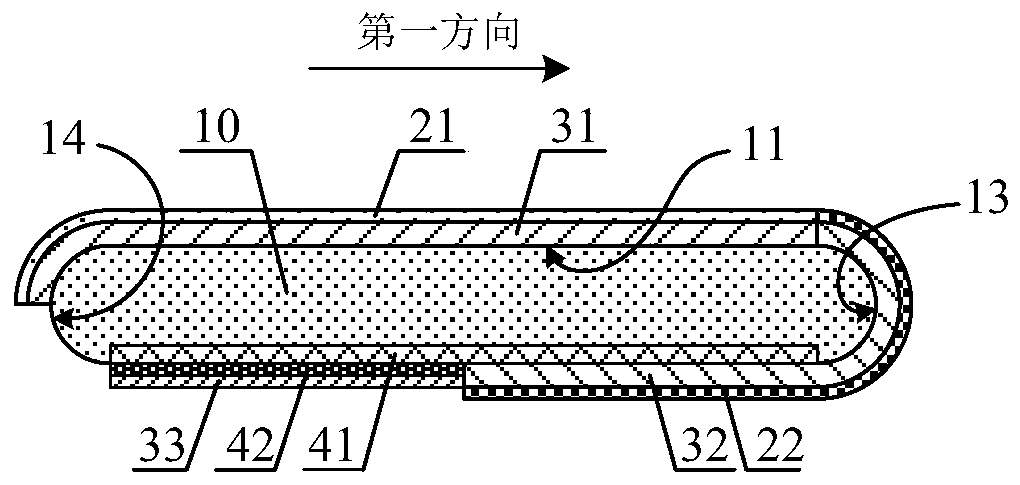

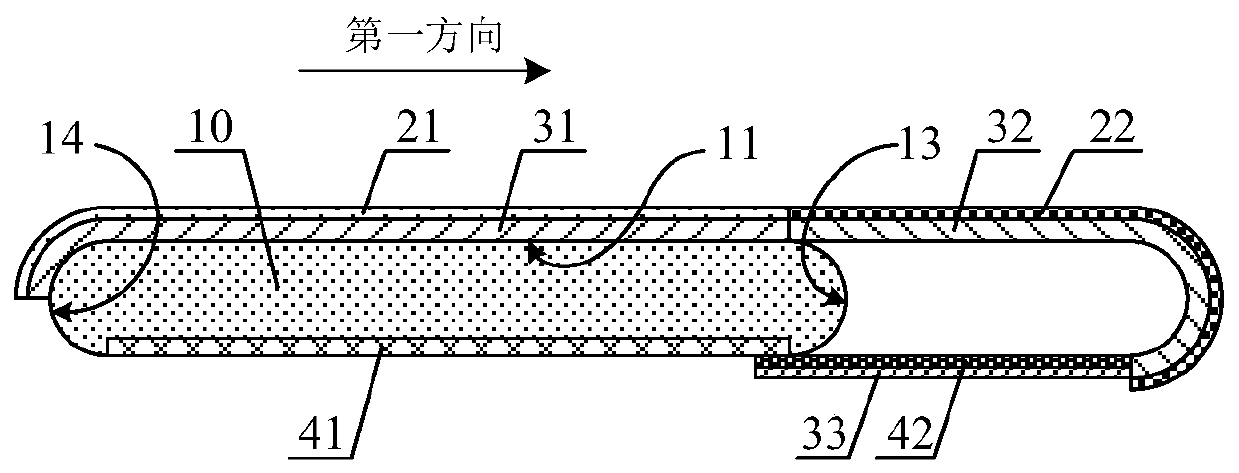

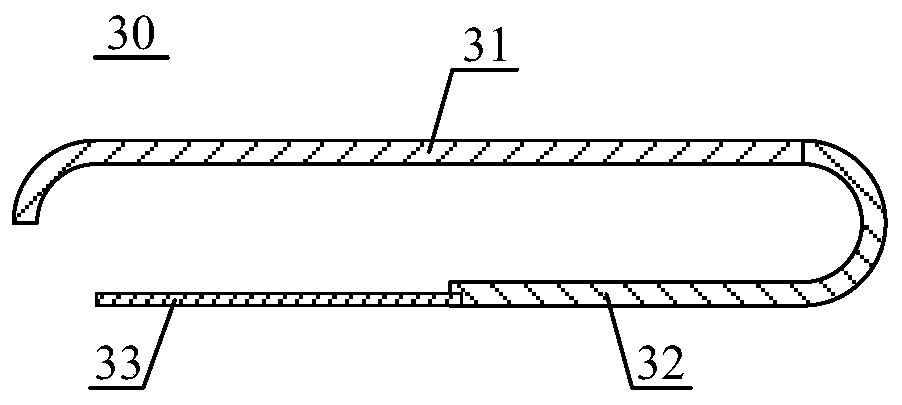

The invention discloses a display device and a using method thereof. The display device comprises a main body, and a first display screen and a flexible second display screen which are arranged alonga first direction; the main body comprises a front surface facing one side of a user and a back surface opposite to the front surface; the first display screen is arranged on the front surface; one end, close to the first display screen, of the second display screen is arranged on the front surface; the end, away from the first display screen, of the second display screen is arranged on the back face through a first sliding mechanism and slides in the first direction through the first sliding mechanism, so that the area of the side, facing the front face, of the second display screen is increased or decreased. According to the display device, the second display screen is driven by the first sliding mechanism to slide, so that the display area of the display device in the front direction isexpanded, the thickness of the display device is not increased, and the display device is convenient to store and carry.

