Color inkjet device for textile yarn

A color inkjet and yarn technology, applied in printing, typewriter and other directions, can solve the problems of cumbersome process, low efficiency, superimposition of different colors or large separation distance, etc., to achieve recycling, improve sealing and uniformity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

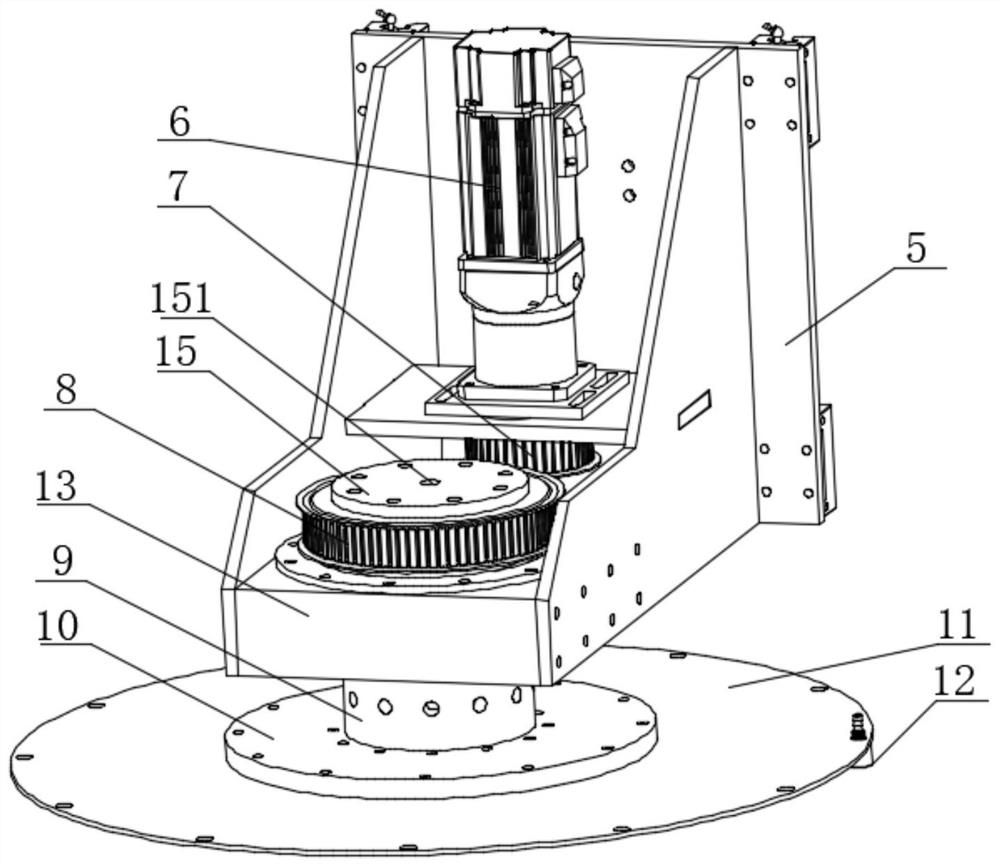

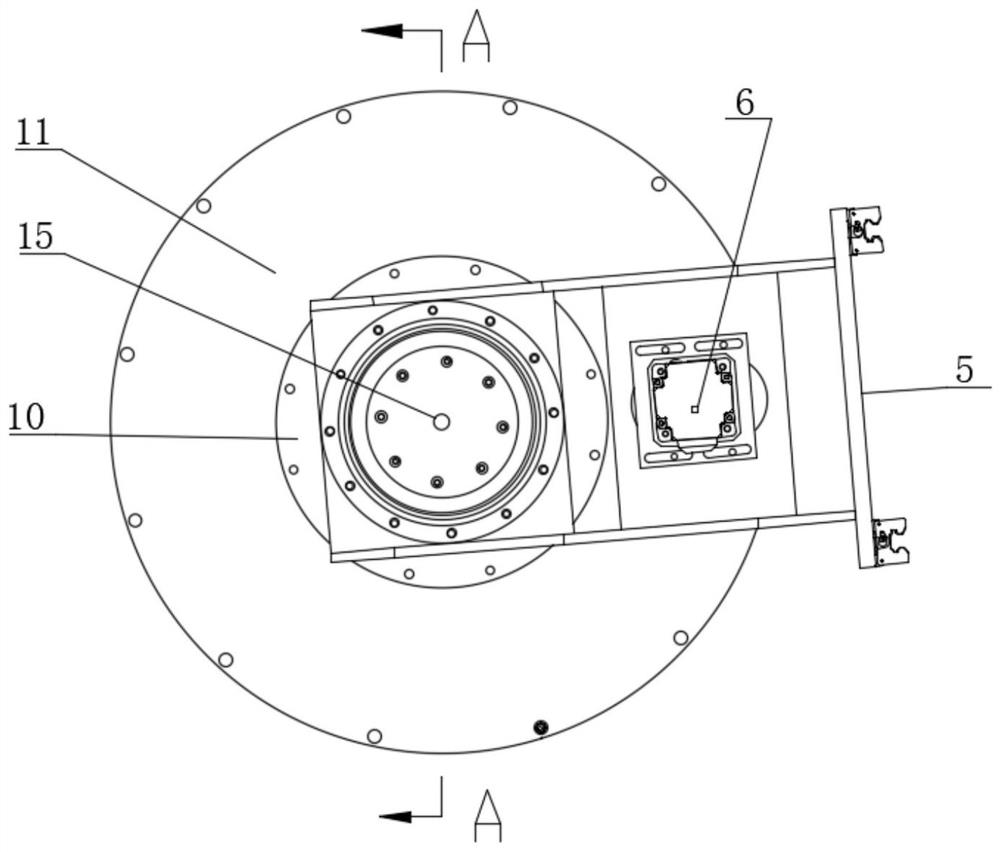

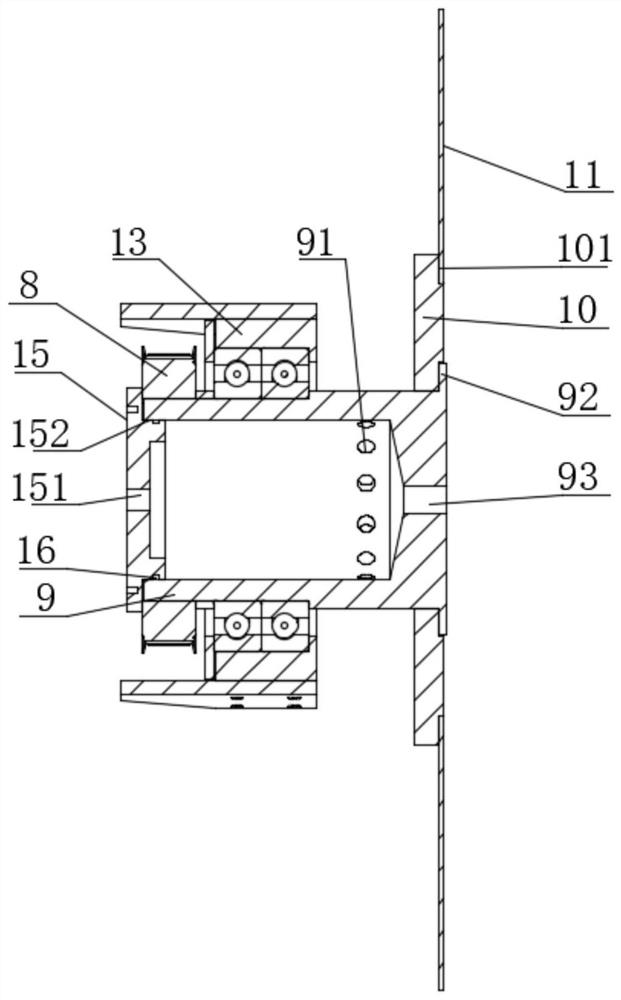

[0026] Such as Figure 5 , Figure 1-Figure 3 As shown, it includes multiple groups of rotary nozzle assemblies, and multiple groups of rotary nozzle assemblies are arranged at intervals along the direction of the yarn. Each group of rotary nozzle assemblies has the same structure, including a sliding support 5, which moves up and down in the vertical direction, The sliding support 5 is equipped with a rotary shaft 9 through a bearing box 13. The rotary shaft 9 is a cylindrical structure with an open top and a hollow cavity inside. The top of the rotary shaft 9 is provided with a cover plate 15 that closes the hollow cavity. The lower part is provided with a plurality of liquid outlet holes 91 along the circumference, and the bottom of the rotary shaft 9 is connected with a rotary disc 11 with an enlarged diameter. The circumference of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com