Filtering device and extractor hood with filtering device

A filter device and oil filter technology, which can be applied in application, oil fume removal, household stoves, etc., can solve the problems of difficult cleaning, large filter screen size, and the filtering effect has not been greatly improved, so as to achieve the improvement effect and improve the oil separation. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

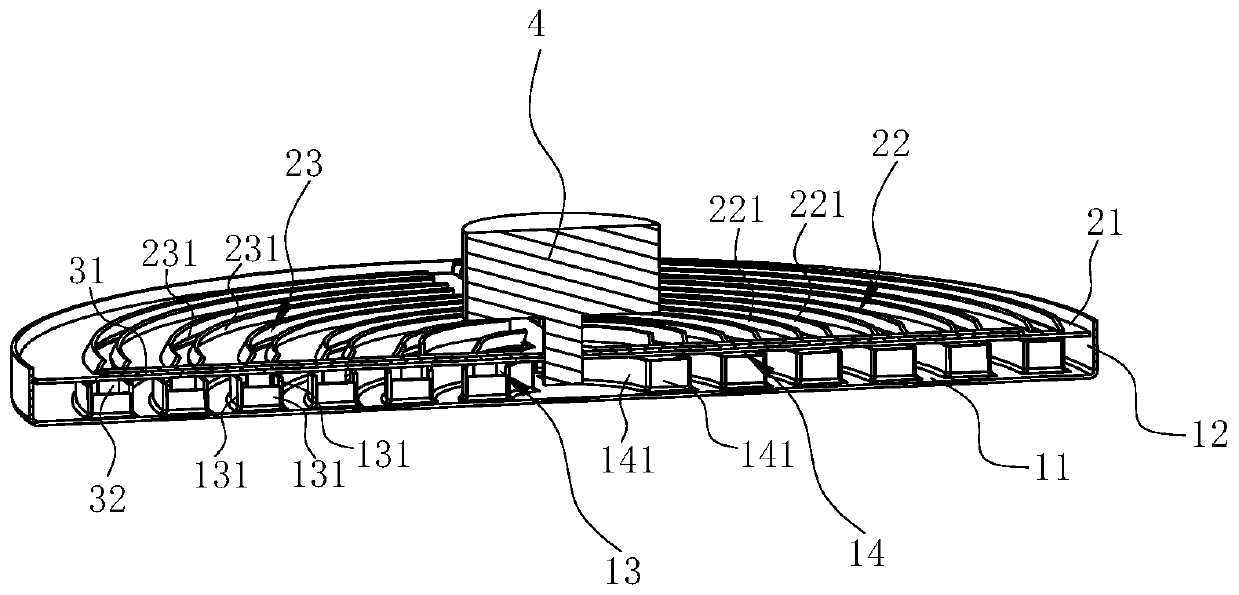

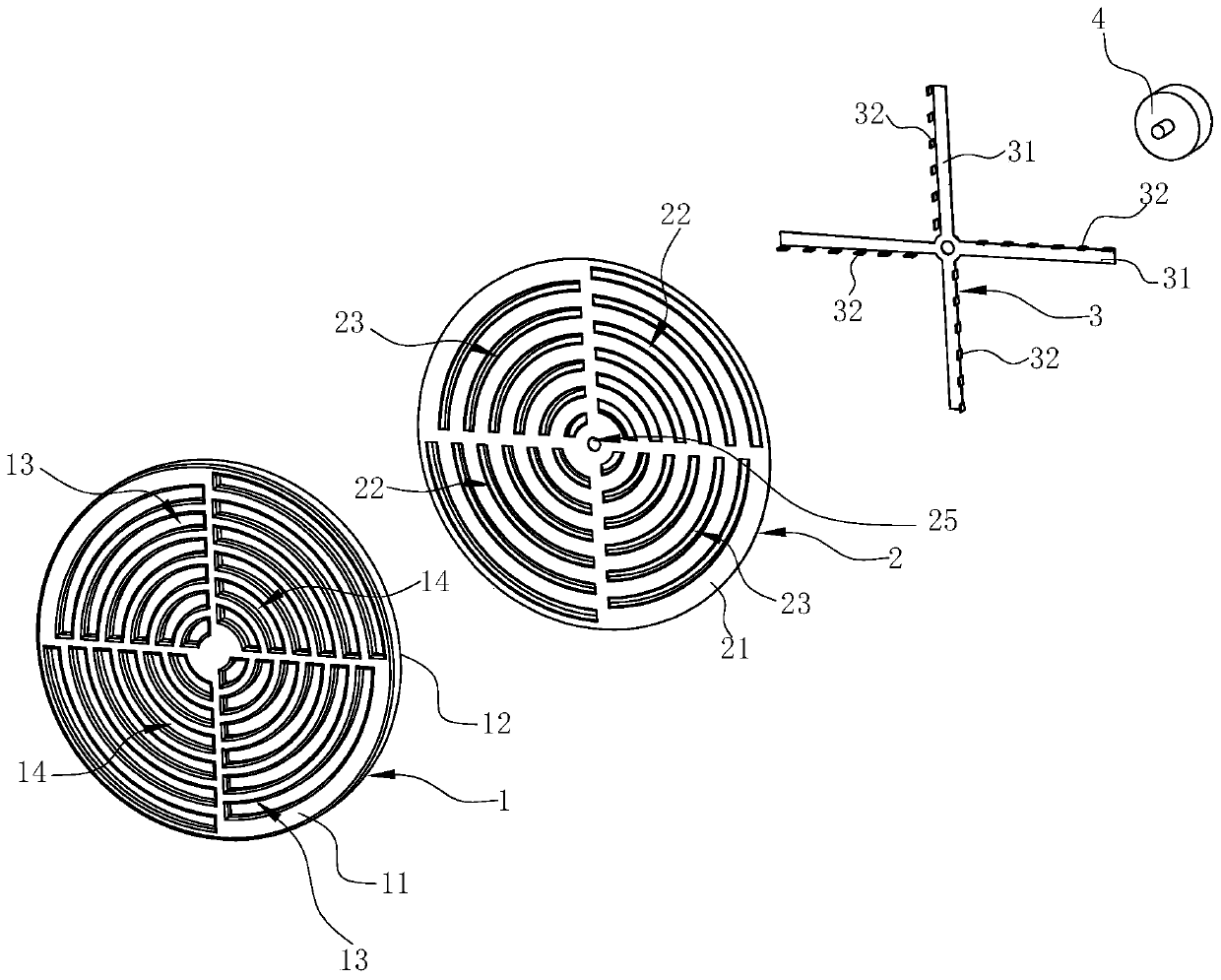

[0036] see Figure 1 ~ Figure 3 , a filtering device, including a first oil filter screen 1, a second oil filter screen 2, an oil screen 3 and a driving mechanism 4. This filter device is mainly used for range hoods.