Owner:BOE TECH GRP CO LTD

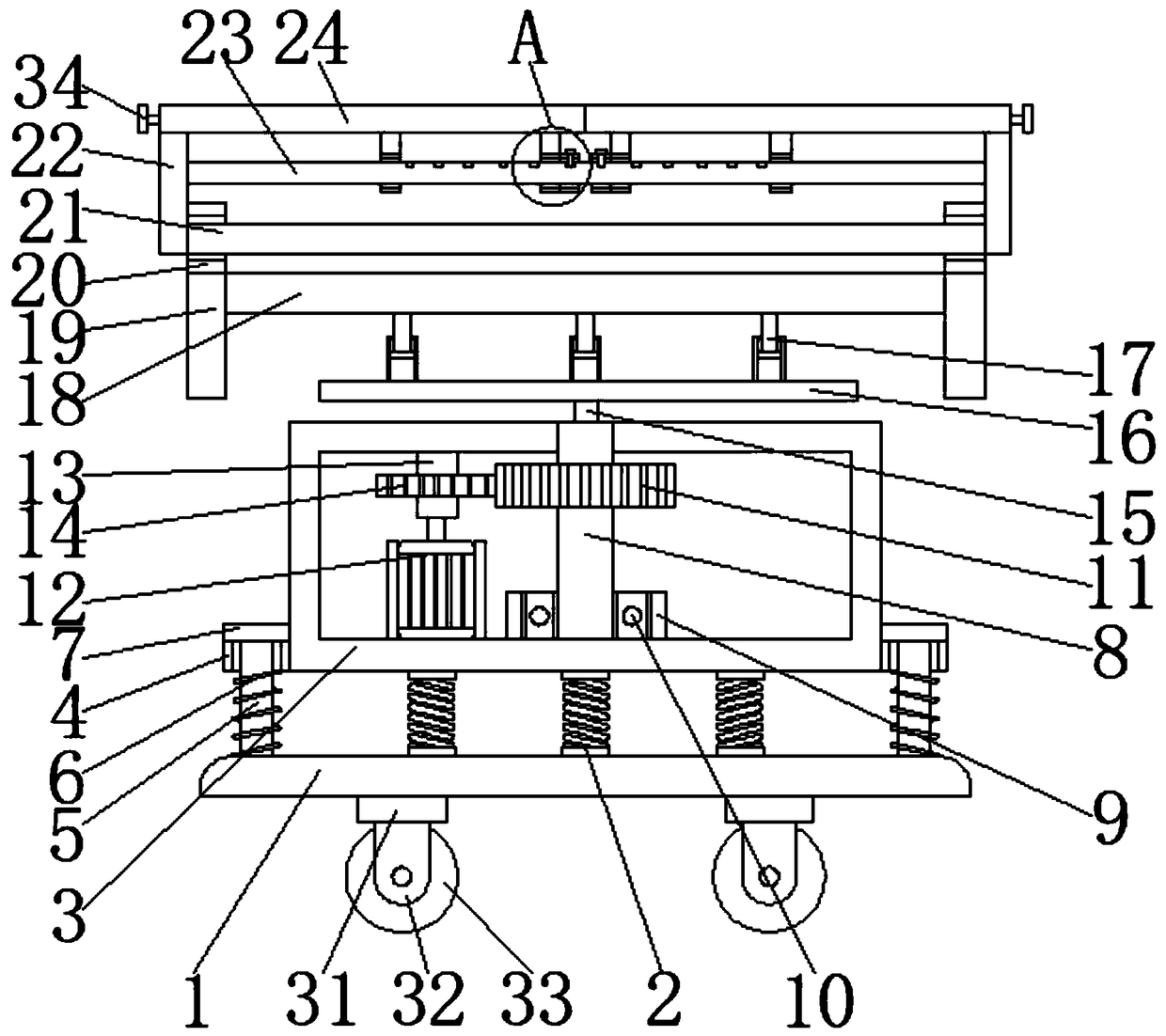

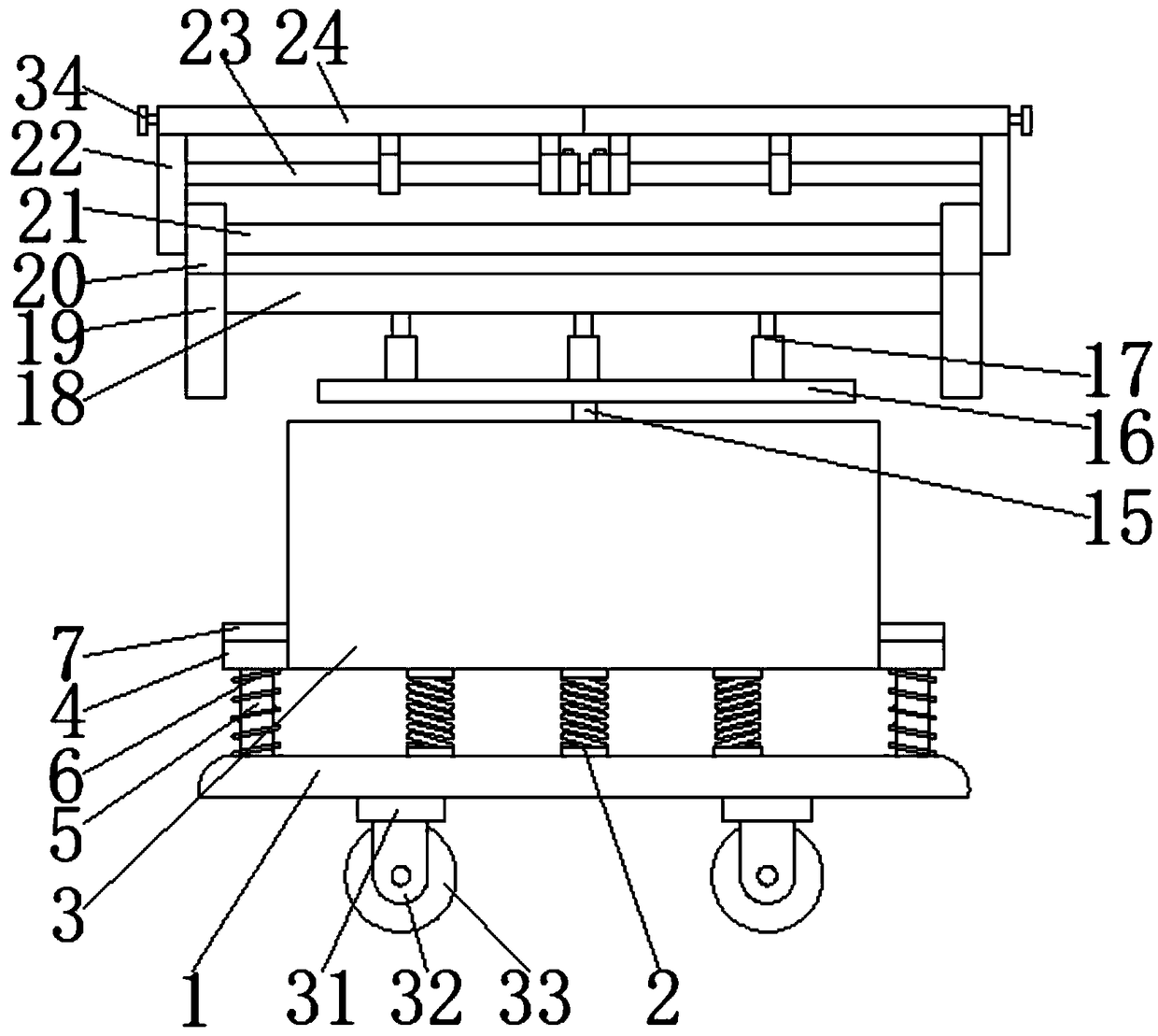

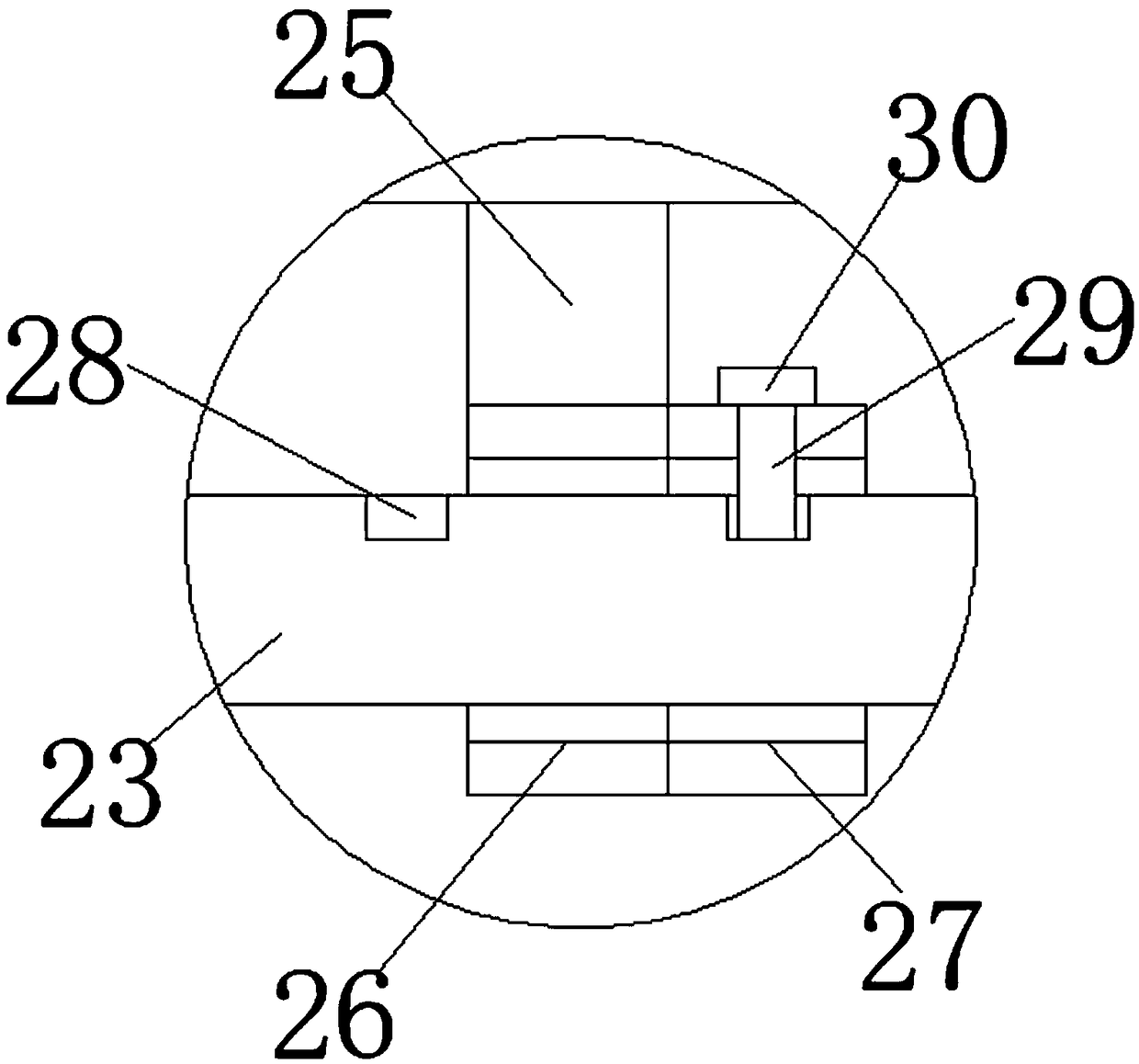

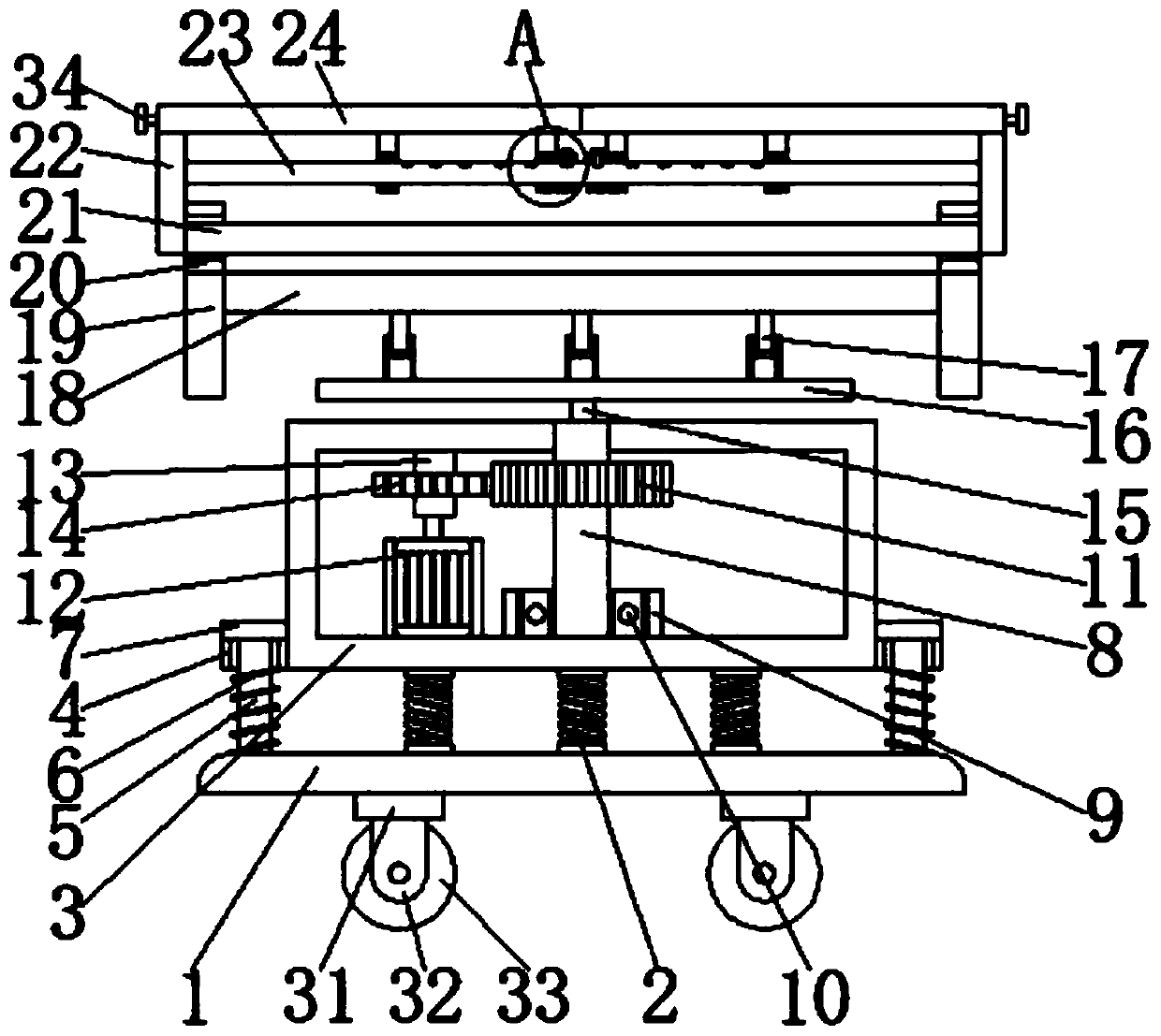

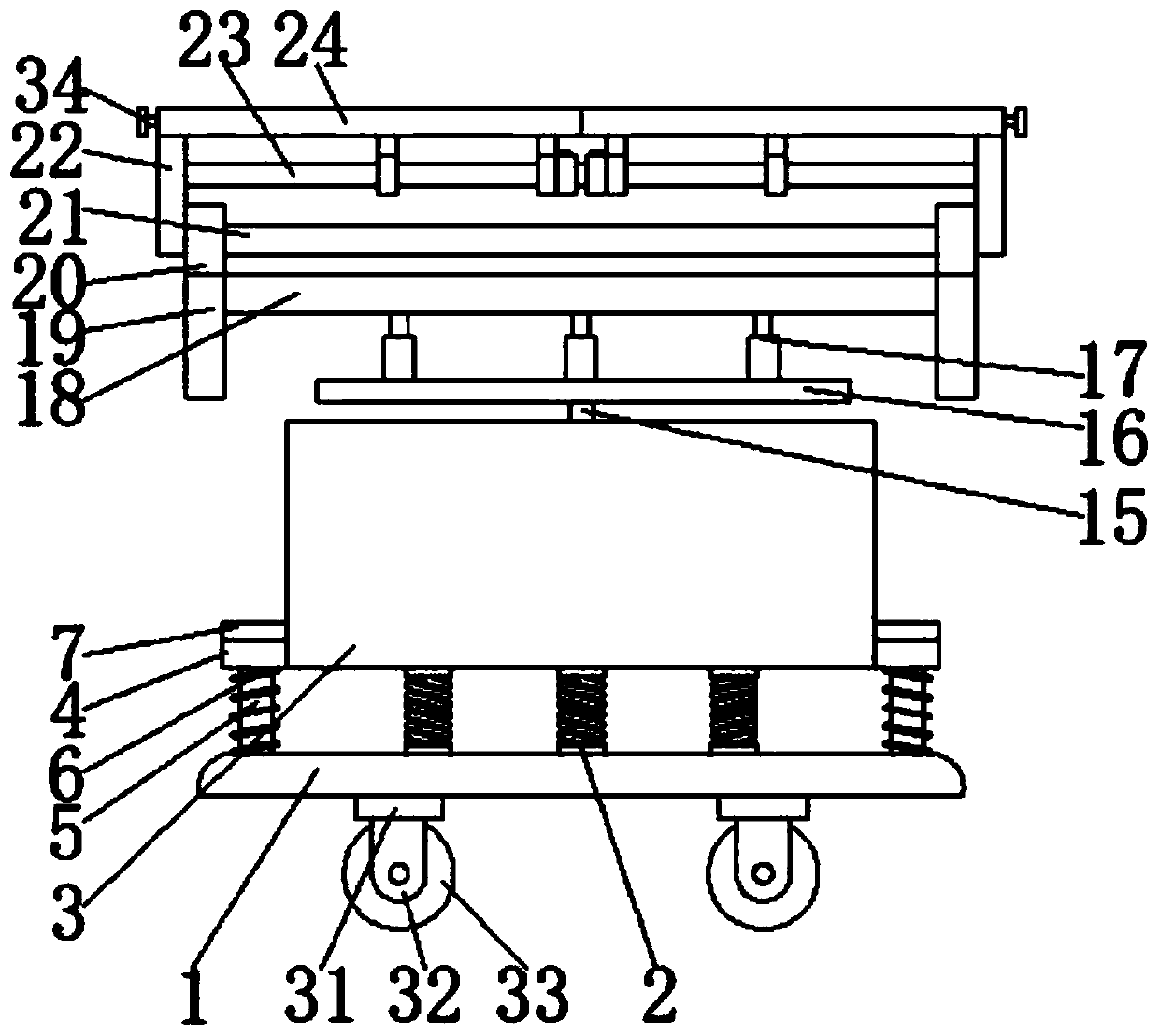

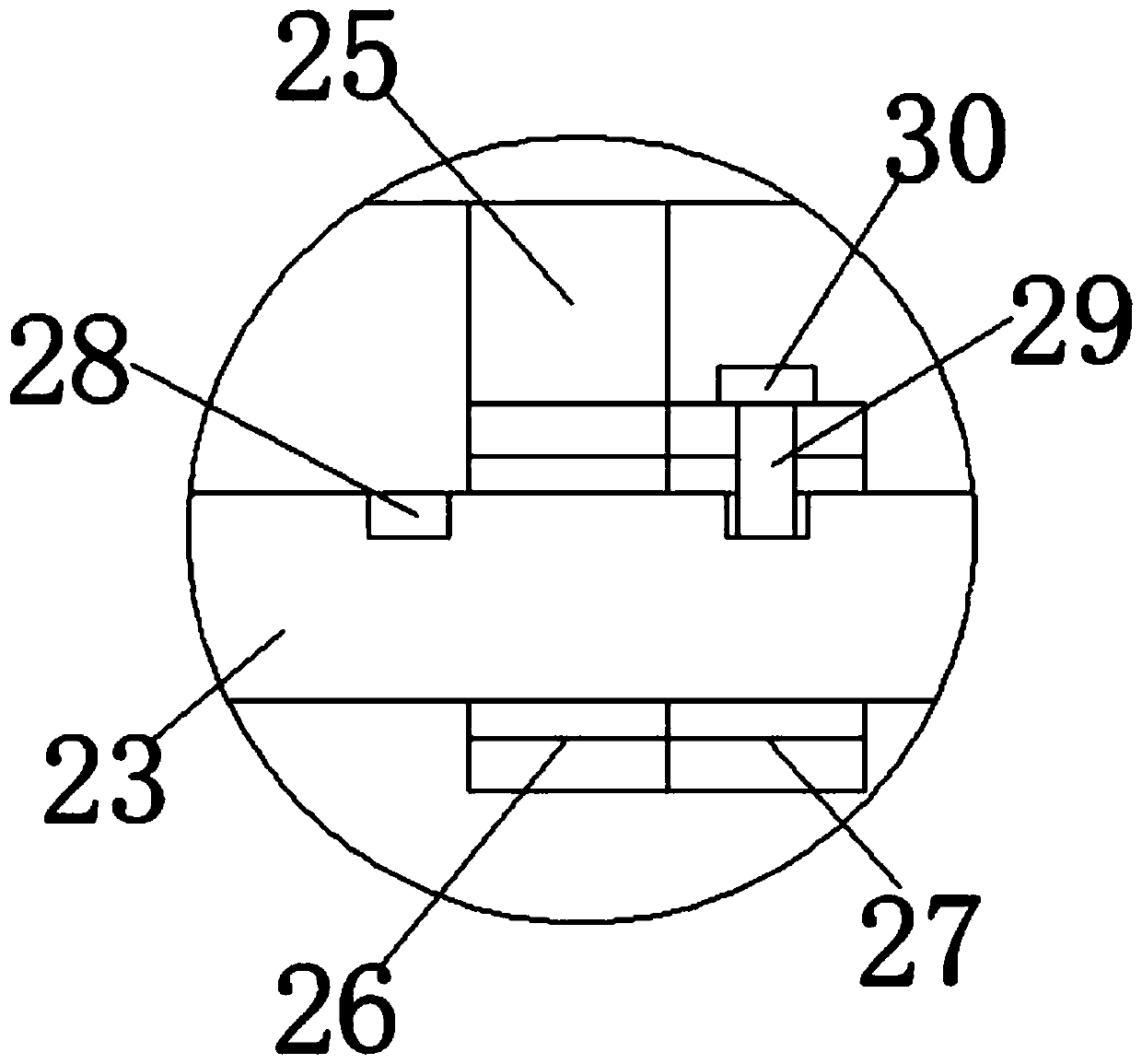

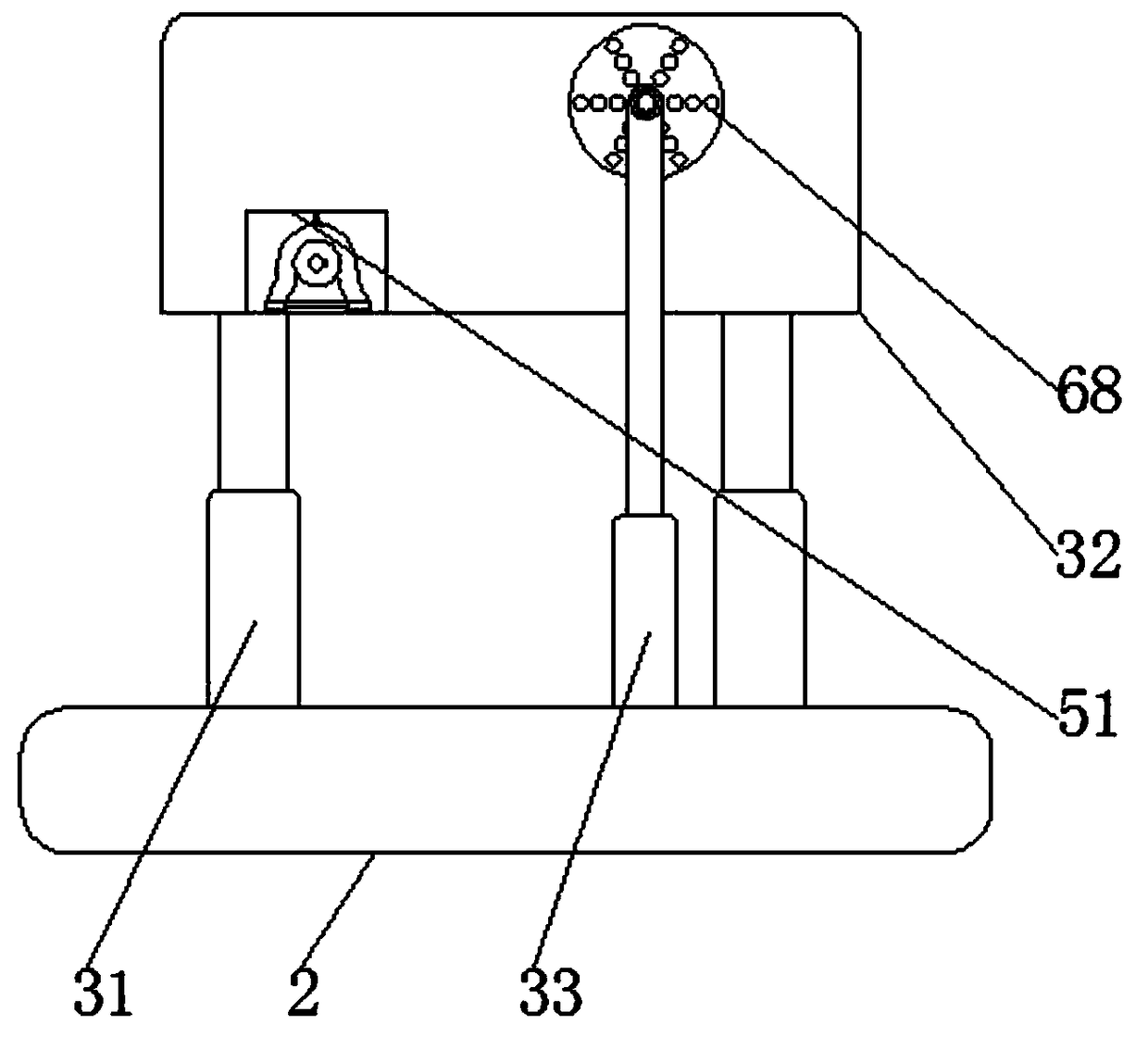

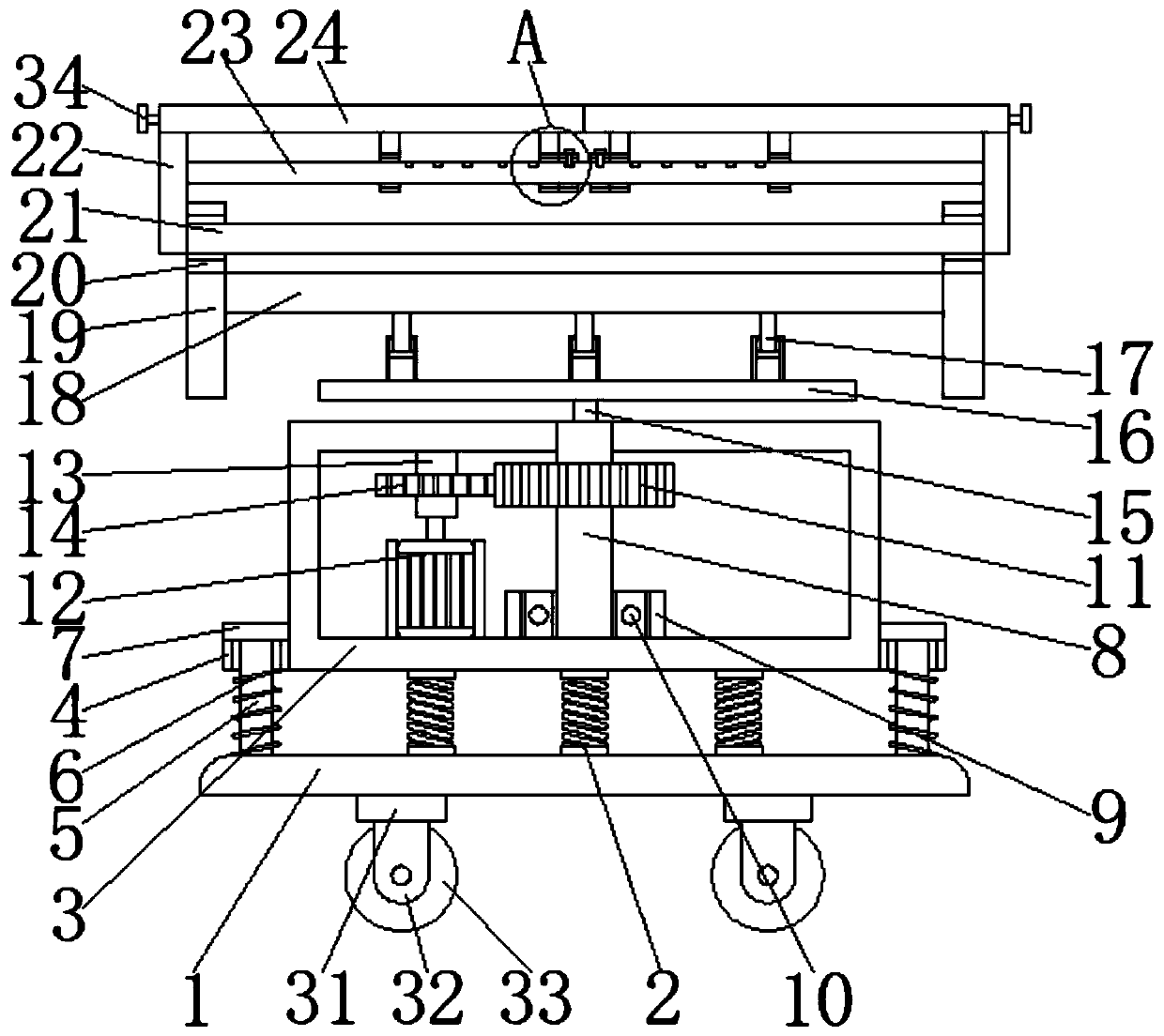

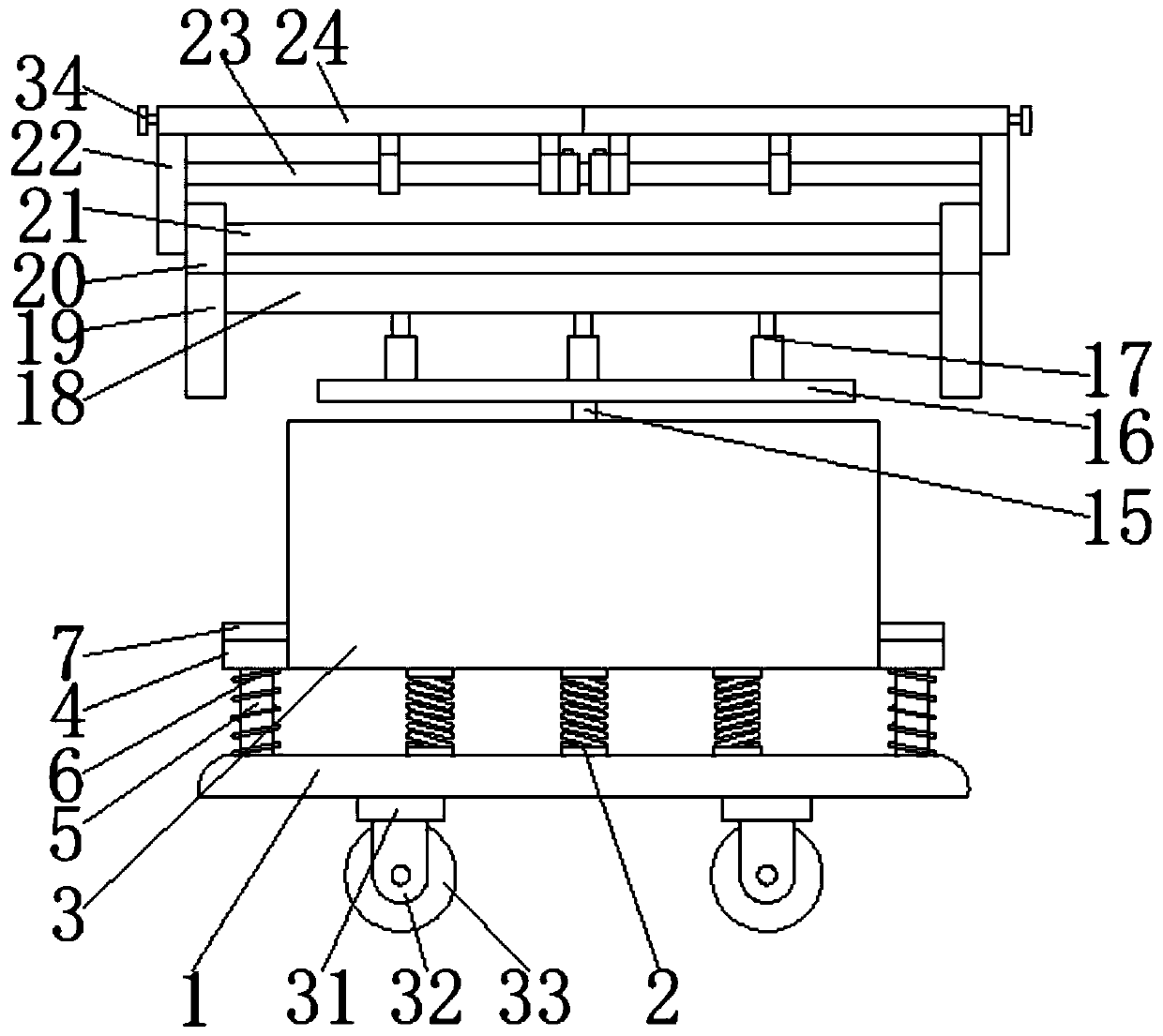

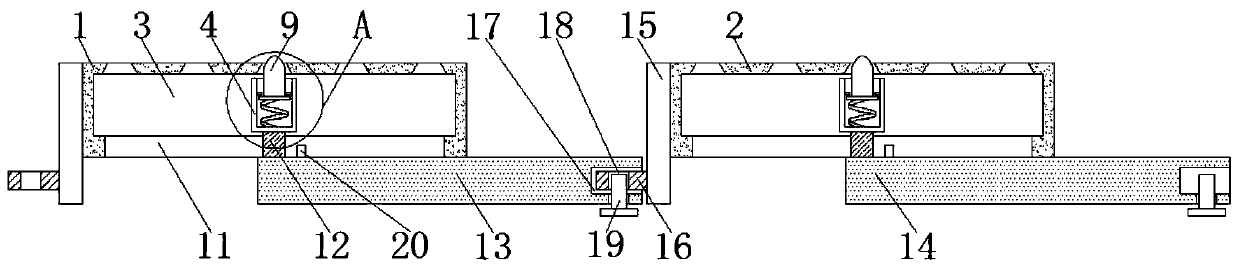

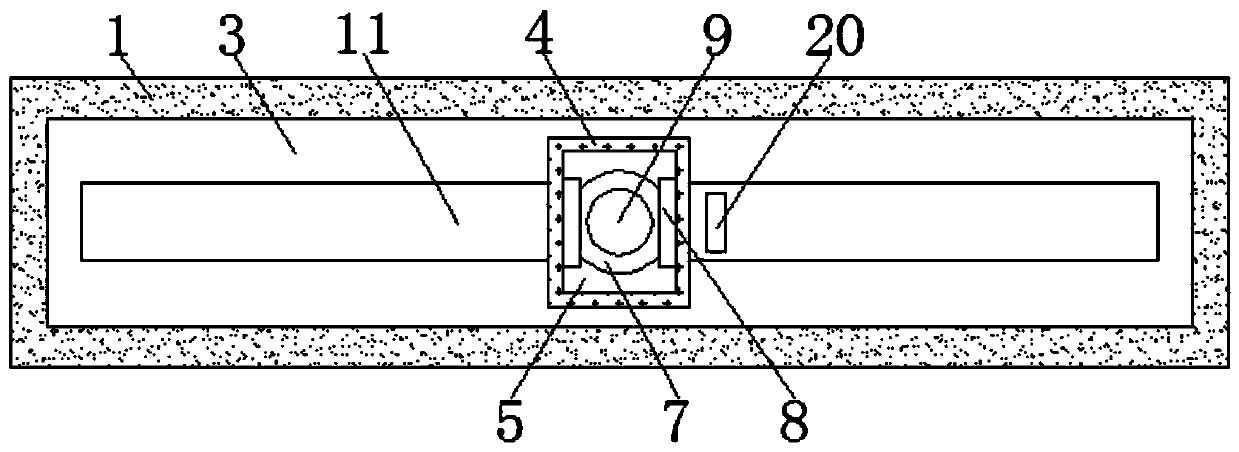

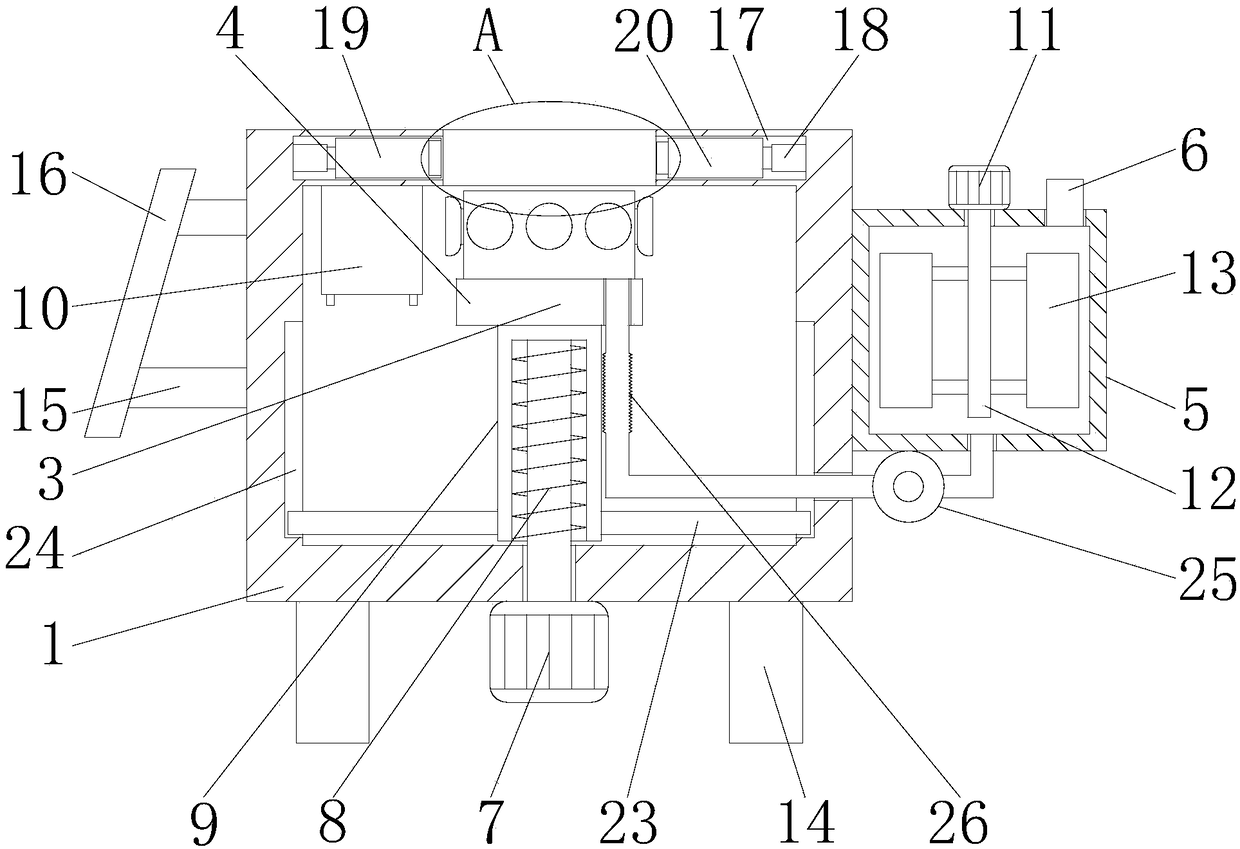

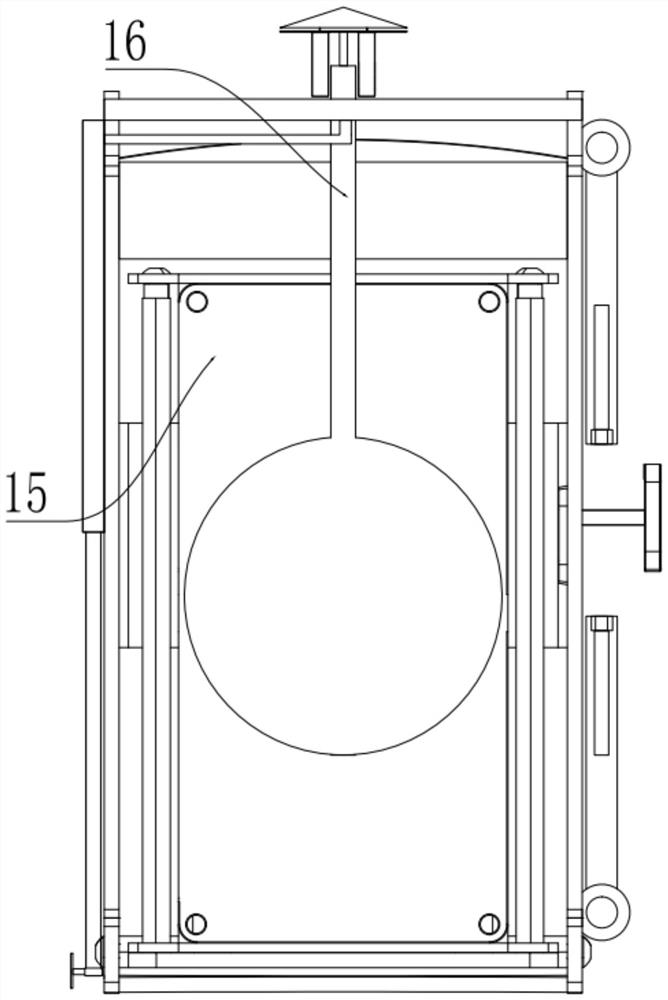

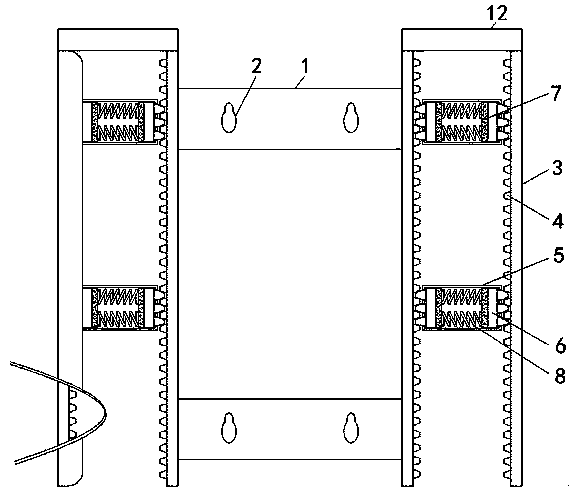

Drawing show shelf for industrial design

ActiveCN109043972AArea adjustmentThe area is easy to adjustShow cabinetsVibration suppression adjustmentsDisplay boardEngineering

The invention provides a drawing show shelf for industrial design, and relates to the technical field of industrial design. The drawing show shelf for the industrial design comprises a base, wherein asupporting spring is welded to the top of the base, a box body is welded to the end, away from the base, of the supporting spring, movable rings are welded to the bottoms of the left and right sidesof the box body, the inner portions of the movable rings are movably connected with movable rods, the ends, away from the movable rings, of the movable rods are welded to the left and right sides of the top of the base, and the surfaces of the movable rods are in movable sleeved connection with telescopic springs. The drawing show shelf for the industrial design has the advantages that a display board, a connecting block and a lantern ring are arranged so that the display board can move laterally on the surface of a transverse rod through the lantern ring, the area of the display board can beadjusted, the effect of adjusting the area of the display board conveniently is achieved, and the problems that when some existing devices are in use, the area of the display board is adjusted inconveniently, and drawings with different sizes are displayed inconveniently are solved.

