Systems and methods for implementing multi-layer addressable curing of ultraviolet (UV) light curable inks for three dimensional (3D) printed parts and components

a technology of ultraviolet light and curable inks, applied in the field of system and method for implementing adjustable curing of ultraviolet light or photo curable ink layers in the formation and/or manufacture of three-dimensional (3d) printed parts and components, can solve the problems of reducing image quality, difficult to cure thoroughly enough without over-curing, and causing yellowing in the curing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

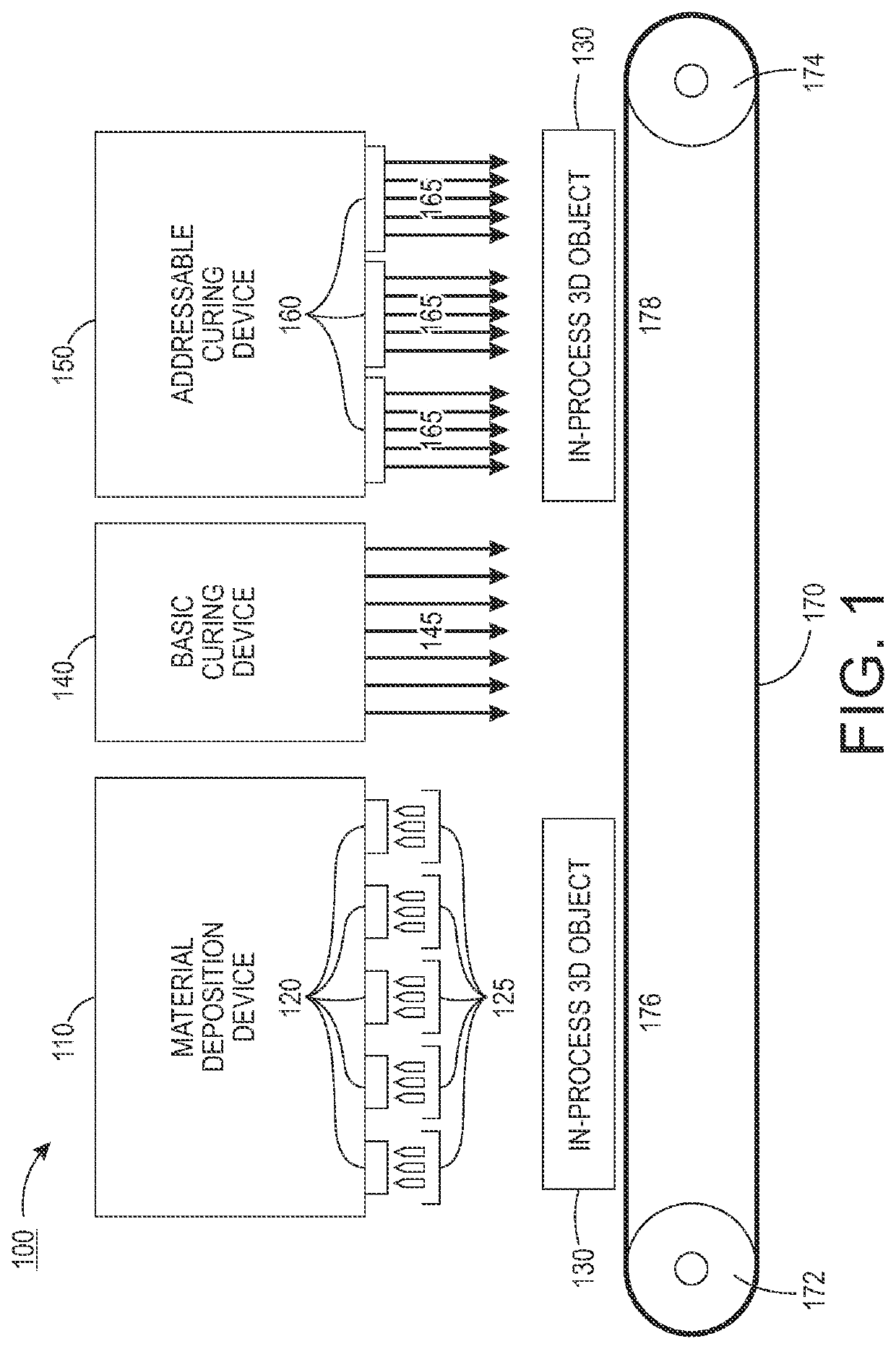

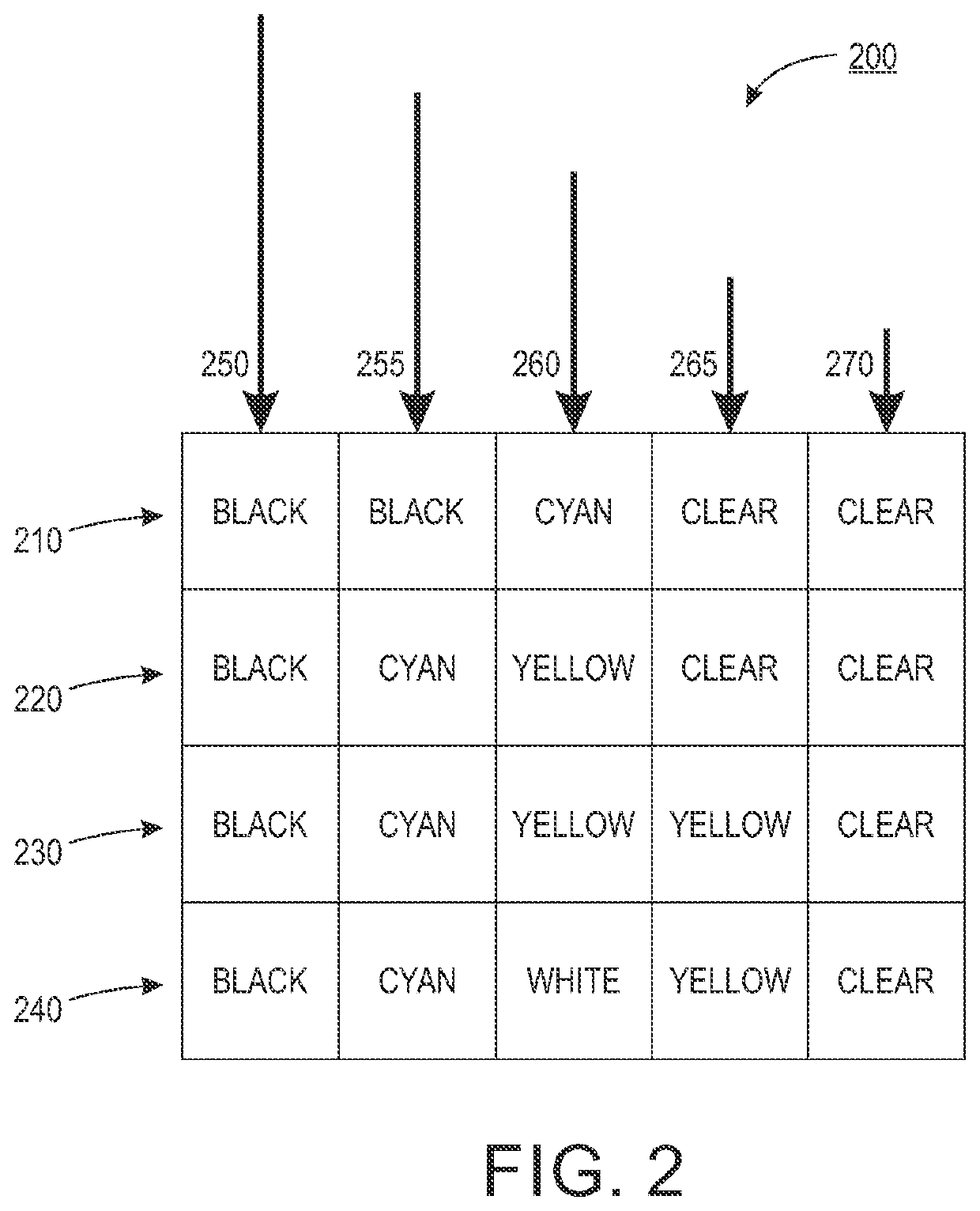

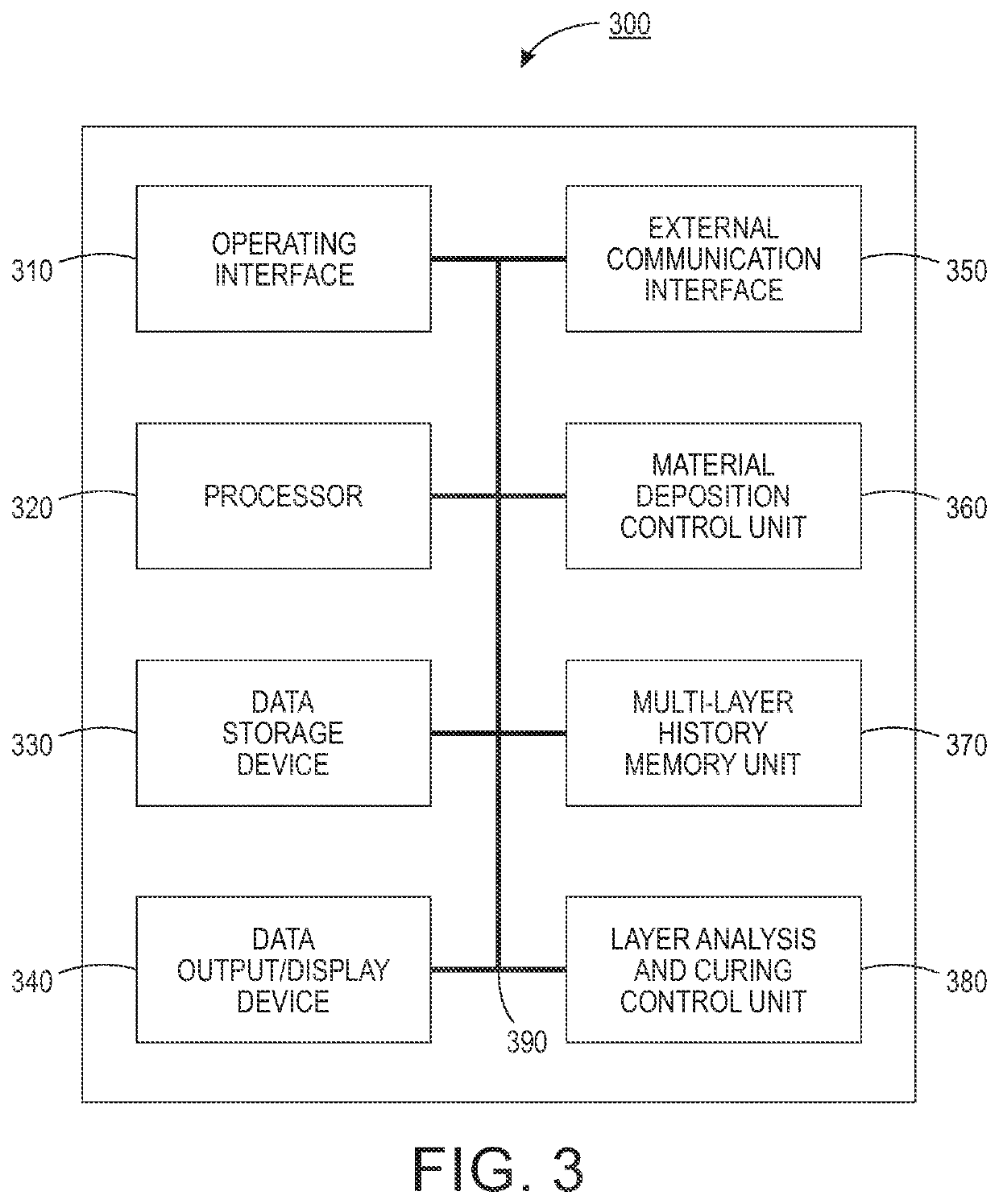

[0002]This disclosure relates to systems and methods for implementing adjustable curing of ultraviolet (UV) light or photo curable ink layers in the formation and / or manufacture of three-dimensional (3D) printed parts and components, particularly those parts and components formed in 3D jetted ink printing systems.

[0003]2. Related Art

[0004]Three-dimensional or 3D printing generally refers to a broad class of techniques (also referred to as “additive material manufacturing” or AM techniques) that are usable for producing three-dimensional parts, objects or components (“3D printed parts”) often through a repetitive layer-by-layer material deposition process. 3D printing techniques employ one or more processes that appear, in many respects, similar to well-known comparable processes for forming two-dimensional (2D) printed images on image receiving media substrates. The significant differences in the output structures produced by the 3D printing techniques, even as those techniques may ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| curing energy | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

| flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com