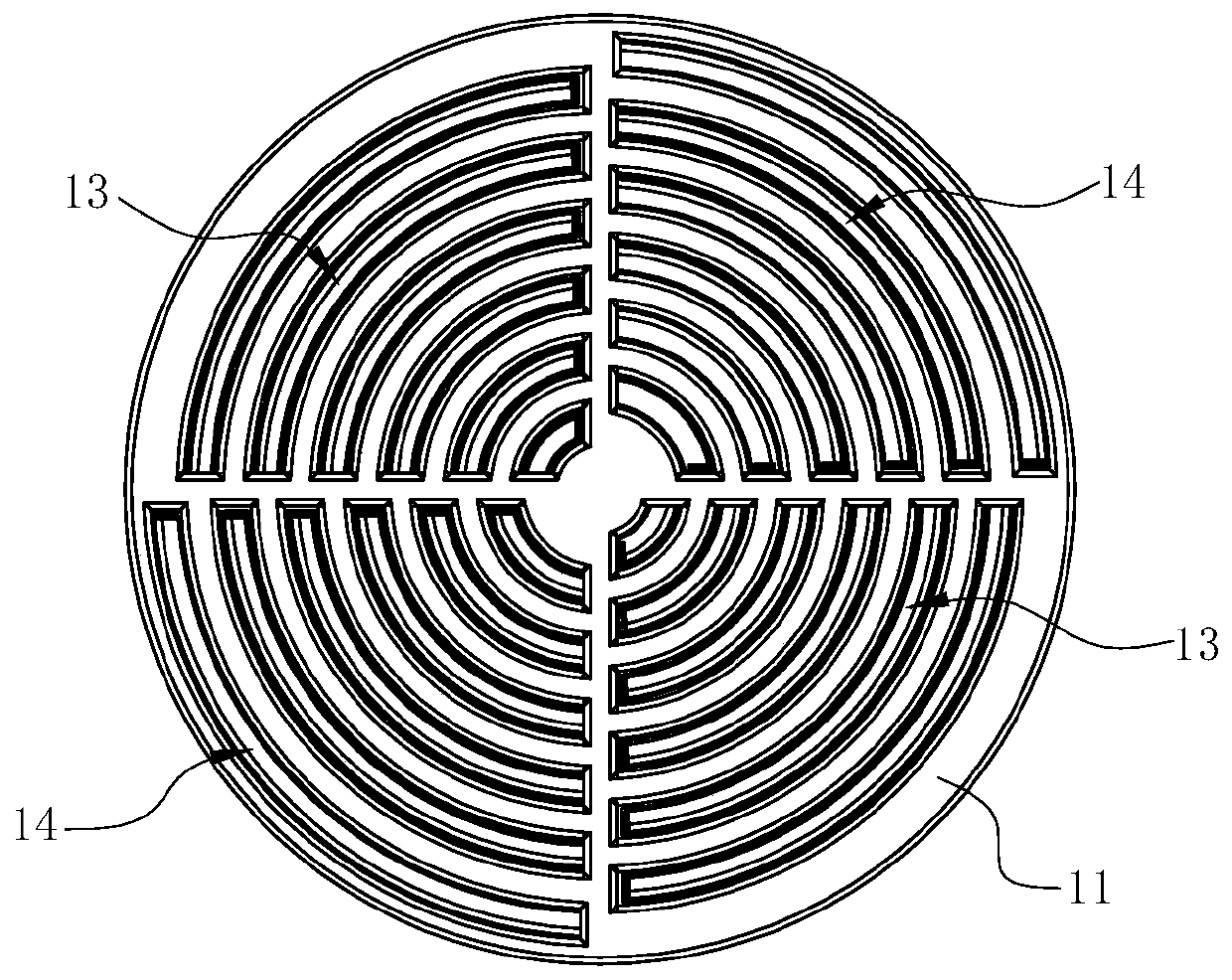

[0037] combine Figure 4 , the first oil filter screen 1 includes a circular first net pan 11 as a whole, a flange 12 bent along the axial direction of the first net pan 11 at the periphery of the first net pan 11, and set on the first net The first air inlet 13 and the second air inlet 14 on the disk 11, and the folded edge 12 are annular. The first air inlet 13 is arc-shaped and has at least two symmetrically arranged relative to the center of the first mesh disk 11 ; the second air inlet 14 is arc-shaped and has at least two symmetrically arranged relative to the center of the first mesh disk 11 . In this embodiment, there are at least four first air inlets 13, at least two on each side of the center of the first grid tray 11, and the first air inlets 13 on ...

Embodiment 2

[0053] see Figure 9 ~ Figure 12 , in this embodiment, the difference from the first embodiment above is that the first air inlet 13 of the first oil filter screen 1 has only one set, and each first air inlet 13 is close to a semicircle, and the second air inlet 14 has only one set, and each second air inlet 14 is close to a semicircle, and there is only one oil guiding groove 15 . Correspondingly, there is only one set of third air inlets 22 of the second oil screen 2, and each third air inlet 22 is close to a semicircle, and there is only one set of fourth air inlets 23, and each fourth air inlet 23 is close to a semicircle, and there is only one connecting rib 24 . The oil screen 3 has only one screen body 31 .

[0054] The working principle of the filtering device of this embodiment is the same as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com