Owner:芜湖文青机械设备设计有限公司

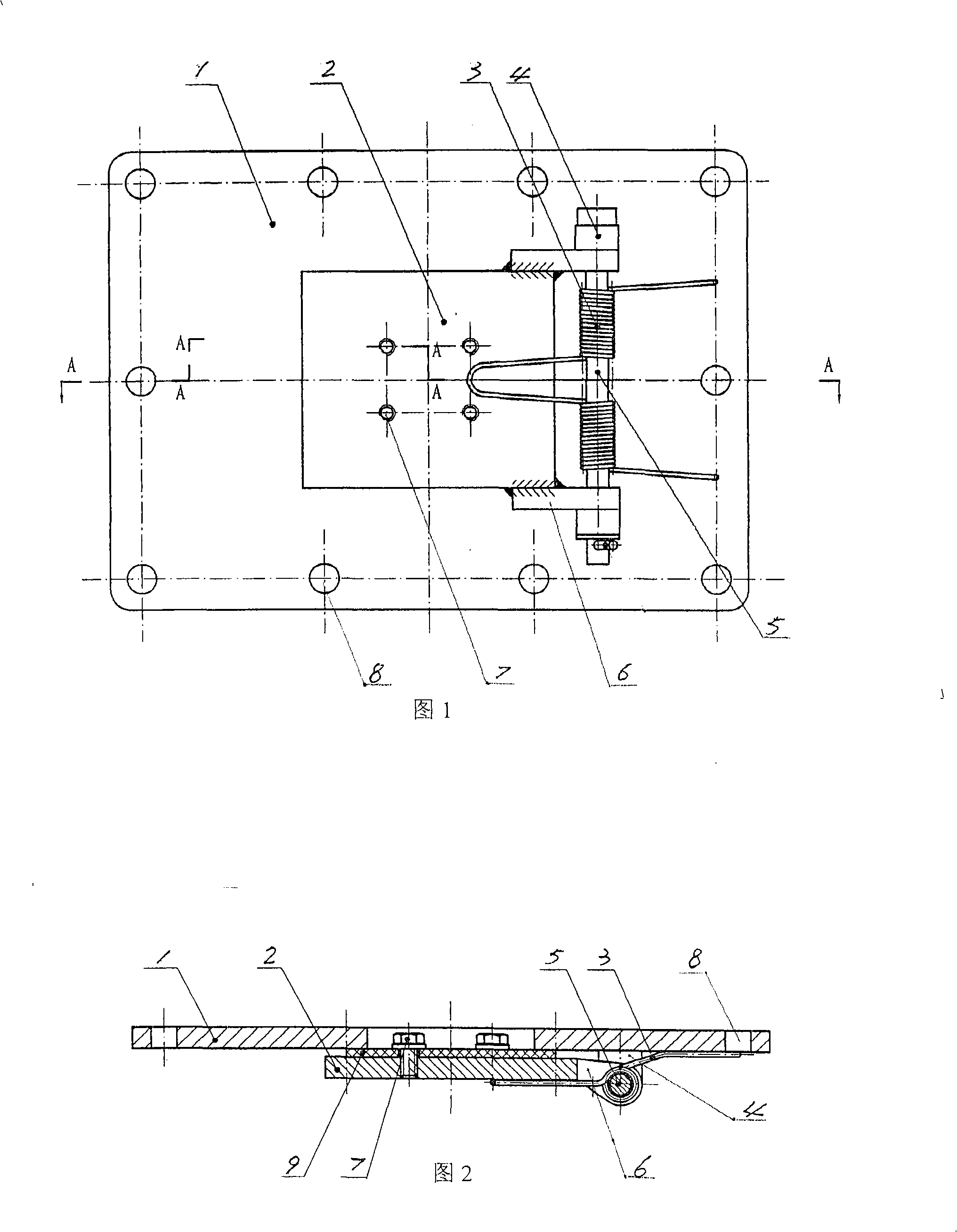

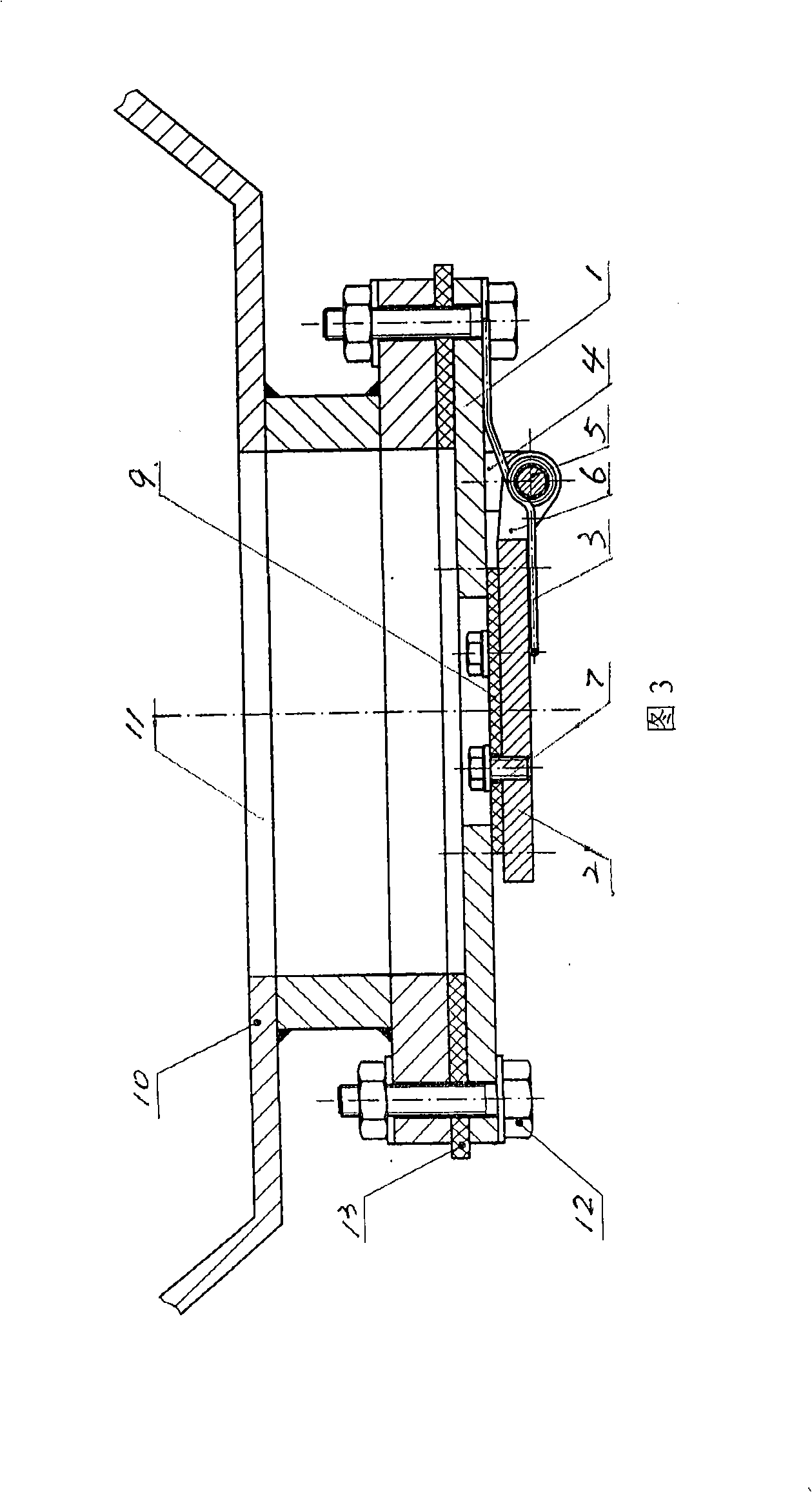

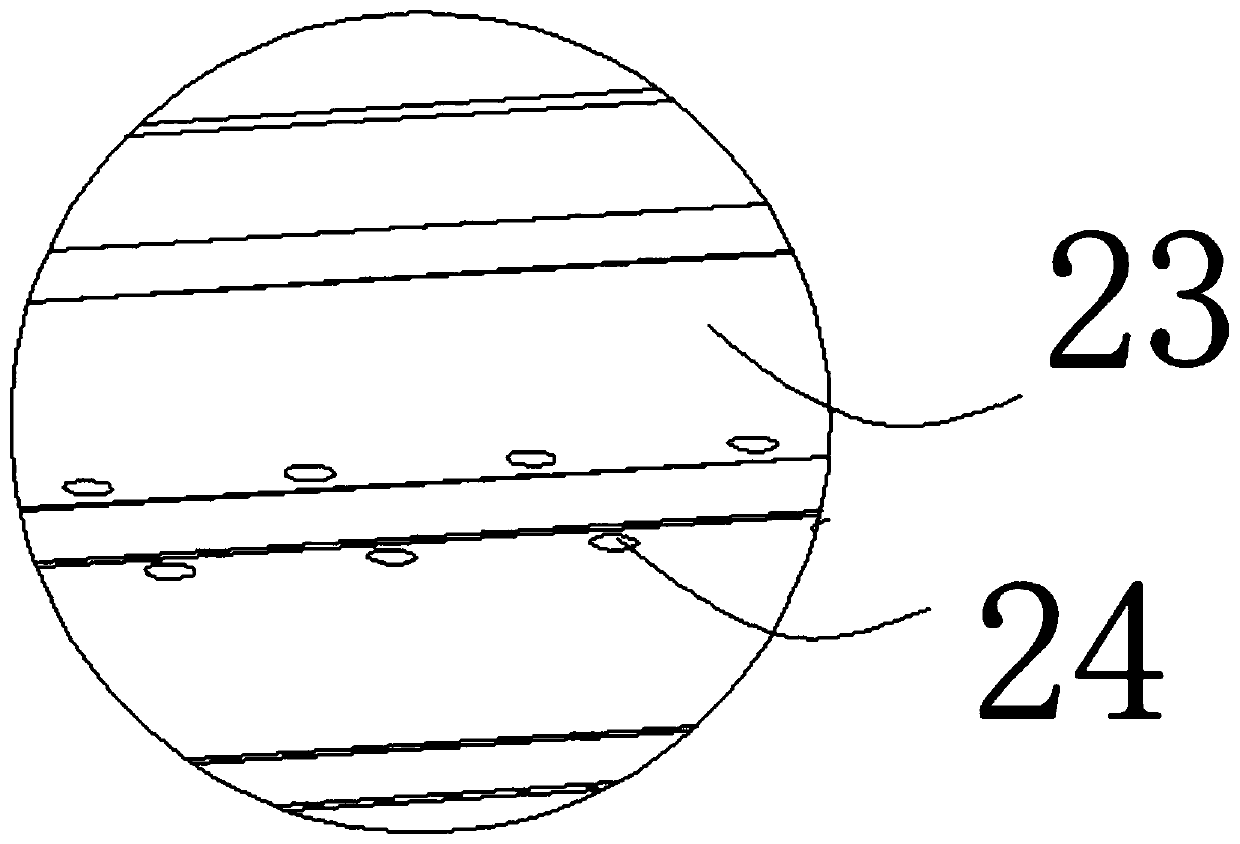

Turning plate mechanism for ballast water tank water pouring and draining system

InactiveCN101323361AReduce build-up pressureArea adjustmentUnderwater vesselsUnderwater equipmentEngineeringTorsion spring

The invention discloses a plate turning structure used for a bottom stowage water injection box and a drainage system, and the structure is characterized by comprising a cover plate and a turnover plate. The middle of the cover plate is provided with an opening, one side of which is fixed with two supports, both of which are provided with pin holes. Between the two supports, a rotating shaft is arranged and both ends of the rotation shaft insert into and are fixed in the pin holes of the two supports. The area of the turnover plate is larger than the opening area of the cover plate and two sides of one side of the turnover plate are both provided with pin lugs. The two pin lugs are parallel to each other and the corresponding position of the external ends of the two pin lugs are also provided with axis holes and the two pin lugs are movably pinned on the rotation shaft by means of the axis hole. The rotation shaft is sheathed with a parallel double torsion spring, which is located between the two pin lugs. One end of the parallel double torsion spring presses outside the turnover plate, and the other end presses on the cover plate at the out side of the two supports, and the turnover plate presses on the opening of the cover plate in a sealing way by means of the parallel double cross spring. The plate-turning structure is adopted, therefore, not only the adjustment of the effective area of the sea opening of the bottom stowage water tank can be realized, but also the weight and size of the deep-sea manned submersible can be reduced and the structure can be used for automatically opening and closing the sea opening of the bottom stowage water tank.

Owner:中国船舶重工集团公司第七〇二研究所

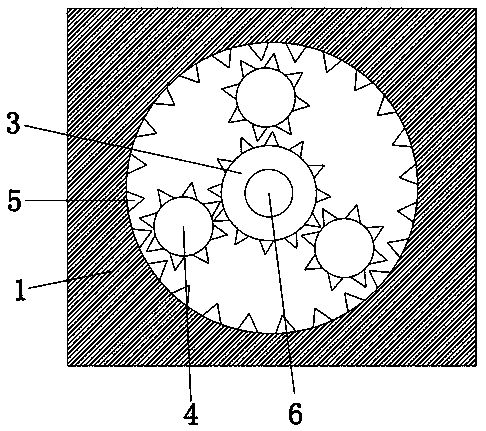

Display device for linguistics courses for English majors

The invention discloses a display device for linguistics courses for English majors. The display device comprises a base, wherein an upper surface of the base is provided with a first groove, an innerwall circumference of the first groove is clamped with teeth, the center of an inner cavity of the first groove is axially coupled with a first gear, an outer wall of the first gear is meshed with asecond gear, and the second gear is meshed with the teeth. The display device is advantaged in that through turning a first display panel clockwise, a connecting rod and the first gear can be driven to turn clockwise, through turning the first gear clockwise, the second gear is driven to turn counterclockwise, the area of a display stand of the teaching display device can be adjusted in the display process, so teaching materials of a user are displayed on the surface of the display stand at one time, the display angle is further adjusted, the display device is convenient for the user to use, and the display effect is improved.

Owner:JINING MEDICAL UNIV

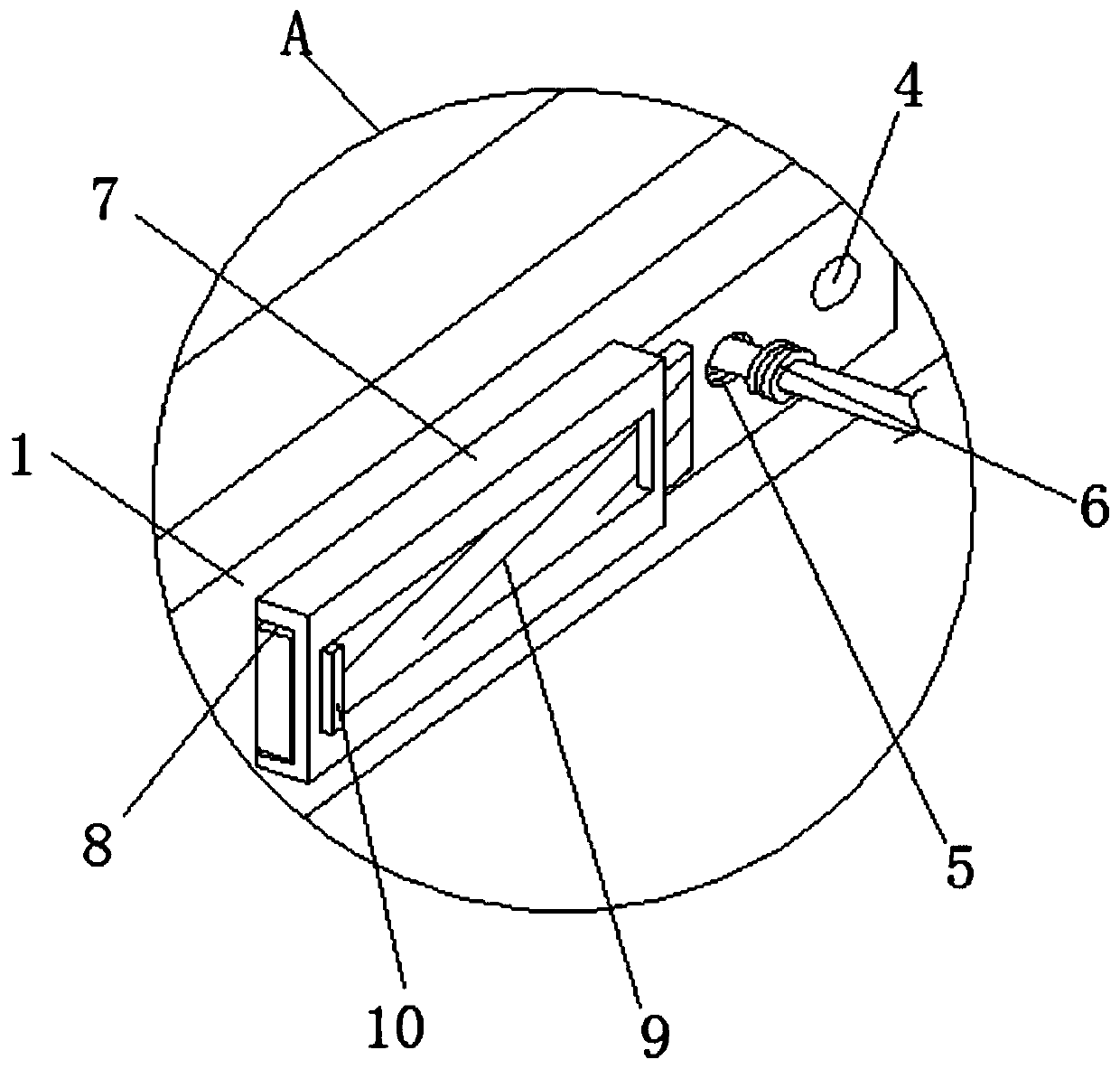

A computer software and hardware detection device convenient to move and adjust

InactiveCN109885445AEasy to move and adjustAvoid enteringError detection/correctionData connectionComputer software

The invention discloses a computer software and hardware detection device convenient to move and adjust. The device comprises a computer software and hardware detection device body, a data connectionport, a sealing block and a protective shell, wherein a data connection port is formed in one end of the computer software and hardware detection device main body; the sealing block is arranged on theside face of the data connection port, the protection shell is arranged in the computer software and hardware detection device body, the two ends of a baffle are arranged in second sliding grooves, aclamping block is fixed to one side of the baffle, and a clamping groove is formed in the side, away from the baffle, of the clamping block. In the computer software and hardware detection device convenient to move and adjust, the protective shell is provided with the ventilation opening, the second sliding groove, the baffle and the clamping block, the clamping block is pushed to drive the baffle to slide in the second sliding groove according to different wind power areas needing to be used, then the baffle slides out of the protective shell, and therefore the area of the ventilation opening is adjusted, and calculation software and hardware of different sizes can be detected through the device.

Owner:ZHEJIANG BOLUONI ELECTRONICS

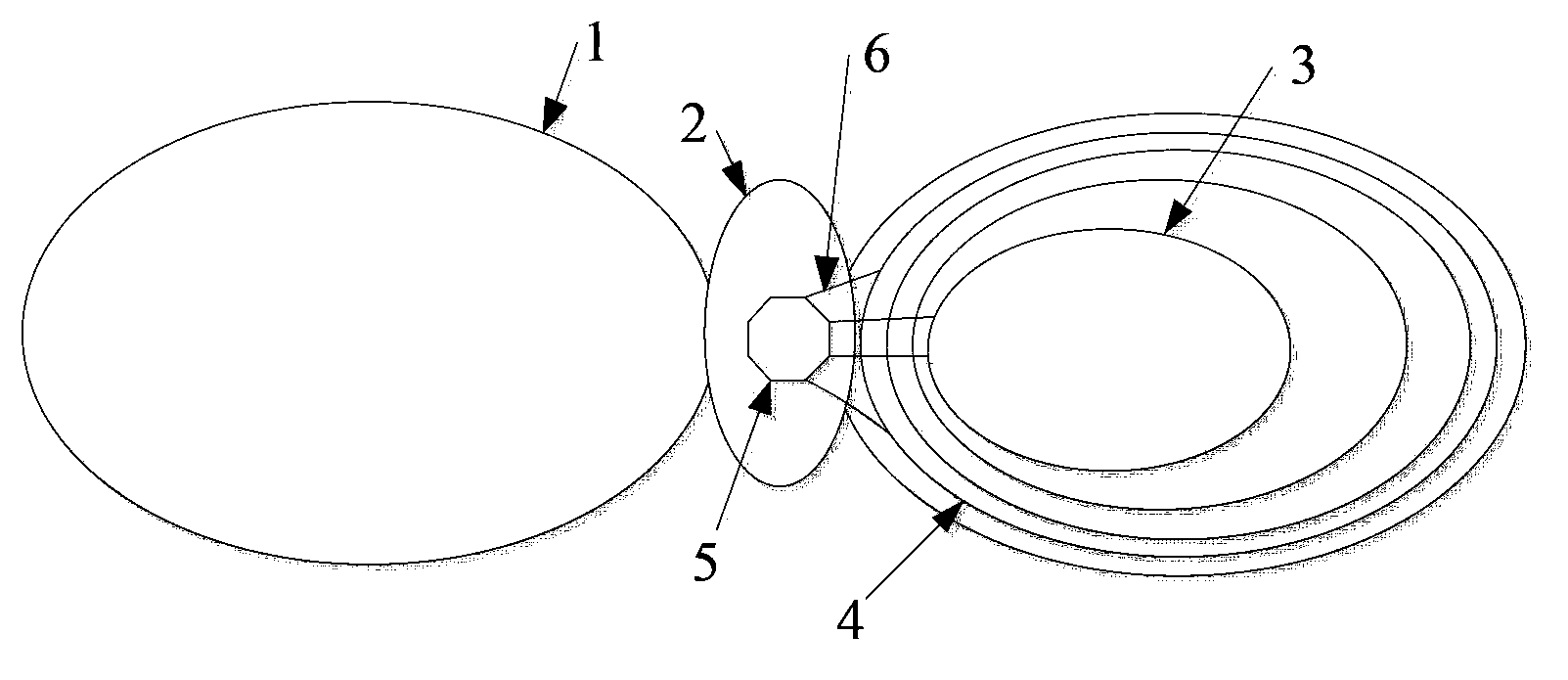

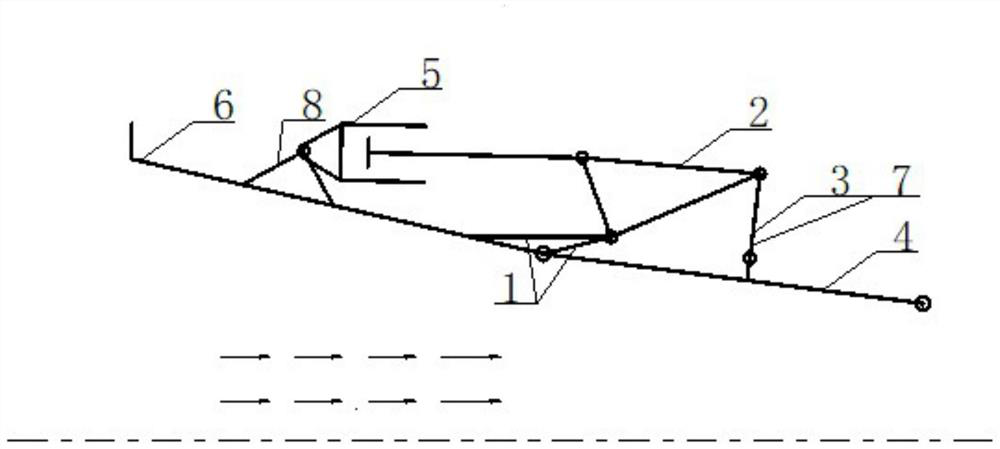

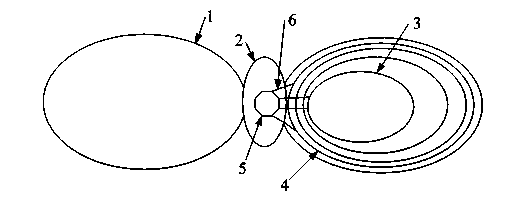

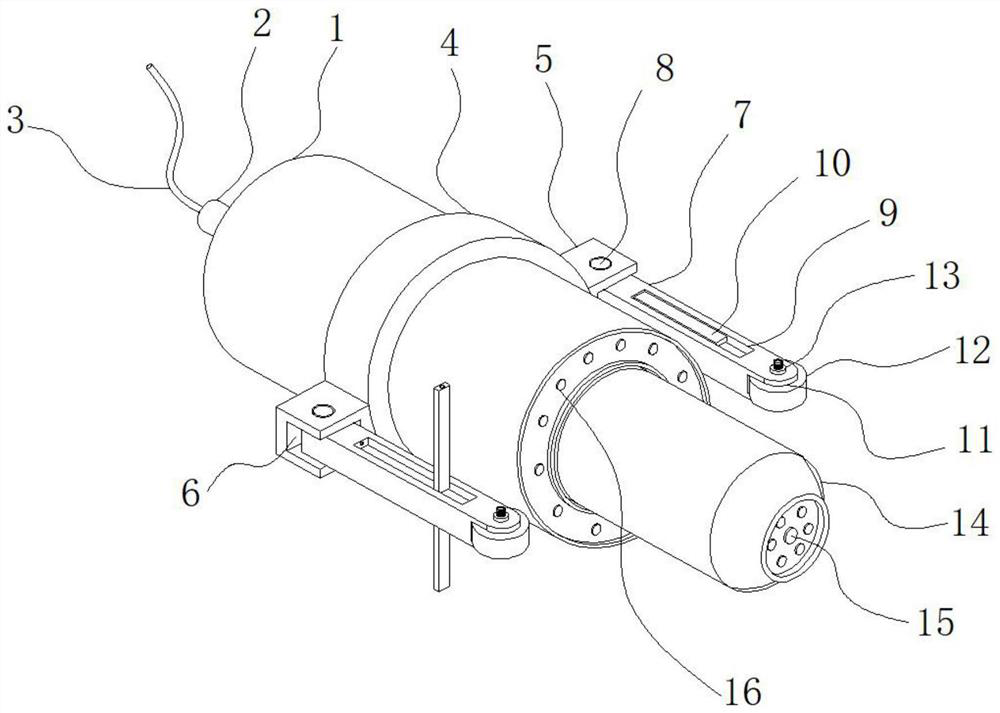

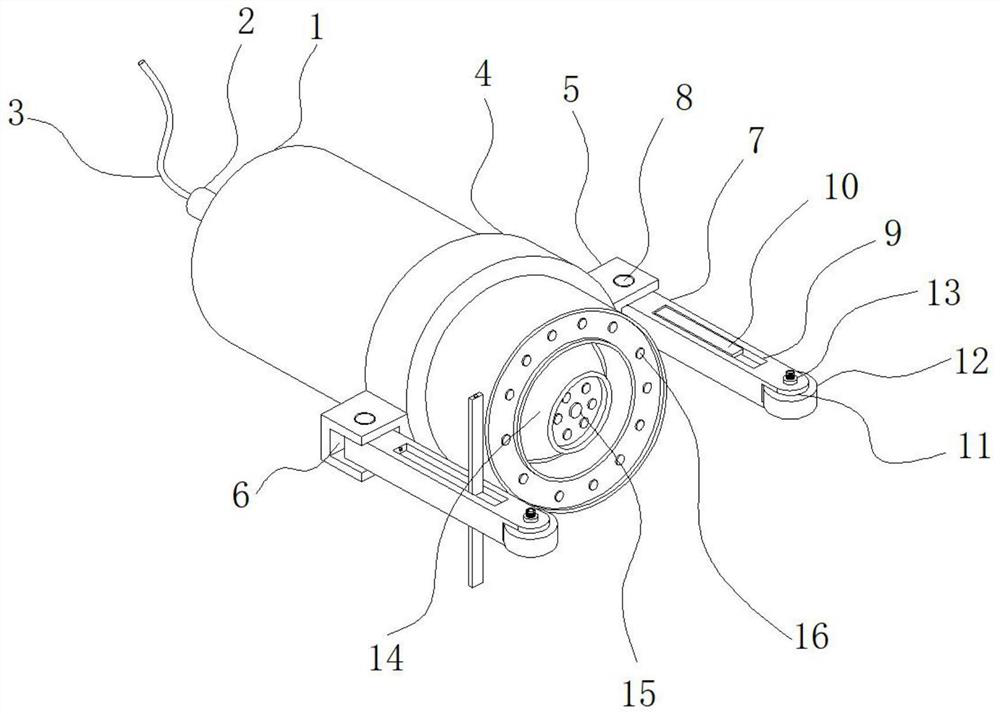

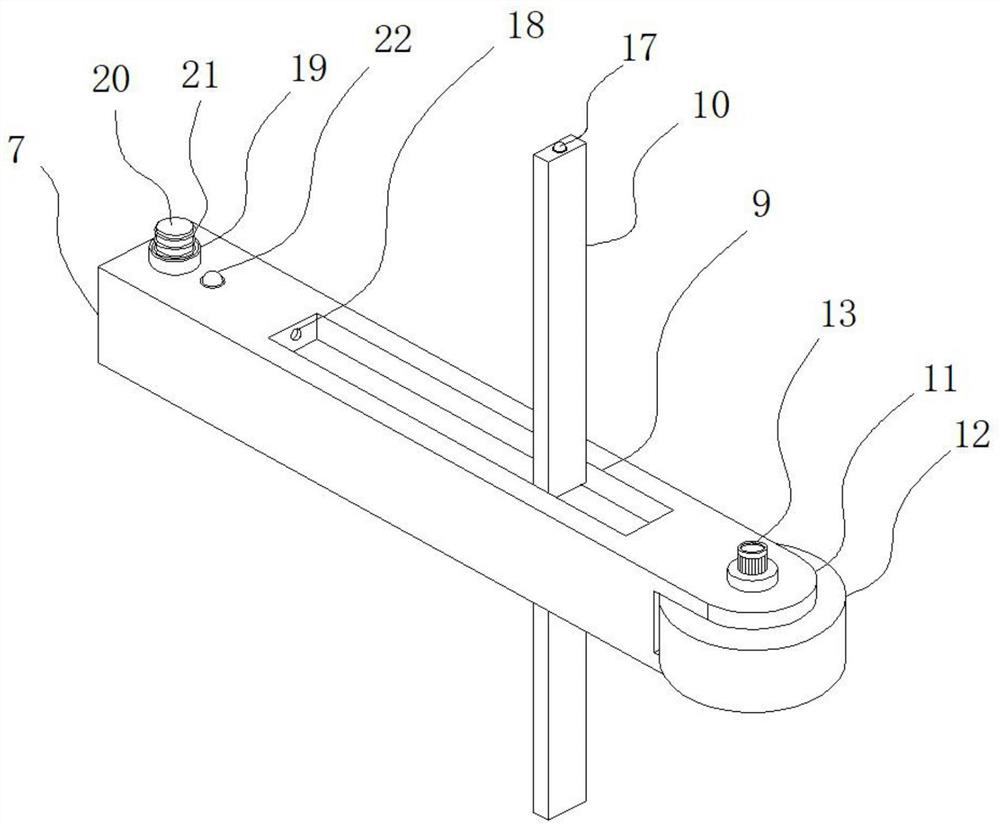

Flapping wing flight device with adjustable flapping wing

InactiveCN103507953ASimple Flight ControlsNo significant increase in weightOrnithoptersFlapping wingControl system

The invention discloses a flapping wing flight device with an adjustable flapping wing. The device comprises a flapping wing 1, a connecting structure 2, an inner boundary guide pipe 3, an outer boundary guide pipe 4, a gas pump 5 and gas inflating guide pipes 6. The flapping wing flight device with the adjustable flapping wing, which is provided by the invention, is simple in structure, can adjust the shape and the area of the flapping wing through the gas pump and the guide pipes, achieves the simple flight control of an aircraft, and does not use a complex flight control system; the weight of the whole flight device is not increased obviously because gases are used in the guide pipes.

