Turning plate mechanism for ballast water tank water pouring and draining system

A ballast water tank and drainage system technology, which is applied in the direction of motor vehicles, underwater ships, special-purpose ships, etc., can solve the problem that the effective area of the sea opening cannot be adjusted, increase the weight and volume of deep-sea manned submersibles, and increase deep-sea manned diving device weight etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

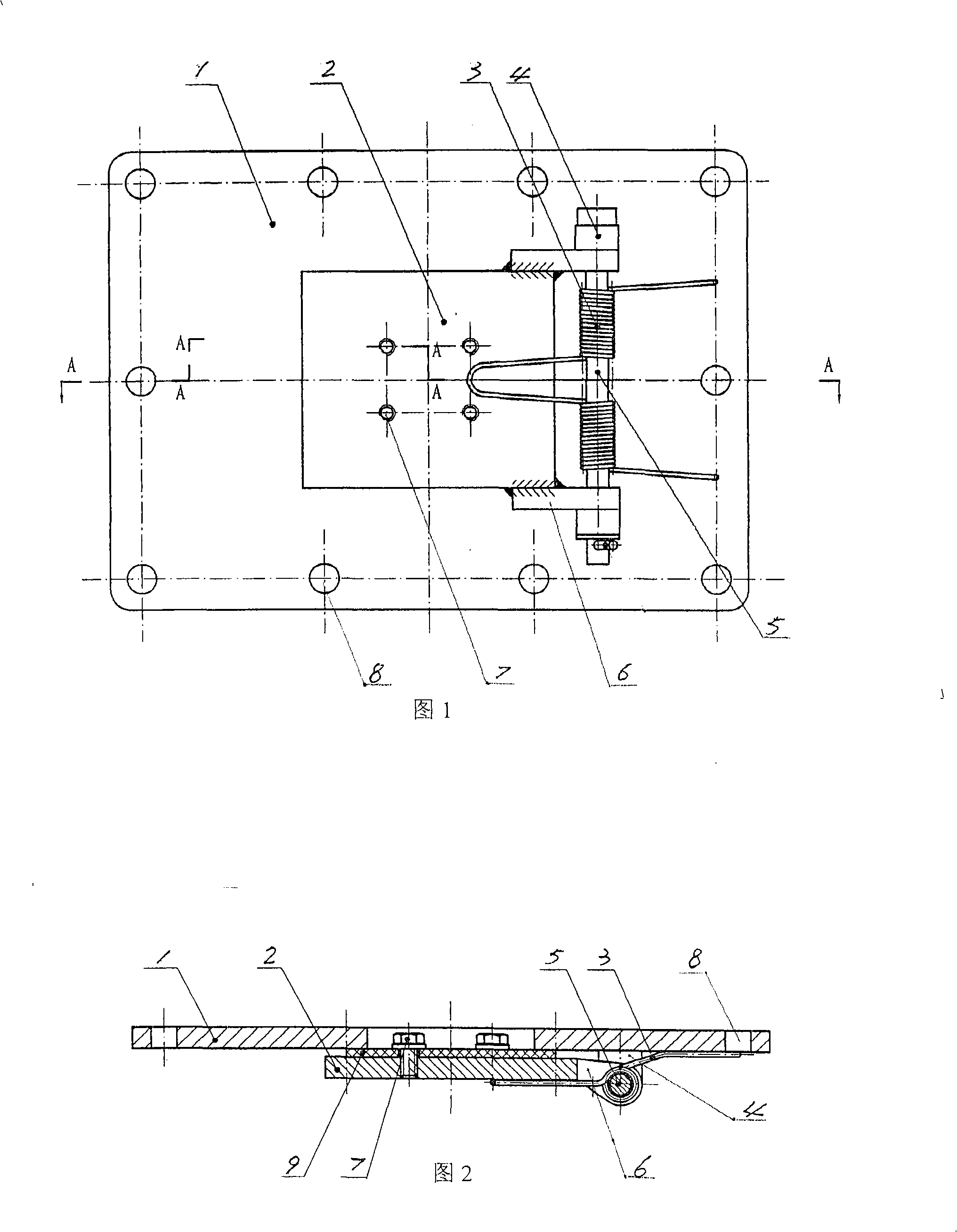

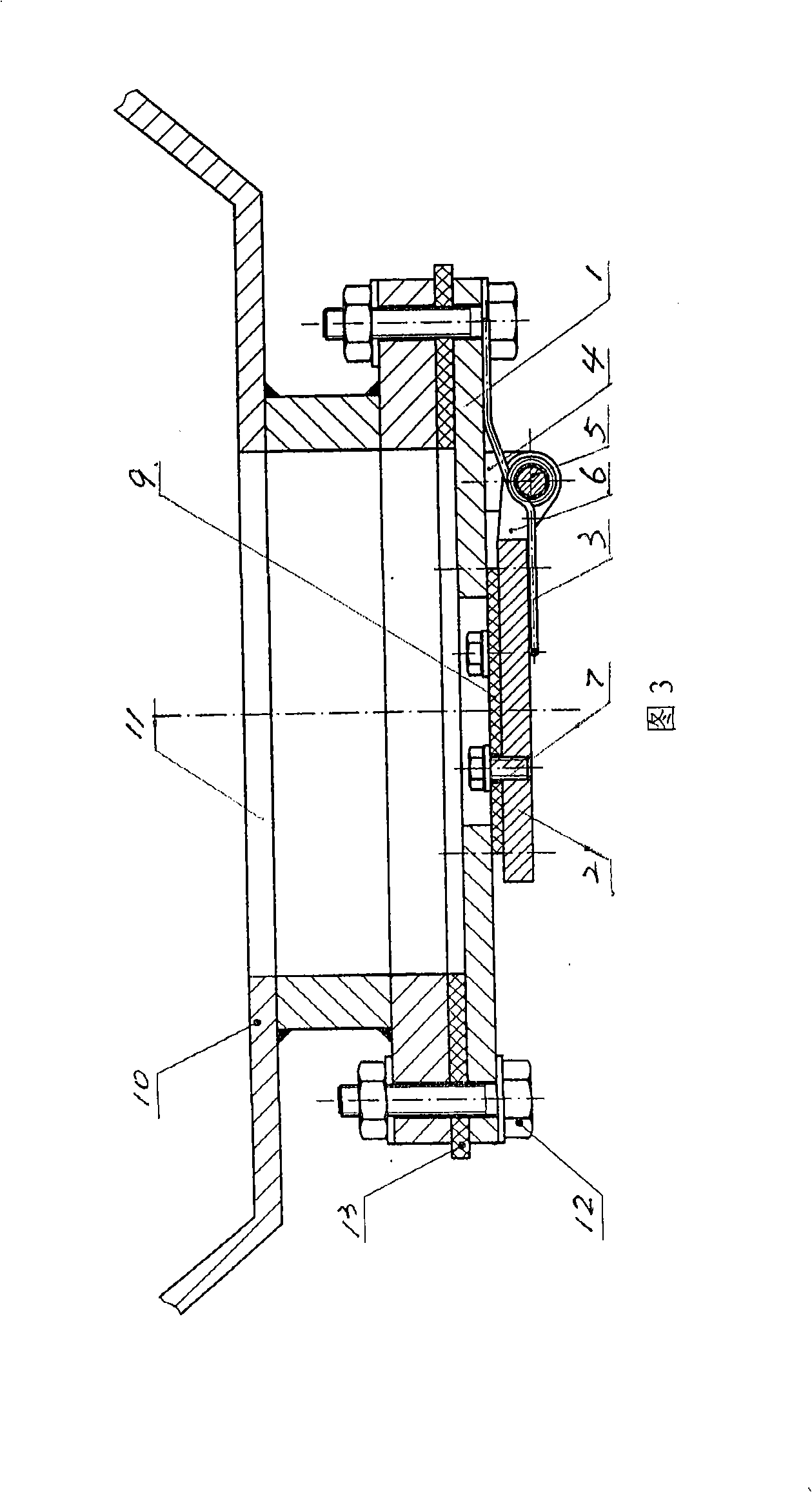

[0013] As shown in Fig. 1 and Fig. 2, the flap mechanism for the ballast water tank injection and drainage system of the present utility model includes a cover plate 1 and a flap 2. An opening is processed in the middle of the cover plate 1, and two supports 4 are fixed on one side of the opening, and pin holes are all processed on the two supports 4. A rotating shaft 5 is arranged between the two supports 4 , and both ends of the rotating shaft 5 are inserted into and fixed in pin holes on the two supports 4 . The area of the turnover plate 2 is larger than the opening area of the cover plate 1, and pin lugs 6 are welded on both sides of one side. Two pin lugs 6 are parallel, and their outer end corresponding positions are all processed with shaft holes, and they are movable pinned on the rotating shaft 5 by means of the shaft holes. The rotating shaft 5 is covered with a parallel double torsion spring 3, the parallel double torsion spring is located between the two pin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com