Lens module

A lens module and lens holder technology, applied in the field of optical systems, can solve the problems affecting the optical coupling between optical imaging elements and image sensors, the separation of the lens barrel and the lens holder, and the lack of tight combination of the lens barrel and the lens holder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

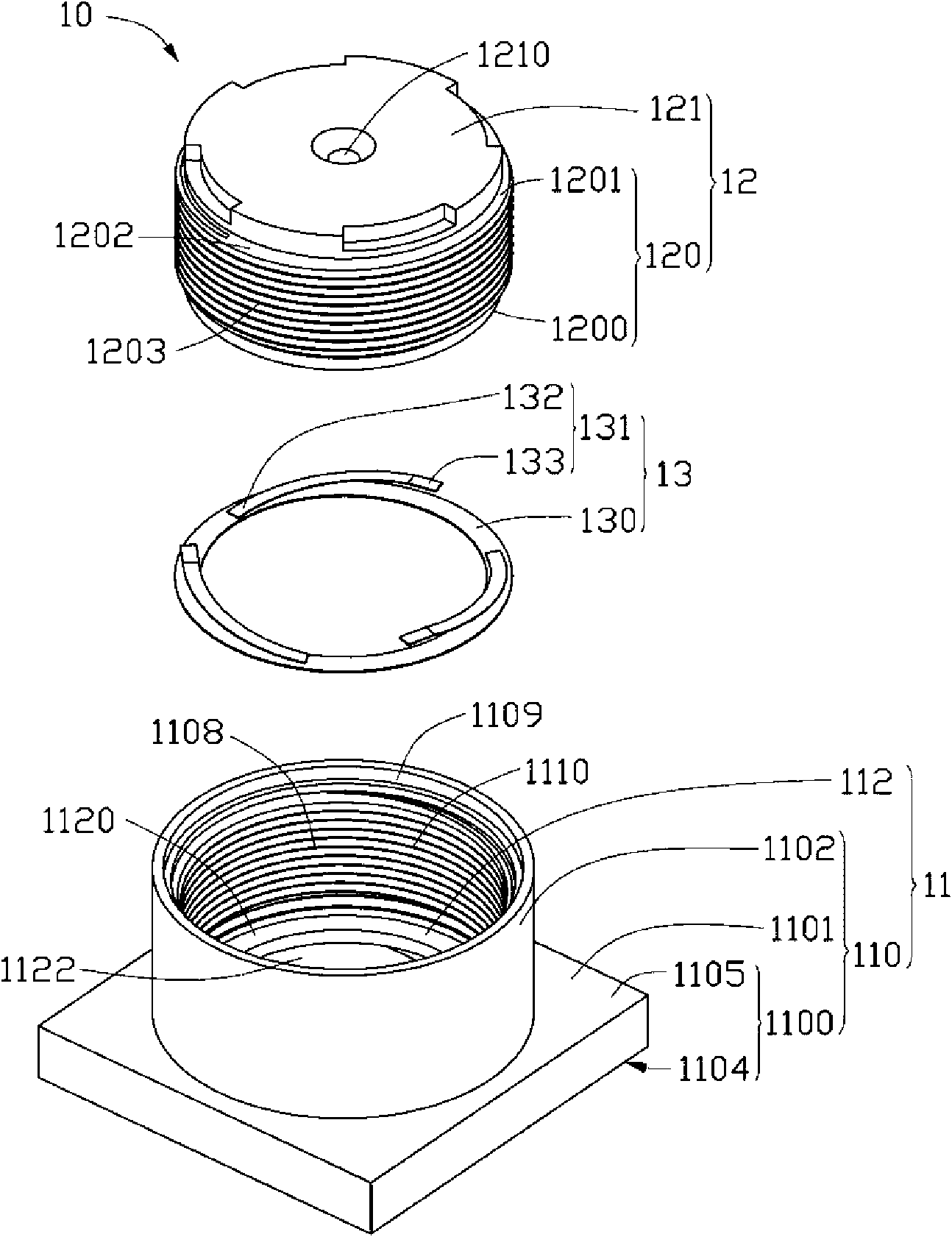

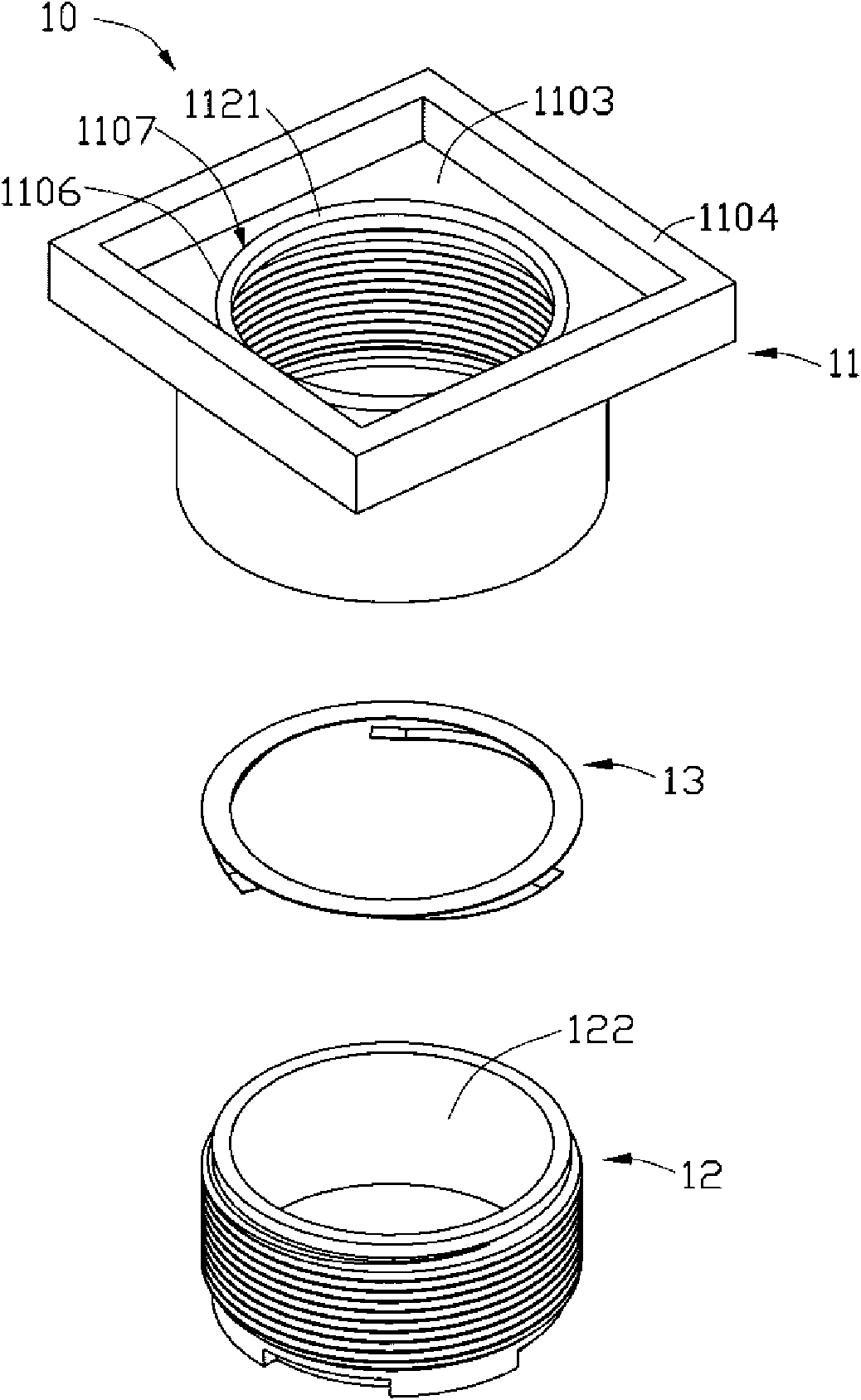

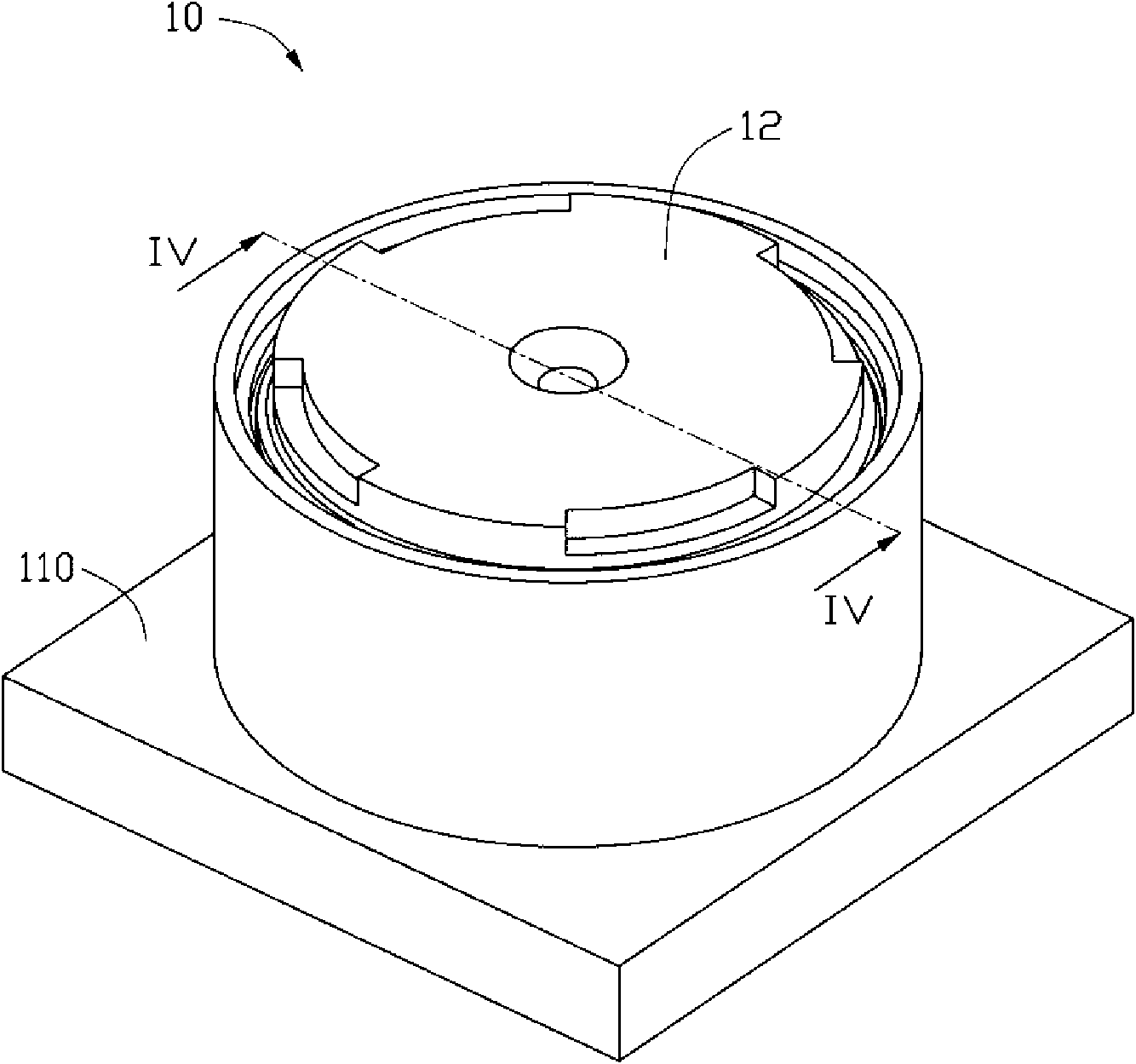

[0016] The lens module of the technical solution will be further described in detail below with reference to the accompanying drawings and multiple embodiments.

[0017] Please refer to Figure 1 to Figure 5 , A lens module 10 provided by an embodiment of the technical solution includes a lens holder 11, a lens barrel 12, and an elastic element 13.

[0018] The lens holder 11 includes a holder body 110 and a bearing platform 112. The carrier 112 extends from the base 110 to a direction close to the central axis of the lens module 10.

[0019] The base 110 includes a first side wall 1100, a first bottom wall 1101, and a second side wall 1102 that are connected in sequence.

[0020] The first side wall 1100 encloses and forms a first receiving cavity 1103 for receiving the image sensor. The cross section of the first receiving cavity 1103 may be square. The first side wall 1100 has a first end surface 1104 and a second end surface 1105 opposite to each other.

[0021] The first bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com