Owner:XINCHANG GUANYANG TECH DEV +1

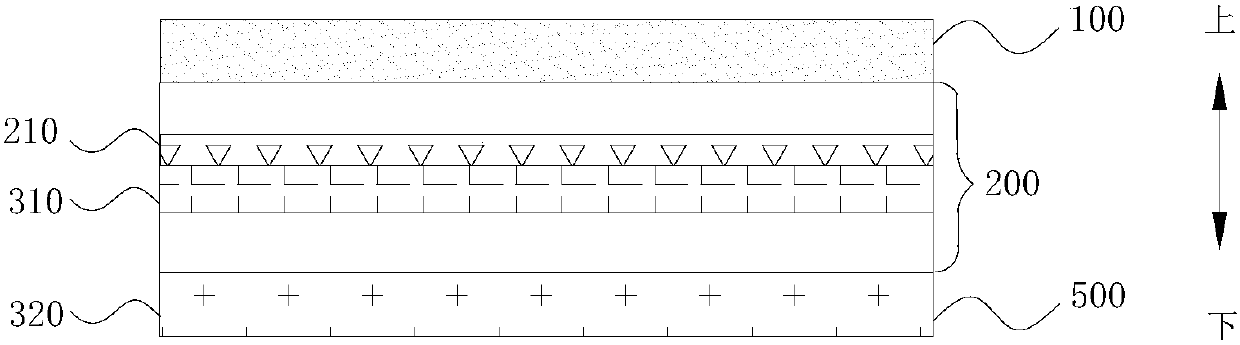

Touch screen and electronic equipment

PendingCN107562292APrevent overflowAppropriate spacingInput/output processes for data processingElectricityCapacitance

The invention provides a touch screen and electronic equipment. Specifically, the touch screen includes: a protection cover plate; a display module, which is disposed under the protection cover plate;and a pressure sensing structure, which includes a first pressure sensing layer and a second pressure sensing layer which are electrically connected and form pressure sensing capacitance of which aninitial capacitance value is not greater than 50% of an upper limit of an IC detection capacitance value. Through design for a distance between the first pressure sensing layer and the second pressuresensing layer and areas, the initial capacitance value of the pressure sensing capacitance formed by the same is enabled to have a certain proportional relationship with the upper limit of the IC detection capacitance value, and thus it is prevented that when pressure sensing is carried out, increasing of the pressure sensing capacitance after pressing causes the pressure sensing capacitance after pressing to exceed the upper limit of IC detection and signal overflow to occur.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

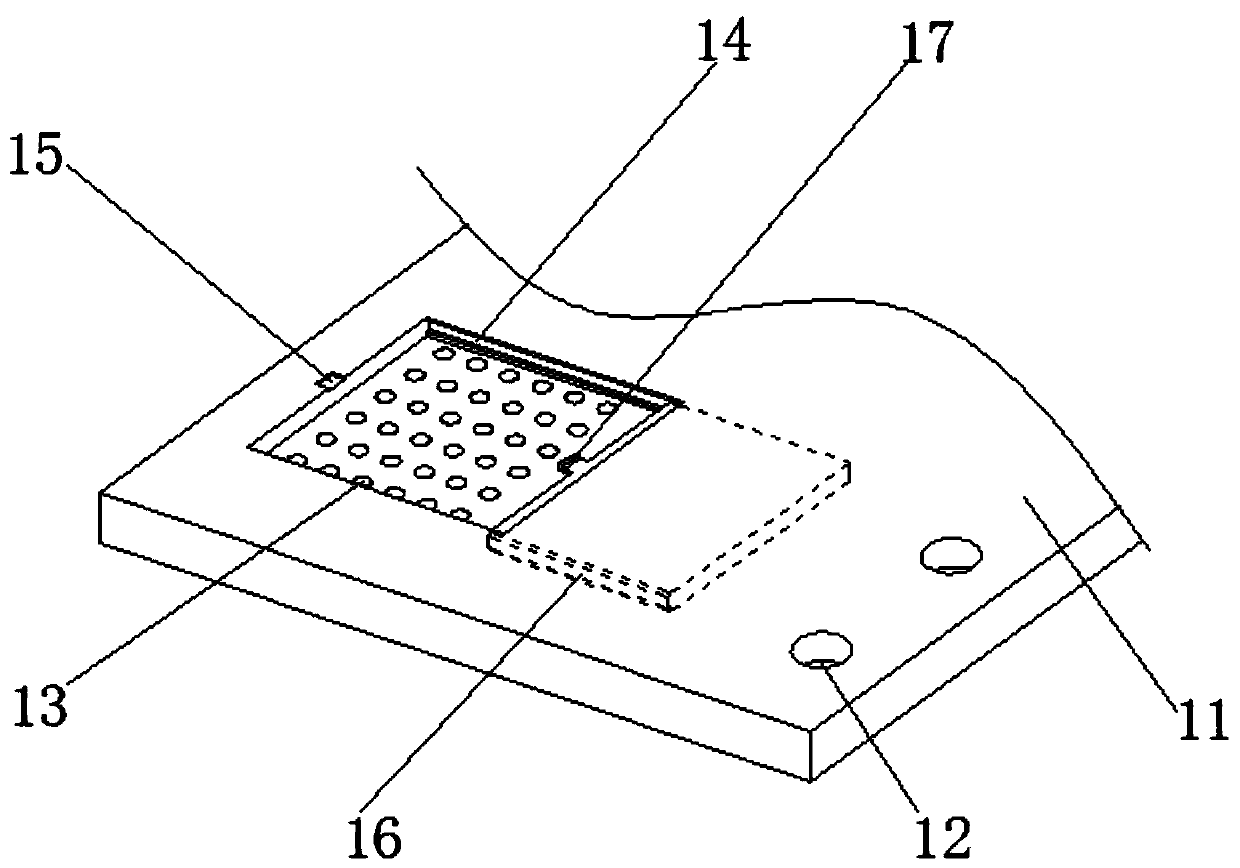

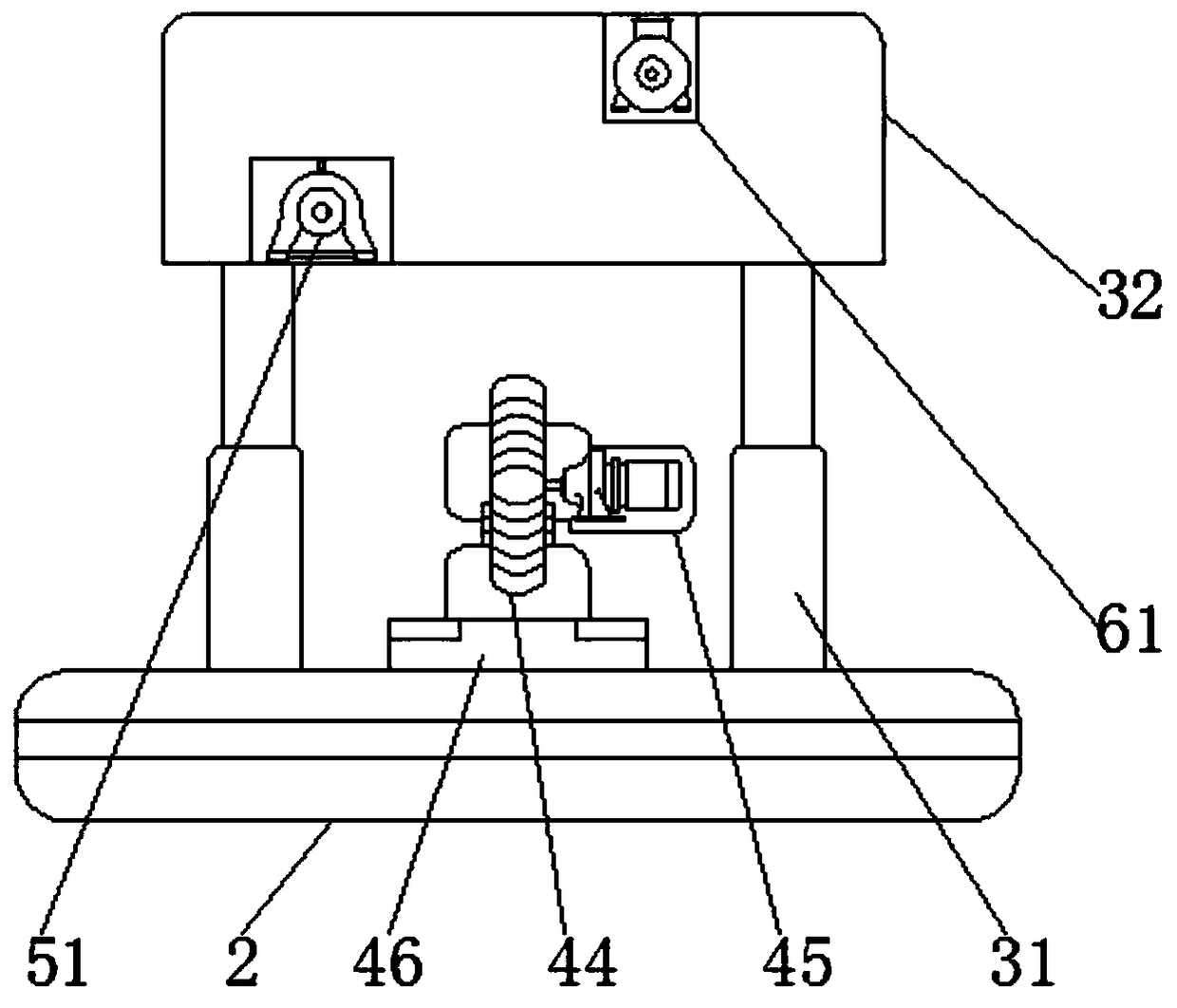

Drawing showing stand for industrial design and using method

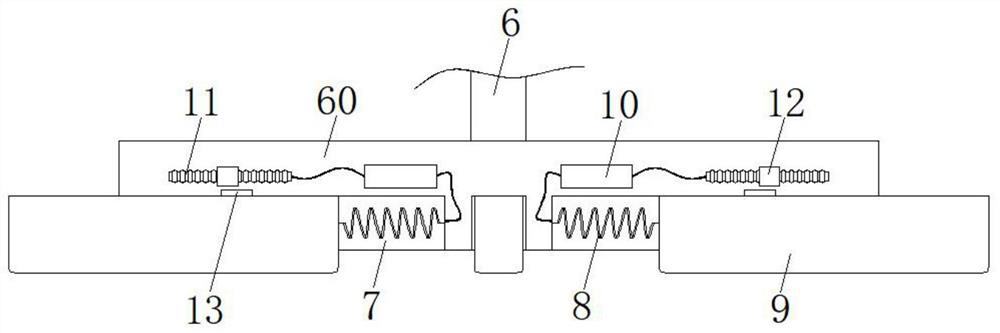

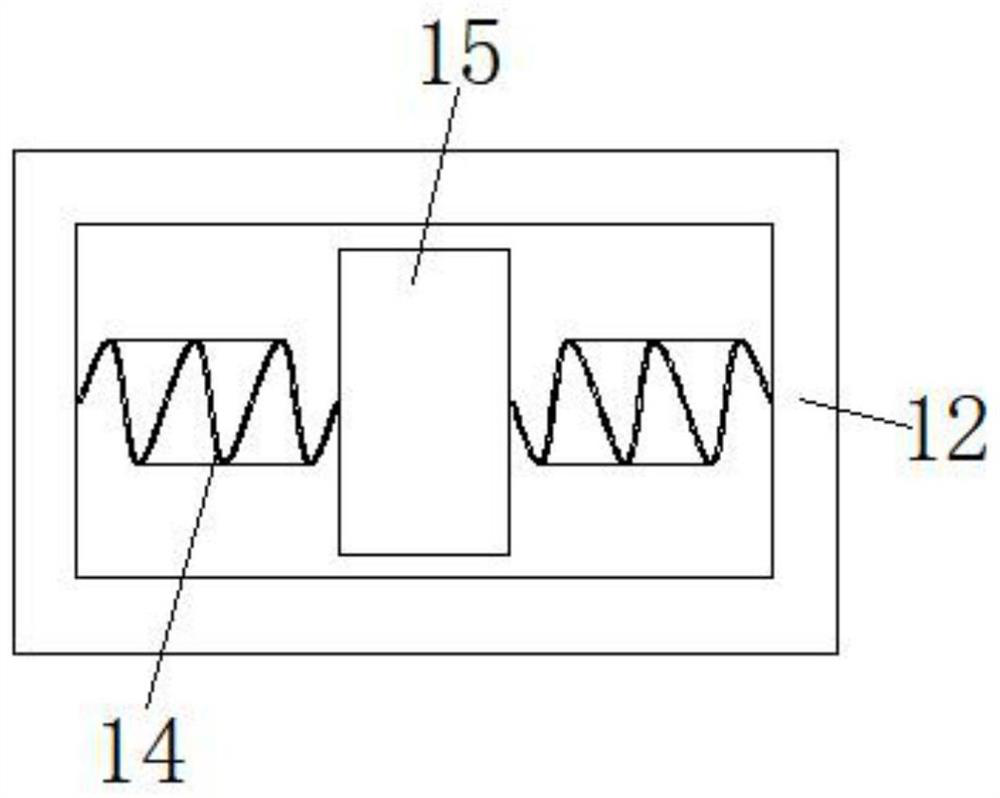

ActiveCN110897433AArea adjustmentThe area is easy to adjustShow cabinetsVibration suppression adjustmentsDisplay boardIndustrial engineering

The invention provides a drawing showing stand for industrial design and a using method, and relates to the technical field of industrial design. The drawing showing stand for industrial design includes a base, and supporting springs are welded to the top of the base. A box is welded to the ends, away from the base, of the supporting springs, movable rings are welded to the bottoms of the left side and the right side of the box, movable rods are movably connected into the movable rings, the ends, away from the movable rings, of the movable rods are welded to the left side and the right side ofthe top of the base correspondingly, and the surfaces of the movable rods are movably sleeved with telescopic springs. According to the drawing showing stand for industrial desig, a display board, aconnecting block and lantern rings are arranged; the display board can move left and right on the surface of the cross rod through the lantern rings, so that the area of the display board can be adjusted, the effect of conveniently adjusting the area of the display board is achieved, and the problems that when some existing devices are used, the area of the display board is inconvenient to adjust,and drawings of different sizes are inconvenient to display are solved.

Owner:WUHU WENQING MASCH EQUIP DESIGN CO LTD

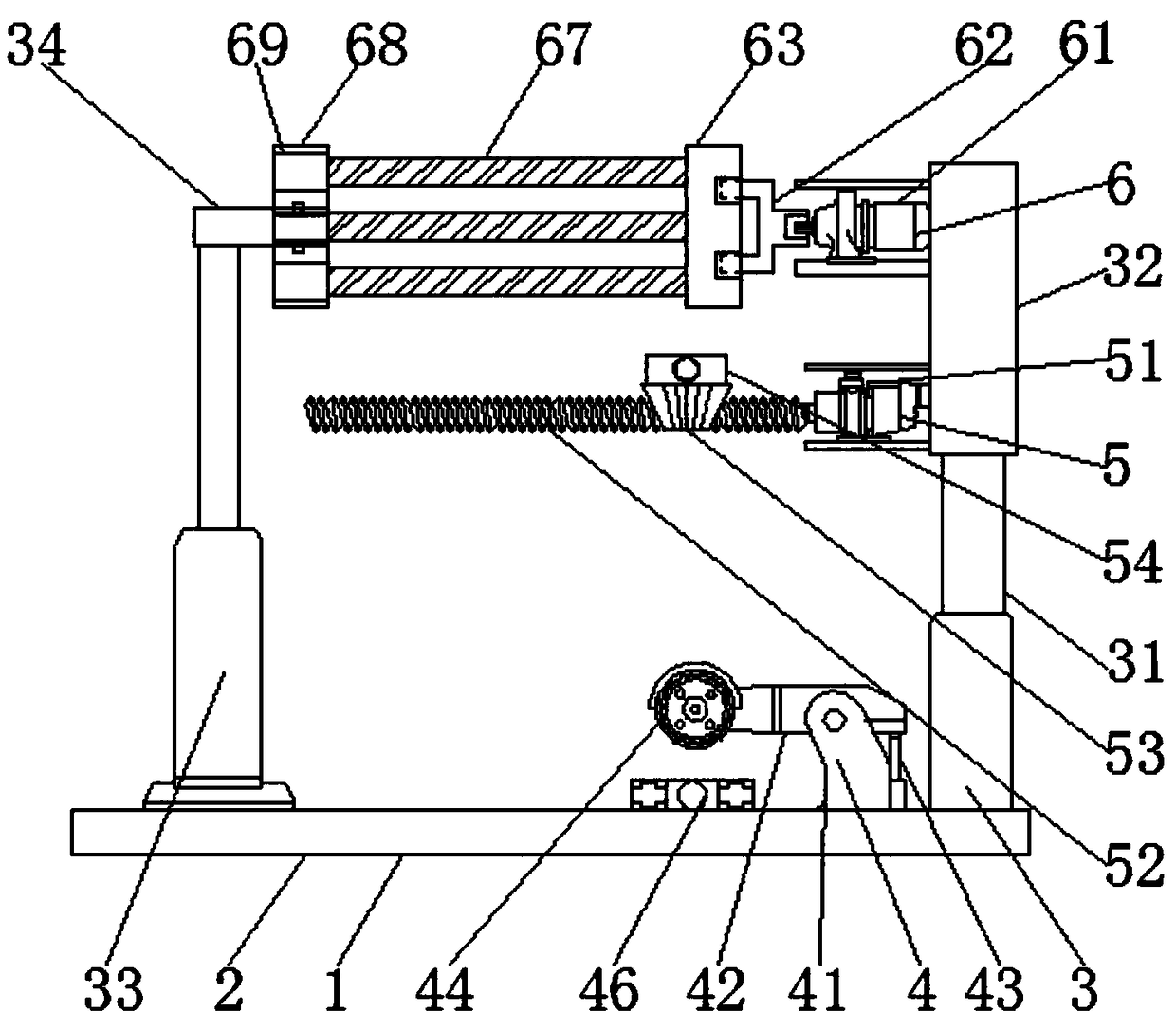

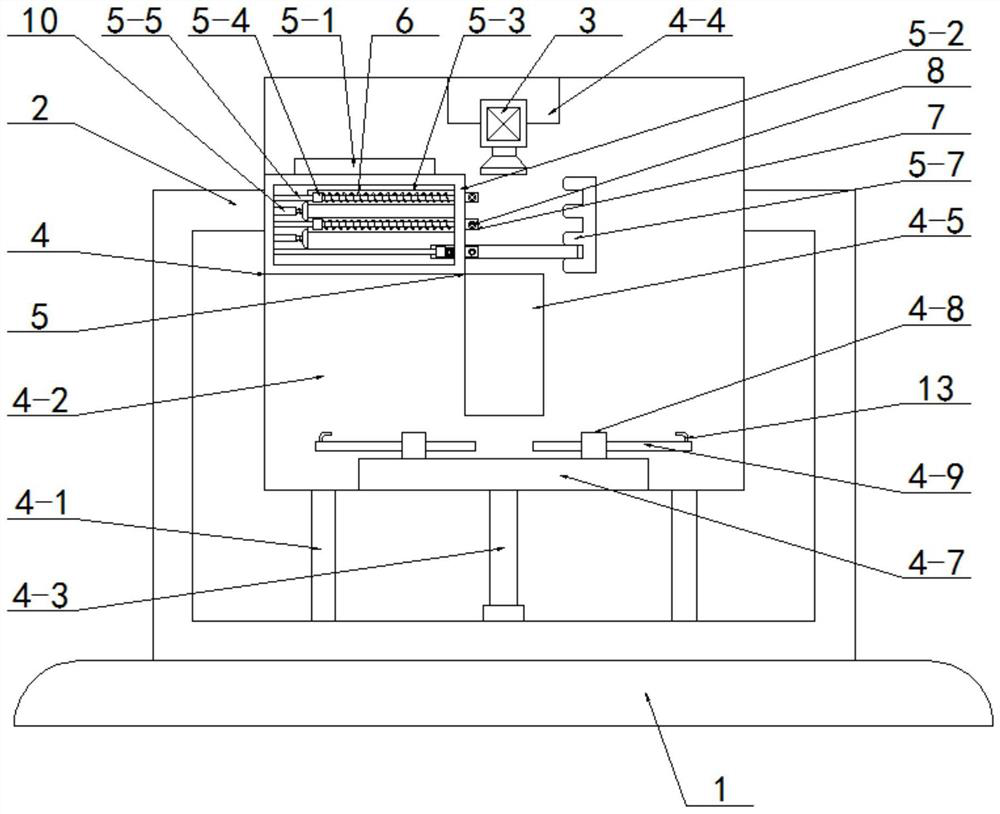

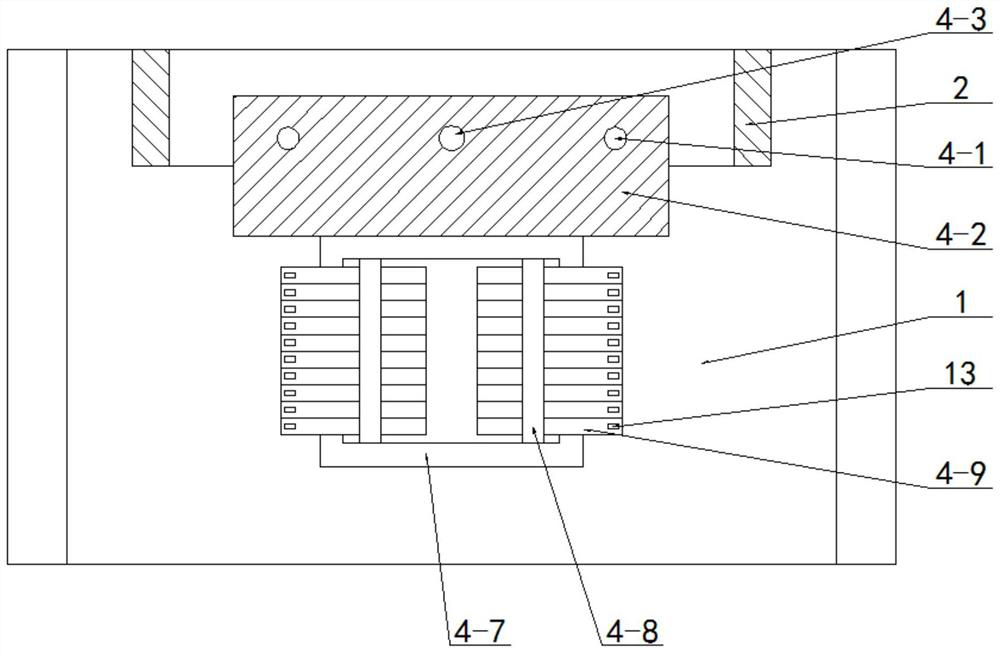

Winding facility for plastic wire and cable manufacturing

The invention relates to a winding facility for plastic wire and cable manufacturing. The winding facility for plastic wire and cable manufacturing comprises a machine body, a base, a lifting mechanism, a cutting mechanism, a wire bundling mechanism and a winding mechanism. The base is installed at the bottom of the machine body. The lifting mechanism and the cutting mechanism are installed on thebase, the wire bundling mechanism is installed on the side far away from the lifting mechanism on the base, and the winding mechanism is installed on the side far away from the wire bundling mechanism on the base. After operation of the winding facility for plastic wire and cable manufacturing is accomplished, a connecting plate can be moved, through holes in the connecting plate and wire windingrods can be separated, and therefore the connecting plate moves to one end of an insertion rod, a second hydraulic rod is opened, the insertion rod, a bearing and the connecting plate downwards movealong with the second hydraulic rod under the action of the second hydraulic rod, the bearing sleeves the insertion rod, electric telescoping rods are opened, and insertion grooves can carry the wirewinding rods to move under the action of the electric telescoping rods. In this way, cables which are wound can be better separated from the wire winding rods, the cables which are well wound can be well taken down, and therefore the follow-up packaging operation is conducted on the cables.

Owner:黄杰琦

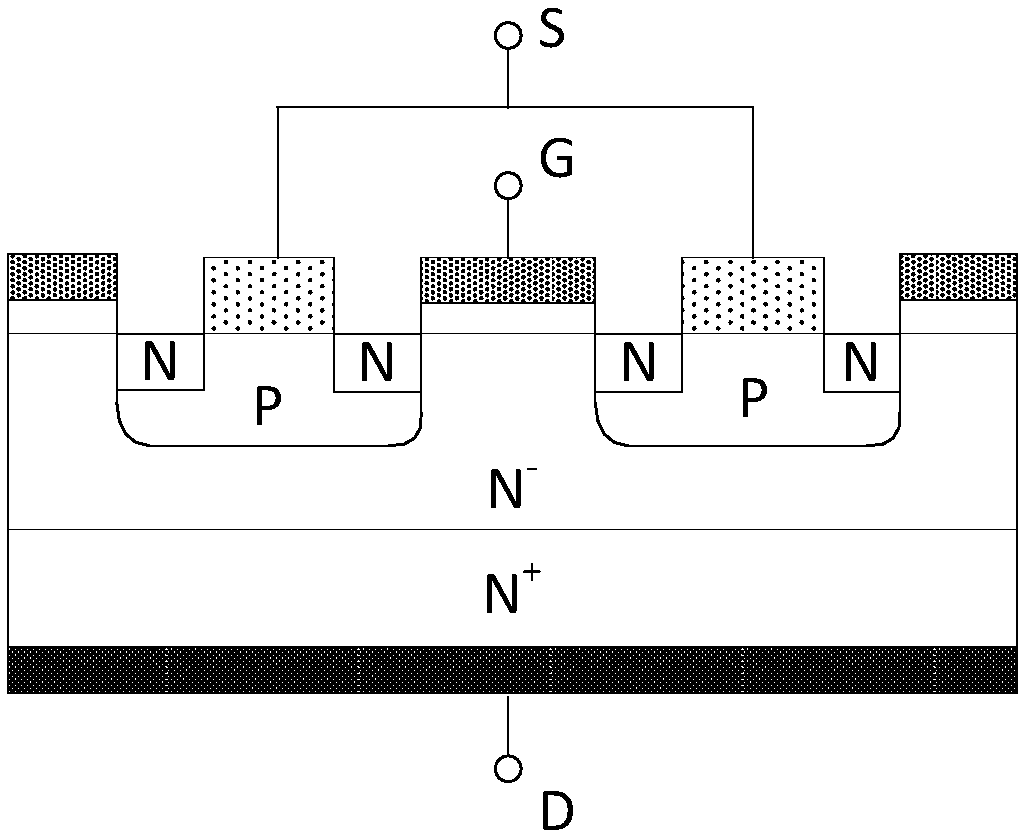

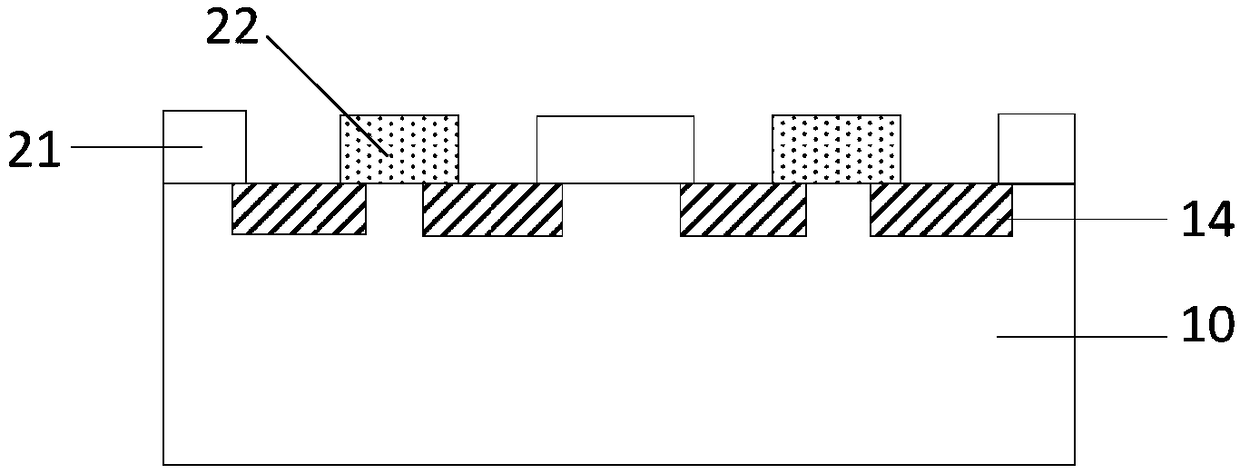

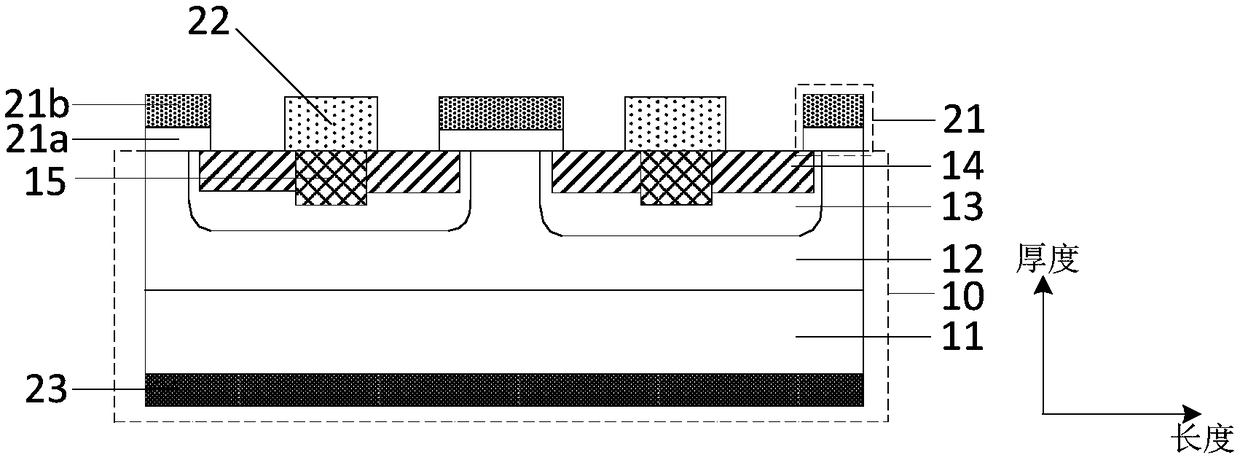

Semiconductor device and preparation method thereof

InactiveCN109148590AModulation time lossModulation Switching LossTransistorSemiconductor/solid-state device manufacturingCapacitanceSwitching time

The invention relates to the technical field of semiconductors, and provides a semiconductor device and a preparation method thereof, wherein, the semiconductor device comprises a semiconductor layer;a gate electrode and a source electrode formed over the semiconductor layer; A semiconductor region formed in the semiconductor layer between the gate electrode and the source electrode, and having aportion overlapping with the gate electrode and / or the source electrode; Wherein the ion doping concentration in the semiconductor region is 1E16-5E21cm<-3>, that conductivity type of the semiconductor region is the same as that of the semiconductor lay. By forming a semiconductor region in the semiconductor layer between the gate electrode and the source electrode, The semiconductor region has aportion overlapping with the gate and / or the source, wherein the area of the overlapping portion may be used to change the MOS capacitance at the coincidence of the gate and / or the source, thereby realizing modulation of switching characteristics such as switching time and switching loss of the grid control semiconductor device.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

A blueprint display stand for industrial design

ActiveCN109043972BArea adjustmentThe area is easy to adjustShow cabinetsVibration suppression adjustmentsDisplay boardBlueprint

The invention provides a drawing display stand for industrial design, which relates to the technical field of industrial design. The blueprint display stand for industrial design includes a base, the top of the base is welded with a support spring, the end of the support spring far away from the base is welded with a box, and the bottoms of the left and right sides of the box are welded with movable rings. The inside of the ring is movably connected with a movable rod, and one end of the movable rod away from the movable ring is welded to the left and right sides of the top of the base respectively, and the surface of the movable rod is movably socketed with a telescopic spring. The blueprint display stand for industrial design is provided with a display board, a connecting block, and a collar, so that the display board can move left and right on the surface of the cross bar through the collar, so that the area of the display board can be adjusted, so that the device can achieve The effect of being convenient to adjust the area of the display board solves the problems that the area of the display board is inconvenient to adjust when some existing devices are in use, and that it is inconvenient to display drawings of different sizes.

Owner:芜湖文青机械设备设计有限公司

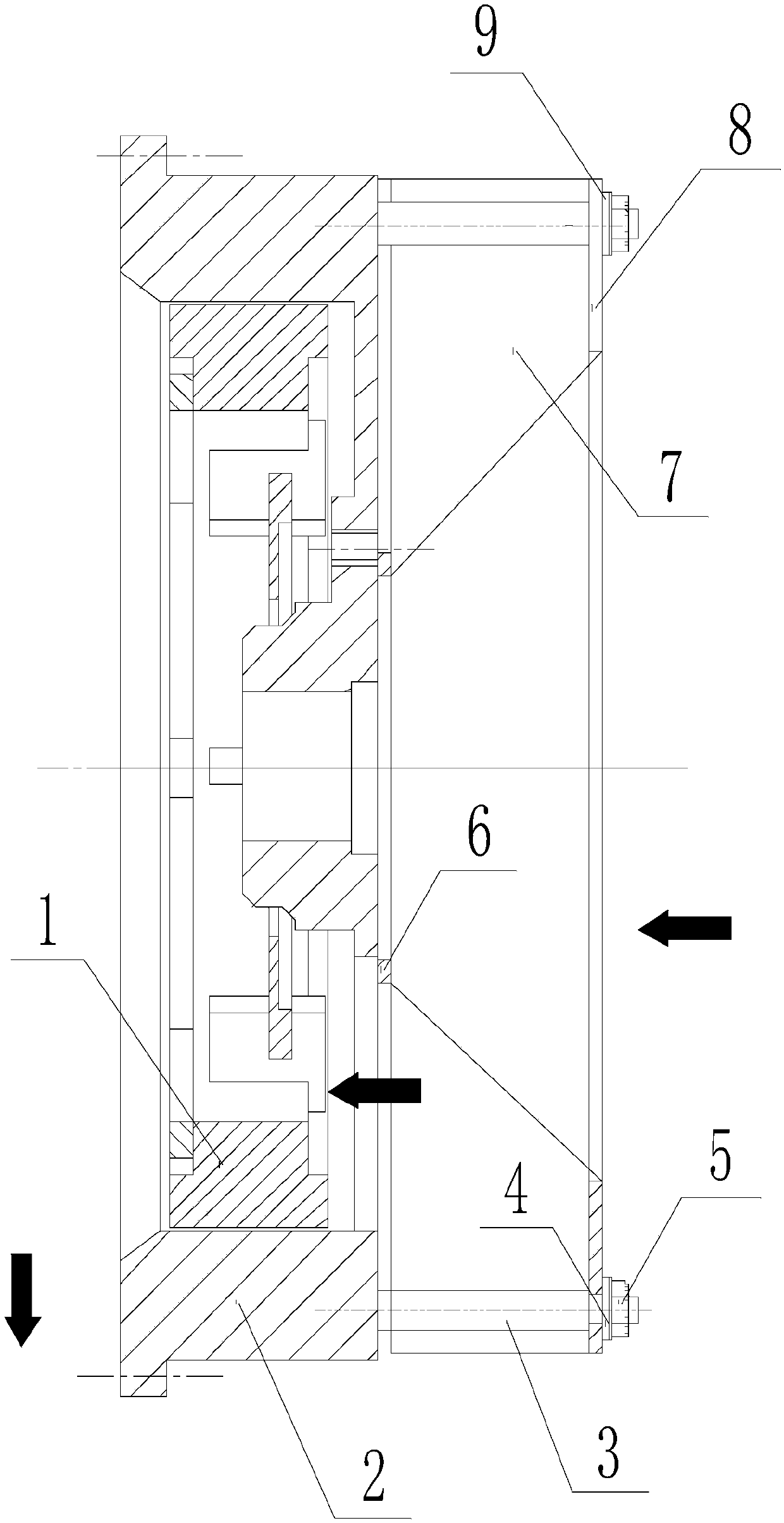

Multifunction integrated valve

InactiveCN101922450AImprove temperature control sensitivitySolve the problem of insufficient temperature control functionRotary/oscillating piston pump componentsLiquid fuel engine componentsTemperature controlEngineering

The invention provides a multifunction integrated valve which can make the volumes of a hot oil channel and a cooler oil channel to change in inverse proportion, has high temperature control sensitivity and is suitable for the wider range of temperature control working condition. The invention has the technical scheme that the multifunction integrated valve comprises a valve body; the valve body is connected with an oil filter; an oil cut valve assembly and a temperature control valve assembly are embedded in the valve body; the temperature control valve assembly comprises a temperature control valve core; and the temperature control valve core is arranged in the temperature control valve cavity of the valve body. The multifunction integrated valve is characterized in that the valve body is provided with an annular step on the periphery of the temperature control valve cavity; the annular step and the temperature control valve core are matched to divide the temperature control valve cavity into a left cavity and a right cavity; and the periphery of the temperature control valve core is provided with a circular hole.

Owner:无锡市海航电液伺服系统股份有限公司

Combined type EPP plate material with convenient area adjustment function

InactiveCN109798286AConvenient area adjustment functionArea adjustmentSheet joiningMechanical engineering

Owner:ANHUI YOURFRIEND PULP MOLDING TECH

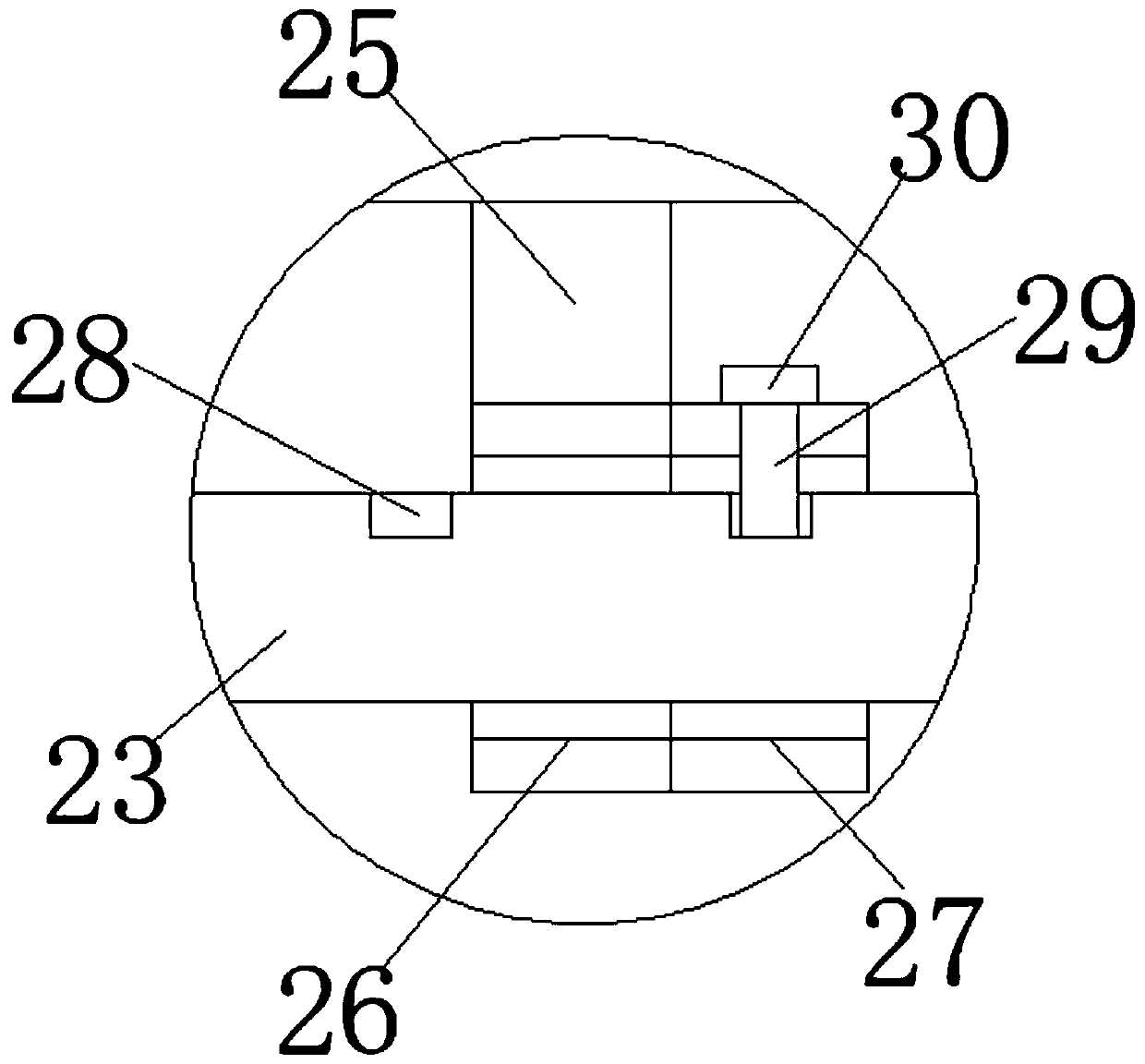

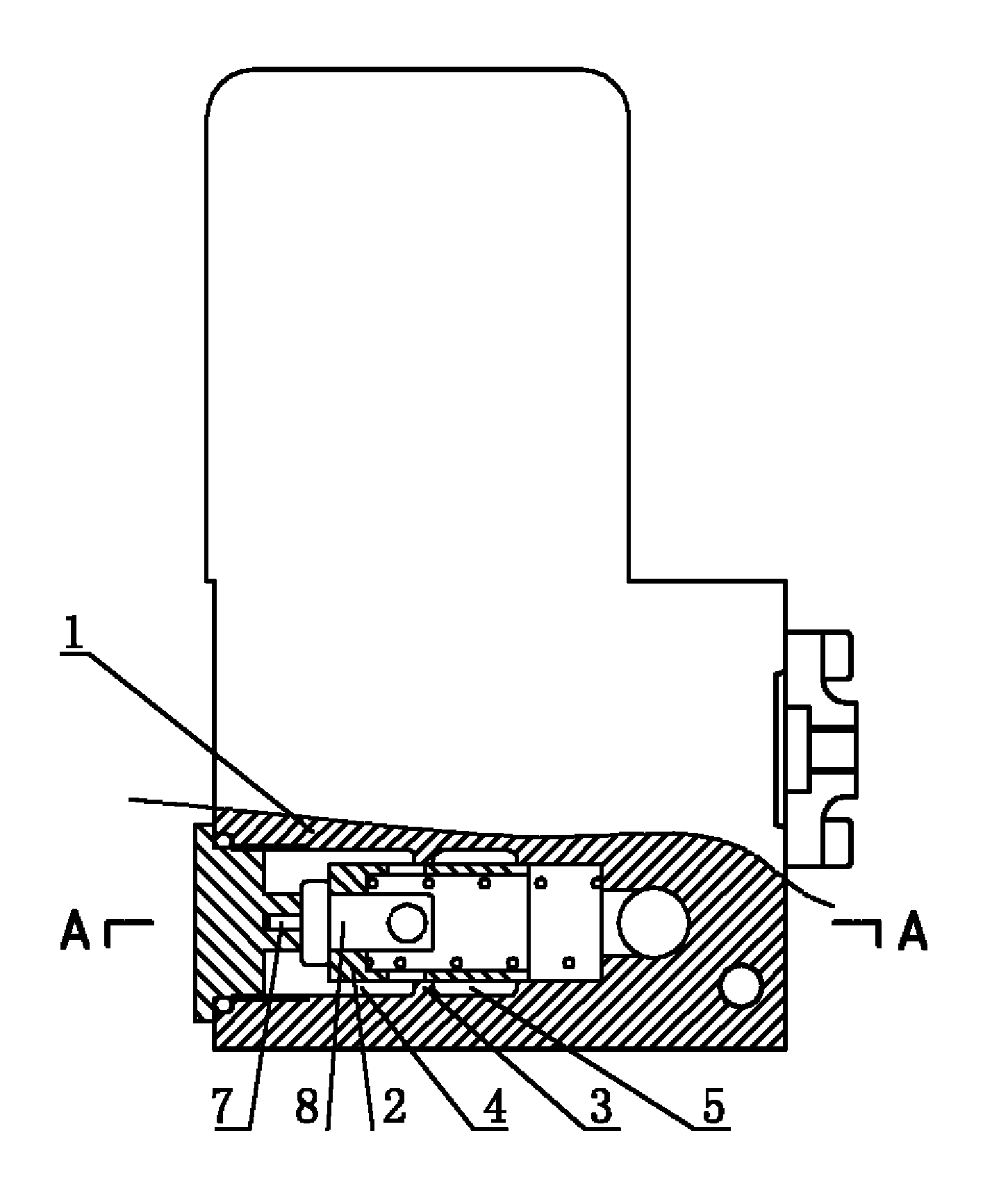

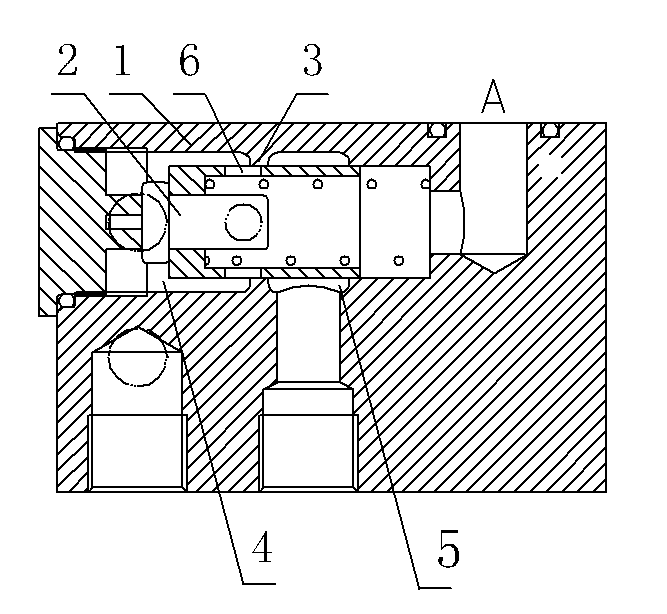

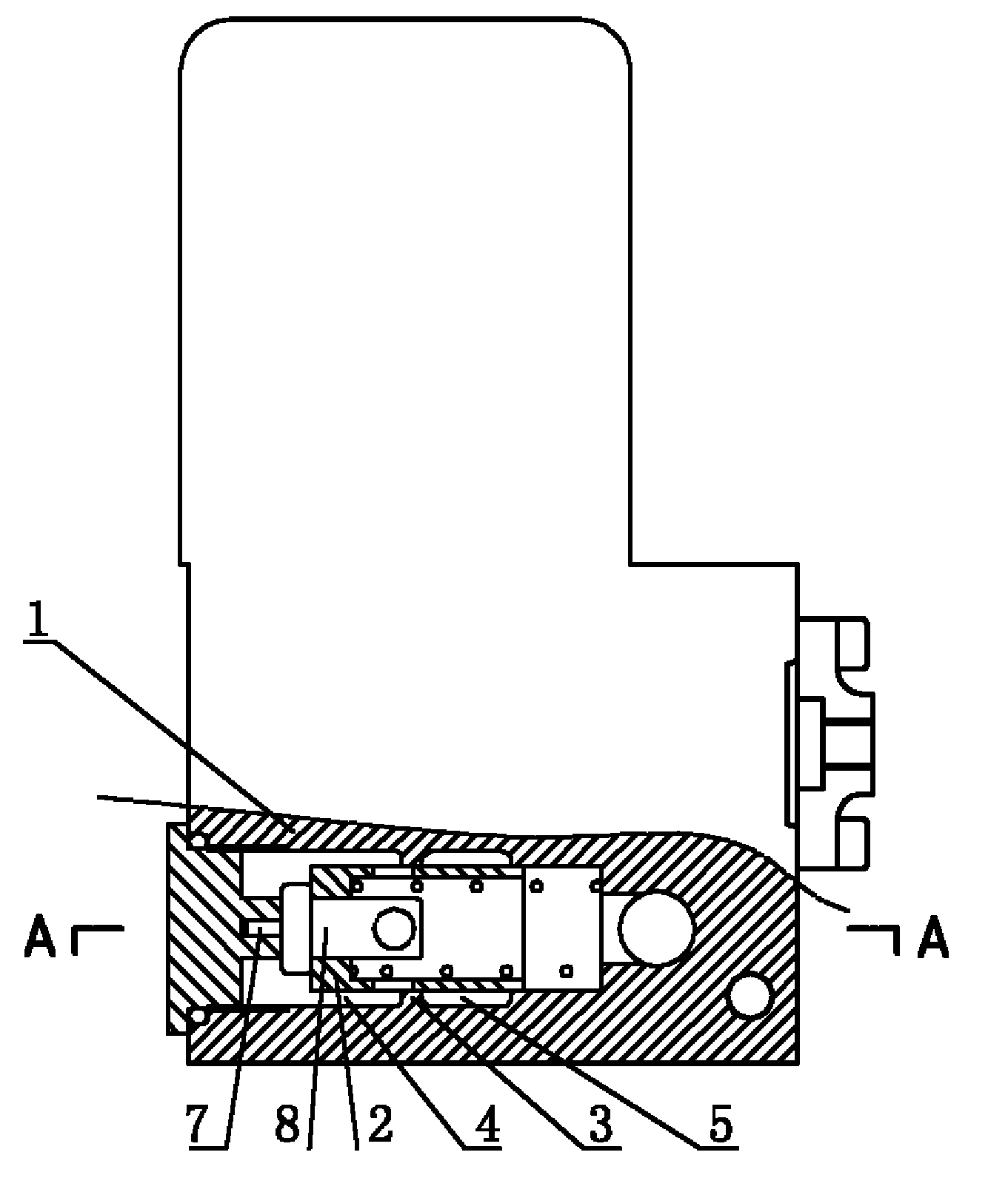

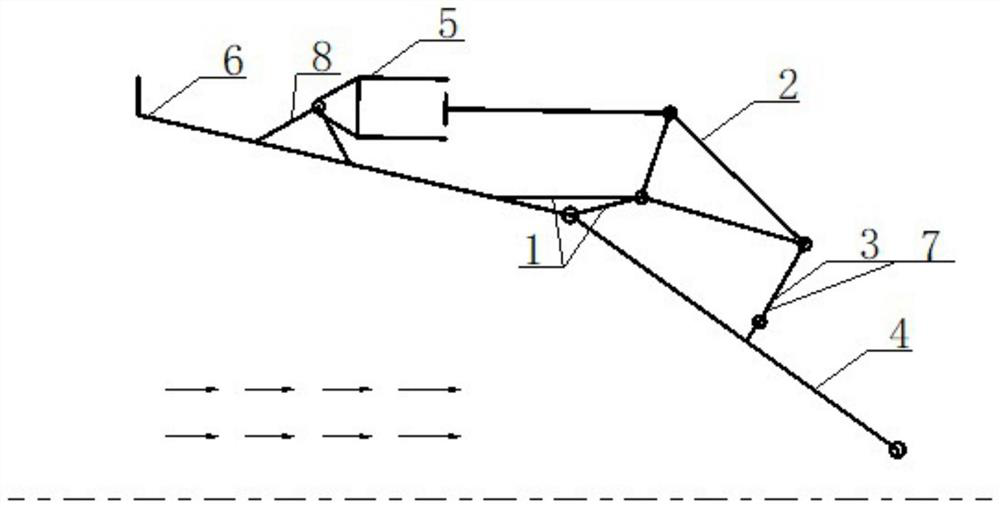

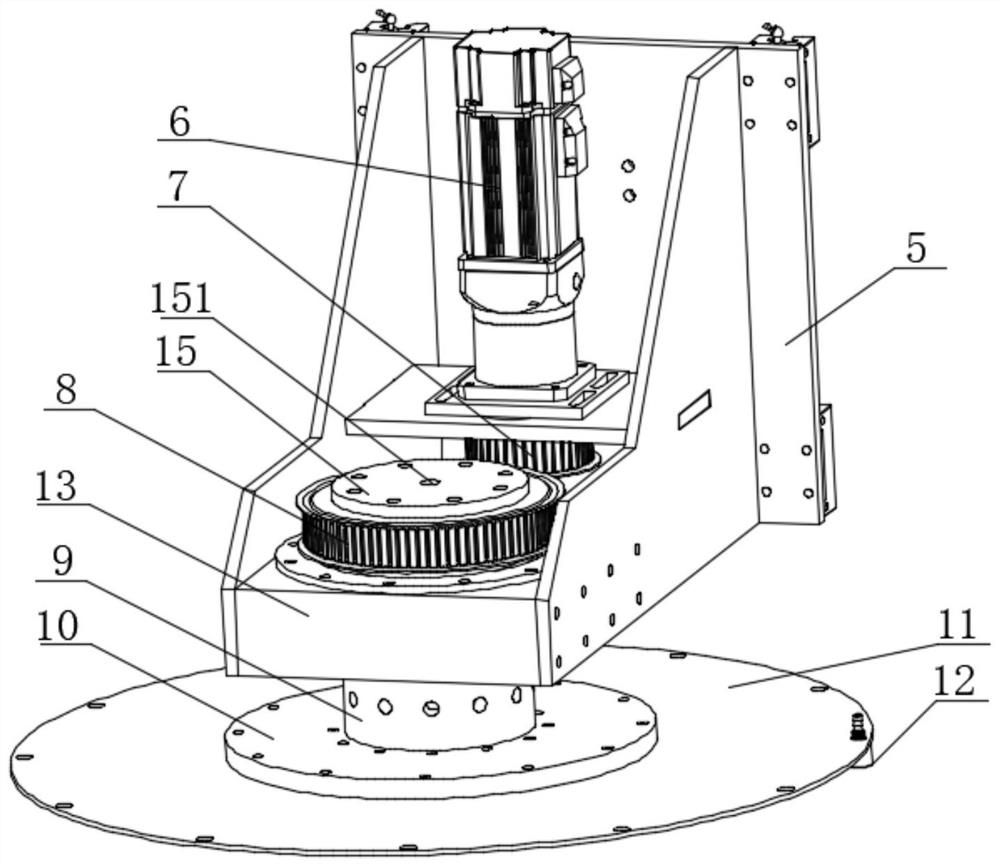

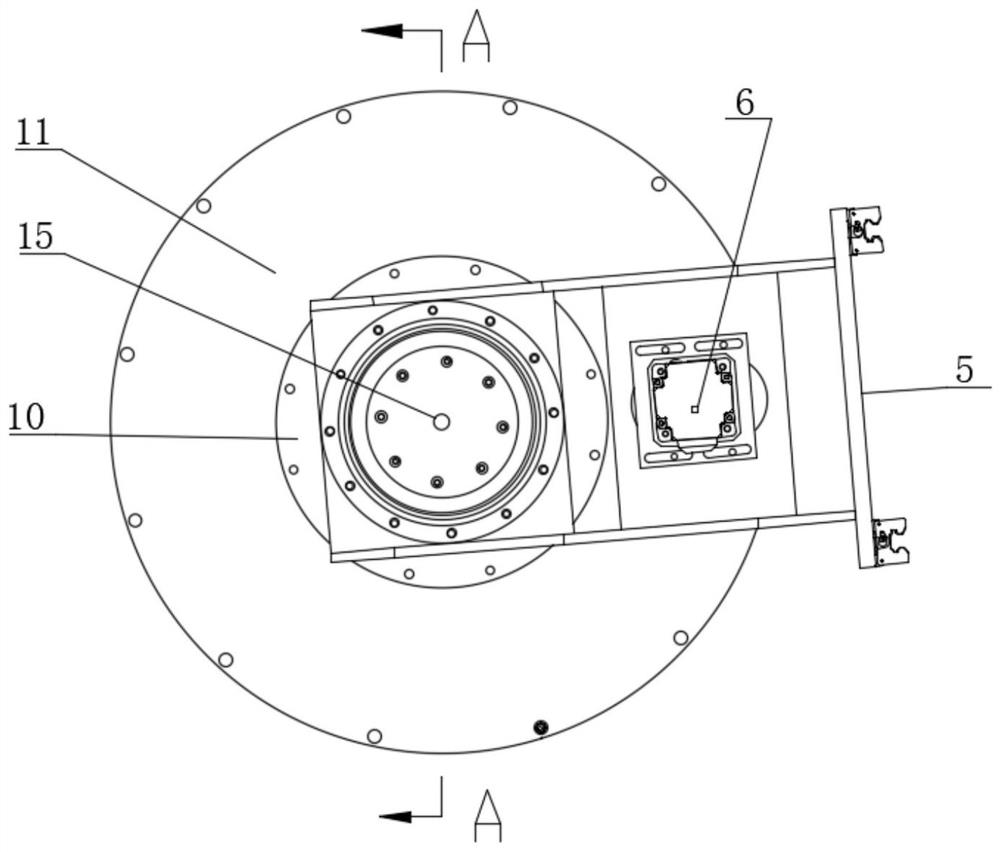

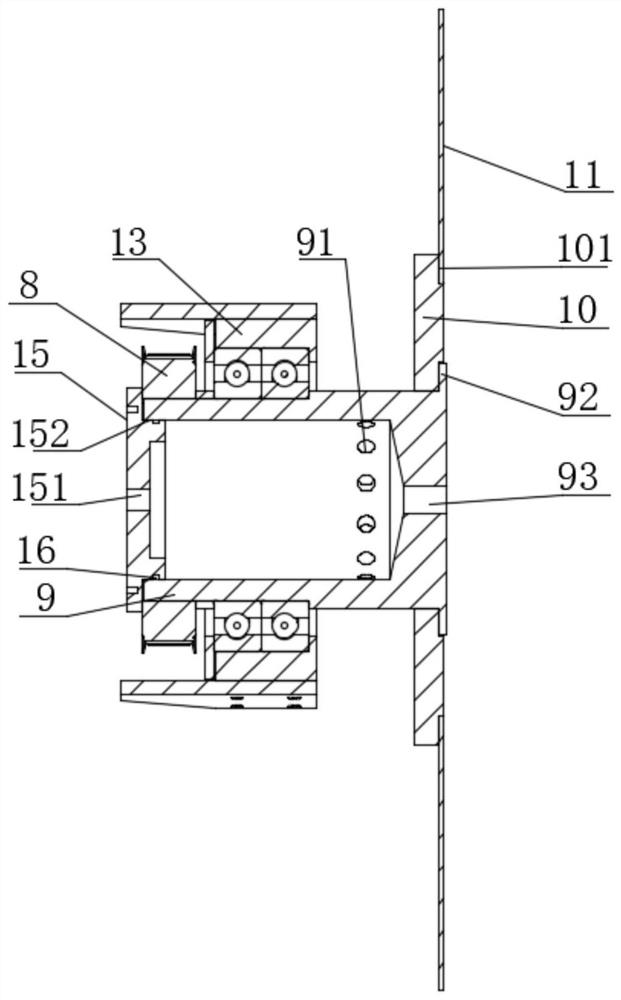

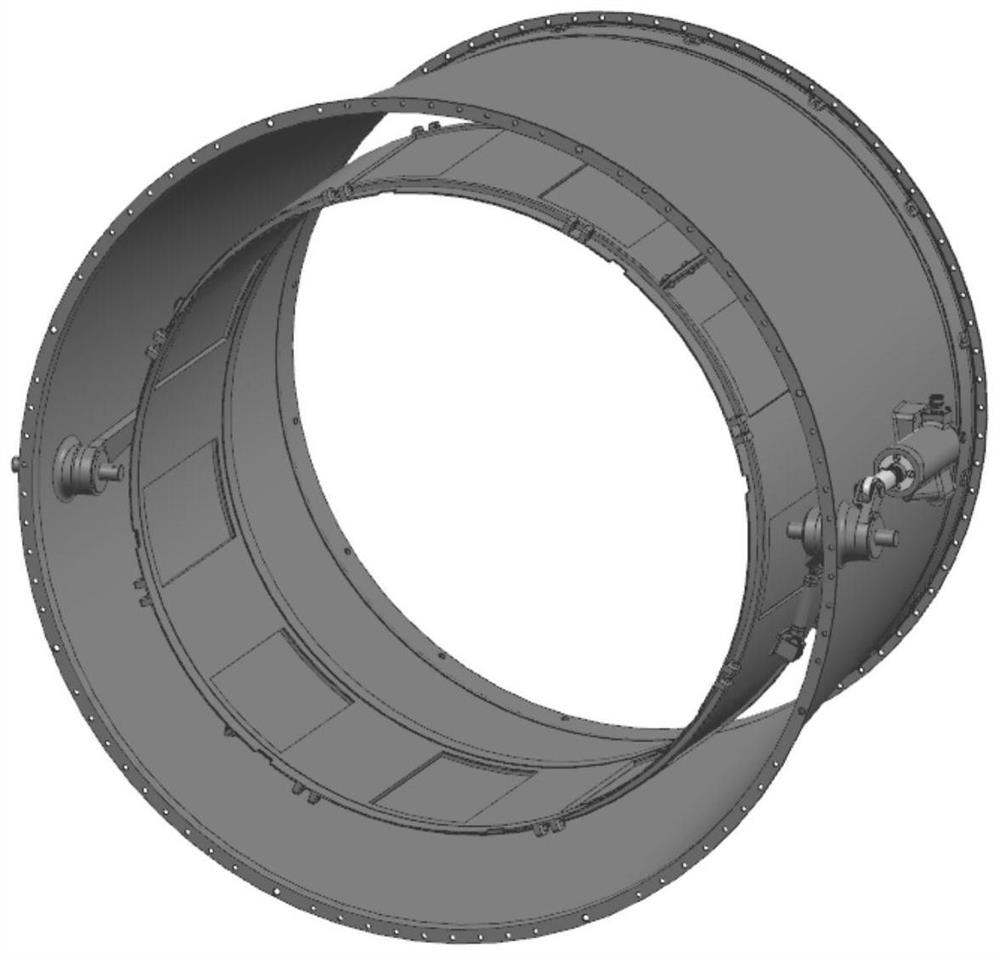

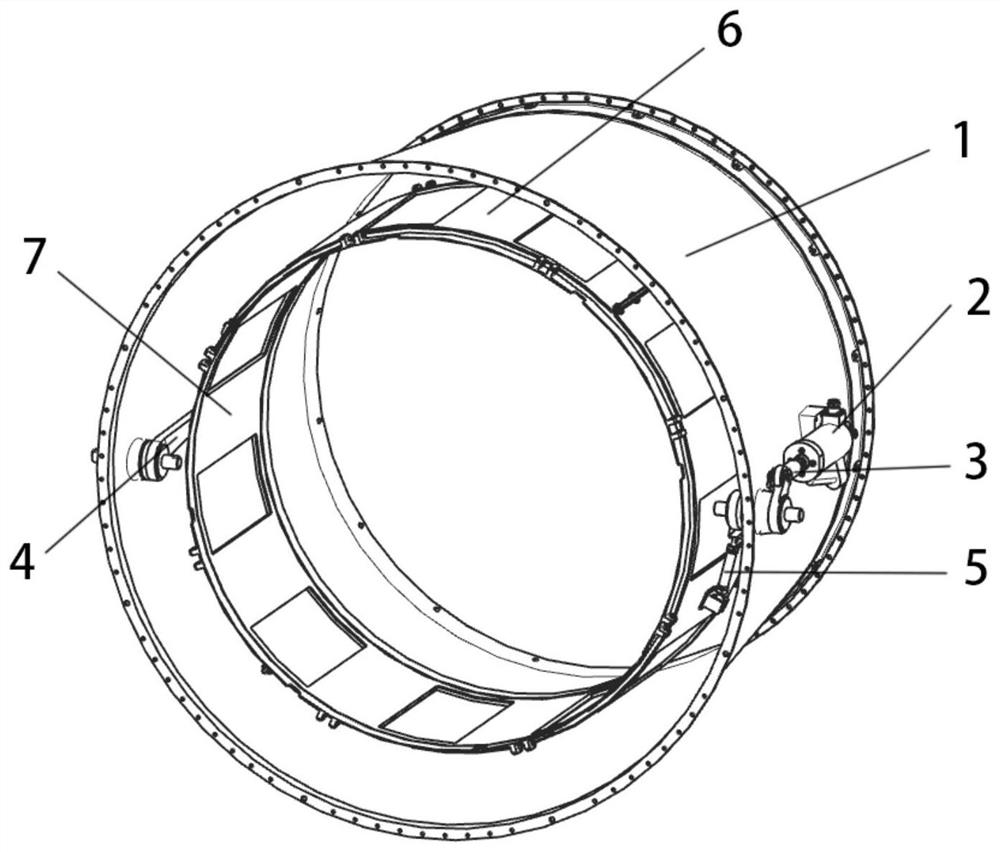

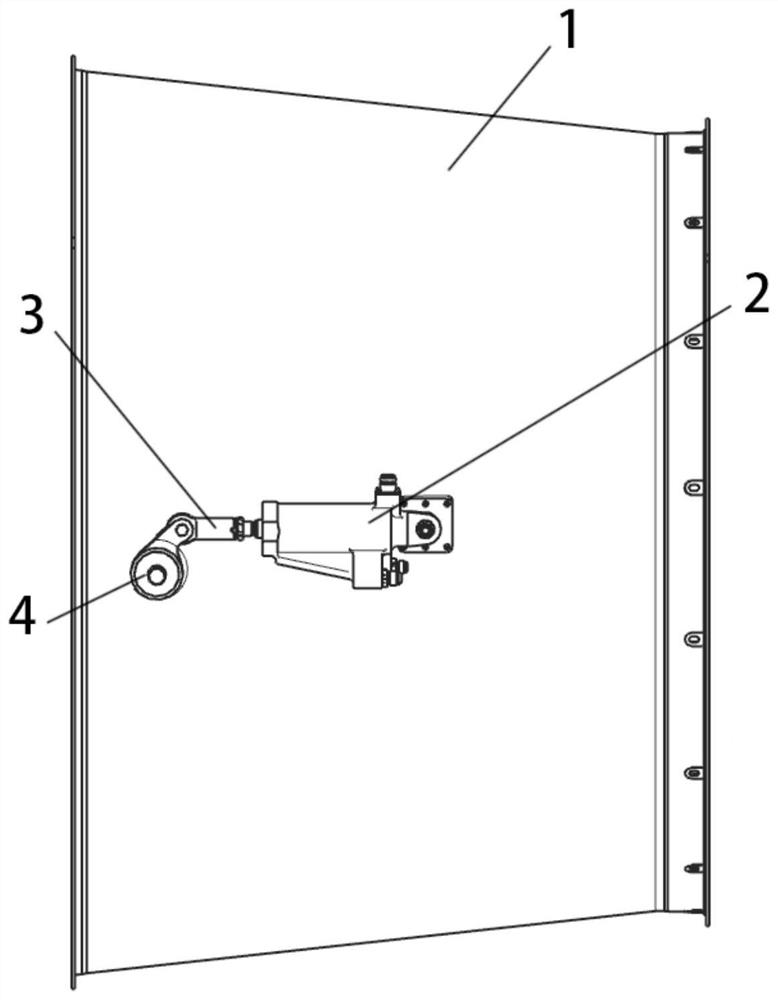

Aero-engine jet pipe throat area adjusting mechanism

The invention belongs to the technical field of aero-engine jet pipe throat area adjusting design, and particularly relates to an aero-engine jet pipe throat area adjusting mechanism. The mechanism comprises: a plurality of supporting beams, wherein the supporting beams are used for being connected to the outer wall of a jet pipe connecting cylinder and distributed in the circumferential direction; a plurality of rocker arms, wherein each rocker arm is correspondingly hinged to one supporting beam; a plurality of pull rods, wherein one end of each pull rod is correspondingly hinged to one rocker arm, and the other end of each pull rod is correspondingly hinged to the outer wall of one convergence piece; and a plurality of actuating cylinders, wherein a cylinder body of each actuating cylinder is used for being hinged to the outer wall of a jet pipe connecting cylinder, and a piston rod is correspondingly hinged to one rocker arm so as to drive the corresponding rocker arm to rotate around the hinged part of the rocker arm and the corresponding supporting beam, so that the corresponding convergence piece is driven to move through the corresponding pull rod, and the throat area of a jet pipe is adjusted.

Owner:AECC SHENYANG ENGINE RES INST

Color inkjet device for textile yarn

The invention relates to a color inkjet device for a textile yarn. The device comprises multiple sets of rotating nozzle assemblies. The rotating nozzle assemblies are arranged at intervals along thedirection of the yarn. Each set of rotating nozzle assemblies has the same structure, and comprises a sliding support. The sliding support moves up and down in the vertical direction. A rotary shaft is installed in the sliding support through a bearing box. The rotary shaft is a columnar structure with an opening at the top and a hollow cavity inside. The top of the rotary shaft is provided with acover plate. The cover plate closes the hollow cavity. The lower part of the rotary shaft is provided with a plurality of liquid outlet holes along the circumferential direction. The bottom of the rotary shaft is connected with a rotary disc with a larger diameter. The circumference of the rotary disc is provided with a plurality of nozzle installation holes for installing nozzles. The positionsof the nozzles correspond to the positions of the liquid outlet holes one to one. The device has the function of multi-color jet printing so as to realize the color inkjet of the yarn, and at the sametime, the device can form dot-like or mist-like ink spot patterns as required to meet the inkjet requirements of different products.

Owner:无锡市德赛数码科技有限公司

Irrigation equipment for agricultural production

InactiveCN108617471AAchieve the effect of rotationAchieve stirring effectRotary stirring mixersTransportation and packagingThreaded pipeWater source

The invention discloses irrigation equipment for agricultural production. The irrigation equipment comprises a box body; a through hole is formed in the top of the box body; a supporting plate is arranged inside the box body; the top of the supporting plate is fixedly connected with a spray head; the right side of the box body is fixedly connected with a water tank; the right side of the top of the water tank communicates with a filling pipe; the axial position of the bottom of the box body is fixedly connected with a first motor; a rotating shaft of the first motor is fixedly connected with athreaded rod; and the top of the threaded rod extends to the inside of the box body. The effect of driving the threaded rod to rotate is achieved due to the arrangement of the first motor, the effectof driving the supporting plate and the spray head to move is achieved due to the arrangement of the threaded rod and a threaded pipe, the effect of placing a water source is achieved due to the arrangement of the water tank, the effect of stirring water and nutrient substances is achieved due to the arrangement of a second motor and a stirring blade, and the effect of spraying water is achieveddue to the arrangement of the spray head. By using the irrigation equipment, the land can be irrigated, the irrigation area can also be regulated, and the irrigation efficiency is guaranteed.

Owner:芜湖千创智能科技有限公司

Flapping wing flying device with adjustable flapping wing

InactiveCN103832590ASimple Flight ControlsNo significant increase in weightOrnithoptersFlapping wingFlight vehicle

The invention discloses a flapping-wing-shaped flying device realized by guide pipes. The device comprises a flapping wing 1, a connecting structure 2, an inner boundary guide pipe 3, an outer boundary pipe 4, an air pump 5 and an air-filled guide pipe 6. According to the device, the structure is simple, the air pump and the guide pipes can be used for adjusting the shape and the area of the flapping wing, the simple flying control of the flying device is realized, and a complicated flying control system is not used; and as air is used in the guide pipes, the weight of the whole flying device is not remarkably increased.

Owner:SHANGHAI PUDONG INTPROP PROTECTION ASSOC +1

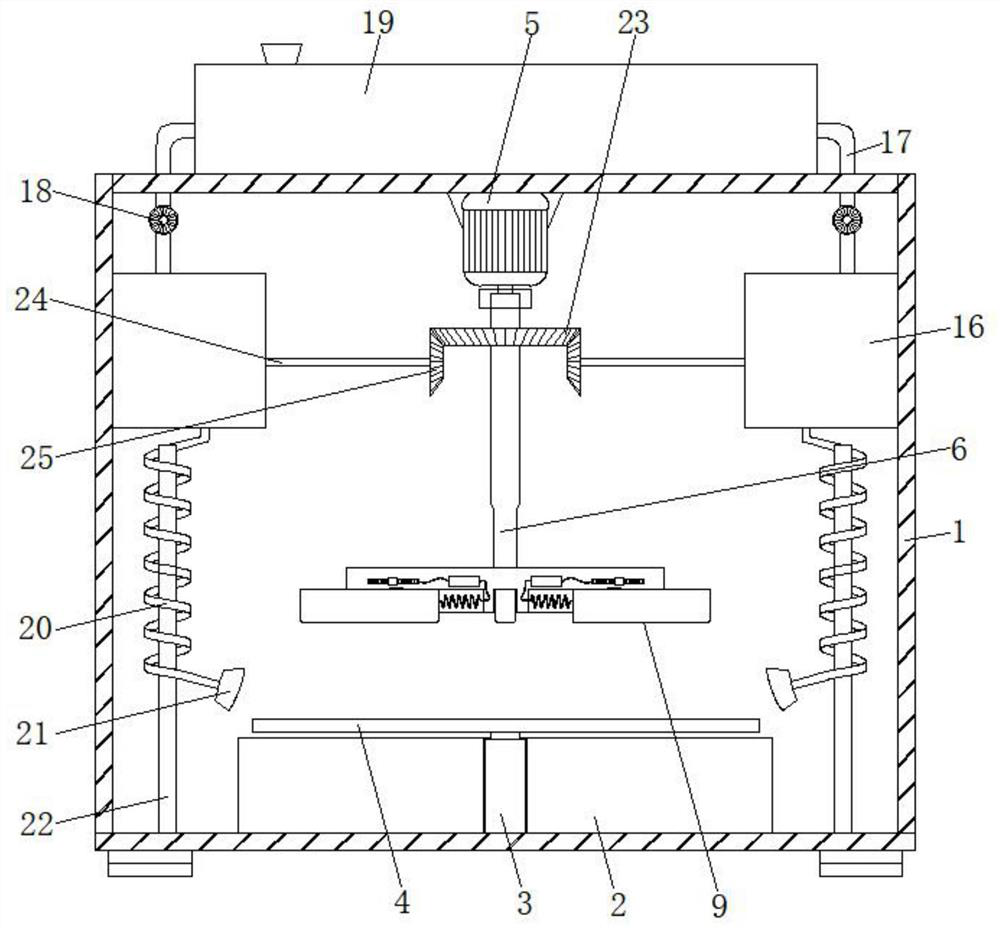

Water-based ink printing press capable of changing printing area

ActiveCN112937092AIncrease temperatureImprove printing efficiencyRotary pressesOther printing apparatusElectric machineEngineering

The invention discloses a water-based ink printing press capable of changing printing area. The water-based ink printing press comprises a case body; the inner bottom wall of the case body is fixedly provided with a reference seat, and an automatic telescopic rod is fixedly installed in the reference seat; the telescopic end of the automatic telescopic rod is fixedly connected with a tool holding table; a driving motor is fixedly installed on the inner top wall of the case body; and the output end of the driving motor is fixedly connected with a rotating shaft. According to the water-based ink printing press capable of changing the printing area, in the rotating process of a printing mechanism, the power of the driving motor is controlled to increase to make the rotating speed increase, and accordingly, centrifugal force increases; print heads move outwards along base plane telescopic grooves under the action of the centrifugal force, and at this time, the centrifugal force is larger than the elastic force of the print heads to overcome the elastic force of springs, so that the printing area increases, so that larger to-be-printed matter can be conveniently printed, and on the contrary, if the power of the driving motor is reduced, the printing area is reduced; and the printing area is adjusted by the water-based ink printing press according to the specification of the to-be-printed matter, thus avoiding waste of electric energy.

Owner:浙江华众标签有限公司

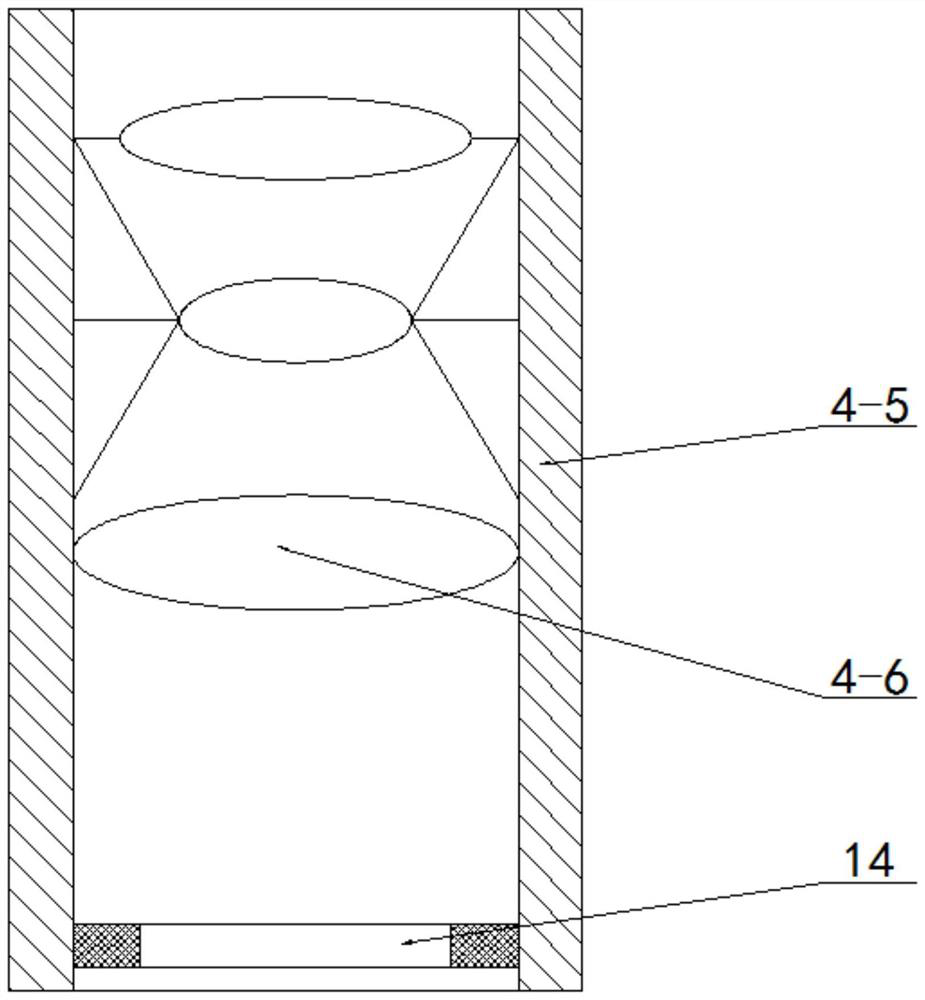

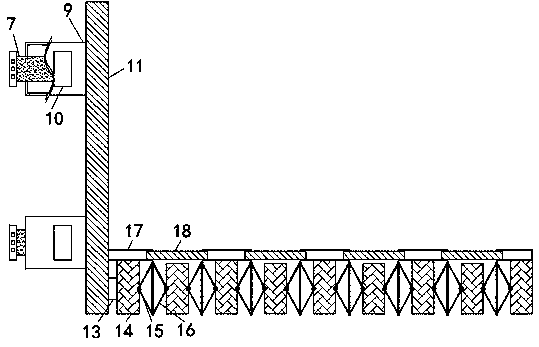

Terminal output light spot regulator of laser beauty instrument

PendingCN113900261AAchieving Light TherapyArea adjustmentLight therapyMountingsMechanical engineeringFacula

A terminal output light spot regulator of a laser beauty instrument relates to the technical field of laser beauty instrument equipment and comprises a base, a support and a laser generator, the support is fixedly arranged on the base, and the laser generator is arranged on the support; a light spot irradiation area adjusting assembly is fixedly arranged on the support, the laser generator is fixedly arranged at the input end of the light spot irradiation area adjusting assembly, and the light spot intensity adjusting assembly is fixedly arranged between a working area on the light spot irradiation area adjusting assembly and the laser generator; An overall liftable mounting structure, a narrow-strip-shaped shading structure and afilter lens structure are arranged, so that the illumination intensity and the illumination area can be adjusted conveniently, and equipment parameters can be adjusted conveniently according to the requirements of a user to meet the normal treatment requirements.

Owner:杭州知橙生物科技有限公司

A display device and method of using the same

ActiveCN110868486BIncrease the display area towards the frontDisplay area adjustment towards the frontDevices with multiple display unitsTelephone set constructionsComputer hardwareComputer graphics (images)

The invention discloses a display device and a using method thereof. The display device includes a main body, a first display screen and a flexible second display screen arranged along a first direction, the main body includes a front side facing the user and a back side opposite to the front side, the first display screen is set On the front side, an end of the second display screen close to the first display screen is arranged on the front side, and an end of the second display screen away from the first display screen passes through a first sliding mechanism It is arranged on the back side and slides in the first direction through the first sliding mechanism, so that the area of the second display screen facing the side of the front side increases or decreases. In the display device, the second display screen is driven to slide by the first sliding mechanism, which realizes the expansion of the display area of the display device toward the front direction, without increasing the thickness of the display device, and facilitates storage and portability of the display device.

Owner:BOE TECH GRP CO LTD

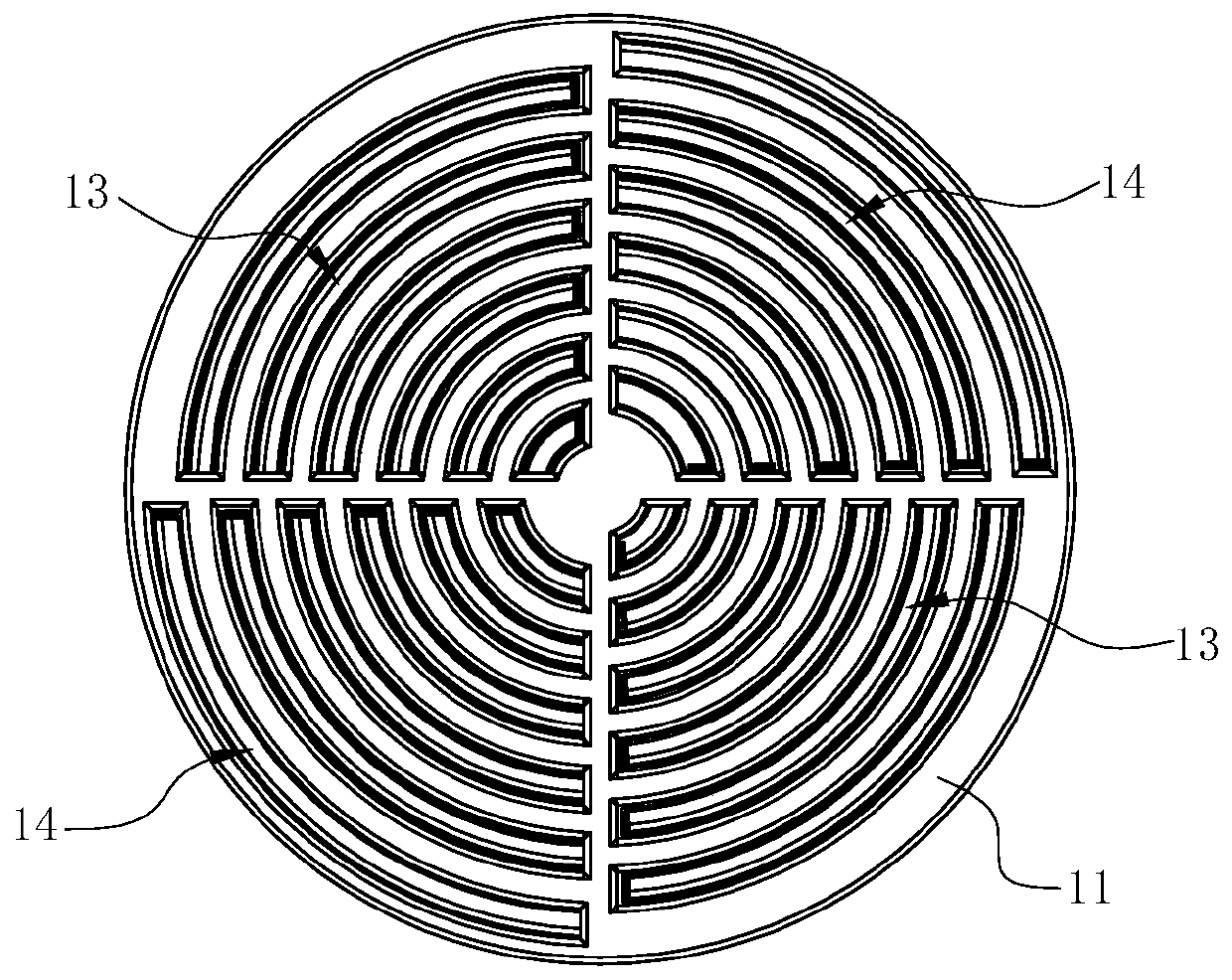

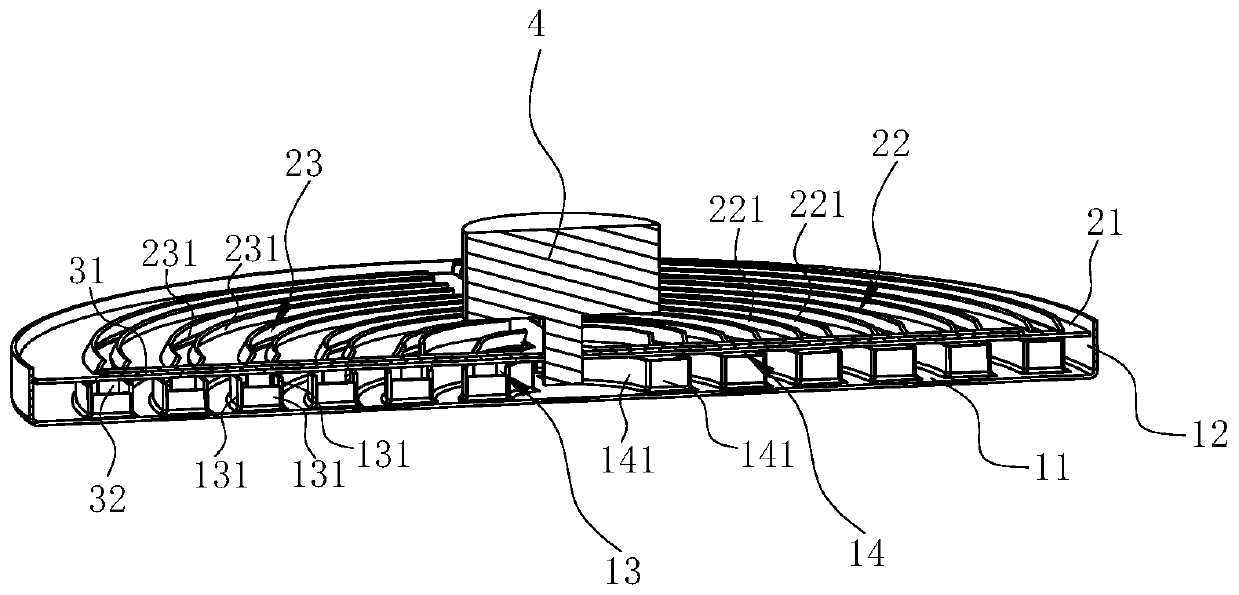

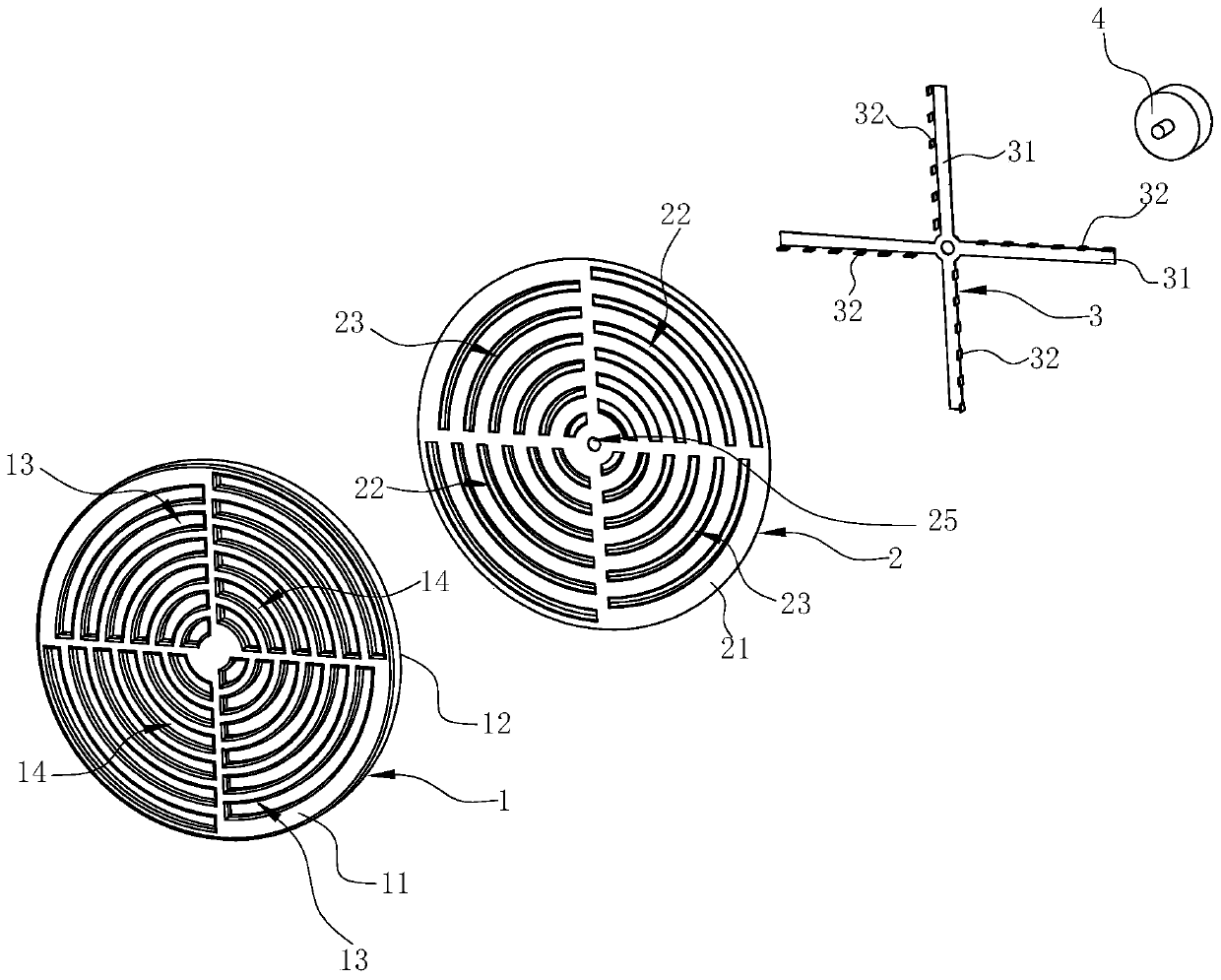

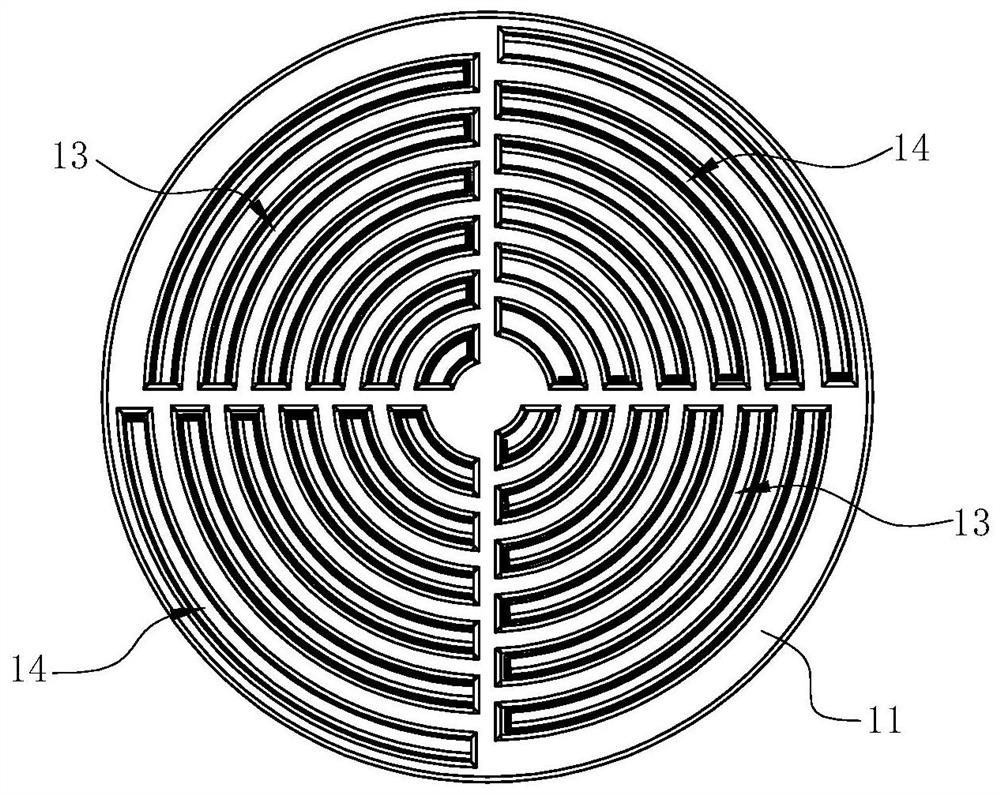

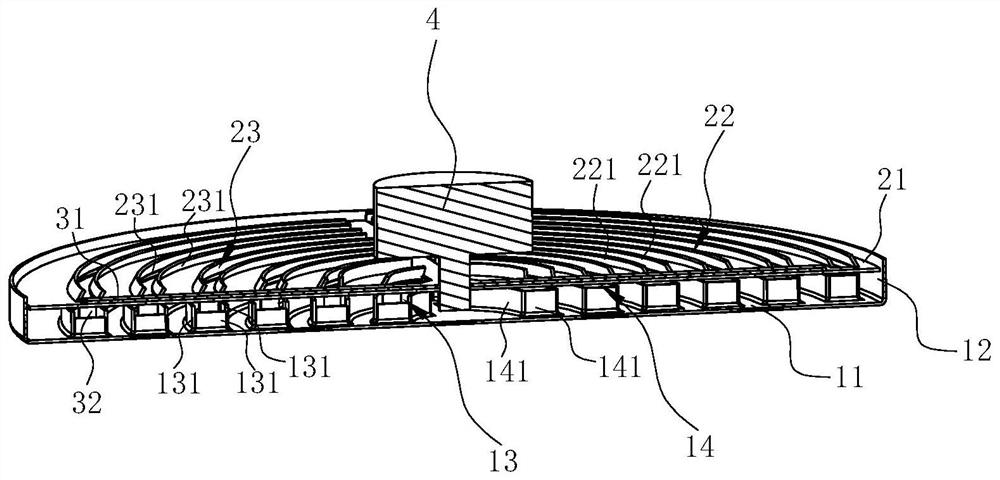

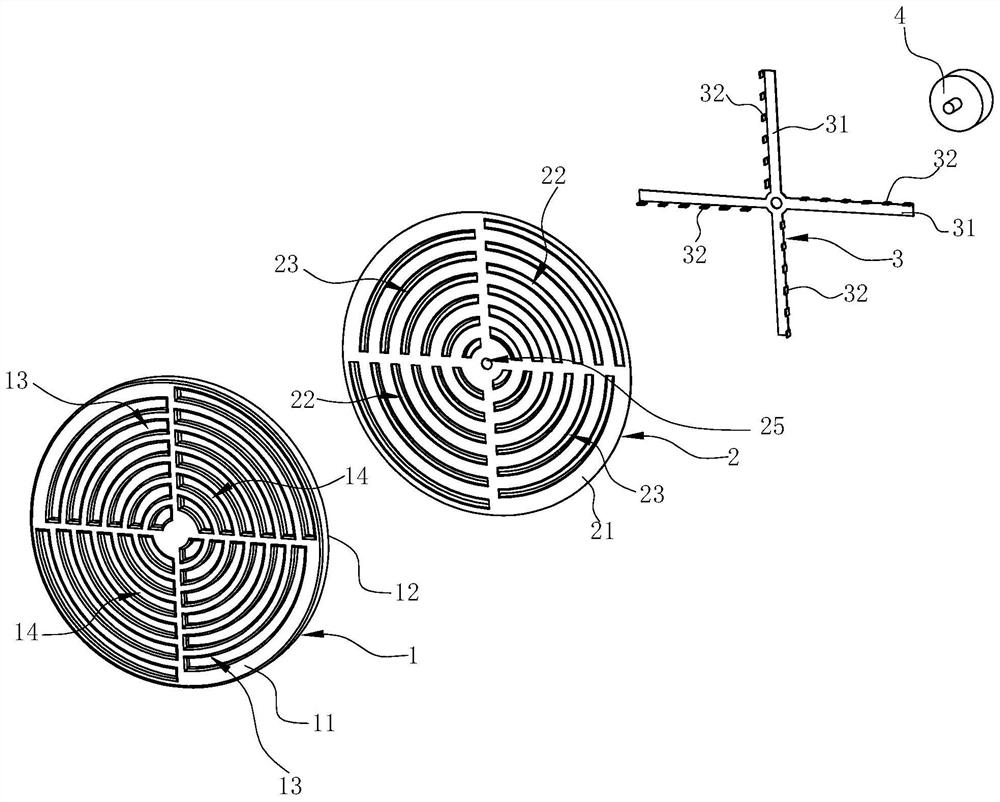

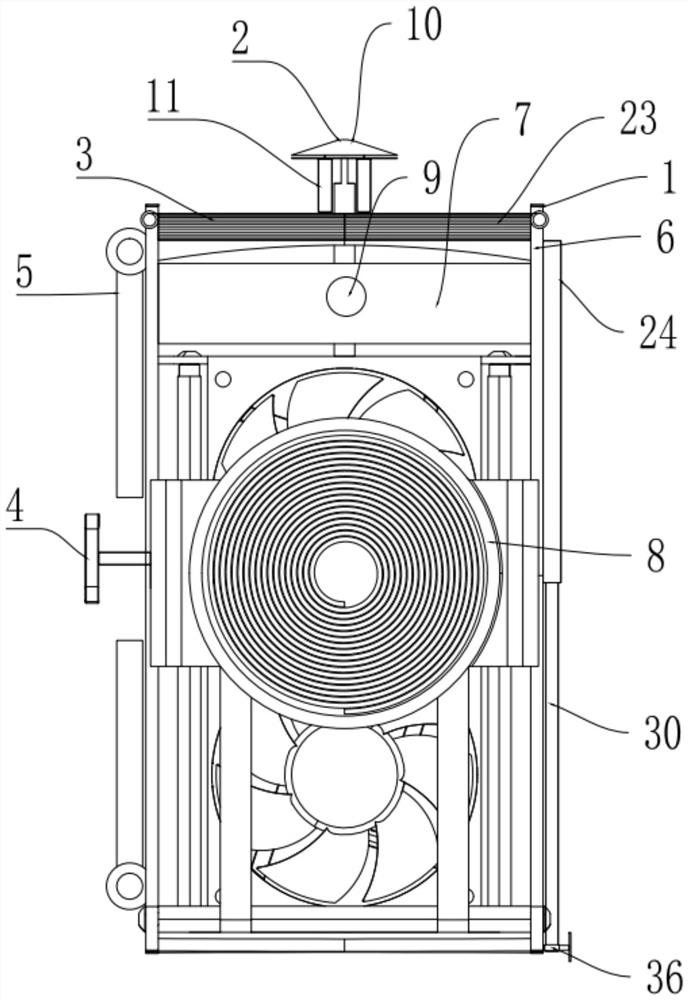

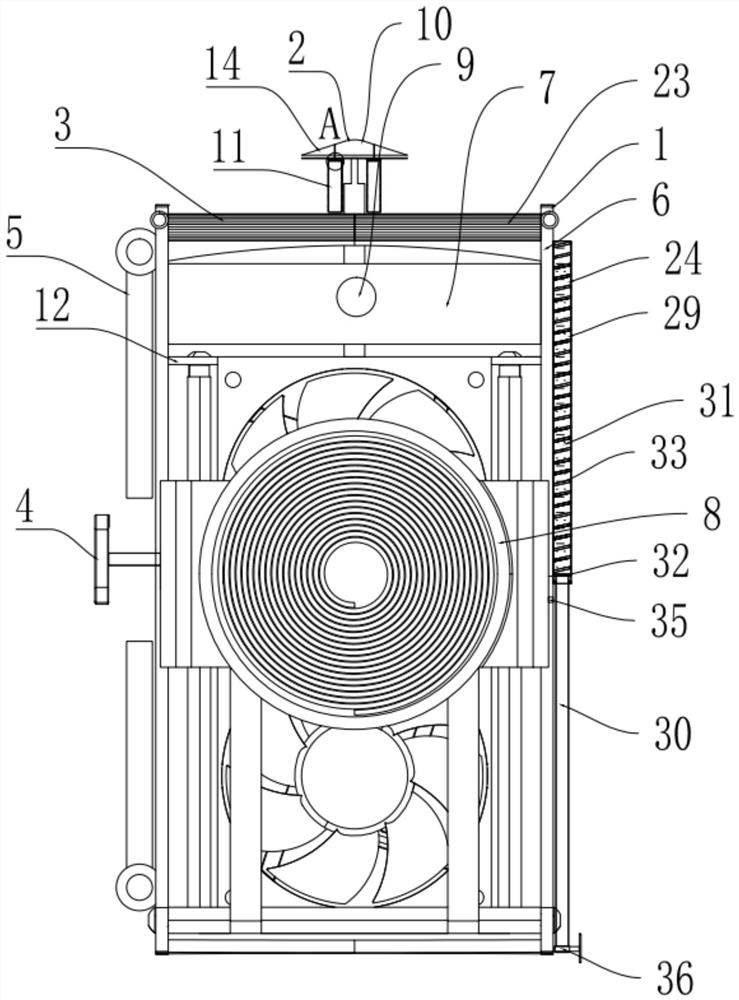

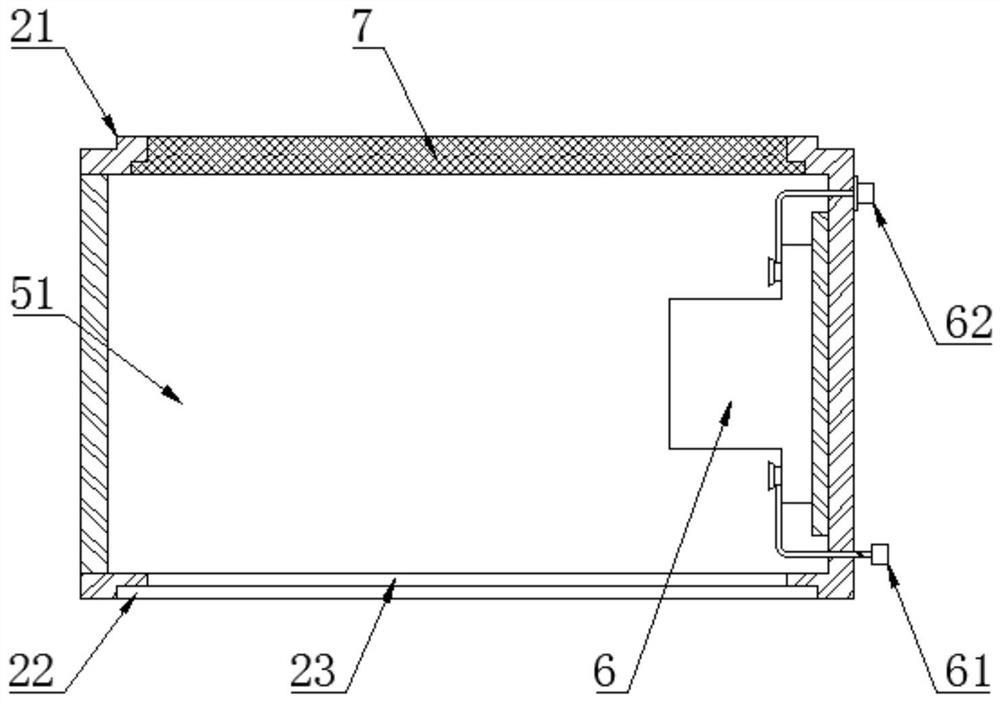

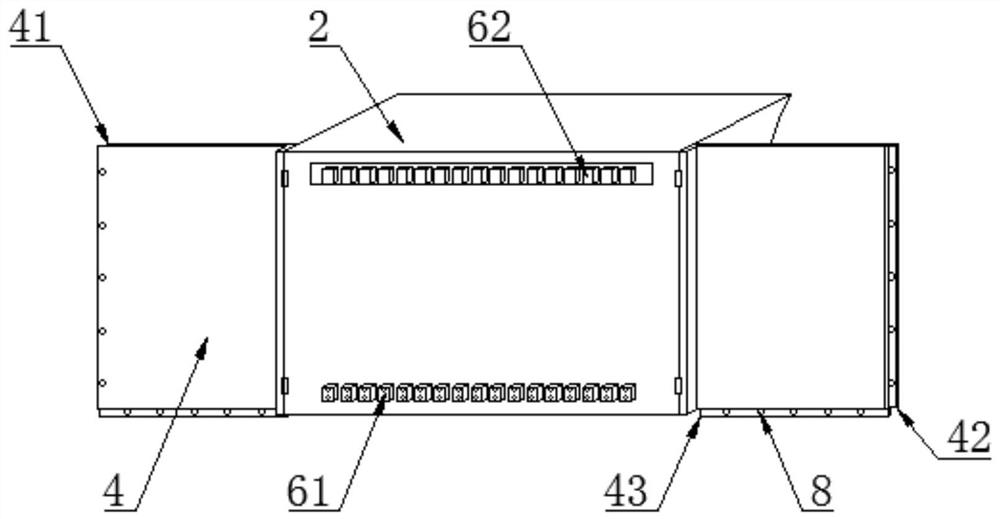

Filtering device and extractor hood with filtering device

ActiveCN111156556AAchieve closureImprove separation efficiencyDomestic stoves or rangesLighting and heating apparatusMechanical engineeringOil filter

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

A filter device and range hood using the filter device

ActiveCN111156556BAchieve closureImprove separation efficiencyDomestic stoves or rangesLighting and heating apparatusFiltrationMechanical engineering

The invention discloses a filtering device, which comprises a first oil filter net and a second oil filter net, the first oil filter net includes a first mesh pan, the second oil filter net includes a second net pan, and the first net pan is provided with a There are first air inlets and second air inlets arranged at intervals in the circumferential direction of the first grid tray, the first air inlets and the adjacent second air inlets are arranged alternately in the radial direction of the first grid tray, and the second grid tray There are third air inlets and fourth air inlets on the top, and they are arranged at intervals in the circumferential direction of the second grid tray, and the third air inlets and adjacent fourth air inlets are staggered in the radial direction of the second grid tray; the second The oil filter screen can rotate relative to the first oil filter screen so that the filter device is in an open state and a closed state. When the filter device is in an open state, the first air inlet and the second air inlet of the first oil filter screen are opened; when the filter device When in the closed state, the second oil filter screen blocks the first air inlet and the second air inlet of the first oil filter screen. Also disclosed is a range hood applied with the filter device.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Portable mobile phone wireless charging seat and use method thereof

ActiveCN114844171AAvoid damageSolve the problem of hot sun exposureElectric powerTelephone set constructionsEmbedded systemMobile phone

The invention discloses a portable mobile phone wireless charging seat and a use method thereof, and the charging seat comprises a charging main body, an open type outdoor shooting mobile phone protection mechanism, a hidden folding type anti-exposure sunshade mechanism, a manual clamping type fixing mechanism, and a lateral storage type supporting mechanism. The open type outdoor shooting mobile phone protection mechanism is arranged at the upper end of the charging main body, the hidden folding type anti-exposure sunshade mechanism is arranged at the upper end of the front side of the charging main body, the manual clamping type fixing mechanism is arranged on the charging main body, and the lateral storage type supporting mechanism is arranged on the side edge of the charging main body; the invention belongs to the technical field of portable mobile phone wireless charging seats, and particularly relates to a portable mobile phone wireless charging seat and a use method thereof.

Owner:诚罡科技(天津)有限公司

A Handheld Semiconductor Laser Therapeutic Instrument

ActiveCN113350703BMeet the regulatory useAvoid the impact of sliding left and right againLight therapyHand heldLaser light

The present invention provides a hand-held semiconductor laser treatment instrument, which includes a laser treatment instrument body, the laser treatment instrument body includes a support cylinder, a fixing ring is installed on the support cylinder, and a fixing block is welded on the fixing ring. There is an opening inside the fixed block, and a support plate is installed inside the opening, and the support plate is installed on the fixed block through a fixed shaft. The hand-held semiconductor laser therapeutic instrument is equipped with a clamping ball on the movable cylinder, and the clamping ball is in the shape of The isosceles triangle is matched with the chute. When the movable cylinder on one side collides, the clamping ball on the corresponding side is separated from the clamping hole, and the spring force inside the remaining two clamping beads is less than the tension of the supporting spring, so that the movable cylinder The cylinder quickly shrinks to the inside of the support cylinder for protection. In addition, according to the requirements of the use, the area to use the laser can be adjusted. The laser lamp can be used alone or two laser lamps can be used together.

Owner:WUHAN GIGAA OPTRONICS TECH

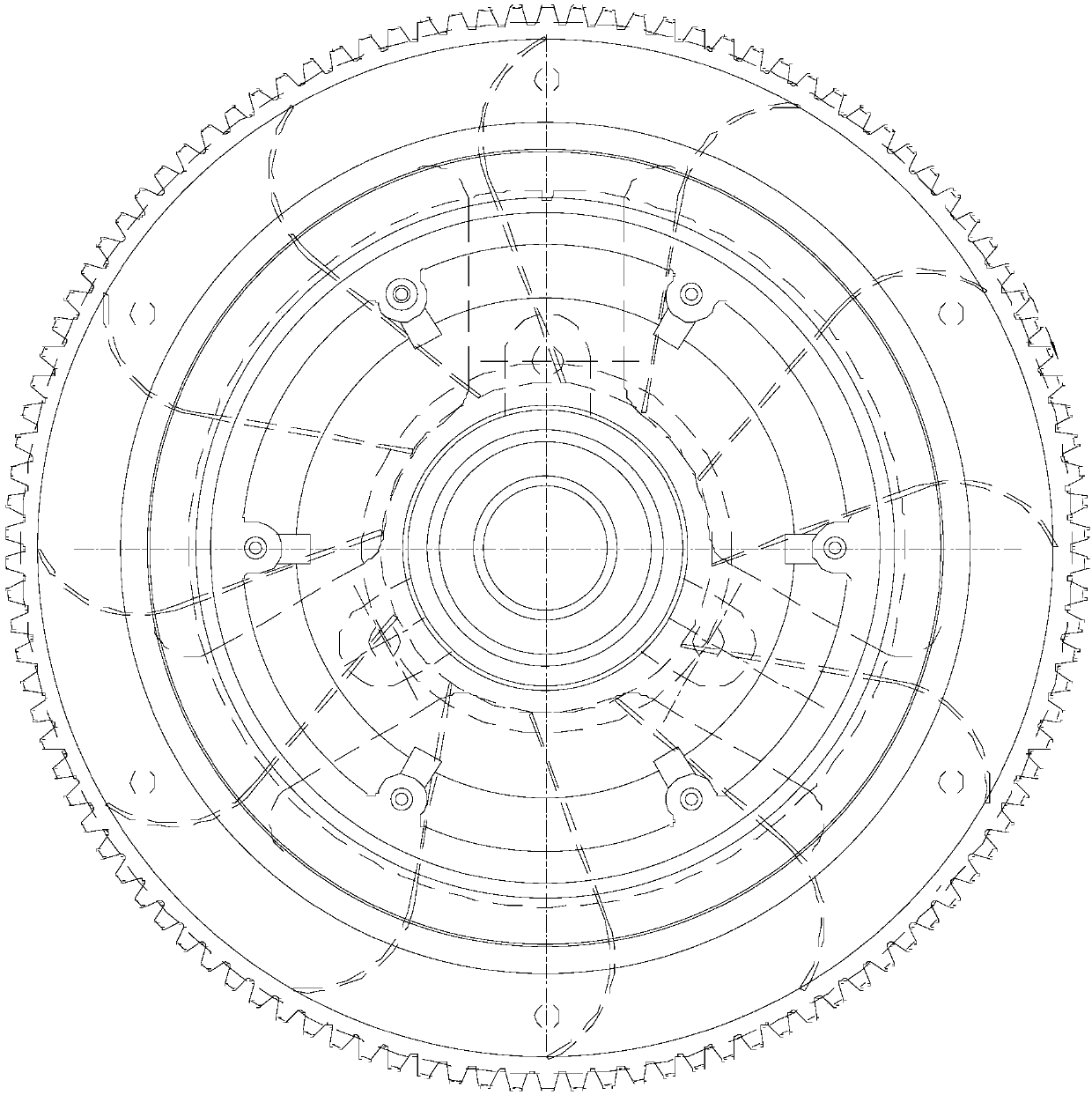

Diesel generating set stator cooling device

PendingCN107659054AGuaranteed working temperatureImprove coolingCooling/ventillation arrangementFlywheelMagnet

The invention discloses a diesel generating set stator cooling device which comprises a stator, a flywheel, a double-end stud, an elastic pad, a nut, an inner ring plate, blades, a ring plate and a gasket. The stator is mounted in the central hole of the flywheel. The inner ring plate is mounted on the right end surface of the flywheel. A plurality of blades are mounted between the inner ring plate and the ring plate. The left end of the double-end stud is mounted in the screw hole on the right end surface of the flywheel. The middle part of the double-end stud is mounted in the mounting holeof the blade. The gasket is mounted on the double-end stud and abuts against the right end surface of the ring plate. The elastic pad is mounted on the double-end stud and furthermore abuts against the right end surface of the gasket. The nut is mounted on the double-end stud and abuts against the right end surface of the elastic pad. The diesel generating set stator cooling device settles problems of easy aging of stator enameled long-term high temperature and magnesium reduction of a magnet by high temperature. Furthermore the diesel generating set stator cooling device improves cooling effect of the whole set.

Owner:江苏东方康弛机电科技有限公司

Folding type engine suspension installing structure

The invention relates to the technical field of suspension equipment, and discloses a folding type engine suspension installing structure. The folding type engine suspension installing structure comprises suspension plates, fixing holes are formed in the obverse sides of the suspension plates, fixing blocks are fixedly installed on the left sides and the right sides of the suspension plates, a stop block is fixedly installed on the top of each fixing block, toothed blocks are fixedly installed on the left side wall and the right side wall of each fixing block, sliding blocks are movably installed in each fixing block, and two limiting blocks are movably installed in each sliding block. According to the folding type engine suspension installing structure, no less than nine supporting blocksare movably connected through supports and connected through rotating rods to form a prismatic four-fulcrum moving frame, and therefore the supporting blocks can relatively horizontally move; and inaddition, installing plates are installed on the tops of the supporting blocks and movably installed through sliding plates, therefore, the area of the installing plate is adjusted through moving of the supporting blocks, and folding of a suspension bracket is achieved.

Owner:雀来宝科技江苏有限公司

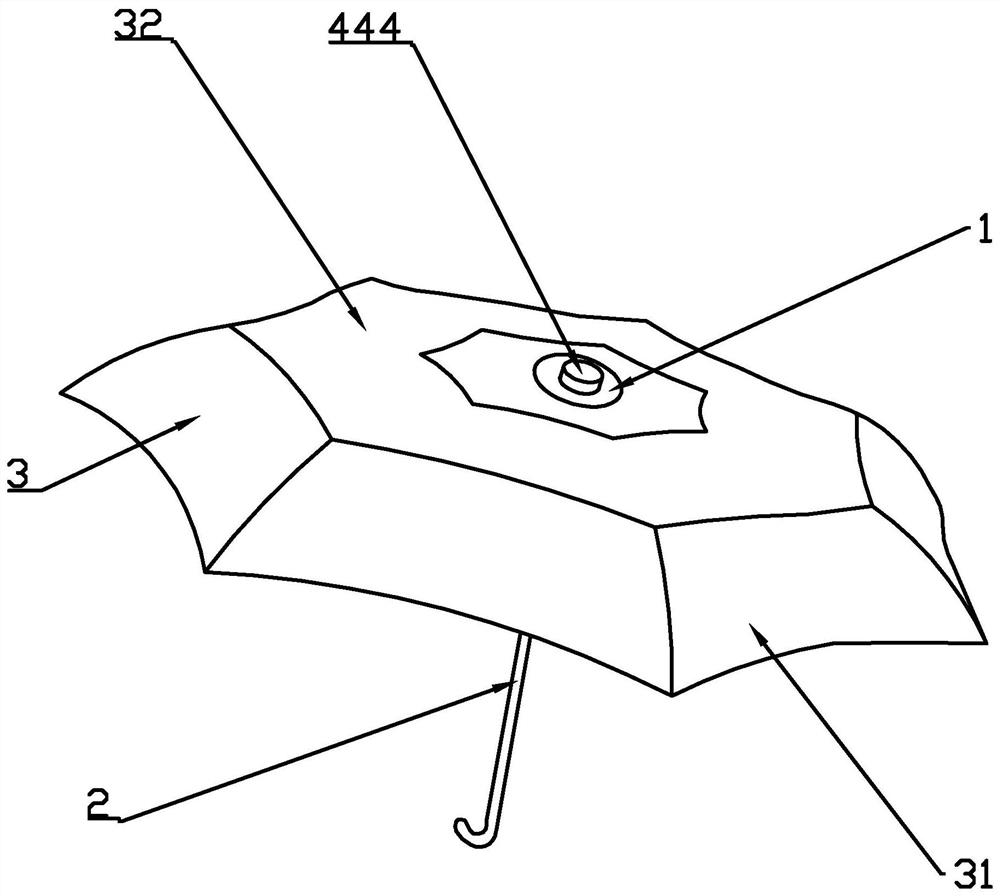

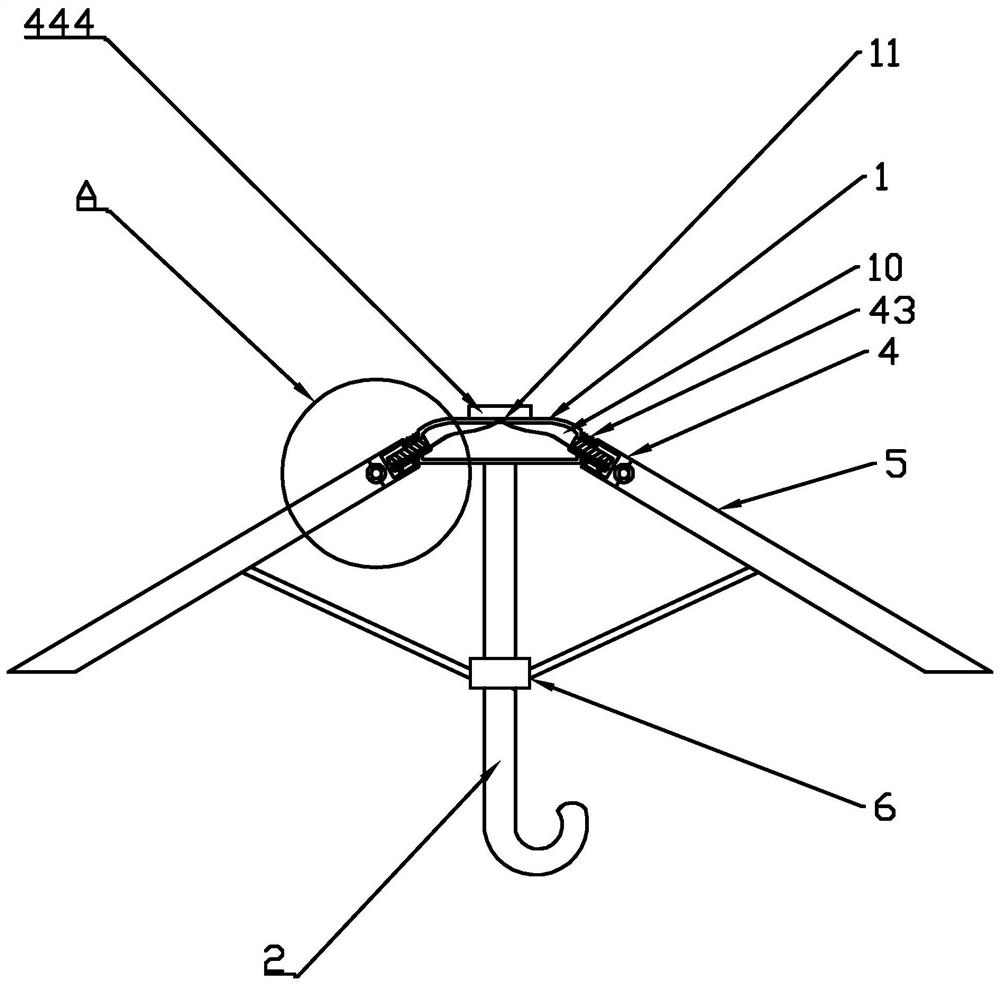

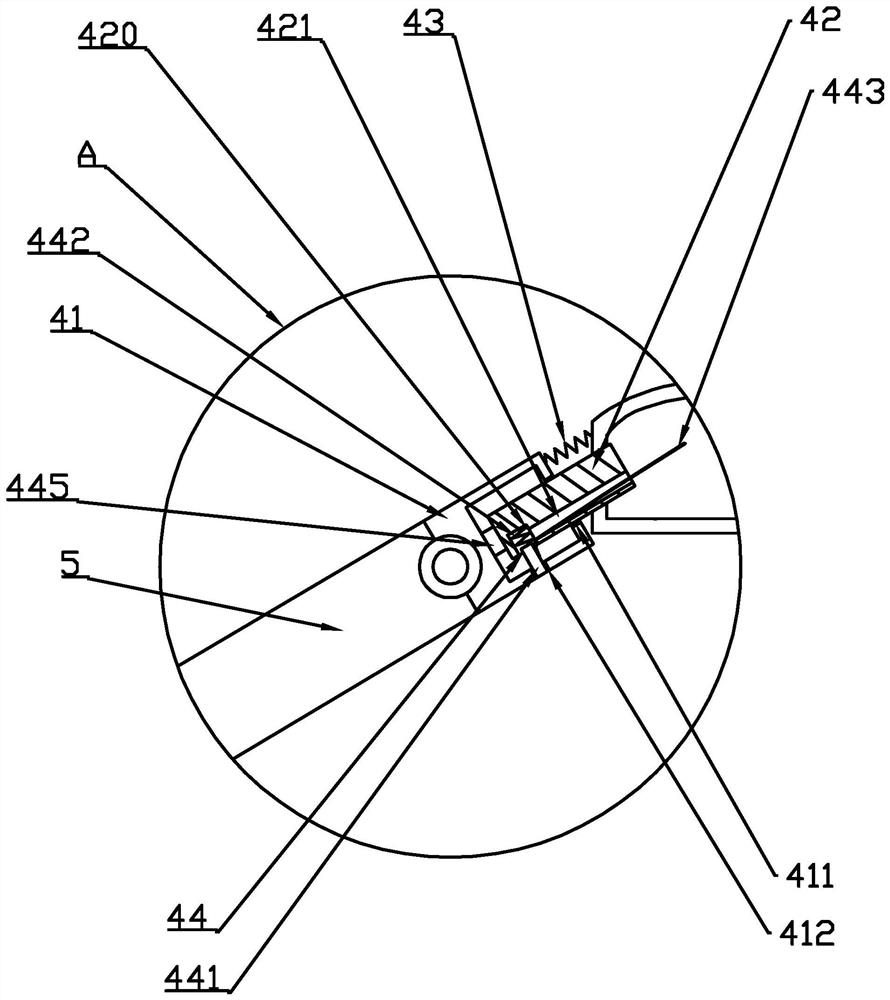

A convertible single and double umbrella

ActiveCN110326866BSimple structureEasy to useWalking sticksStructural engineeringMechanical engineering

The invention discloses a convertible single- and double-person umbrella, which comprises an umbrella crown, an umbrella handle, an umbrella surface, several extension rod groups and several umbrella ribs, the umbrella crown is arranged on one end of the umbrella handle, and several said extension One end of the rod group is connected to the outer peripheral wall of the umbrella crown, and several of the expansion rod groups are distributed in a circle, and the ends away from the umbrella crown are all inclined to the umbrella handle, and the several umbrella ribs are respectively hinged on several expansion rods On the end of the rod group away from the umbrella crown, the umbrella surface includes an unfolded surface and a folded surface. On one side of the handle, the expansion rod group is used to expand the folded surface to increase the area of the umbrella surface. The expansion rod group includes an outer rod, an inner rod, a first spring and a fixing piece. The beneficial effect of the present invention is that the umbrella can The size of the umbrella surface is adjustable, suitable for single or multiple use.

Owner:诸暨市昱锦电子商务商行

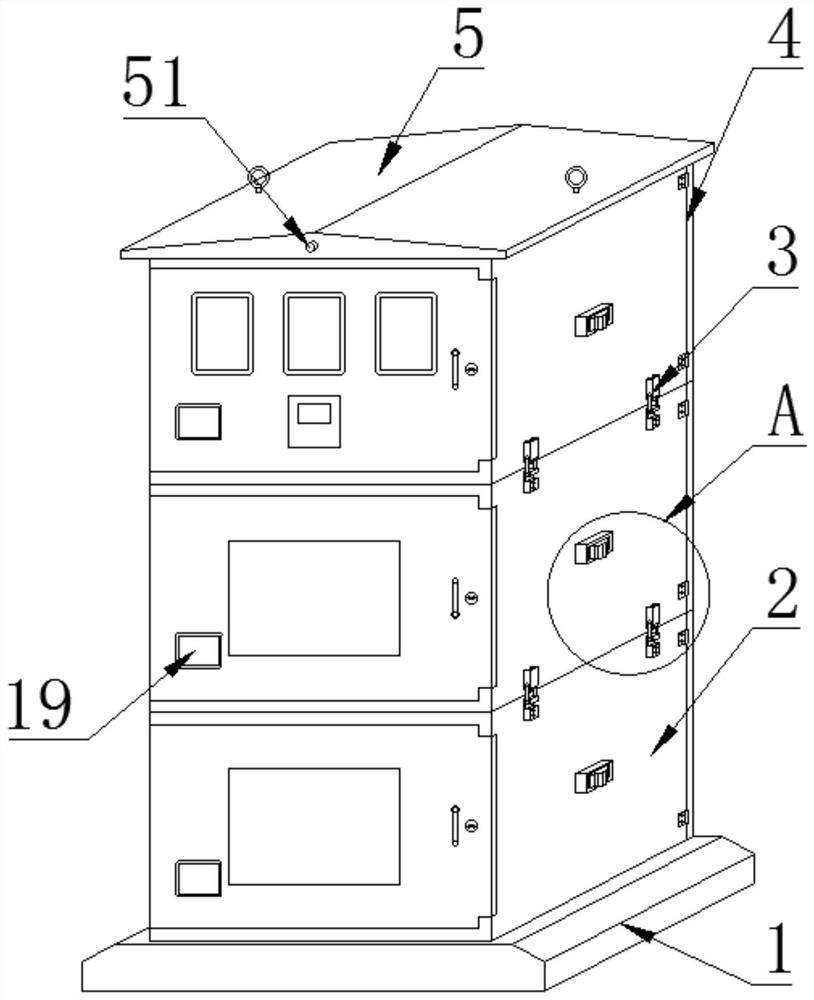

Convenient-to-overhaul combined electrical cabinet

PendingCN113612126AEasy to separateEasy to carrySubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringStructural engineering

The invention provides a convenient-to-overhaul combined electrical cabinet, which comprises a base and a rain cover, a plurality of groups of cabinet bodies are arranged between the rain cover and the base, electrical components and air suction outer pipes are arranged in the cabinet bodies, the electrical components are fixed on the inner rear walls of the cabinet bodies through base plates, the bottom of the air suction outer pipe is integrally connected with an air suction inner pipe, and the air suction inner pipe downwards penetrates through the cabinet body and correspondingly extends into the air suction outer pipe on the next cabinet body. According to the invention, through a combined assembly mode, the electrical cabinet can be placed and carried separately and conveniently, the electrical cabinet does not need to be transported integrally, the transportation difficulty is reduced, and a plurality of electrical cabinets can be stacked together conveniently, so that the space utilization rate is improved, the electrical cabinet is convenient to disassemble and assemble, the maintenance and replacement of the electrical components are facilitated, the maintenance time is shortened, and the working efficiency is high.

Owner:合肥市飞龙电气设备有限公司

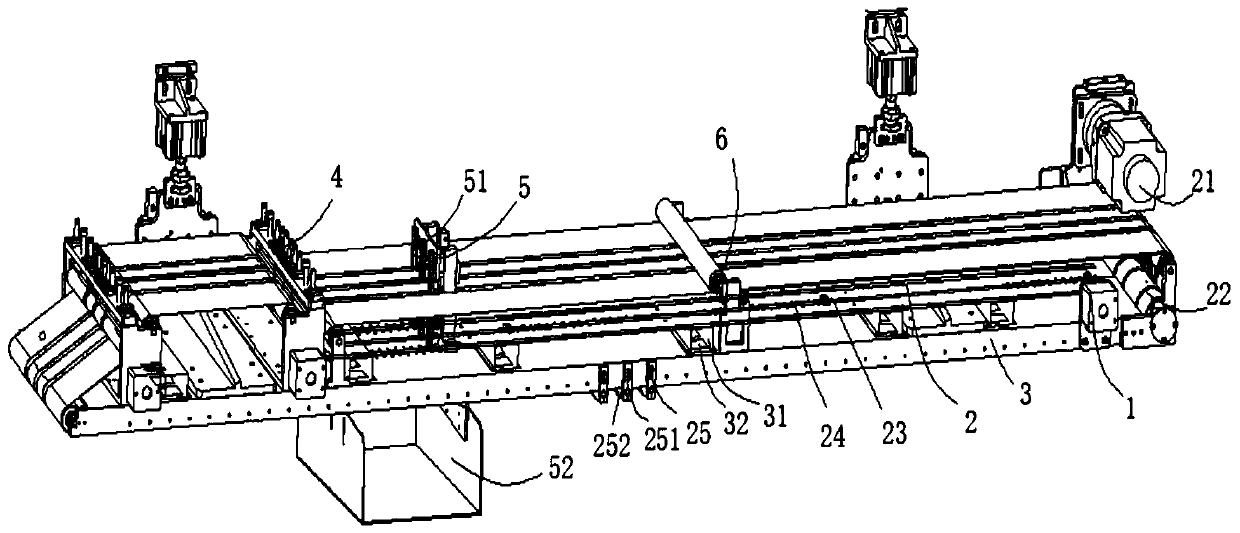

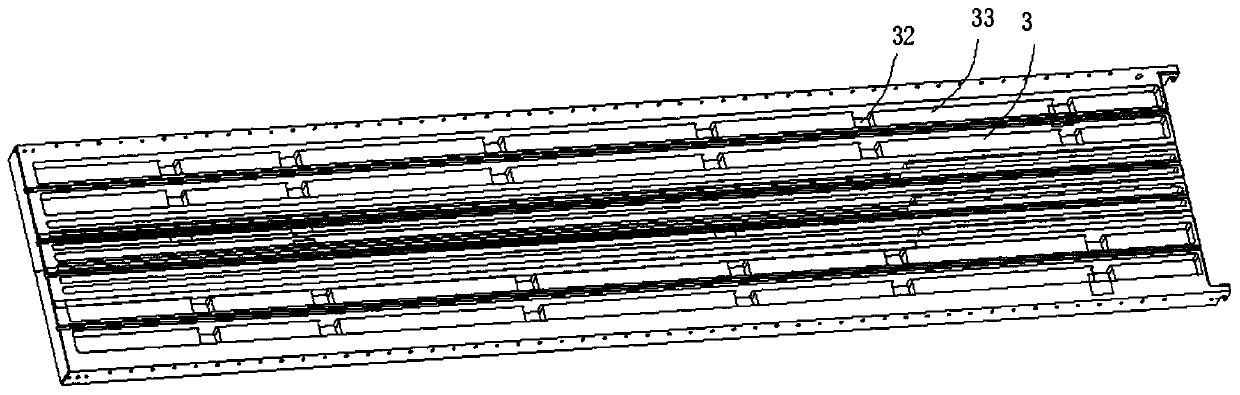

Pole piece conveyer

The invention discloses a pole piece conveyer which comprises a machine station, a vacuum belt component arranged on the machine station and capable of driving, and a vacuum mechanism arranged on themachine station, wherein the vacuum belt component is cooperated with the vacuum mechanism to generate vacuum adsorption force; the vacuum mechanism comprises a plurality of vacuum cavities formed inthe machine station at intervals, and a plurality of vacuum draught hoods cooperated with the vacuum cavities correspondingly; a vacuum suction opening is formed in each of the vacuum cavities; and the vacuum draught hoods are correspondingly arranged on the vacuum cavities and communicate with the interiors of the vacuum cavities via the vacuum suction openings. The pole piece conveyer can reducethe power of a vacuumizing fan to further realize the purposes of saving energy and lowering equipment noise, can more conveniently adjust the vacuum adsorption area as demanded and increases the integral vacuum flow rate and pressure.

Owner:深圳市阿尔斯自动化科技有限公司

A rear channel ejector with the valve body tightly closed in the circumferential direction

The invention discloses a rear duct ejector whose valve body is tightly covered in the circumferential direction. Circumferentially actuated valve body and inner casing for crank and pair of ball-joint links. The technical scheme of the present invention can adjust the outlet area of the variable cycle engine; there is a circumferential sliding groove between the valve body and the inner casing, so the opening and closing of the airflow channel can be realized by circumferential rotation; the valve body is a circumferential sliding groove. Tighten to a tightly capped one-piece valve body, not multiple valve body pieces. It solves the problem that it is difficult to realize the synchronous movement of multiple valve body pieces due to different stress conditions.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com